Choosing the right PPR pipe size is crucial for optimal water flow and system performance. The wrong size leads to pressure drops, noise, and reduced efficiency.

Understanding PPR Pipe Sizing Basics

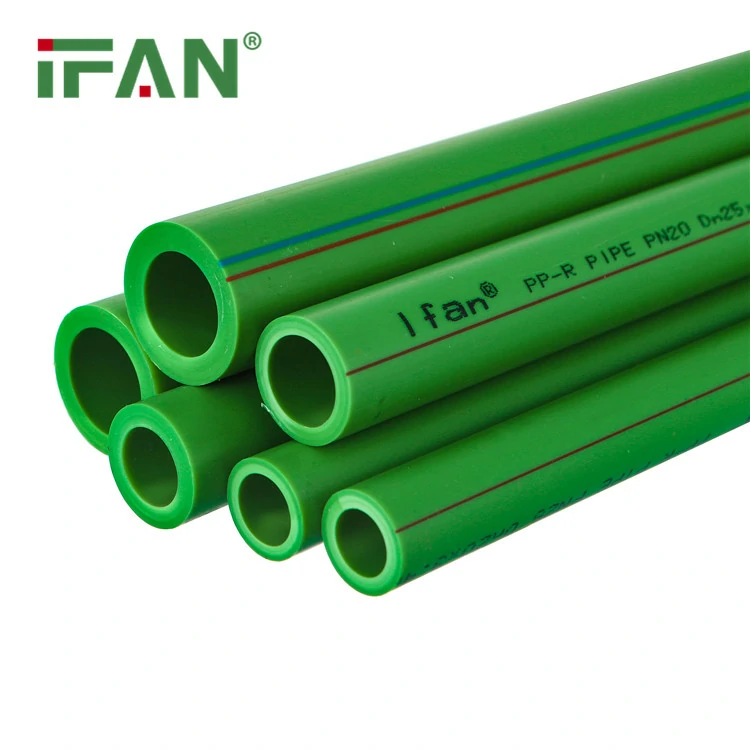

PPR pipes come in standard sizes ranging from 20mm to 160mm in diameter. Wall thickness varies based on pressure ratings and applications.

Common residential sizes:

- 20mm: Small fixtures, washbasins

- 25mm: Kitchen sinks, bathroom connections

- 32mm: Main supply lines, multiple fixtures

- 40mm: Commercial applications, high-demand areas

Key Factors in PPR Pipe Selection

Water Flow Requirements

Calculate your system’s flow rate in liters per minute. Higher flow rates require larger pipe diameters to maintain adequate pressure.

A 20mm pipe handles 15-20 L/min effectively. A 32mm pipe accommodates 40-50 L/min without pressure loss.

Pressure Rating Considerations

PPR pipes have different pressure classes (PN ratings). PN10 suits low-pressure systems. PN20 handles standard residential applications. PN25 works for high-pressure commercial use.

Match the pressure rating to your system requirements. Undersized pressure ratings cause pipe failure.

Distance and Pipe Layout

Longer pipe runs need larger diameters to compensate for friction losses. Multiple bends and fittings increase resistance.

Add 10-15% to diameter calculations for complex layouts with numerous connections.

Step-by-Step Sizing Process

1. Determine Peak Demand

Count simultaneous fixture usage during peak hours. Kitchen sink, shower, and washing machine might run together.

Calculate total flow requirements for worst-case scenarios.

2. Calculate Pipe Diameter

Use the continuity equation: larger diameters reduce flow velocity. Keep velocity between 0.5-2.0 m/s for residential applications.

Higher velocities create noise and wear. Lower velocities allow sediment buildup.

3. Account for Future Expansion

Size pipes 20-30% larger than current needs. This accommodates future additions without complete system replacement.

Commercial applications require more generous sizing margins.

Common Sizing Mistakes to Avoid

Undersizing Main Lines

Small main supply lines create bottlenecks. All downstream pipes suffer from inadequate pressure.

Size main lines first, then branch down to smaller diameters.

Ignoring Elevation Changes

Water flowing upward requires additional pressure. Add 0.1 bar per meter of elevation gain.

Multi-story buildings need careful pressure calculations at each level.

Mixing Incompatible Sizes

Sudden diameter changes create turbulence and pressure drops. Use gradual transitions between different pipe sizes.

Standard reducers minimize flow disruption.

Professional Sizing Tools and Resources

Flow Calculation Software

Modern design software accounts for all variables simultaneously. Input fixture counts, pipe lengths, and elevation changes.

Software provides accurate diameter recommendations and pressure analysis.

Manufacturer Sizing Charts

PPR pipe manufacturers provide detailed sizing tables. These charts consider specific pipe characteristics and regional standards.

Reference manufacturer data for precise specifications.

Installation Best Practices

Proper Support Spacing

Larger pipes need closer support intervals. 32mm pipes require supports every 80cm. 63mm pipes need supports every 120cm.

Inadequate support causes sagging and joint stress.

Thermal Expansion Accommodation

PPR pipes expand with temperature changes. Larger pipes expand more significantly.

Install expansion loops or flexible connectors in long straight runs.

Quality Fittings Selection

Use fittings rated for the same pressure as your pipes. Undersized fittings create weak points in the system.

Quality fittings ensure long-term reliability and performance.

Maintenance and Long-term Performance

Regular System Monitoring

Monitor water pressure at multiple points regularly. Pressure drops indicate sizing issues or blockages.

Document pressure readings for trend analysis.

Periodic Flow Testing

Test actual flow rates against design specifications. Reduced flow suggests sizing problems or partial blockages.

Address flow issues promptly to prevent system damage.

Custom Sizing Solutions

Complex systems require professional analysis. Industrial applications, multi-zone buildings, and specialized equipment need custom calculations.

Professional sizing services include:

- Detailed hydraulic analysis

- Computer modeling and simulation

- Pressure optimization recommendations

- Custom pipe specifications

Work with experienced manufacturers who understand local codes and requirements. Quality PPR pipes and proper sizing ensure decades of reliable service.

Conclusion

PPR pipe sizing depends on flow requirements, pressure ratings, and system layout. Calculate peak demand accurately. Account for elevation changes and future expansion needs.

Avoid common mistakes like undersizing main lines or ignoring thermal expansion. Use professional tools and manufacturer resources for complex systems.

Proper sizing ensures optimal performance, energy efficiency, and long system life. Invest time in accurate calculations to avoid costly retrofits later.

Recent Comments