I once saw a project where metal pipe clips rusted completely in a damp basement, failing within two years. The entire run of pipes had to be re-supported. This frustrating and costly problem is exactly why I now recommend PVC clips.

You should choose PVC clips over metal because they offer superior corrosion resistance, are easier and faster to install, reduce overall costs, and provide better electrical and thermal insulation. This makes them the more reliable and economical choice for most residential, commercial, and industrial pipe-fixing applications.

Let’s look closely at the specific advantages of PVC clips and when they are the best choice for your project.

How Does PVC’s Corrosion Resistance Benefit Pipe Clips in Humid Environments?

Rust is the enemy of any metal fixing. In places like basements, bathrooms, or factories, moisture can ruin a support system quickly.

PVC’s corrosion resistance is a major benefit in humid environments because PVC is a plastic that does not rust, corrode, or react with most chemicals. This means PVC clips will not weaken, stain, or fail over time due to moisture, salt spray, or chemical fumes, ensuring long-term pipe support integrity where metal would degrade.

The Problem with Metal in Wet Conditions

The biggest weakness of metal clips is corrosion. Galvanized steel clips can rust, especially at cut edges or scratches. Stainless steel is better but more expensive and can still suffer from certain types of corrosion. In humid environments, this is not just a cosmetic issue.

When a metal clip corrodes, two bad things happen. First, the clip itself loses strength. It can become brittle and snap, or it can simply lose its grip on the pipe. Second, rust can stain the pipe and the surrounding wall or ceiling. In critical settings like food processing plants or water treatment facilities, rust contamination is completely unacceptable.

How PVC Solves This Problem

PVC, or Polyvinyl Chloride, is inert. It does not react with water, moisture in the air, or many common industrial chemicals. This makes it perfect for:

- Bathrooms and Kitchens: Where steam and humidity are constant.

- Basements and Crawl Spaces: Which are often damp.

- Coastal Areas: Where salt spray in the air accelerates metal corrosion.

- Chemical Plants and Laboratories: Where fumes can attack metal.

- Water and Wastewater Facilities: Where everything is constantly wet.

A PVC clip will look and perform the same years after installation. It won’t rust, so it won’t stain pipes or structures, and it won’t lose its holding strength.

Application Guide: Where PVC Clips Excel

This table shows where PVC’s corrosion resistance is most valuable.

| Environment | Risk to Metal Clips | PVC Clip Advantage |

|---|---|---|

| High Humidity (Indoor) | Surface rust, weakened strength over time. | Maintains full strength and appearance. |

| Outdoor / Coastal | Rapid corrosion from rain and salt air. | Completely unaffected by weather. |

| Chemical Exposure | Can corrode or degrade depending on the chemical. | Highly resistant to a wide range of chemicals. |

| Potable Water Systems | Risk of rust contaminating water. | Guarantees no contamination. |

From our experience at IFAN, clients who switch to PVC clips for these challenging environments eliminate callbacks for repair and replacement. This saves them significant time and money in the long run.

Why Are PVC Clips Easier and Faster to Install Than Metal Alternatives?

Time on the job site is money. I’ve watched installers struggle with drilling into hard surfaces for metal anchors and dealing with sharp edges.

PVC clips are easier and faster to install because they are lightweight, can be cut and adjusted easily with common tools, and often use simpler fixing methods. Their smooth edges and pre-designed shapes allow for quick placement and secure fastening without the need for heavy drilling or special protective gear.

Simplifying the Installation Process

The installation advantage of PVC clips comes from their material properties and design. Let’s break down the process.

First, PVC is light. A box of PVC clips is much easier to carry up a ladder or around a job site than a box of heavy metal clips. This reduces worker fatigue right away.

Second, PVC is easy to work with. If a clip needs to be trimmed or notched to fit around an obstacle, a utility knife or a fine-tooth saw can do it quickly and cleanly. Try doing that with a galvanized steel clip—you need tin snips, which leave sharp, dangerous edges that must be filed down. PVC clips have no sharp edges, making them safer to handle.

Faster Fixing Methods

The installation speed often comes down to the fastener. Many metal clip systems require drilling a pilot hole, inserting a heavy-duty wall plug, and then driving a screw. For PVC clips, especially for lighter pipes or in softer materials, faster options are available:

- Push-In Anchors: For drywall or hollow substrates, a PVC clip with integrated push-in spikes can be installed with just a hammer—no drilling needed.

- Adhesive Backing: Some PVC clips come with strong adhesive pads for very quick mounting on smooth, clean surfaces.

- Lighter-Gauge Screws: Because PVC is strong yet light, installers can often use smaller screws that drive in faster than the large screws needed for heavy metal straps.

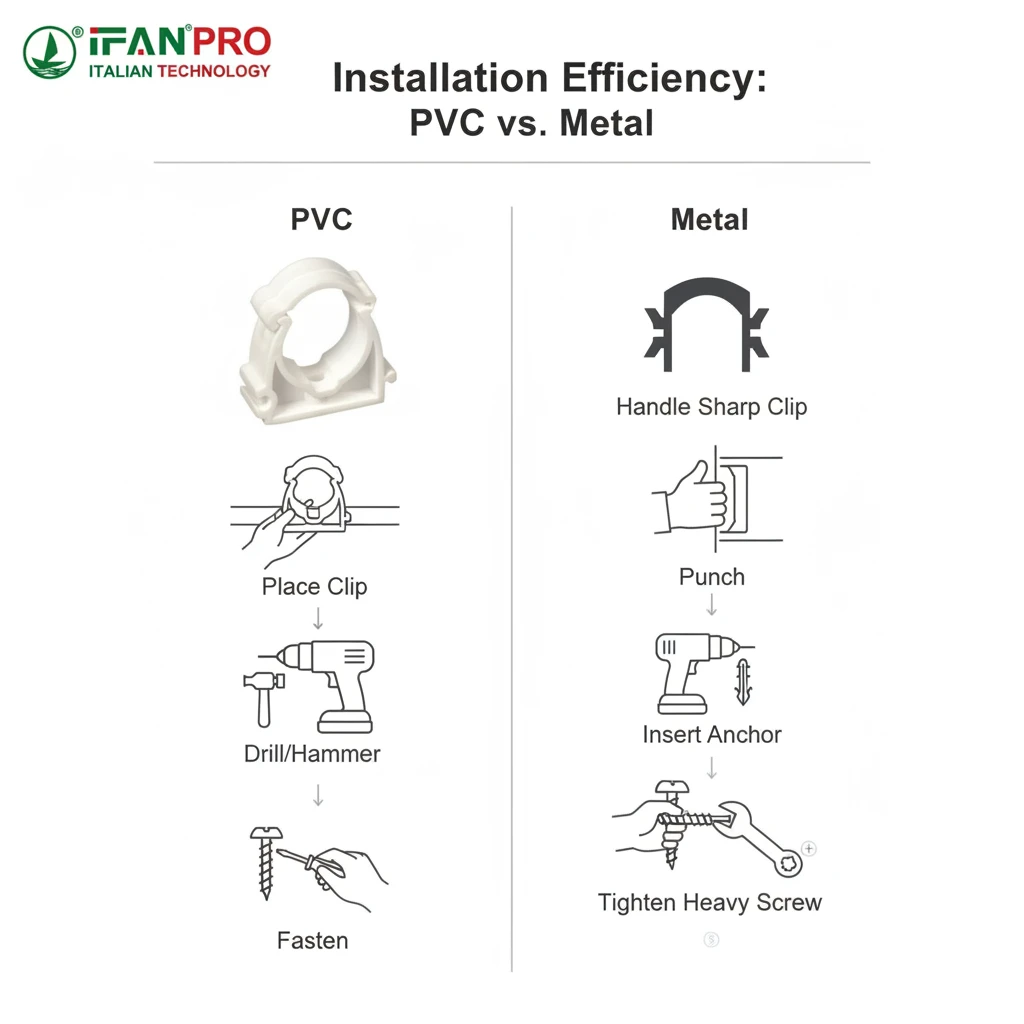

Step-by-Step Time Comparison

Here is a simple comparison of installing a single clip support:

| Step | Typical Metal Clip | Typical PVC Clip |

|---|---|---|

| 1. Handle Material | Heavy, sharp edges require gloves. | Lightweight, smooth, safe to handle. |

| 2. Mark & Prepare | Mark hole, often need to punch a starter dent. | Mark hole. |

| 3. Drill Hole | Drill pilot hole for anchor (necessary for most walls). | May skip drilling if using push-in anchor. |

| 4. Insert Anchor | Insert plastic wall plug. | Push-in anchor is part of the clip. |

| 5. Fasten Clip | Drive screw through clip into anchor. | Drive screw (or simply hammer for push-in type). |

| Total Effort & Time | Higher effort, more time. | Lower effort, less time. |

This speed adds up over hundreds of clips in a large project. The easier installation also means fewer mistakes and a lower chance of injury on site.

How Do PVC Clips Reduce Overall Pipe Support and Installation Costs?

Choosing cheaper materials can sometimes cost more later. But with PVC clips, the savings are clear from start to finish.

PVC clips reduce overall costs because they have a lower initial purchase price than most metal alternatives, require less labor time to install, and eliminate future expenses related to corrosion replacement, repainting, or contamination cleanup. This makes their total cost of ownership much lower.

Breaking Down the Cost Savings

To understand the cost savings, we need to look beyond the price tag on the box. We need to consider the total cost over the life of the installation.

1. Lower Material Cost: Raw PVC resin is generally less expensive than processed steel. This translates directly to a lower unit cost for PVC pipe clips compared to galvanized or stainless steel clips. For a project requiring thousands of clips, this initial saving can be substantial.

2. Lower Labor Cost: As we discussed, installation is faster. Faster installation means less time spent by skilled workers on the fixing task. Labor is often the most expensive part of a project. Saving 30 seconds per clip might seem small, but it results in huge savings on a large-scale installation. Also, no special tools or blades for cutting metal are needed.

Eliminating Future Costs

This is where PVC clips provide the biggest financial advantage. Metal clips, especially non-stainless types, have ongoing costs that PVC avoids:

- No Replacement Costs: You will not need to replace PVC clips every 5-10 years due to rust, unlike galvanized steel.

- No Maintenance Costs: PVC clips do not need to be inspected for corrosion or repainted to protect them.

- No Failure-Related Costs: A failed metal clip can lead to a pipe sagging or breaking, causing water damage or production stoppage. The cost of this repair is enormous compared to the clip itself.

Total Cost of Ownership Comparison

Let’s compare the costs for supporting 100 meters of pipe in a humid industrial setting over 10 years.

| Cost Factor | Galvanized Steel Clips | PVC Clips |

|---|---|---|

| Initial Clip & Fastener Cost | $300 | $180 |

| Estimated Installation Labor | $500 (slower) | $350 (faster) |

| Maintenance/Painting (Year 5) | $150 | $0 |

| Replacement of Failed Clips (Year 7) | $200 | $0 |

| Total 10-Year Cost | $1,150 | $530 |

The table shows that while the upfront saving is good, the long-term avoidance of maintenance and replacement makes PVC clips the truly cost-effective choice. At IFAN, we help our clients see this bigger picture, which leads to smarter, more profitable project budgeting.

When Should You Specifically Choose PVC Clips for Electrical or Thermal Insulation?

Sometimes, the pipe isn’t the only thing that needs protection. The clip itself must be safe and non-disruptive.

You should specifically choose PVC clips for electrical insulation when supporting electrical conduits or near live wires to prevent accidental grounding. Choose them for thermal insulation when supporting hot or cold pipes to prevent heat loss (thermal bridging) through the clip, which improves energy efficiency.

The Role of Clips in Electrical Safety

In electrical installations, safety is the most important thing. Metal is a conductor of electricity. If a live wire touches a metal conduit that is held by a metal clip grounded to the building structure, it can create a dangerous shock hazard or short circuit.

PVC is an excellent electrical insulator. This means:

- Safe for Conduits: PVC clips are the standard choice for supporting PVC electrical conduits. They keep the entire run non-conductive.

- Safe in Mixed Environments: In places where water pipes and electrical cables run close together, using PVC clips for all supports removes the risk of creating an accidental electrical path through a metal pipe and clip.

- Compliance: Many electrical codes explicitly recommend or require non-conductive supports for certain applications to ensure safety.

Preventing Thermal Bridging

Thermal bridging is when heat transfers through a more conductive material. In plumbing, this is a hidden source of energy waste.

- For Hot Water Pipes: Metal clips act as little radiators. Heat from the pipe travels through the metal clip into the wall or stud, where it is lost. This makes your water heater work harder.

- For Cold Water or Chilled Lines: Metal clips can draw heat from the room into the cold pipe, causing condensation (sweating) and making the cooling system less efficient.

PVC has low thermal conductivity. A PVC clip acts as a thermal break. It significantly reduces the flow of heat between the pipe and the building structure.

Decision Guide: Insulation Applications

Use this guide to decide when PVC’s insulating properties are critical.

| Application | Problem with Metal Clip | Why PVC is the Better Choice |

|---|---|---|

| Supporting Electrical Conduit | Can conduct electricity, creating a shock or fire risk. | Acts as an insulator, enhancing electrical safety. |

| Pipes Near Electrical Cables | Risk of creating a conductive path if cables are damaged. | Eliminates risk of accidental grounding. |

| Hot Water Supply Lines | Conducts heat away from pipe (thermal bridging), wasting energy. | Reduces heat loss, saving energy and money. |

| Chilled Water or AC Condensate Lines | Can cause condensation (sweating) on the pipe and clip. | Prevents condensation by reducing thermal transfer. |

Based on our project experience at IFAN, specifying PVC clips for these scenarios is a mark of professional, high-quality installation. It shows attention to detail that prevents future problems with energy bills, condensation damage, or safety.

Conclusion

For a durable, cost-saving, and safer pipe support solution, PVC clips are the smart choice over metal. For reliable, high-quality PVC pipe clips and supports, trust IFAN‘s range of products for your next installation.

Commentaires récents