PEX (cross-linked polyethylene) pipe have become a popular choice for DIY home plumbing projects due to their flexibility, durability, and ease of installation. This guide will walk you through the steps to use PEX pipes effectively in your home project.

Benefits of Using PEX Pipe

Flexibility

PEX pipe can bend around corners, reducing the need for elbow fittings. This flexibility makes installation easier and quicker.

Durability

PEX pipe resist scale and chlorine, and they do not corrode or develop pinholes. They can withstand high and low temperatures, making them suitable for various plumbing applications.

Ease of Installation

PEX pipe are lighter and easier to handle compared to traditional copper or PVC pipes. The installation process is simpler, requiring fewer tools and connections.

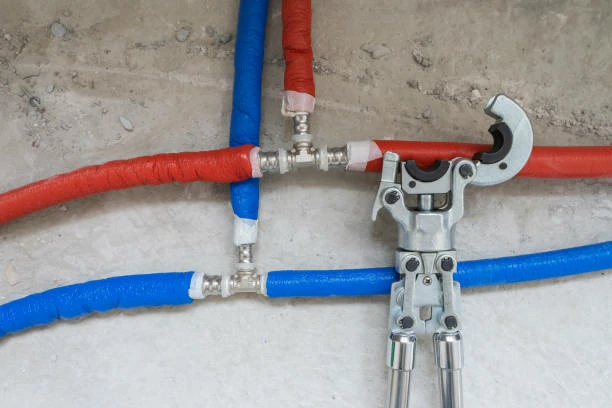

Tools and Materials Needed

Tools

- PEX pipe cutter

- Crimping tool or cinch tool

- Go/No-Go gauge

- Deburring tool

- Adjustable wrench

Materials

- PEX pipes

- PEX fittings (couplings, elbows, tees)

- Crimp rings or cinch clamps

- Manifold (if applicable)

- Pipe insulation (for exposed areas)

Planning Your Project

Assess Your Plumbing Needs

Determine the scope of your project. Identify the areas where you need to replace or install new pipes, and decide on the pipe diameters required for different sections.

Measure and Plan

Measure the lengths of PEX pipe needed for your project. Plan the layout to minimize the number of fittings required, utilizing the flexibility of PEX to reduce joints and potential leak points.

Choose the Right PEX Type

PEX pipe come in three types: PEX-A, PEX-B, and PEX-C. PEX-A is the most flexible and resistant to kinking, making it ideal for complex layouts. PEX-B and PEX-C are slightly less flexible but still suitable for most applications.

Cutting and Preparing PEX Pipes

Measure and Cut

Measure the required lengths of PEX pipe and use a PEX pipe cutter to make clean, straight cuts. Ensure the cuts are smooth and free from burrs.

Deburr the Pipe Ends

Use a deburring tool to smooth the cut ends of the PEX pipe. This step ensures a secure and leak-free connection with the fittings.

Making Connections

Slide Crimp Rings or Cinch Clamps onto the Pipe

Slide a crimp ring or cinch clamp onto the end of the PEX pipe. Position it about an inch from the cut end.

Insert the Fittings

Insert the appropriate PEX fitting (such as a coupling, elbow, or tee) into the end of the pipe. Push the fitting in until it bottoms out against the pipe.

Secure the Connections

Use a PEX crimping tool or cinch tool to secure the crimp rings or cinch clamps around the pipe and fittings. Ensure the tool is properly calibrated and that the rings or clamps are evenly tightened.

Check the Connections

Use a Go/No-Go gauge to verify that the crimp connections are secure. The gauge should slide over the crimp ring without obstruction.

Installing the PEX Pipes

Run the Pipes

Run the PEX pipes along the planned route, securing them with pipe supports or hangers as needed. Avoid sharp bends or kinks in the pipe, and use proper supports to maintain alignment.

Install Manifolds (if applicable)

If your project includes a manifold system, connect the PEX pipes to the appropriate ports on the manifold. Manifolds provide a centralized distribution point for water supply, reducing the number of connections and potential leak points.

Insulate Exposed Pipes

Insulate any exposed sections of PEX pipe, especially in unheated areas, to prevent freezing and maintain energy efficiency.

Testing and Final Steps

Turn On the Water Supply

Slowly turn on the main water supply. Check all connections for leaks. If you find any leaks, turn off the water and re-tighten the connections.

Inspect the System

Thoroughly inspect the entire system for signs of leaks or improper connections. Ensure that all fittings are secure and that the pipes are properly supported.

Monitor for Leaks

Monitor the system for a few hours after installation to ensure there are no leaks. If any issues arise, address them promptly to prevent water damage.

Regular Maintenance

Perform regular maintenance checks on your PEX plumbing system. Inspect for signs of wear, and ensure that all connections remain secure over time.

Tips for Success

Proper Installation Techniques

Follow proper installation techniques to avoid common mistakes. Ensure that all cuts are clean, fittings are properly inserted, and connections are secure.

Use Quality Materials

Invest in high-quality PEX pipes and fittings to ensure the longevity and reliability of your plumbing system. Inferior materials can lead to leaks and other plumbing issues.

Protect Against Freezing

Protect PEX pipes from freezing temperatures by insulating pipes in unheated areas and maintaining a warm indoor environment.

Avoid Kinking the Pipe

Be careful not to kink the PEX pipe during installation. Kinks can weaken the pipe and lead to leaks over time.

Consult Professional Help if Needed

If you are unsure about any aspect of the installation process, consider consulting a professional plumber for guidance or assistance.

Conclusion

Using PEX pipes in a DIY home project can significantly simplify your plumbing work while providing durable and reliable results. By following these steps and tips, you can ensure a successful transition to PEX plumbing, enhancing the efficiency and longevity of your home’s water supply system.

Connect

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interest in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments