I’ve seen this question cause real confusion on job sites. A plumber once asked me if mixing these types would cause a major failure in his project.

Yes, it is generally safe to use PEX B fittings on PEX A pipes, as they are designed to be compatible within the same nominal size. However, the key to a reliable connection lies in understanding their manufacturing differences and using the correct, manufacturer-approved installation method for the fitting, not the pipe.

This topic can be tricky, so let’s clear up the confusion step by step. We will look at compatibility, material science, practical installation, and what the official codes say.

Are PEX A Pipes and PEX B Fittings Generally Compatible and Interchangeable?

In the field, plumbers often need to connect different PEX types. I’ve advised many on how to do this without risking leaks.

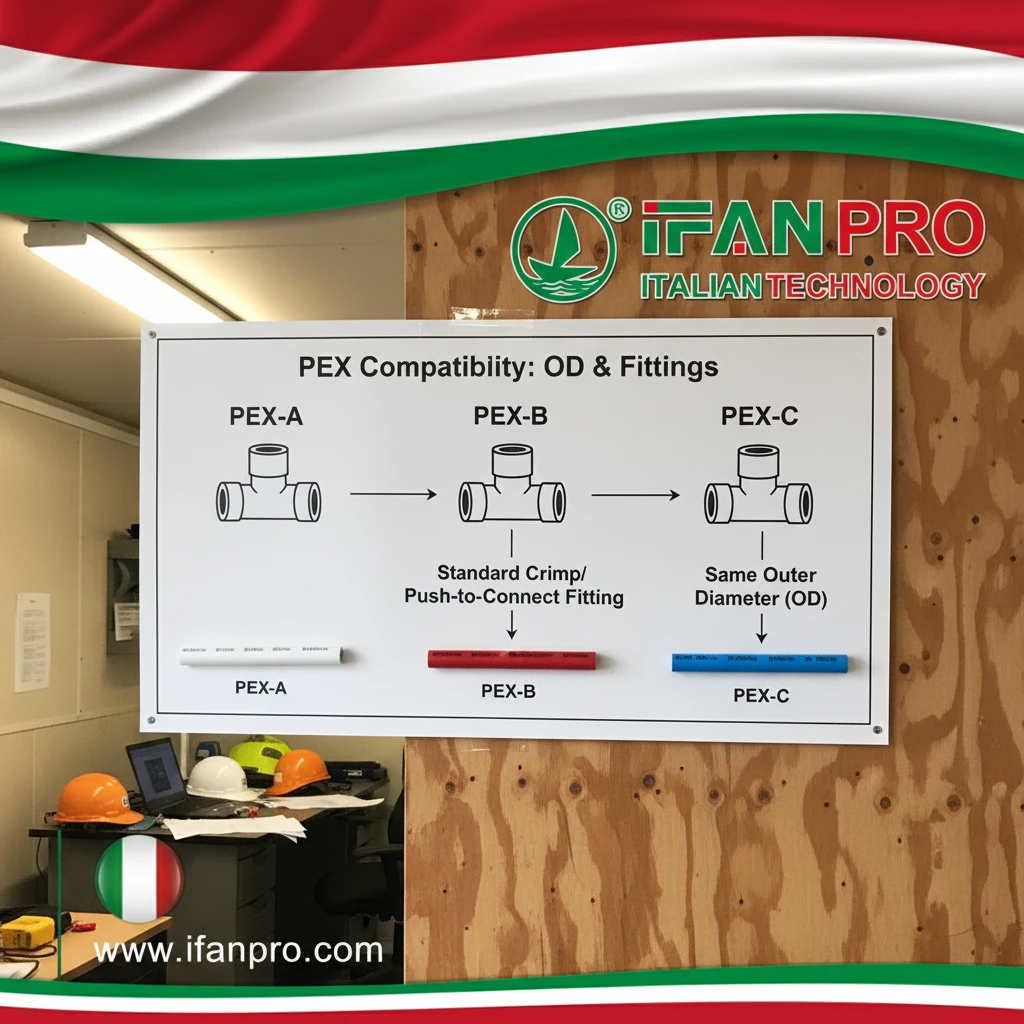

PEX A pipes and PEX B fittings are generally compatible and interchangeable in terms of physical dimensions for standard cold- and hot-water plumbing systems. They share the same outside diameters and are designed to work with the same family of fittings, making a physical connection possible.

Understanding PEX Types and Compatibility

First, it’s important to know what “PEX A” and “PEX B” mean. The letters refer to how the polyethylene material is cross-linked to make it stronger and more heat-resistant.

- PEX-A is made using the Engel method. This process creates a higher degree of cross-linking. This makes the pipe more flexible and gives it a strong “memory” – it wants to return to its original shape.

- PEX-B is made using the Silane method. It is slightly less flexible and has a different molecular structure.

Now, for compatibility. The most important fact is that both PEX-A and PEX-B tubes are manufactured to the same standard outside diameters (OD). For example, a 1/2-inch PEX-A pipe and a 1/2-inch PEX-B pipe have the exact same outer size. This is what allows them to fit into the same standard fittings.

The Role of Fittings

Fittings are separate from the pipe type. Common fittings include brass or polymer elbows, tees, and couplings. The most popular systems for connecting PEX are:

- Crimp (or Clamp) Fittings: A metal ring is compressed around the pipe and fitting using a special tool.

- Push-to-Connect Fittings: The pipe is pushed into the fitting, where an internal grip and O-ring seal hold it.

Here is a simple table to show how fitting systems generally work with pipe types:

| Fitting Connection Type | Commonly Used With | Works on Both PEX-A & PEX-B? |

|---|---|---|

| Expansion (using PEX-A tool) | Specifically for PEX-A pipes | No, this method is for PEX-A only. |

| Crimp / Clamp | PEX-B, PEX-C, and also PEX-A | Yes, this is the standard method for connecting PEX-B fittings to any PEX type. |

| Push-to-Connect | All PEX types (A, B, C) | Yes, these are universal fittings. |

So, can you use a PEX-B fitting on a PEX-A pipe? Absolutely. You are not mixing pipe materials inside a single pipe. You are connecting a standardized fitting to a standardized pipe. The fitting doesn’t “know” if the pipe is A or B; it only knows that the pipe’s outside diameter is correct. Therefore, from a pure size and connection standpoint, they are interchangeable. The critical rule is to follow the installation instructions for the fitting you are using.

How Do Manufacturing Differences Affect the Connection Between PEX A and PEX B?

The different manufacturing processes affect how the pipe behaves during installation. Ignoring this is a common source of problems.

The main manufacturing difference is that PEX A pipe is more flexible and has a stronger “memory” than PEX B. When using a clamp or crimp ring on PEX A, this memory creates a continuous outward force against the ring, which can actually improve seal strength over time if installed correctly. However, forcing a stiff PEX B pipe onto a fitting not designed for it can lead to stress and potential failure.

The Science of “Memory” and Seal Pressure

The Engel method used for PEX-A creates a more uniformly cross-linked polymer. Think of the material structure as a very consistent, tight net. This structure gives PEX-A two key traits:

- High Flexibility: It can be bent into tighter radii without kinking.

- Strong Shape Memory: When you stretch it (like when expanding it over a fitting in its native method), it wants to shrink back to its original size with great force.

Now, when you use a crimp or clamp fitting on PEX-A, you are not expanding it first. You are sliding the fitting in and squeezing a metal ring around the pipe. The pipe’s natural “memory” is now working outward against the constriction of the ring. This constant outward pressure helps maintain a tight seal on the fitting’s barbs over many years, even as the materials naturally relax a tiny amount. This is a positive effect.

Potential Risks of Misapplication

The risk comes from misunderstanding the system. PEX-B is less flexible. If you try to use an expansion fitting system (the native method for PEX-A) on a PEX-B pipe, you may have problems. The PEX-B pipe may not expand as easily or fully, and its weaker memory means it will not shrink back onto the fitting with the same force, likely resulting in a weak seal and a leak.

Another point is chemical compatibility. Both PEX-A and PEX-B are made from high-density polyethylene that is cross-linked. They are chemically very similar and compatible. There is no harmful reaction when they are in contact. The issue is purely mechanical – how the physical connection is made and maintained.

Comparing Pipe Properties

This table summarizes how the manufacturing differences play out in a practical connection using standard crimp/clamp fittings:

| Property | PEX-A Pipe with Crimp/Clamp Fitting | PEX-B Pipe with Crimp/Clamp Fitting | Implication for Mixed Connection (PEX-A pipe + PEX-B fitting) |

|---|---|---|---|

| Flexibility | Very High | Moderate | Easier to handle and maneuver PEX-A pipe during installation. |

| Shape Memory | Very Strong | Moderate | PEX-A’s strong memory provides continuous sealing force against the crimp ring. |

| Initial Seal Creation | Good (created by crimp tool force) | Good (created by crimp tool force) | The initial seal relies 100% on the proper crimping of the ring. |

| Long-Term Seal Maintenance | Excellent (aided by pipe’s memory) | Good | The connection benefits from the extra holding power of PEX-A’s memory. |

In short, the manufacturing difference of PEX-A (its memory) can be an advantage when using crimp/clamp fittings, making the connection to a PEX-B fitting potentially more robust, not less. The key is to never use the wrong installation method.

What Installation Techniques Ensure a Safe PEX B to PEX A Pipe Connection?

A safe connection relies 100% on proper technique. I always tell clients that the right tool and a simple checklist prevent almost all failures.

To ensure a safe connection, always use the installation method specified for the PEX B fitting—typically a crimp or clamp system—not the method for the PEX A pipe. This requires using a calibrated crimp or clamp tool, a go/no-go gauge to check every connection, and ensuring the pipe is properly deburred and fully seated on the fitting before crimping.

Step-by-Step Guide for a Reliable Connection

Mixing materials is fine, but you must follow a disciplined process. Here is the safe way to connect a PEX-B brass crimp fitting to a PEX-A pipe.

Step 1: Cut the Pipe Cleanly

Use a sharp, dedicated PEX tube cutter. Do not use a regular saw, as it will leave rough edges and plastic debris. A clean, square cut is essential.

Step 2: Deburr and Chamfer the Pipe

This is a critical step many skip. After cutting, use a deburring tool to:

- Remove the slight inner plastic ridge (burr) that can disrupt water flow.

- Slightly chamfer (bevel) the outer edge of the pipe. This helps the pipe slide smoothly into the fitting and prevents the O-ring (in some fittings) or the pipe itself from getting scratched or rolled.

Step 3: Inspect and Mark the Pipe

Check that the fitting is clean and undamaged. Slide the crimp ring onto the pipe first. Then, push the pipe all the way onto the fitting until it hits the shoulder. Use a felt-tip pen to mark a line on the pipe at the edge of the fitting. This visual check proves the pipe is fully seated before you crimp.

Step 4: Crimp with the Correct Tool

Place the jaws of your calibrated crimp tool over the crimp ring, centered on the fitting’s barb. Squeeze the tool handles firmly and completely until they release. You will hear or feel a distinct click or release. Do not use pliers or an uncalibrated tool.

Step 5: Verify with a Go/No-Go Gauge

After every single crimp, you must verify it. Take your go/no-go gauge. The “Go” side should slide easily over the crimped ring. The “No-Go” side should NOT fit over the ring. If the No-Go side fits, the crimp is under-sized and will leak. You must cut out the fitting and redo it.

Essential Tools Checklist

Never attempt this connection without the right tools. Here is what you need:

| Tool | Purpose | Why It’s Mandatory |

|---|---|---|

| PEX Tubing Cutter | Creates a clean, square cut. | A jagged cut prevents proper seating and can damage seals. |

| Deburring/Chamfering Tool | Smoothes inner and outer edges. | Removes burrs that cause turbulence and chamfers the edge for easy insertion. |

| Calibrated Crimp Tool | Compresses the metal ring to exact specs. | Only a calibrated tool applies the precise, even force needed for a seal. |

| Go/No-Go Gauge | Checks the final crimp diameter. | This is your quality control. It confirms a perfect crimp every time. |

By following these steps and using these tools, you create a mechanical connection that is completely safe and reliable, regardless of the PEX type combination. The system’s safety depends on your technique, not the brand of pipe.

Do Plumbing Codes Approve Using PEX B Fittings with PEX A Pipe Systems?

This is the final and most important question for professional installers. My advice is always to check the local code first.

Most major international plumbing codes, like the IPC and UPC, approve the use of PEX B fittings with PEX A pipe systems, provided the entire assembly (pipe + fittings + method) is listed and certified by an approved third-party organization such as IAPMO, NSF, or UL. The approval is based on the tested performance of the complete system, not individual components.

How Codes Evaluate Plumbing Systems

Plumbing codes exist to ensure safety and reliability. They do not typically say “PEX-B fittings can be used with PEX-A pipe.” Instead, they require that all plumbing products be listed and labeled.

- Listed: This means the product (like a specific brand of fitting) has been tested by a recognized agency (like IAPMO or NSF) and meets a particular standard (like ASTM F1807 for brass crimp fittings).

- Labeled: This means each individual fitting has a marking showing it is part of that listed product line.

Crucially, listings are often for systems. A manufacturer will have their PEX-B crimp fittings tested and certified for use with PEX pipes that meet specific standards (like ASTM F876 for PEX). Because PEX-A and PEX-B pipes both meet these material standards, the fitting’s listing generally covers its use with both.

Key Standards and Certifications

To be code-compliant, your mixed system must align with these standards. Look for markings on the pipes and fittings.

| Component | Relevant Standard | What It Means |

|---|---|---|

| PEX-A or PEX-B Pipe | ASTM F876 | Standard Specification for Crosslinked Polyethylene (PEX) Tubing. This covers the material performance for all PEX types. |

| Crimp Fittings (Brass) | ASTM F1807 | Standard for metal insert fittings using copper crimp rings. This is the key standard for the fittings. |

| System Certification | IAPMO PS-144 / NSF 14 | These are comprehensive standards that certify the performance of the entire system (pipe + fitting + ring) under pressure and temperature cycling. |

The Golden Rule for Code Compliance

The installer’s responsibility is to ensure all components are from a manufacturer that has tested and approved their combination. For example, if you use Brand X’s PEX-A pipe, the safest and most code-defensible practice is to use Brand X’s (or their explicitly recommended) crimp fittings and rings.

Using fittings from one reputable brand with pipe from another is usually acceptable if both are listed to the same standards and the connection method is followed precisely. However, the ultimate authority is your local building inspector. Before starting a large project, it is wise to present your planned materials (pipe, fitting samples, tool) to the inspector for approval.

In summary, the codes approve systems that are tested and proven. A PEX-B crimp fitting on a PEX-A pipe, when installed correctly with the proper tool, forms a system that meets all major code requirements for durability and safety.

Conclusion

Yes, connecting PEX B fittings to PEX A pipes is safe and code-compliant when you follow the correct crimp method and use quality components. For a reliably compatible system, consider IFAN‘s PEX-A pipes and our full range of brass crimp fittings, all manufactured to international standards for peace of mind on every job.

Recent Comments