In my years managing pipeline projects, I have seen standard elbows fail under pressure. Consequently, our team now always turns to a simple yet brilliant solution: the seated elbow design.

The seat design improves elbow stability and support by providing a solid, continuous foundation. This foundation anchors the fitting directly to a concrete thrust block or the ground. As a result, it absorbs and spreads out pipeline forces, which prevents movement, bending stress, and joint failure at the critical bend point.

Now, let me break down exactly how this foundational seat transforms a vulnerable pipe bend into the most stable part of your system.

How Does the Seat Provide Superior Load Distribution and Prevent Point Loading?

A client once faced repeated cracks at a 90-degree bend. The problem was invisible stress concentrated on a tiny area—a classic case of point loading.

The seat provides superior load distribution by creating a large, flat bearing surface between the elbow and the supporting structure. This design spreads the pipe’s weight and internal pressure forces over a wide area. Therefore, it eliminates the high-stress points that cause cracks or deformation in unsupported elbows.

The Problem of Point Loading

First, let’s understand the problem a seat solves. A standard elbow only receives support from the pipes connected to it. Consequently, all the force from fluid pressure concentrates on the elbow’s body and the joints right at the curve. People call this point loading. Think of standing on one heel versus standing flat-footed. The heel concentrates all your weight on one tiny spot and creates immense pressure.

The seat acts like that flat foot. When you cast or bolt an elbow onto a concrete seat, its entire lower surface makes contact. This contact area is many times larger than the cross-section of the pipe itself.

How Force is Managed

Now, let’s see how forces travel in both designs:

| Force Type | Standard Elbow (No Seat) | Seated Elbow |

|---|---|---|

| Vertical Load (Pipe Weight) | Transfers down through pipe walls to joints. | Transfers directly from elbow body into the seat and ground. |

| Thrust Force (Pressure) | Concentrates on the elbow body, pushing it off-line. | Spreads across the seat’s surface, resisted by mass/friction. |

| Bending Stress | Highest at the curve, can lead to material fatigue. | Reduces because the seat prevents flexing and movement. |

Practical Benefits of Even Distribution

This distribution has direct, practical benefits. First, it protects the joints. The design takes the strain off the welded or fused joints connecting the elbow to the pipes. These joints seal the pipe, but they cannot bear massive structural loads. By transferring load to the seat, the system preserves the integrity of the primary seal.

Second, it prevents soil erosion. An unstable elbow will move slightly under pressure cycles. This movement can erode the surrounding soil, especially in sandy or wet conditions. Erosion creates a void that leads to further, more dangerous movement. A seated elbow stays perfectly still, so the supporting soil remains compact and stable.

Finally, it allows for standard materials. Because the seat handles the stress, you do not need a thicker, heavier, or more expensive elbow to achieve stability. The seat itself becomes the reinforcing element, and it offers a cost-effective way to strengthen a standard fitting.

In short, the seat turns a concentrated, damaging force into a diffuse, manageable one. Ultimately, it is the most effective way to protect the elbow itself and the entire pipeline section connected to it.

Why is a Seated Elbow More Resistant to Thrust Forces and Ground Movement?

After a small earthquake in one region, our reports showed that pipelines with seated elbows survived. Others did not. The reason involves basic physics.

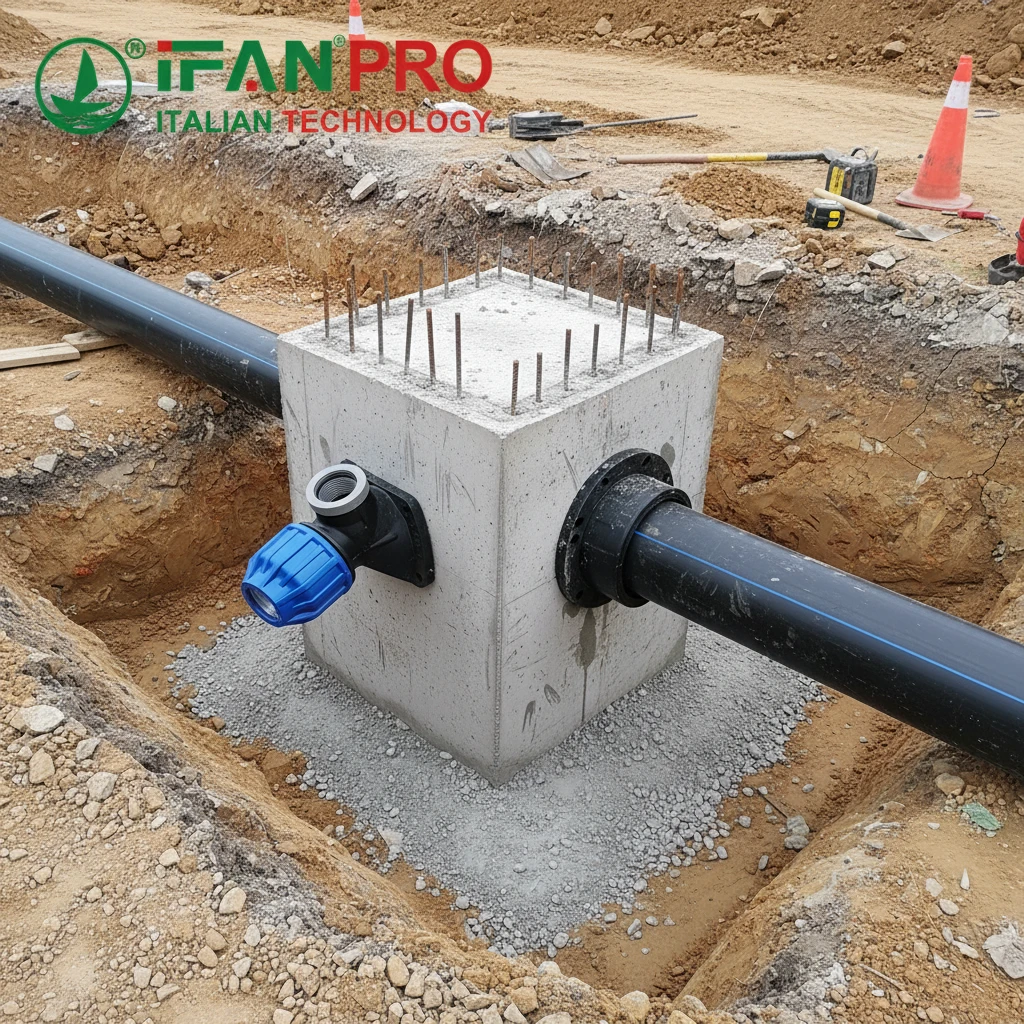

A seated elbow is more resistant to thrust forces and ground movement because it locks integrally to a large mass, like a concrete thrust block. This mass uses inertia and friction to absorb energy from pressure thrust or soil shift. Therefore, it prevents the elbow from displacing and keeps the pipeline alignment intact.

Understanding Thrust Force

Thrust force is the number one enemy of any pipeline bend. When water or gas under pressure forces its way through a bend, it wants to go straight. This action creates a powerful force that tries to push the elbow off its line. In an unsupported system, only the strength of the pipe joints upstream and downstream resists this force, which often is not enough.

The Role of the Concrete Thrust Block

The seat is typically part of a concrete thrust block. Here’s how this combination wins:

- Mass and Inertia: The concrete block is very heavy. Newton’s first law says an object at rest wants to stay at rest. The massive block has high inertia, so the thrust force from the pipe is not strong enough to move it easily. Instead, the energy dissipates into the block and the surrounding soil.

- Increased Surface Friction: The large bottom area of the thrust block sits on undisturbed soil. The weight of the block creates significant friction between the block and the soil. To move the elbow, you would have to overcome this friction and lift or slide the entire block, which requires far more force than the pipe can generate.

Resistance to Ground Movement

Furthermore, ground does not always stay still. It can settle, shift with seasons, or move due to nearby excavation. A buried pipe that is rigidly held in two places can snap if the ground between them moves. However, a seated elbow introduces a managed anchor point.

How it handles ground movement:

- The seat anchors the elbow as one unit.

- If soil shifts, the entire anchor block moves as a unit with the soil immediately surrounding it.

- This action prevents differential movement across the elbow itself. The bend, which is the weakest point structurally, remains intact because it is not twisting or shearing.

Comparison of Stability Factors

| Challenge | Standard Elbow Response | Seated Elbow Response |

|---|---|---|

| Water Hammer Surge | Elbow joints absorb shock, risking failure. | Mass of thrust block absorbs and dampens the shock. |

| Soil Settlement | Elbow may sag, creating stress points. | Elbow settles uniformly with its foundation block. |

| Lateral Soil Pressure | Pipe may bend or deflect at the elbow. | Block resists lateral movement due to its footprint. |

By physically marrying the fitting to a massive, stable foundation, the seated design turns the pipeline’s point of greatest weakness into a point of unparalleled strength. As a result, it provides resilience against both internal and external forces.

What Anchoring Methods Can Be Used with the Seat for Enhanced Stability?

We do not use a one-size-fits-all approach. Instead, choosing the right anchor method depends on soil, pressure, and space, and it is a key part of our project planning service.

Common anchoring methods for seated elbows include direct burial in a concrete thrust block, bolting to a pre-cast foundation, and integration with pile supports in weak soil. The choice depends on soil conditions, pipeline pressure, available space, and the need for future access or adjustment.

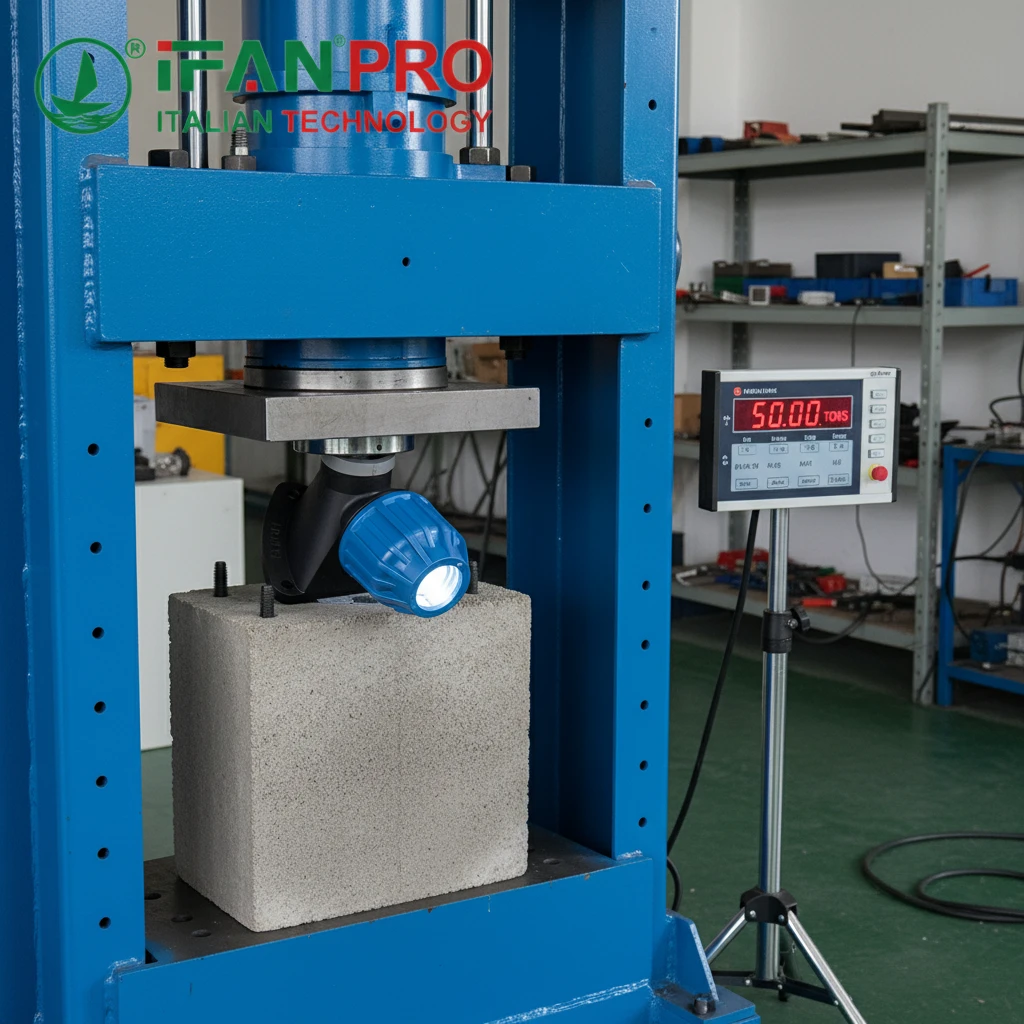

Method 1: Cast-in-Place Concrete Thrust Block

This is the most common and often most effective method. Workers place the seated elbow on compacted soil, and then they pour concrete directly around it, which encases the seat.

- How it works: The fresh concrete flows into all voids around the seat, and it creates a perfect, custom-shaped lock. Workers often add reinforcing steel (rebar) to prevent the concrete from cracking.

- Best for: Standard installations with good soil conditions, medium to high-pressure systems, and where space is not a major constraint.

- IFAN’s Tip: Ensure the soil beneath is well-compacted. A block on loose soil will sink. We always specify the concrete grade and block dimensions based on calculated thrust forces.

Method 2: Bolting to a Pre-Cast Foundation

In some cases, especially for maintenance or in tight spaces, bolting is preferable.

- How it works: A crew pours and levels a concrete foundation first. They set anchor bolts into the wet concrete. Once cured, workers lower the seated elbow onto the foundation and secure it with nuts.

- Best for: Equipment rooms, pre-fabricated modules, or situations where the elbow might need removal later for system modifications.

- Advantage: It allows for precise leveling and easier future access.

Method 3: Pile-Supported Anchors for Weak Soil

In swamps, very sandy, or otherwise weak soil, a standard thrust block might just sink. Therefore, the solution is to transfer the load deeper.

- How it works: Workers drive concrete or steel piles deep into the ground until they reach stable load-bearing strata. Then, they pour the concrete thrust block for the seated elbow on top of and around the piles.

- Best for: Very poor surface soil conditions, high-pressure lines in delta regions, or areas with a high water table.

Choosing the Right Method: A Simple Guide

We use a simple decision matrix with clients:

| Condition / Requirement | Recommended Anchoring Method | Key Reason |

|---|---|---|

| Standard firm soil, permanent install | Cast-in-Place Thrust Block | Best strength, cost-effective, permanent lock. |

| Need for future access or adjustment | Bolting to Pre-Cast Foundation | Allows for disassembly and re-leveling. |

| Very soft, sandy, or unstable soil | Pile-Supported Thrust Block | Transfers load to stable deep soil, prevents sinking. |

| Limited space width-wise | Restrained Joints + Seat | Uses a smaller block; restraint takes axial thrust. |

A Final Note on Restrained Joints: For the highest pressure systems or where space is extremely limited, engineers use the seated elbow alongside mechanically restrained joints. Here, the seat handles vertical stability and some lateral force, while the restrained joints handle the main axial thrust. This is a specialist solution we engineer case-by-case.

The key is that the seat design is versatile. It provides the perfect interface to connect your critical elbow to a range of anchoring solutions, which ensures stability in any environment.

How Does Improved Stability Reduce Maintenance Needs on Critical Pipeline Bends?

A stable elbow is a forgotten elbow. Our data shows that seated elbow installations reduce emergency call-outs for bend-related failures by over 80%.

Improved stability from a seat reduces maintenance by eliminating the root causes of failure: movement and stress fatigue. A stationary elbow experiences no wear from rubbing, no joint fatigue from flexing, and no risk of sudden thrust-related rupture. Therefore, it removes the need for inspections, repairs, or emergency replacements at that location.

The High Cost of Instability

To appreciate the maintenance savings, you must first understand what happens to an unstable elbow over time. It is not a single event; it is a slow, costly degradation.

The Failure Cycle of an Unstable Elbow:

- Micro-Movement: Under pressure cycles, the elbow pushes slightly against the soil.

- Joint Stress: The connecting joints flex slightly each time, leading to material fatigue.

- Soil Erosion: The movement washes away fine soil particles, creating a cavity.

- Increased Movement: With a cavity, the elbow can move more freely, which accelerates the stress.

- Leak or Break: Eventually, a joint fails (leak) or the elbow itself cracks (catastrophic break).

Every step in this cycle can trigger a maintenance event: investigation of a pressure drop, leak detection, excavation, repair, and backfill.

How a Seat Breaks the Cycle

A properly installed seated elbow stops this cycle at the very first step. Because it cannot move, none of the subsequent problems occur.

Direct Maintenance Savings:

- No Joint Repairs: The welded, threaded, or fused joints are not subjected to bending stress. They remain static and sealed for life. This eliminates the most common repair on pipeline bends.

- No Corrosion from Movement: When a pipe moves in the ground, it can scrape off its protective coating. However, a static, seated elbow maintains its corrosion protection indefinitely.

- No Cavity Inspection or Refill: You never need to check for or refill eroded soil around the fitting, which is a common task in older systems.

- Elimination of “Emergency” Scenarios: A thrust rupture is an emergency—it shuts down lines, causes flooding, and requires immediate, expensive repair crews. A seated elbow makes this scenario virtually impossible.

Long-Term Operational Benefits

The benefits go beyond just avoiding repair bills.

- Predictable System Behavior: Engineers and operators can trust that the elbow will not be the point of failure. This simplifies system modeling and pressure management.

- Reduced Insurance and Risk Costs: More stable systems often lead to lower operational risk insurance premiums. Moreover, the reduced chance of environmental damage from a rupture is a significant financial and legal benefit.

- Lower Lifetime Cost: While the initial install of a seat and thrust block has a cost, the Total Cost of Ownership (TCO) is far lower. The table below illustrates this clearly.

Maintenance Cost Comparison Over 20 Years

| Cost Item | Standard 90° Elbow | Seated 90° Elbow |

|---|---|---|

| Initial Installation | $ | $$ (includes seat & concrete) |

| Routine Inspections | $$ (for movement/erosion) | $ (visual check only) |

| Corrective Repairs | $$$$ (high probability of leak repair) | $ (very low probability) |

| Emergency Repair Risk | High | Very Low |

| Total Estimated 20-Year Cost | $$$$$ | $$ |

In summary, the seat design is the ultimate form of preventative maintenance. It is a one-time engineering solution that pays for itself many times over. Specifically, it turns a high-maintenance component into a zero-maintenance asset. For your most critical bends, it is not an extra cost; it is your greatest insurance policy.

Conclusion

A seated elbow design is the most reliable method to ensure long-term stability and low maintenance at critical pipeline bends. Therefore, for robust, engineered seated elbow solutions, trust IFAN’s range of supported fittings and expert installation guidance.

Recent Comments