Name: UPVC Ball Valve

Size: 1/2″-4″

Color: charcoal

Packing: IFAN Bag+Carton

Sample: Free Sample

Customization: Support

Related products

Durability and Longevity

UPVC ball valve are known for their exceptional durability, which makes them a reliable choice for various applications. These valves are made from unplasticized polyvinyl chloride (UPVC), a material that resists corrosion, rust, and chemical degradation. This inherent resistance ensures that the valves can withstand harsh environmental conditions, including exposure to acids, bases, and other aggressive chemicals. Because UPVC ball valves do not corrode, they last longer than metal valves. For example, in industrial settings where chemical exposure is frequent, UPVC ball valves maintain their integrity, ensuring uninterrupted operation and reduced maintenance costs.Cost-Effectiveness

One of the key advantages of UPVC ball valves is their cost-effectiveness. These valves offer a lower initial cost compared to metal alternatives, making them an economical option for many industries. Moreover, the reduced need for maintenance and the extended lifespan of UPVC ball valves contribute to long-term savings. Companies that choose UPVC valves benefit from lower replacement rates and fewer repairs, which translate into lower operational costs. For instance, in large-scale water treatment plants, using UPVC ball valves can significantly reduce both capital expenditure and ongoing maintenance budgets.Lightweight Design

UPVC ball valves are lightweight, which offers several practical benefits. Their low weight makes them easier to handle and install, reducing labor costs and installation time. This feature is especially advantageous in large piping systems where multiple valves are required. Additionally, the lightweight nature of UPVC valves decreases the overall load on the piping structure, reducing the risk of mechanical stress and potential damage. For example, in residential plumbing, UPVC ball valves simplify installation and minimize the need for heavy-duty support structures.Easy Operation and Maintenance

The design of UPVC ball valves ensures ease of operation and maintenance. These valves feature a simple quarter-turn mechanism, allowing for quick and easy control of fluid flow. This straightforward operation reduces the likelihood of user error and enhances safety. Additionally, UPVC ball valves require minimal maintenance due to their corrosion-resistant properties and robust construction. Regular inspections and occasional cleaning are usually sufficient to keep them in optimal working condition. For example, in agricultural irrigation systems, the ease of operation and low maintenance needs make UPVC ball valves a preferred choice.Versatility in Applications

UPVC ball valves are versatile and can be used in a wide range of applications. Their chemical resistance and durability make them suitable for various industries, including water treatment, chemical processing, food and beverage, and pharmaceutical manufacturing. These valves can handle different types of fluids, from water to aggressive chemicals, without compromising performance. For instance, in the chemical industry, UPVC ball valves are often used to regulate the flow of corrosive substances, ensuring safety and efficiency in the production process.Environmental Friendliness

Choosing UPVC ball valves contributes to environmental sustainability. UPVC, as a material, is recyclable, and its production generates fewer carbon emissions compared to metal valves. Additionally, the long lifespan of UPVC ball valves reduces the frequency of replacements, leading to less waste. This environmental benefit aligns with the growing demand for eco-friendly industrial solutions. For example, in green building projects, using UPVC ball valves supports sustainable construction practices by minimizing the environmental impact.Temperature and Pressure Resistance

UPVC ball valves offer excellent resistance to a wide range of temperatures and pressures. Although they are not suitable for extreme conditions, these valves perform reliably within moderate temperature and pressure ranges. This makes them ideal for applications where the fluid’s temperature and pressure remain within safe limits. For instance, in residential water supply systems, UPVC ball valves effectively manage the flow of water under typical household pressure conditions, ensuring consistent performance and safety.Safety and Reliability

Safety is a crucial factor in choosing UPVC ball valves. These valves are designed to provide a secure and reliable seal, preventing leaks and ensuring the safe transport of fluids. The chemical resistance of UPVC also contributes to the overall safety of the system by reducing the risk of chemical reactions that could compromise the valve’s integrity. For example, in the pharmaceutical industry, where contamination risks must be minimized, UPVC ball valves offer a reliable solution for safely handling sensitive fluids.This structure ensures that each key aspect of UPVC ball valves is thoroughly covered, providing a clear, comprehensive, and well-organized overview of their advantages.| Best UPVC ball valve Manufacturers | ||

| Companies | Headquarter/Location | Year Founded |

| IFAN | ZHEJIANG,CHINA | 1993 |

| RAKtherm | UAE | 1963 |

| REHAU | Muri bei Bern, Switzerland | 1948 |

| POLOPLAST | Leonding, Austria | 1954 |

| ERA | ZHEJIANG,CHINA | 1983 |

| LESSO | GUANGDONG,CHINA | 1986 |

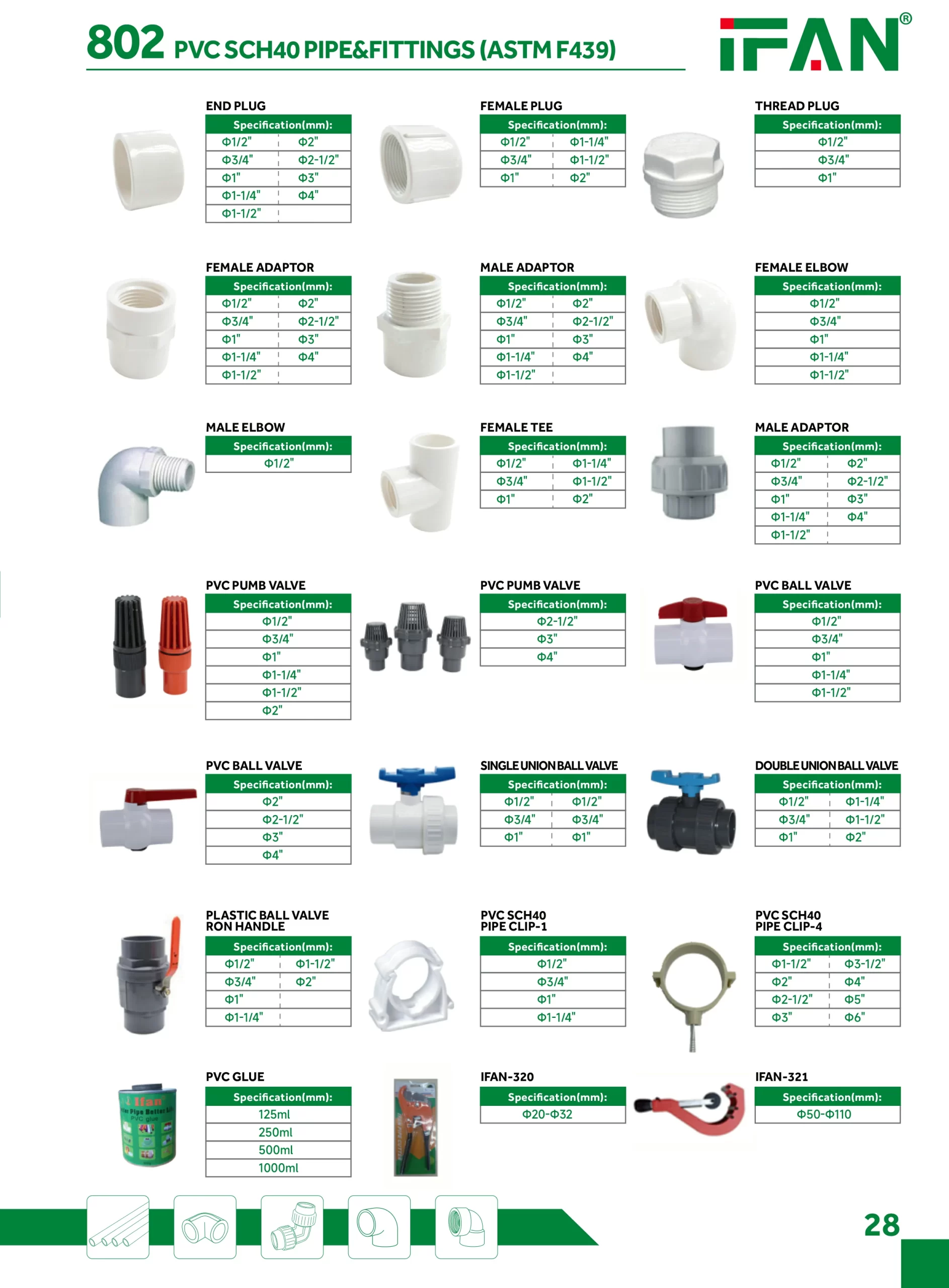

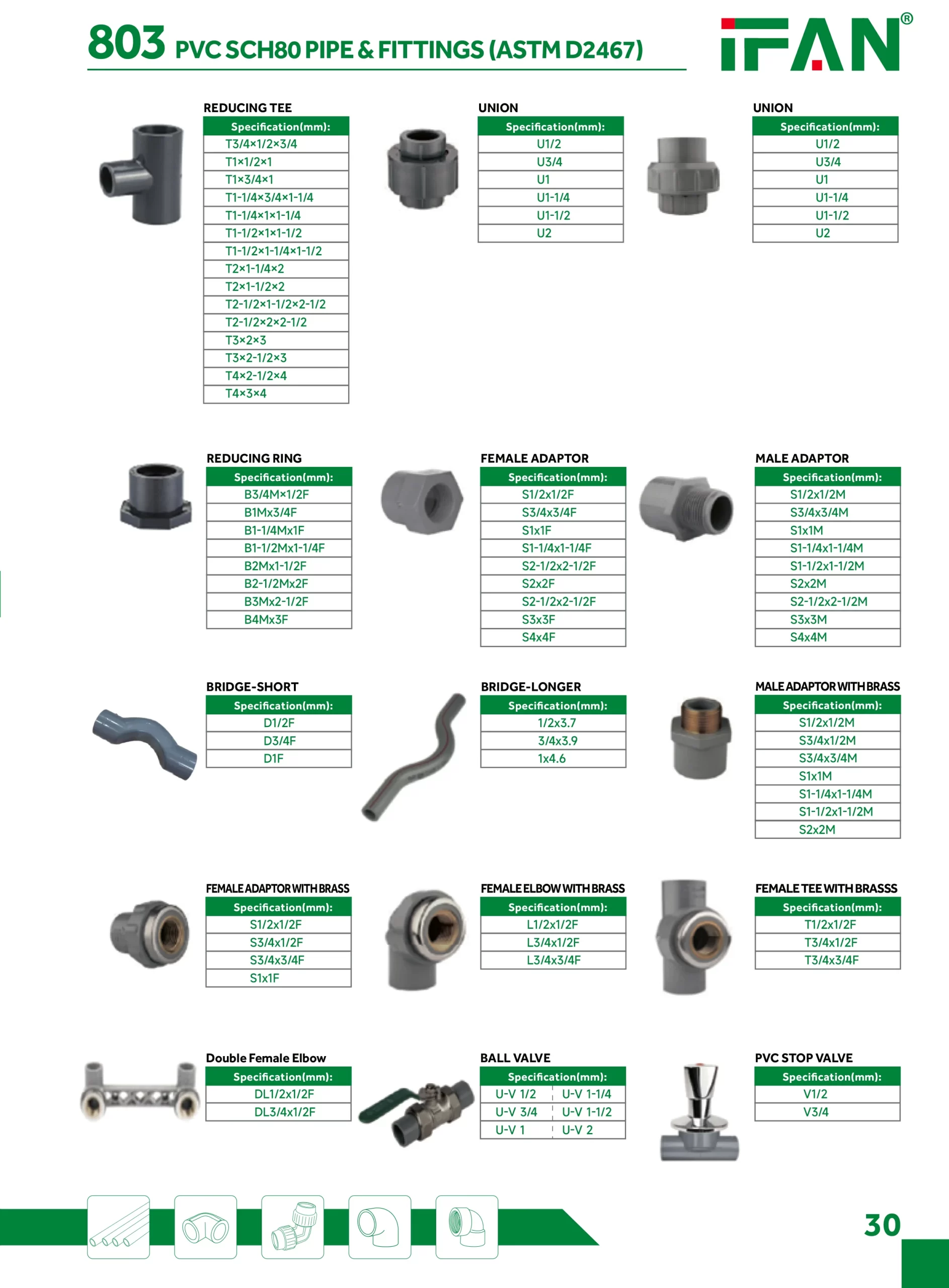

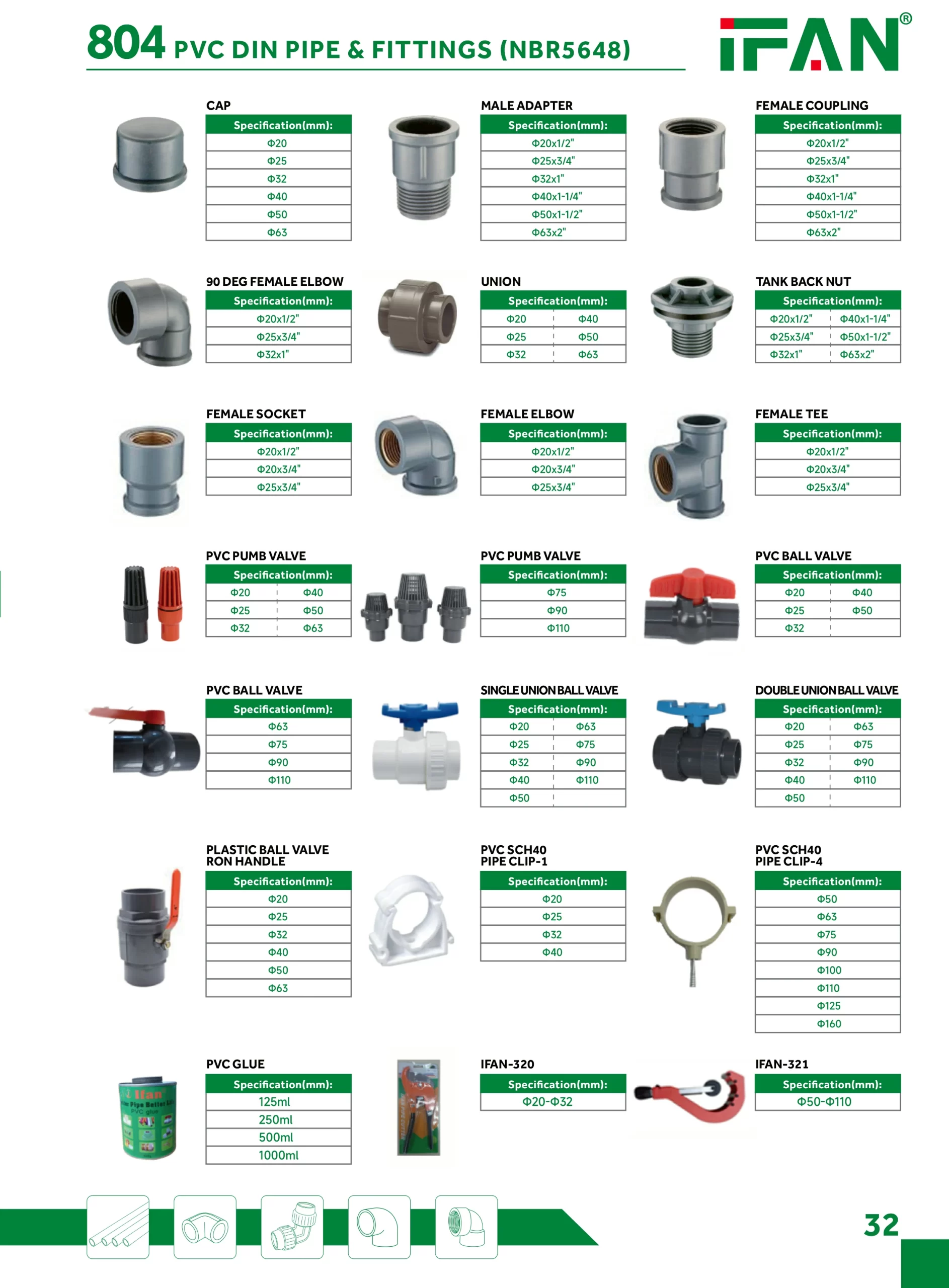

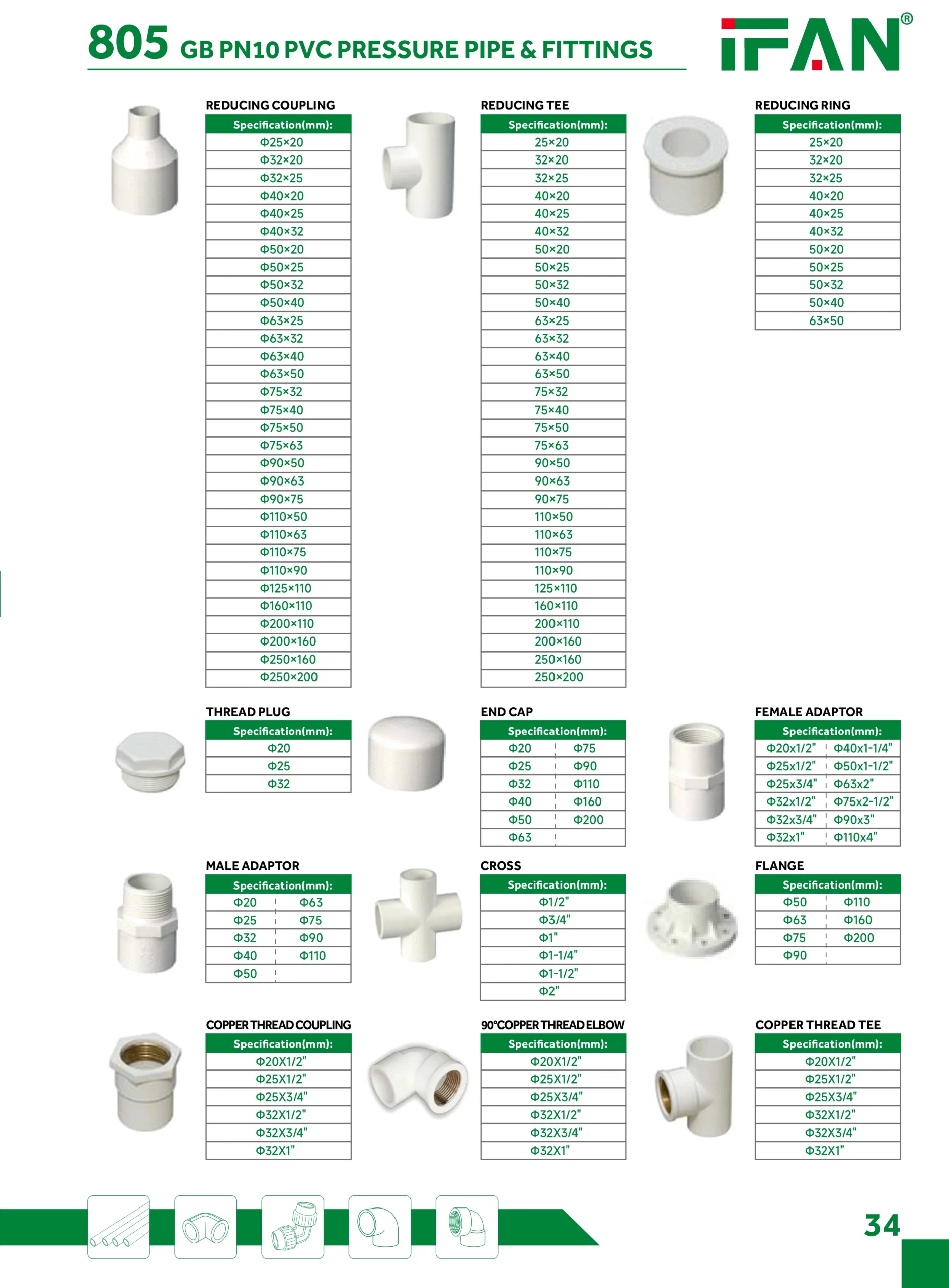

UPVC products international standard

Adhering strictly to international and regional standards is paramount in the design and manufacturing of piping systems. For instance, British Standards BS 3505 and BS 4346 (801) ensure the quality and performance of piping materials meet the rigorous demands of the UK market. In the US, ASTM D1785 standards for SCH40 (802) and SCH80 (803) pipes cater to high-strength and durable solutions across various pressure systems. Meanwhile, DIN (804) and GB (805, 806, 901) series standards represent Germany and China’s technical specifications for pipeline design and production, enhancing global competitiveness.

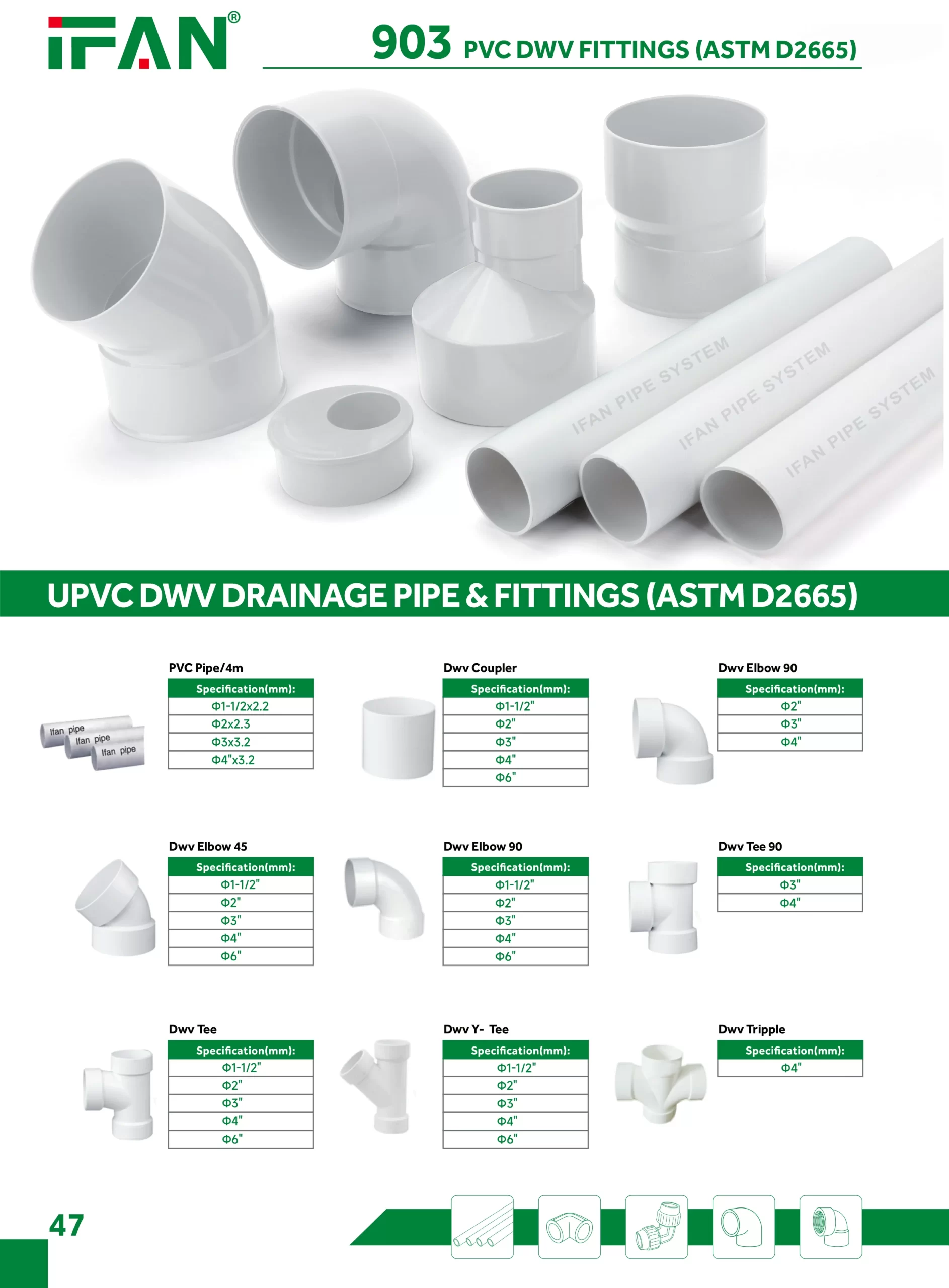

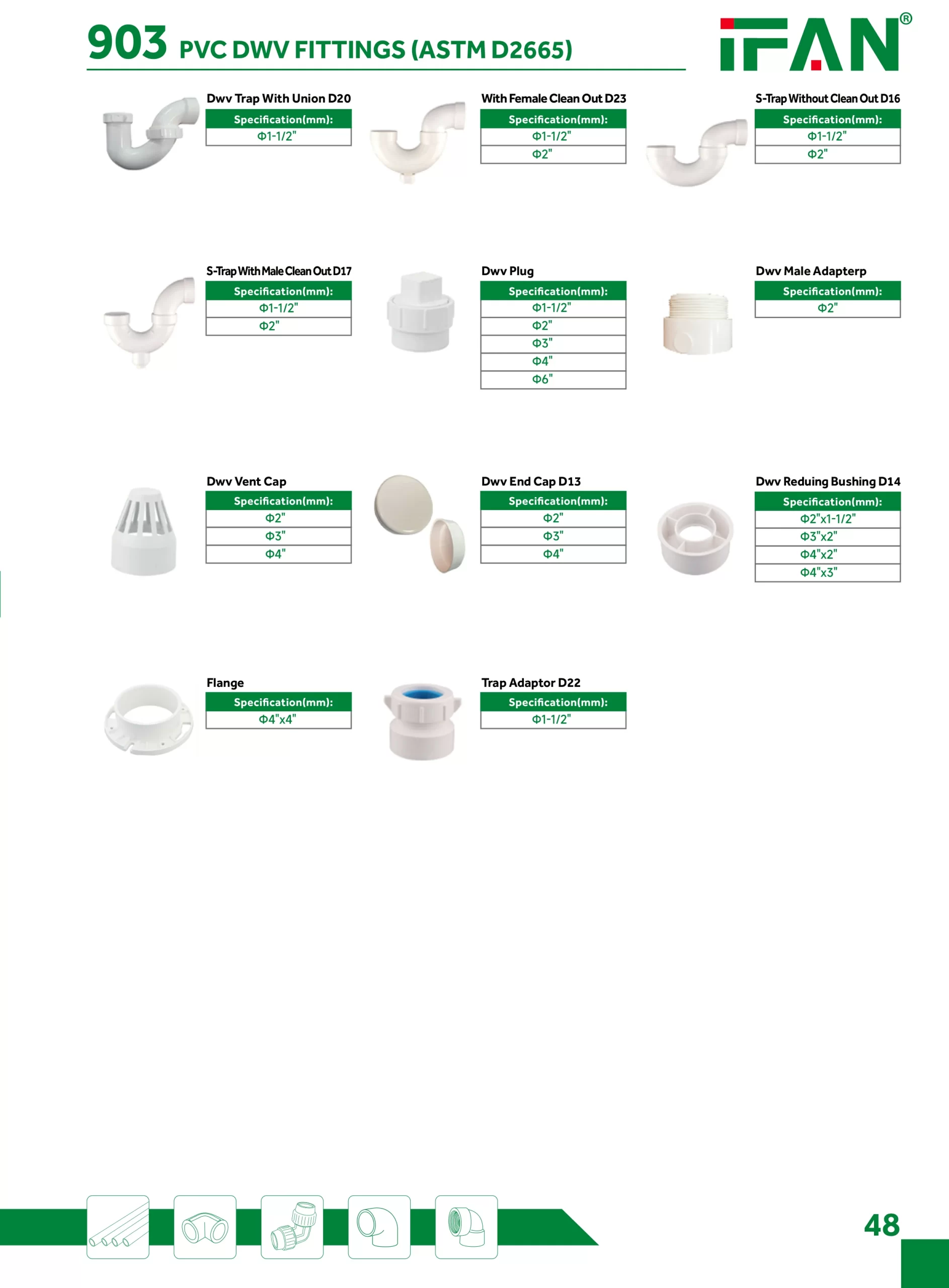

Moreover, Drain-Waste-Vent (DWV, 902) systems adhere to specific standards to optimize fluid transmission efficiency, while ASTM D2665 (903) focuses on material standards for polyethylene (PE) piping systems, safeguarding safe usage in diverse environments. Standards such as ASTM D2241, D2729, and F441/F441M further detail design and manufacturing guidelines for pipes, fittings, and connections.

The ISO 1452 series, including EN ISO 1452, provides a unified framework for assessing the performance of piping systems globally. DIN 8061/8062 and GB/T 10002 series standards specify detailed technical specifications for specific types of pipes and fittings. AS/NZS 1477, JIS K6741, CSA B137.3, among others, represent piping system norms in regions like Australia/New Zealand, Japan, and Canada.

Furthermore, standards like NSF/ANSI 14 and TIS 17-2532/1131-2535 prioritize health and safety, as well as environmental considerations, ensuring products comply with stringent health standards when applied to potable water systems or specific industrial environments.

Connect

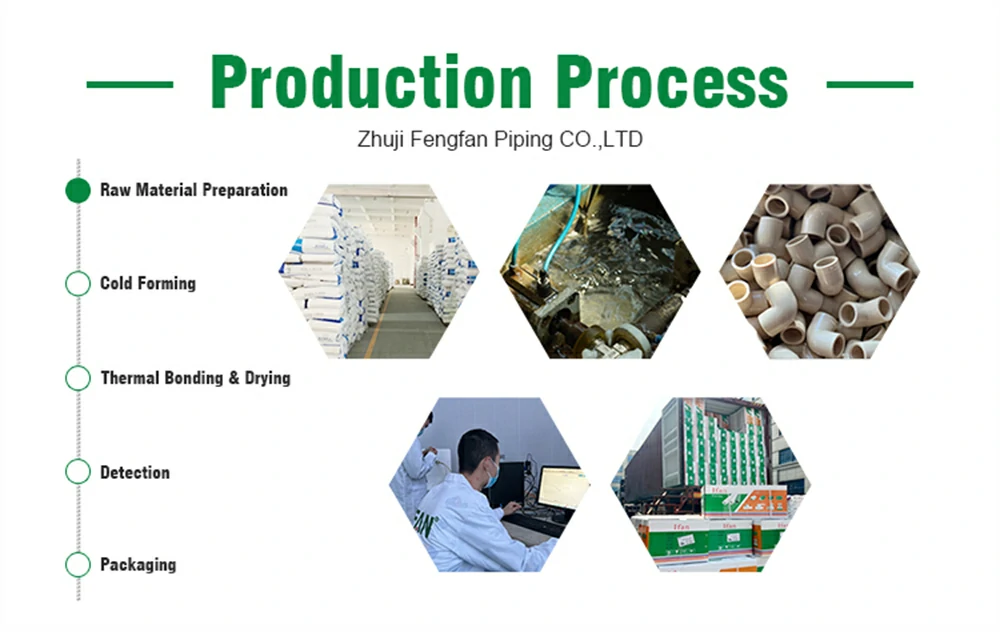

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interest in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.We will reply your email or fax within 24 hours. You can call us at any time if there is any question on our production.For more information,pls visit our webside https://ifanpro.com/ Pls Mailto: [email protected] Whatsapp: + 86 198579489821. Q:Are vou a manufacture or trading company?

A:Yes. we’re professional manufacture in China, and have been in this field for more than 29 years.

2. Q:What payment terms do you support?

A:TT, L/C, Western Union, Money Gram are available, and for TT we accept 30% deposit in advance. 70% balance against copy of B/L.

3. Q:How long is your deliverv time?

A:15-30 days after receiving deposit.

4. Q:lt is possible to get samples from your factory?

A:Yes. free samples will be sent if needed, but the freight can be negotiated or chargeable, it will be refunded after confirmation of the order.

5. Q:Can I visit your factory?

A:Yes. It is an honor to invite you to visit our factory. We have professionals to accompany you to visit the factory.

6. Q:What Services Does IFAN Provide?