I once saw a project delayed for weeks because standard elbows forced a clumsy, inefficient pipe route. That frustration is exactly why custom angles matter.

You should order a custom HDPE elbow when your pipeline layout requires a precise angle that standard fittings (like 45° or 90°) cannot provide. This is crucial for complex routing, to optimize flow efficiency, minimize pressure loss, and ensure a perfect fit in confined or uniquely designed spaces, ultimately saving on long-term energy and maintenance costs.

Let me explain why settling for a standard elbow can be a costly compromise. Then, I’ll show how a custom solution creates a superior system.

Why Are Standard Elbow Angles Insufficient for Complex Pipeline Routing Layouts?

Imagine trying to connect two pipes at a 73-degree angle using only 45 and 90-degree elbows. The result is messy, inefficient, and weak.

Standard elbow angles are insufficient for complex routing because they force engineers to use multiple fittings and extra pipe segments to approximate a needed angle. This creates more joints (potential leak points), increases friction and pressure drops, takes up more space, and often results in an awkward, structurally weaker pipeline assembly.

The Core Problem with Compromise

In an ideal world, every pipeline could use perfect 90-degree turns. But real-world engineering is rarely that simple. Topography, existing structures, equipment placement, and design specifications often demand non-standard angles. Consequently, when you only have standard elbows, you face several big problems.

First, you must create a “dogleg” or offset. To connect two pipes that aren’t at a standard angle, you link together several standard elbows with short pipe pieces in between. For example, to make roughly a 60-degree turn, you might combine a 45 and a 22.5-degree elbow. This immediately adds two more fusion joints to the system. Importantly, every joint is a point where something could go wrong during installation or in the future.

Key Drawbacks of Multi-Fitting Assemblies

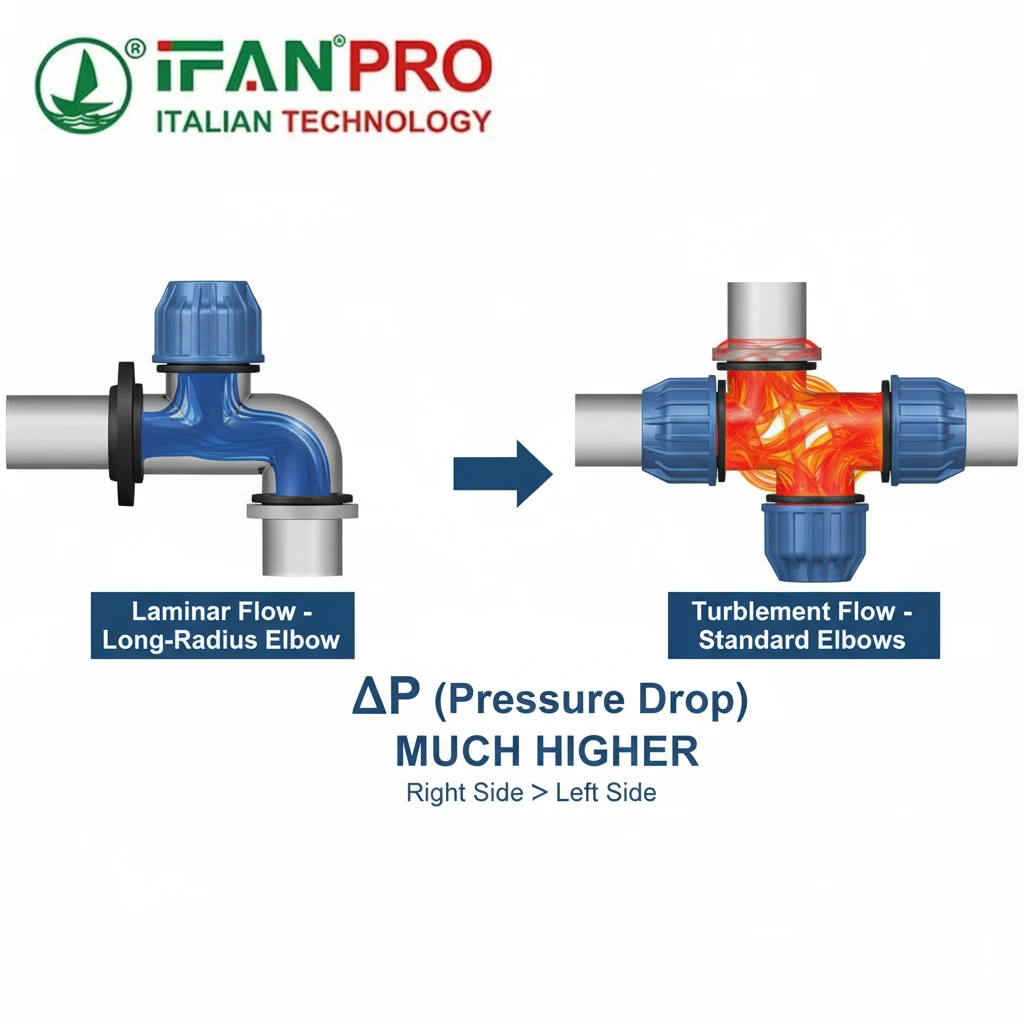

Second, this multi-fitting assembly increases fluid resistance. Specifically, each elbow adds turbulence and friction. So, two elbows cause more pressure loss than one smooth, custom elbow. As a result, this forces pumps to work harder, using more energy from day one.

Third, these assemblies take up much more space. For instance, the zigzag pattern of multiple elbows needs a larger installation footprint. In tight spaces like plant rooms, tunnels, or pre-designed frames, there might simply not be enough room for a bulky standard-elbow workaround.

Structural and Aesthetic Concerns

Furthermore, the mechanical stress on the pipeline is not ideal. The force from the flowing liquid (thrust) is not smoothly redirected along a single, continuous curve. Instead, it gets transferred through multiple, short segments, putting uneven stress on the joints and supports. This can lead to premature wear or failure.

Finally, it simply looks unprofessional. A system built with multiple elbows to hit a basic angle often appears like a temporary fix, not a permanent, engineered solution. Therefore, it signals a lack of precision and can raise concerns during client or inspector reviews.

Comparison: Standard vs. Custom Solution

| Scenario | Using Standard Elbows | Using a Custom Elbow |

|---|---|---|

| To achieve a 60° turn | Requires (2) fittings: 45° + 22.5° elbow, plus a spool piece. | Requires (1) fitting: a single 60° elbow. |

| Number of Fusion Joints | 4 joints (2 for each elbow connection). | 2 joints (one at each end of the single elbow). |

| Pressure Drop | Higher due to turbulence from two direction changes. | Lower due to one smooth, continuous direction change. |

| Space Required | Larger footprint due to the offset layout. | Minimal, direct footprint. |

| Structural Integrity | Multiple points of potential stress concentration. | Clean, predictable load distribution. |

In summary, a custom elbow turns this compromised assembly into a single, sleek, and efficient component. Ultimately, it is the difference between a detour and a direct road.

How Does a Custom Angle Optimize Flow Efficiency and Reduce Pressure Drops?

In piping, every unnecessary bend is like a kink in a garden hose—it steals energy and reduces performance.

A custom angle optimizes flow by providing a single, smooth change in direction tailored to the pipeline’s hydraulic design. This minimizes turbulence and friction compared to a series of standard elbows, resulting in a lower pressure drop. This means pumps consume less energy to move the same volume of fluid, leading to significant operational savings.

Understanding Hydraulic Resistance

To understand why custom angles are better for flow, we need to talk about hydraulics. When fluid moves through a pipe, it loses energy due to friction against the pipe walls. This loss is called “pressure drop.” Importantly, fittings, especially elbows, cause a lot of pressure drop because they disrupt the smooth flow, creating turbulence and eddies.

Every elbow has a “loss coefficient.” This is a number that represents how much pressure is lost when fluid goes through it. For example, a long-radius 90° elbow has a lower loss coefficient than a short-radius 90° elbow because the turn is more gradual. However, when you use two elbows close together (like a 45° + 22.5° combo), you add the loss coefficients of both fittings, plus the extra friction from the short pipe between them.

The Single-Bend Advantage

A custom elbow is designed as one long-radius turn at the exact angle you need. Therefore, a single, smooth 60° elbow will always have a much lower loss coefficient than a 45° and 22.5° elbow combined. The flow path is more natural, with less abrupt change in momentum.

This directly translates to energy savings. Specifically, the pump’s job is to create enough pressure to overcome the total pressure drop in the system and deliver the fluid. A higher pressure drop means the pump motor must work harder, using more electricity. Over a year of continuous operation, even a small reduction in required pump pressure can save thousands of dollars in energy costs.

Additional System-Wide Benefits

Optimizing flow efficiency also has other benefits. First, with lower pressure drops, you might be able to use a smaller, less expensive pump or specify smaller pipe diameters in other sections, reducing capital costs. Next, smooth flow helps maintain ideal fluid velocity. High velocity can cause erosion and noise; conversely, low velocity can allow sedimentation. A custom elbow helps keep the velocity in the perfect range. Finally, reduced turbulence means less vibration and hydraulic hammer (pressure surges), putting less stress on the entire pipeline system and its supports.

Estimated Pressure Drop & Energy Cost Comparison

| Fitting Assembly for a 60° Turn | Estimated Loss Coefficient (K) | Annual Energy Cost* (Est.) |

|---|---|---|

| Standard Combo: 45° + 22.5° Elbow | K ~ 0.5 + 0.3 = 0.8 | $12,000 |

| Custom 60° Long-Radius Elbow | K ~ 0.4 | $9,600 |

*Example based on a water system moving 500 m³/h, 24/7 operation, at $0.10/kWh. This shows how a custom elbow can save over $2,400 annually on energy alone.

In short, a custom elbow isn’t just a fitting; it’s an efficiency device. As a result, it makes the entire system more streamlined and cost-effective to operate from the moment it is turned on.

What Long-Term Maintenance Savings Justify the Cost of a Custom HDPE Elbow?

The upfront price of a custom fitting can give pause. But true cost is measured over decades, not just on the invoice.

The long-term maintenance savings that justify a custom HDPE elbow come from its leak-proof reliability, resistance to abrasion and corrosion, and elimination of weak points. By having fewer joints and a perfect fit, you avoid costly repairs, unplanned downtime, and premature system replacements, making the initial higher cost a wise investment.

The True Cost of Ownership

When clients balk at a custom part’s price, I ask them to think about the total cost of ownership over 50 years. A pipeline is not an item you replace often. Therefore, the initial material and installation cost is a small part of its life story. Conversely, the big expenses are maintenance, repairs, energy, and potential production losses from failure.

A custom HDPE elbow directly targets and reduces these long-term costs. Here’s how.

Savings from Fewer Failure Points

First, as covered earlier, a custom elbow replaces multiple standard fittings. In other words, fewer fusion joints mean fewer potential leak points. A leak in an industrial or municipal pipeline can be catastrophic, causing environmental damage, massive cleanup costs, service interruption, and fines. The cost of excavating, repairing, and reinstating a single failed joint can be many times the price of a custom elbow. Therefore, by designing a simpler, more robust system with custom parts, you buy insurance against these failures.

Savings from HDPE’s Inherent Durability

Next, HDPE itself is a maintenance champion. For instance, it doesn’t corrode like metal. It is also highly resistant to chemical attack and abrasion from slurries. As a result, a custom HDPE elbow inherits these properties. Specifically, you will never need to:

- Repaint it to prevent rust.

- Inspect it for wall thinning due to corrosion.

- Replace it because it has been eaten away by aggressive fluids.

For abrasive materials like mining tailings, a custom HDPE elbow with a consistent, smooth radius wears evenly. Consequently, it lasts far longer than metal equivalents, which can wear thin at the bend and fail.

Avoiding Costly Downtime and Strain

Furthermore, a system built with awkward, multi-elbow offsets experiences more internal stress and vibration. This strain can lead to fatigue failures not just at the elbows, but also at pumps, valves, and supports downstream. This means more frequent inspections and part replacements.

Moreover, if a standard-elbow assembly fails and needs replacement, you often have to shut down the entire line. The cost of this downtime—lost production, emergency labor, expedited shipping—can be enormous. So, a robust, custom-fitted system maximizes uptime and predictability.

Cost Justification Analysis Over 20 Years

| Cost Category | Pipeline with Standard Elbow Workarounds | Pipeline with Custom HDPE Elbows |

|---|---|---|

| Initial Fitting Cost | Lower | Higher |

| Installation Labor | Higher (more joints to fuse) | Lower (fewer joints to fuse) |

| Estimated Repair Events | 2-3 (leaks, joint fatigue) | 0-1 (very unlikely) |

| Cost of Unplanned Downtime | High Risk | Very Low Risk |

| Energy Consumption | Higher (as calculated previously) | Lower |

| Total 20-Year Projected Cost | HIGH | LOW |

The table shows that while you pay more at the beginning for the custom part, you save money every year afterward on energy, and you avoid huge, unpredictable repair bills. For a critical pipeline, this reliability is priceless. In the end, the custom elbow pays for itself by not causing problems.

How Do You Determine the Exact Required Angle for a Custom HDPE Elbow?

Guessing the angle leads to waste and delay. Precision measurement is the key to a perfect custom fit.

You determine the exact required angle by using professional survey methods on the actual installation site, not just paper plans. This involves measuring the deflection angle between the two pipe sections to be connected using tools like a digital angle finder, theodolite, or 3D laser scanning, then accounting for the pipe’s bend radius to specify the elbow’s correct included angle.

Step 1: Move from Plans to Physical Reality

The most common mistake is assuming the angle on the engineering drawing is the angle you need for the elbow. However, in the field, things are different. Pipe supports may shift, foundation settling occurs, and as-built conditions rarely match the CAD model perfectly. If you order an elbow based on the drawing, it might not fit when delivered, causing expensive rework and delays.

Therefore, the correct angle must be measured in the field, on the actual pipe ends or their intended alignment, before they are connected. Here is a practical guide based on how we do it for our clients at IFAN.

Step 2: On-Site Measurement Process

First, ensure the two pipe sections to be connected are correctly positioned and secured on their supports. They should be in their final, stable location. Then, clean the area around the pipe ends so you can take clear measurements.

Next, measure the deflection angle. This is the angle by which the pipeline is changing direction. Remember, you are not measuring an elbow; you are measuring the gap that the elbow needs to fill.

- Method A (Direct): Use a digital angle finder or protractor. Place the tool’s base along the straight run of the first pipe section and note the angle. Then, place it along the second pipe section. The difference between these two readings is your deflection angle.

- Method B (Reference Lines): Stretch string lines or use laser pointers along the centerline of each pipe run, extending them until they intersect. Finally, measure the angle of intersection with an angle finder.

Step 3: Convert Your Measurement for Ordering

This step is crucial. What you measured in the field (e.g., 60°) is usually the deflection angle—how much the pipe turns. However, the elbow itself is described by its included angle. They are complementary.

| If the Pipeline Turns (Deflects) by: | Then the Custom Elbow’s Included Angle is: |

|---|---|

| 60° | 120° |

| 45° | 135° |

| 22.5° | 157.5° |

Elbow Included Angle = 180° – Deflection Angle. Always confirm this with your manufacturer.

Step 4: Specify the Bend Radius

Additionally, an elbow isn’t a sharp corner; it’s a curve. So, you must also specify the centerline bend radius (e.g., 1.5D, 3D, 5D, where D is the pipe diameter). A larger radius (like 5D) creates a gentler, longer elbow with better flow. However, the radius affects the elbow’s overall length and must fit your spatial constraints. Therefore, provide the manufacturer with the desired radius based on your hydraulic and spatial needs.

Step 5: Finalize Documentation

Create a simple sketch or diagram. Mark the measured deflection angle, the calculated included angle, the pipe size (e.g., 12″ SDR 11), and the required bend radius. Then, send this to your supplier. A good supplier like IFAN will review these details with you to confirm before manufacturing begins.

Tools for Accurate Measurement

| Tool | Best For | Accuracy Note |

|---|---|---|

| Digital Angle Finder | Small to medium pipes in accessible locations. | Very good for most applications. |

| Theodolite / Total Station | Large-diameter pipelines, long runs, civil projects. | Highly accurate, used by surveyors. |

| 3D Laser Scanner | Extremely complex layouts, retrofit in congested plants. | Creates a perfect digital model for design. |

By following this process, you move from guesswork to engineering certainty. The goal is to give the manufacturer one clear instruction. For example: “Make us one 120° included angle elbow, 12″ diameter, SDR 11, with a 3D bend radius.” This results in a part that fits perfectly the first time.

Conclusion

A custom HDPE elbow solves spatial, efficiency, and reliability challenges that standard fittings cannot. For precise, durable, and flow-optimized custom elbows, partner with IFAN for expert guidance and manufacturing.

Commentaires récents