Table of contents

隐藏

1. Introduction: The Critical Role of Tank Connections in Water Storage Systems

- Explain why reliable tank connections are essential for preventing leaks, ensuring flow efficiency, and maintaining water quality in residential, commercial, and industrial applications.

- Highlight common challenges with generic fittings (e.g., poor compatibility, material corrosion) and introduce IFAN’s customizable PPR pipe fittings for tanks as a solution.

- Position IFAN as a China-based factory specializing in OEM/ODM tank connection solutions with a focus on quality, flexibility, and global industry standards (link to ifanpro.com for product range).

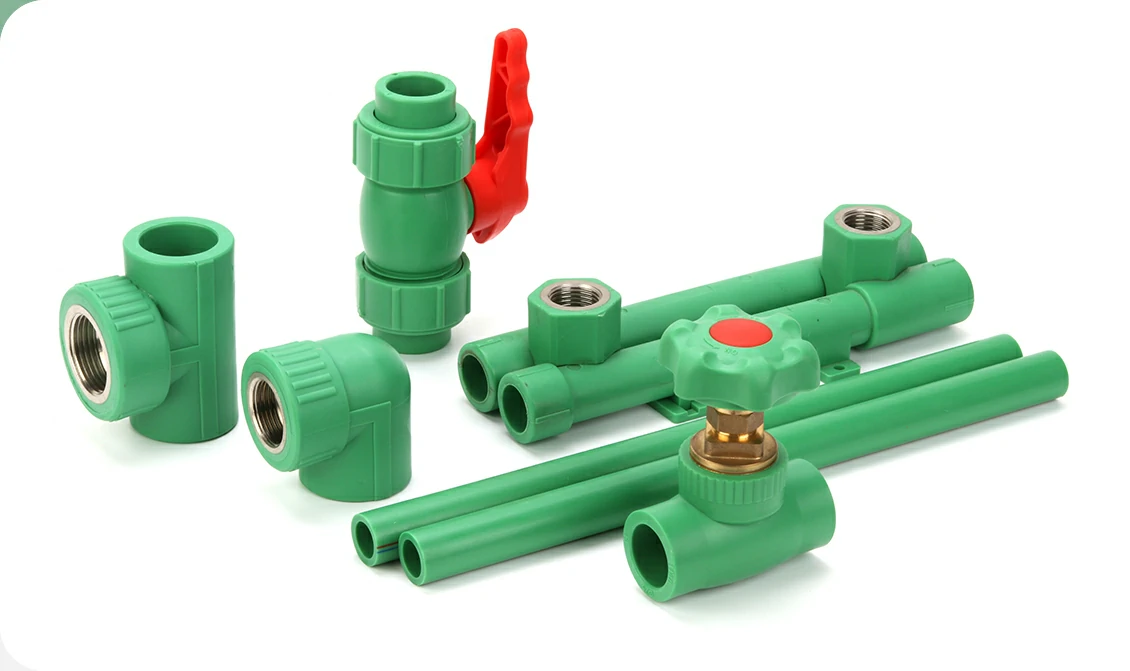

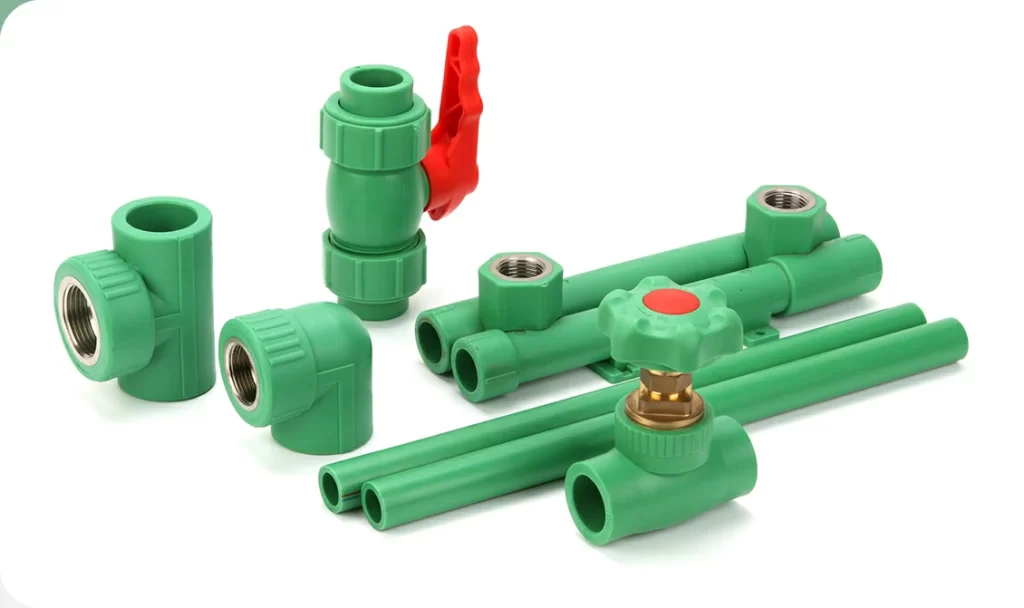

2. What Makes IFAN’s PPR Tank Connects Stand Out? Key Features & Benefits

- Premium PPR Material for Durability:

- Food-grade PPR (polypropylene random copolymer) resistant to chemicals, rust, and scaling, ideal for potable water, wastewater, and industrial liquids.

- High-temperature tolerance (up to 70°C) and pressure resistance (16 bar) for hot water tanks and pressurized systems.

- Tailored Design for Perfect Tank Integration:

- Customizable connectors for all tank types: vertical/horizontal storage tanks, plastic/steel tanks, cylindrical/rectangular shapes.

- Connection types: threaded (BSP, NPT), socket fusion, flange, or quick-release couplings to match existing pipelines.

- OEM/ODM Customization at Every Step:

- Material modifications: UV-stabilized PPR for outdoor tanks, anti-static coatings for industrial use.

- Size range: DN15 to DN200, with custom dimensions available for non-standard tank setups.

- Branding options: Laser-engraved logos, custom packaging, and color matching for corporate visibility.

- Stringent Quality Assurance:

- ISO 9001-certified production and SGS-tested for leak-proof performance and impact resistance.

- 100% pressure testing before shipment to ensure zero defects.

3. Diverse Applications: Where IFAN Tank Connects Excel

- Residential & Commercial Water Tanks:

- Potable water storage systems, rainwater harvesting, and solar thermal tank connections.

- Case example: A Australian property developer reduced installation time by 20% with IFAN’s pre-fitted tank connectors.

- Industrial Liquid Storage:

- Chemical tanks, wastewater treatment plants, and cooling tower systems (corrosion-resistant PPR prevents contamination).

- Agriculture & Irrigation:

- Large-scale water tanks for livestock, greenhouse irrigation, and drip systems (lightweight PPR eases handling and reduces labor costs).

- Marine & RV Applications:

- Compact, leak-proof connectors for onboard water tanks in boats and recreational vehicles.

4. The IFAN Customization Process: How It Works

- Step 1: Consultation & Requirement Analysis:

- Share tank specifications (material, capacity, inlet/outlet positions) and project goals (e.g., high-pressure tolerance, space-saving design).

- Dedicated engineers provide free design suggestions and 3D drawings for approval.

- Step 2: Prototyping & Testing:

- Rapid prototyping via 3D printing or mold sampling to ensure a perfect fit with your tank.

- Physical testing for pressure, temperature, and vibration resistance in real-world conditions.

- Step 3: Mass Production & Delivery:

- State-of-the-art injection molding for consistent quality at scale (MOQ as low as 500 units).

- Global shipping with DDP options, tracked logistics, and 45-day average production lead time.

- Step 4: Post-Sales Support:

- 24/7 technical guidance for installation and maintenance.

- Warranty coverage and free replacement for defective parts (terms apply).

5. Why Choose IFAN for Custom Tank Connection Fittings?

- Factory-Direct Pricing: Cut costs by eliminating distributors—get premium custom fittings at 30% lower prices than competitors.

- Industry Compliance for Global Markets:

- Certifications: CE, NSF (for potable water), KTW (Germany), and AS/NZS (Australia/New Zealand).

- Compliance with regional standards (e.g., USA’s Uniform Plumbing Code, EU’s EN 12201).

- Proven Expertise:

- 10+ years serving 1,000+ clients in 50+ countries, from small businesses to large-scale industrial projects.

- Flexible for both simple modifications (e.g., logo engraving) and complex engineering (e.g., multi-port tank manifolds).

6. How to Optimize Your Custom Purchase: Key Considerations

- Define Your Needs:

- List operating conditions (temperature, pressure, fluid type) and tank specifics (material, shape, existing fittings).

- Prioritize features: leak resistance, ease of installation, or UV protection based on your project environment.

- Leverage IFAN’s Free Resources:

- Download our Tank Connection Fitting Guide (link to resource page) for technical specs and design tips.

- Request a free sample to test compatibility before bulk orders.

7. Ready to Customize Your Tank Connects? Start Here

- Recap the benefits: durable PPR material, fully customizable designs, factory-direct pricing, and global compliance.

- Call-to-Action:

- Visit ifanpro.com/tank-connects to explore standard products and customization options.

- Submit a custom inquiry form with your tank specs for a free quote within 24 hours.

- Follow us on LinkedIn for case studies, industry news, and exclusive offers on custom fittings.

Conclusion: Elevate Your Tank System with Tailored PPR Fittings from IFAN

Emphasize that generic fittings are a risk—custom solutions from IFAN ensure leak-free, efficient, and long-lasting tank connections. Position your factory as the trusted partner for problem-solving through customization, whether for a small residential project or a large industrial plant. End with a strong reminder to act: “Don’t settle for one-size-fits-all—get a fitting that’s built for your tank.”

Recent Comments