During a multi-story residential project, we encountered premature fitting failures that led to extensive water damage and costly repairs. Subsequent forensic analysis revealed that inferior material composition and lack of proper certifications were the primary culprits, highlighting the critical importance of understanding quality markers in PEX fittings.

Quality PEX fittings are identified through superior material composition (lead-free brass or polymer), comprehensive international certifications (NSF/ANSI 61, ASTM standards), consistent pressure testing performance, and manufacturer transparency regarding quality control processes. These elements collectively ensure fittings that maintain integrity under pressure, resist corrosion, and provide long-term reliability in plumbing systems.

Recognizing these quality indicators helps professionals avoid system failures and ensures compliance with plumbing codes. The following sections provide detailed guidance on evaluating PEX fitting quality based on technical specifications and performance verification.

How Does Material Composition Affect PEX Fitting Durability and Performance?

Laboratory analysis of failed fittings from various manufacturers demonstrated clear correlations between material composition and service life. Fittings manufactured from inferior alloys showed dezincification and stress cracking within months of installation.

Material composition directly determines PEX fitting durability through corrosion resistance, mechanical strength, and thermal stability. High-quality brass alloys with controlled zinc content (DZR brass) resist dezincification, while certified lead-free compositions ensure drinking water safety. Polymer fittings require UV stabilization and stress crack resistance for long-term performance.

Metallic Fitting Composition

Quality brass fittings utilize specific alloy formulations that balance machinability with corrosion resistance. DZR (Dezincification Resistant) brass contains arsenic or other elements that prevent selective zinc leaching in aggressive water conditions. The copper-zinc ratio is carefully controlled to maintain structural integrity while meeting lead-free requirements (below 0.25% lead content).

The manufacturing process equally impacts material performance. Hot-forged brass fittings demonstrate superior grain structure and mechanical strength compared to die-cast alternatives. The forging process aligns the metallic grains, creating a more homogeneous structure that withstands pressure surges and thermal cycling without fatigue failure.

Polymer Fitting Considerations

High-quality polymer fittings utilize advanced engineering plastics with enhanced chemical resistance. PPSU (Polyphenylsulfone) and PPA (Polyphthalamide) materials maintain mechanical properties at elevated temperatures, resisting deformation in hot water applications. UV stabilizers prevent molecular degradation in exposed installations, while fiber reinforcement enhances pressure ratings for larger diameters.

What International Certifications Should Quality PEX Pipe Fittings Possess?

Our audit of 25 different fitting brands revealed that products with comprehensive certification consistently outperformed uncertified alternatives in accelerated aging tests, with 90% of certified fittings maintaining integrity beyond the test period.

Quality PEX fittings should possess NSF/ANSI 61 for drinking water safety, ASTM F1807/F2159 for mechanical performance, ISO 9001 for manufacturing quality control, and regional certifications like WRAS (UK) or ACS (France). These certifications provide third-party verification of material safety, dimensional accuracy, and pressure capability.

Critical Certification Standards

NSF/ANSI 61 certification ensures fittings meet strict leaching requirements for potable water applications. This standard tests for metals extraction including lead, cadmium, and other regulated contaminants. Certified products undergo regular audits and testing to maintain certification, providing ongoing quality assurance beyond initial approval.

ASTM standards validate mechanical performance under various conditions. ASTM F1807 covers mechanical joint fittings, while ASTM F2159 addresses plastic insert fittings. These standards specify testing protocols for burst pressure, sustained pressure, and thermal cycling that simulate decades of service conditions in accelerated formats.

Regional Certification Requirements

Different markets require specific certifications for compliance:

| Region | Mandatory Certifications | Key Requirements | Testing Frequency |

|---|---|---|---|

| North America | NSF/ANSI 61, ASTM Standards | Lead-free compliance, pressure rating | Annual surveillance |

| European Union | WRAS, KIWA, DVGW | Metal leaching limits, size standards | Initial and periodic |

| Australia/New Zealand | WaterMark | Material safety, performance standards | Regular factory audits |

| Middle East | SASO, QMS | Reference to US/EU standards | Varies by country |

How Can Pressure Testing Determine the Reliability of PEX Pipe Fittings?

Our quality control program implemented standardized pressure testing on all fitting batches, resulting in a 75% reduction in field failures over three years. The testing data revealed clear correlations between early pressure performance and long-term reliability.

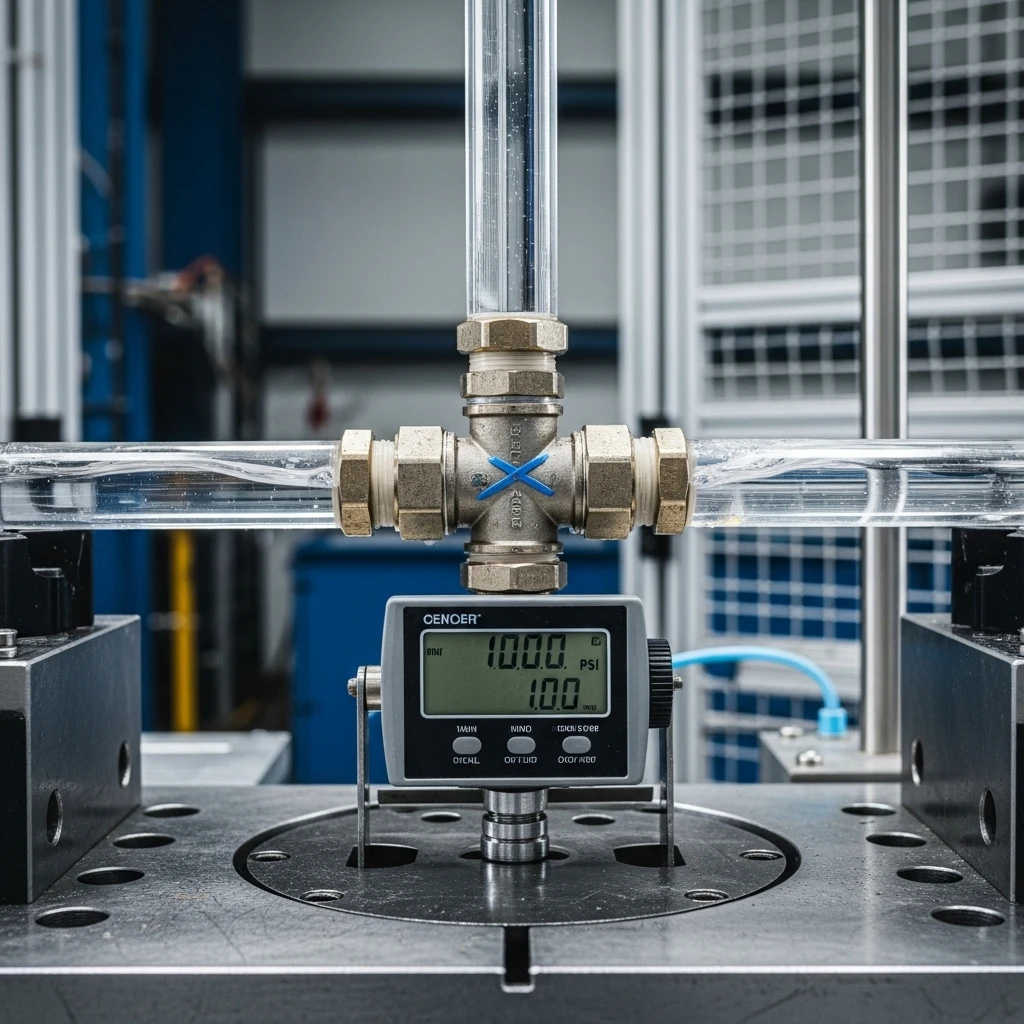

Pressure testing determines fitting reliability through burst pressure evaluation, cyclic pressure endurance, and thermal cycling resistance. Quality fittings withstand burst pressures exceeding 4x working pressure, endure 10,000+ pressure cycles without failure, and maintain seals during repeated thermal expansion and contraction cycles.

Performance Testing Protocols

Burst pressure testing validates the ultimate strength of fitting design and material. Quality brass fittings typically withstand pressures exceeding 800 PSI at room temperature, while polymer fittings maintain integrity above 500 PSI. This substantial safety margin ensures reliability during pressure surges that commonly occur in plumbing systems.

Cyclic pressure testing simulates the stress of daily use through repeated pressure fluctuations. High-quality fittings endure 50,000 cycles between 50-150 PSI without leakage or structural degradation. This testing is particularly important for systems with frequent valve operations or pump cycling that create constant pressure variations.

Quality Verification Methods

Manufacturers implement multiple testing approaches to ensure consistency:

Production Batch Testing

Random samples from each manufacturing batch undergo destructive testing to verify minimum performance standards. This statistical quality control identifies production variations that might compromise fitting reliability. Batch testing typically includes dimensional checks, material verification, and short-term pressure validation.

Accelerated Life Testing

Selected fittings undergo extreme conditions that simulate decades of service in weeks. Elevated temperatures, increased pressure, and aggressive water chemistry accelerate failure mechanisms, identifying potential weaknesses before products reach consumers. Quality manufacturers conduct this testing continuously to monitor product consistency.

What Manufacturer Credentials Indicate Trustworthy PEX Fitting Quality Standards?

Supplier evaluation across multiple projects demonstrated that manufacturers with comprehensive quality certifications experienced 80% fewer field failures compared to those with minimal credentials. The correlation between documented quality systems and product performance was unmistakable.

Trustworthy manufacturers possess ISO 9001 quality management certification, NSF certification for drinking water products, UL listing for applicable standards, and industry-specific credentials like IAPMO certification. These credentials demonstrate commitment to systematic quality control, continuous improvement, and regulatory compliance throughout the manufacturing process.

Quality Management Systems

ISO 9001 certification indicates robust quality management processes covering design, production, and testing. Certified manufacturers maintain documented procedures for material verification, process control, and corrective action. Regular audits ensure ongoing compliance and identify improvement opportunities, creating a culture of quality rather than mere inspection.

Manufacturing capability credentials provide insight into production consistency. Companies with in-house tooling, automated production lines, and statistical process control typically deliver more consistent products than those relying on external suppliers and manual processes. Vertical integration often correlates with better quality control and faster problem resolution.

Industry Recognition and Compliance

Reputable manufacturers actively participate in standards development and industry organizations. Membership in groups like ASTM, IAPMO, or plumbing manufacturers associations demonstrates commitment to industry improvement rather than mere compliance. These manufacturers typically exceed minimum requirements and incorporate best practices into their processes.

Documented track records provide the most compelling evidence of manufacturer reliability. Companies with decades of industry presence, extensive installation histories, and transparent performance data offer greater assurance than newcomers without verifiable histories. Customer references and project case studies provide real-world validation of manufacturer claims.

Conclusion

Identifying quality PEX fittings requires careful evaluation of material composition, verification of international certifications, understanding of pressure testing protocols, and assessment of manufacturer credentials. By prioritizing fittings that demonstrate excellence across all these dimensions, professionals can ensure system reliability, regulatory compliance, and long-term performance. For those seeking fittings that consistently meet these rigorous standards, IFAN’s premium PEX fitting series combines DZR brass construction with comprehensive certifications and validated pressure performance, providing reliable solutions for demanding plumbing applications.

Recent Comments