Introduction to PE Water Pipes in Gas Pipeline Applications

PE water pipe have become a popular choice in gas pipeline applications. Known for their durability, flexibility, and resistance to corrosion, these pipes offer numerous advantages over traditional materials. This article explores the benefits, applications, and considerations for using PE water pipes in gas pipeline systems.

Advantages of PE Water Pipe

PE water pipes provide several benefits for gas pipeline applications. Their inherent properties make them suitable for transporting gas safely and efficiently.

Durability and Flexibility

PE water pipes exhibit excellent durability and flexibility. They can withstand high pressures and resist cracking, even in harsh environmental conditions. The flexibility of PE pipes allows for easy installation, especially in areas with complex layouts.

Corrosion Resistance

One of the main advantages of PE water pipes is their resistance to corrosion. Unlike metal pipes, PE pipes do not corrode when exposed to moisture or chemicals. This property ensures a longer lifespan and reduces maintenance costs.

Leak-Free Joints

PE water pipes can be joined using heat fusion, creating a leak-free joint. This method eliminates the need for additional fittings and reduces the risk of gas leaks. The seamless joints enhance the overall safety and reliability of the gas pipeline system.

Applications in Gas Pipeline Systems

PE water pipes are used in various gas pipeline applications, including residential, commercial, and industrial settings. Their versatility makes them suitable for different types of gas distribution networks.

Residential Gas Distribution

In residential areas, PE water pipes provide a safe and efficient method for gas distribution. They are used to transport natural gas from the main supply lines to individual homes. The flexibility and ease of installation make them ideal for residential projects.

Commercial Gas Networks

PE water pipes are also used in commercial gas networks. They supply gas to commercial buildings, such as offices, restaurants, and shopping centers. The corrosion resistance and leak-free joints ensure a reliable gas supply to these establishments.

Industrial Gas Pipelines

In industrial settings, PE water pipes are use for transporting gas to factories and manufacturing plants. The durability and high-pressure tolerance of PE pipes make them suitable for heavy-duty applications. They can handle the demands of industrial gas distribution without compromising safety.

Installation of PE Water Pipes in Gas Systems

Proper installation is crucial for the performance and safety of PE water pipes in gas pipeline systems. The installation process involves several steps to ensure a secure and efficient gas supply.

Site Preparation

The installation process begins with site preparation. This involves surveying the area, marking the pipeline route, and ensuring the ground is stable. Proper site preparation helps prevent issues during installation and ensures the pipeline’s longevity.

Trenching and Laying Pipes

After preparing the site, trenches are dug along the mark route. The depth and width of the trenches depend on the pipe size and local regulations. PE water pipes are then laid in the trenches, ensuring they are properly aligned and support.

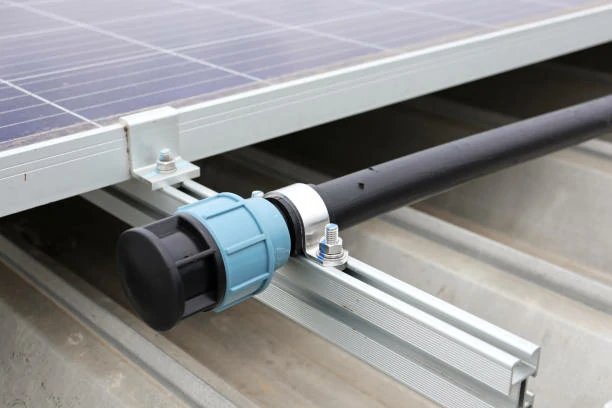

Heat Fusion Joining

The joints between PE water pipes are created using heat fusion. This process involves heating the pipe ends and pressing them together to form a strong, leak-free bond. Heat fusion ensures the integrity of the pipeline and prevents gas leaks.

Pressure Testing

Once the pipes are installed and joined, the entire system undergoes pressure testing. This step ensures there are no leaks and the pipeline can handle the required gas pressure. Pressure testing is essential for verifying the safety and reliability of the gas distribution network.

Maintenance and Safety Considerations

Regular maintenance and safety checks are important for the longevity and performance of PE water pipes in gas pipeline systems. Following best practices ensures the system operates efficiently and safely.

Routine Inspections

Conduct routine inspections to identify any signs of wear, damage, or potential leaks. Inspections should include visual checks and pressure tests to ensure the system’s integrity. Addressing issues promptly prevents major problems and ensures continuous gas supply.

Leak Detection

Implement leak detection systems to monitor the gas pipeline continuously. These systems help identify leaks early, allowing for quick response and repair. Leak detection enhances the safety of the gas distribution network and prevents accidents.

Training and Safety Protocols

Ensure that personnel involve in the installation and maintenance of PE water pipes are properly train. Establish and follow safety protocols to minimize risks during installation and maintenance activities. Proper training and safety measures protect workers and ensure the safe operation of the gas pipeline system.

Environmental Benefits

PE water pipe offer environmental benefits, making them a sustainable choice for gas pipeline applications. Their production and use have a lower environmental impact compared to traditional materials.

Reduced Carbon Footprint

The production of PE water pipes generates fewer carbon emissions compared to metal pipes. Additionally, the energy-efficient manufacturing process contributes to a lower overall carbon footprint. Using PE pipes supports sustainability efforts in gas distribution.

Recyclability

PE water pipes are recyclable, reducing waste and promoting environmental sustainability. At the end of their lifespan, the pipes can be recycl and repurposed, minimizing their impact on landfills. Recycling PE pipes conserves resources and supports a circular economy.

Cost-Effectiveness

PE water pipes are cost-effective for gas pipeline applications. Their long lifespan, low maintenance requirements, and ease of installation translate to significant cost savings over time.

Long Lifespan

The durability of PE water pipes ensures a long service life, reducing the need for frequent replacements. This longevity lowers the overall cost of the gas pipeline system, making it a cost-effective solution.

Low Maintenance

PE water pipes require minimal maintenance due to their resistance to corrosion and leaks. The reduced maintenance needs result in lower operational costs, providing long-term financial benefits.

Ease of Installation

The flexibility and light weight of PE water pipes simplify the installation process. Reduced labor and equipment costs during installation contribute to the overall cost-effectiveness of using PE pipes in gas pipelines.

Conclusion

PE water pipes are an excellent choice for gas pipeline applications due to their durability, flexibility, and resistance to corrosion. Their advantages, including uniform heat distribution, energy efficiency, and space-saving design, make them suitable for various residential, commercial, and industrial settings. Proper installation, maintenance, and adherence to safety protocols ensure the optimal performance and longevity of PE water pipes in gas distribution networks. By utilizing high-quality PE water pipes, users can enhance the reliability, efficiency, and safety of their gas pipeline systems.

Connect

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interest in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments