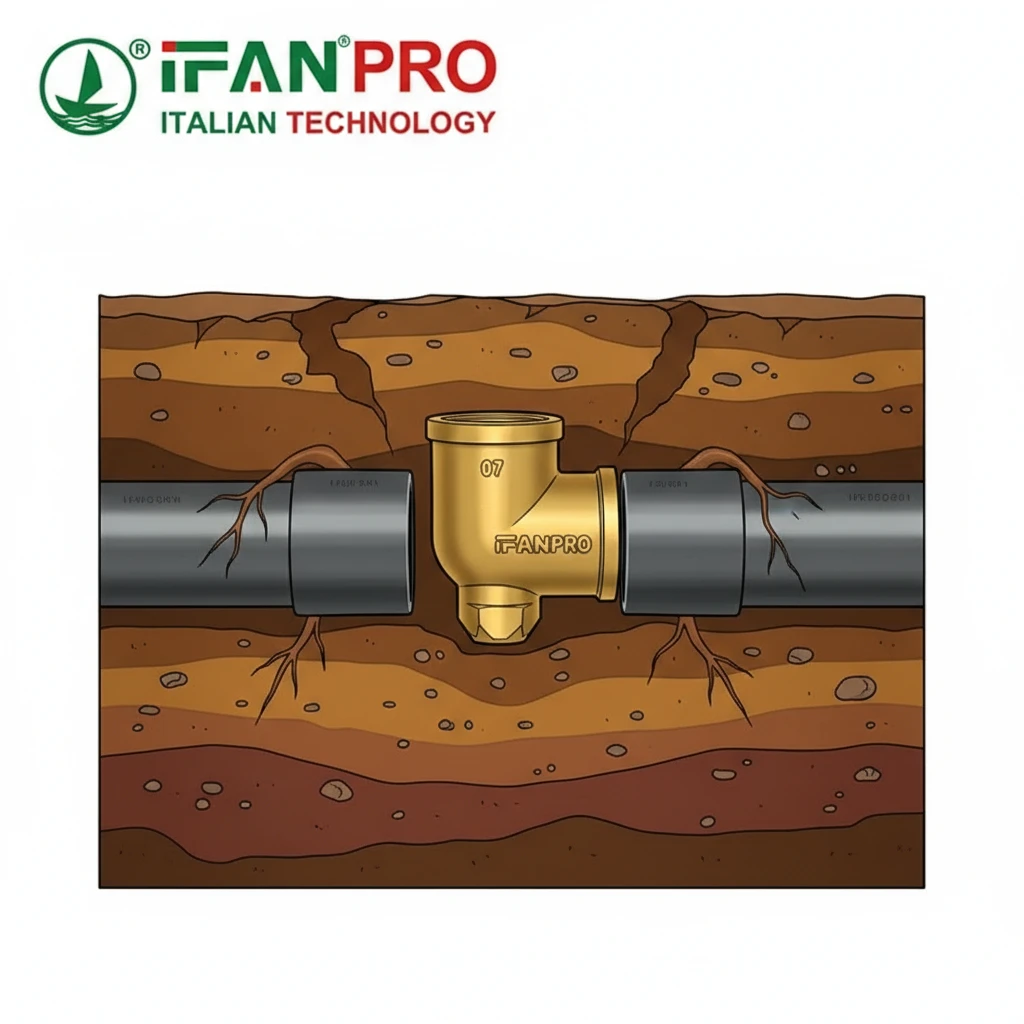

I once reviewed a failed irrigation project where plastic fittings cracked after just one season. The culprit? Unpredictable soil shifting. This common problem clearly shows why material choice is critical.

You should choose a brass elbow over a plastic one for ground movement areas because brass offers far superior mechanical strength and ductility. It can bend slightly under stress without failing, while plastic is brittle and prone to cracking from soil settlement, frost heave, or point loads from rocks, leading to costly leaks and repairs.

While plastic fittings work well in stable, protected environments, areas with active soil demand a more robust solution. Let’s examine the specific reasons brass is the reliable choice.

How Does the Mechanical Strength of Brass Resist Soil Settlement and Shifting?

Soil never truly sits still. It settles, expands with water, and shifts with temperature. I’ve seen plastic systems fail because they simply can’t handle this constant, uneven pressure.

Brass resists soil settlement and shifting due to its high tensile strength and yield strength. These properties allow the metal fitting to withstand the substantial compressive and shear forces from moving soil without deforming permanently or cracking, unlike plastic which may warp or fracture under similar loads.

Understanding the Forces at Play

First, let’s define the forces from ground movement. Soil settlement creates downward and lateral pressure that squeezes pipes. Frost heave applies uplift force from below. These are not gentle pushes; they can generate tons of pressure. A fitting needs intrinsic strength to handle this.

Brass, an alloy of copper and zinc, possesses excellent mechanical properties. Its tensile strength (the resistance to being pulled apart) is significantly higher than that of common plumbing plastics like PP-R or PVC. More importantly, brass has a high yield strength. This means it can undergo a considerable amount of stress before it begins to deform permanently. In practical terms, when soil pushes on a buried brass elbow, the elbow resists the force and maintains its shape.

The Brittleness Problem with Plastic

Plastic fittings have lower strength and behave differently under constant pressure. Over time, a steady load from shifting soil can cause plastic to creep—slowly and permanently deform. This deformation can stress joints and alter flow paths. Furthermore, plastic is more brittle, especially in cold temperatures. A sudden shift or point load is more likely to cause an immediate crack in plastic, whereas brass would absorb the energy.

Key Mechanical Property Comparison

The following table illustrates the stark difference in capability:

| Material Property | Brass (C36000) | PP-R (Typical) | Why It Matters for Ground Movement |

|---|---|---|---|

| Tensile Strength | ~340 MPa (MegaPascals) | ~25 MPa | Brass can handle over 10x the pulling/ stretching force before failing. |

| Yield Strength | ~170 MPa | Not truly defined; deforms easily | Brass resists permanent bending under heavy soil pressure. |

| Ductility | High (Can elongate significantly) | Low (Brittle) | Brass can bend slightly without breaking; plastic cracks. |

In summary, the inherent strength of brass acts like a strong skeletal frame for your underground piping, holding its position and integrity against the dynamic forces of the earth around it.

Why is Brass Less Likely to Crack from Point Loads Compared to Plastic?

A hidden rock or a careless backfill can create a disaster. Point loads—intense pressure on a single small area—are a major killer of buried plastic fittings.

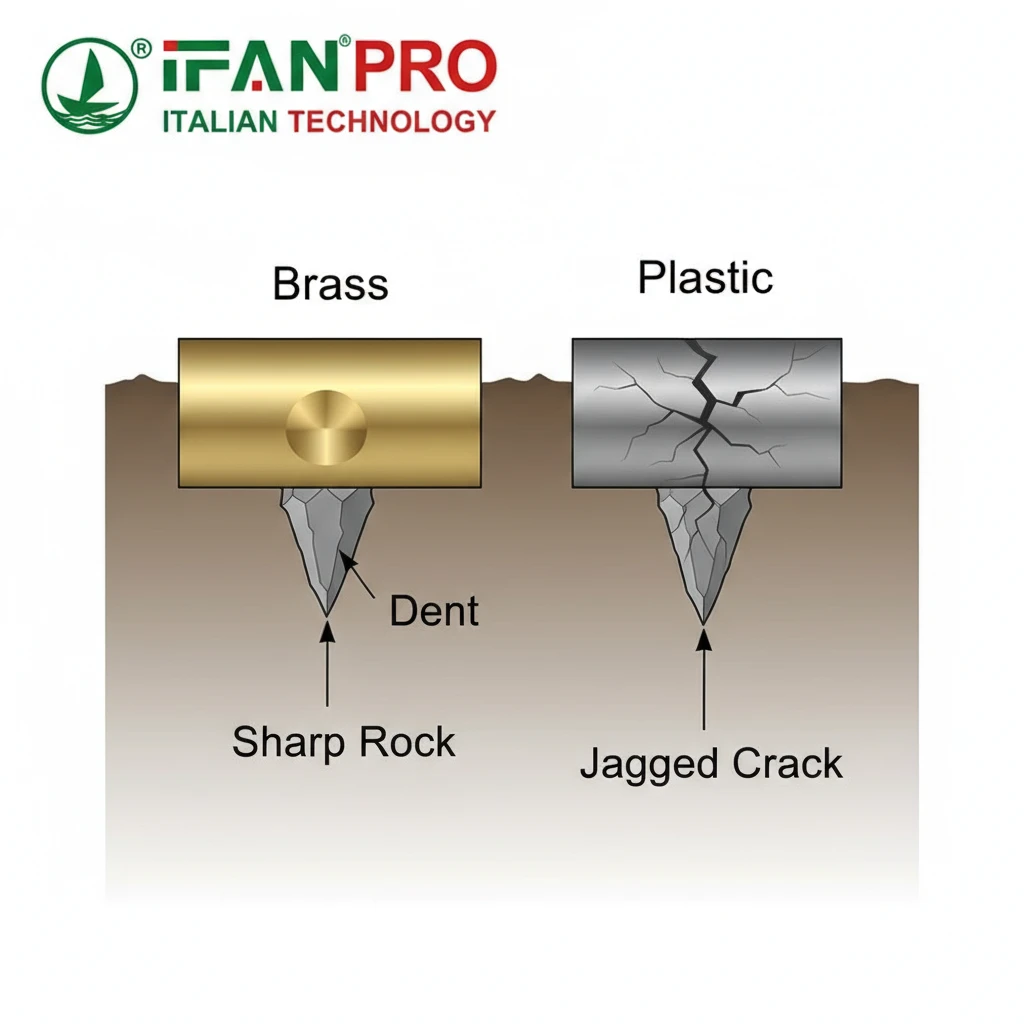

Brass is less likely to crack from point loads because it is a ductile metal. When a sharp rock presses against it, the brass can locally deform (dent) and distribute the stress over a wider area. Plastic, being brittle, concentrates the stress at the point of contact, leading directly to crack formation and failure.

The Science of Stress Distribution

Imagine pressing a pencil tip into a piece of clay and a piece of glass. The clay (ductile like brass) dents. The glass (brittle like plastic) cracks. This is the fundamental difference.

When a point load applies force to brass, the metal’s crystalline structure allows it to undergo plastic deformation (a small, permanent dent). This action absorbs energy and, crucially, spreads the incoming force over a larger internal area. The fitting may get a minor dent, but it remains sealed and functional.

Plastic’s Vulnerability to Stress Concentration

Plastic lacks this ability. When the same rock presses on a plastic elbow, the material cannot yield and deform locally. Instead, the full force remains concentrated at that tiny contact point. This creates a huge stress concentration that exceeds the material’s fracture toughness, initiating a crack. Once a crack starts in plastic, it can propagate quickly through the fitting, especially under the constant pressure of the surrounding soil.

Common Sources of Point Loads

These are not rare events. Point loads come from:

- Rocks and Debris: In backfill material.

- Construction Activity: Equipment running over the buried line.

- Improper Support: The pipe resting on a hard, uneven surface in the trench.

- Frost Heave: Ice lenses forming underneath and pushing up on a specific spot.

Choosing brass is a form of insurance against these unpredictable and common hazards in an excavation environment. It ensures that a single hidden rock doesn’t compromise your entire underground system.

Can Threaded Brass Joints Accommodate Minor Movement Better Than Fused Plastic?

Joints are the weakest link. A rigid system breaks when the ground moves; a system with some forgiveness can survive.

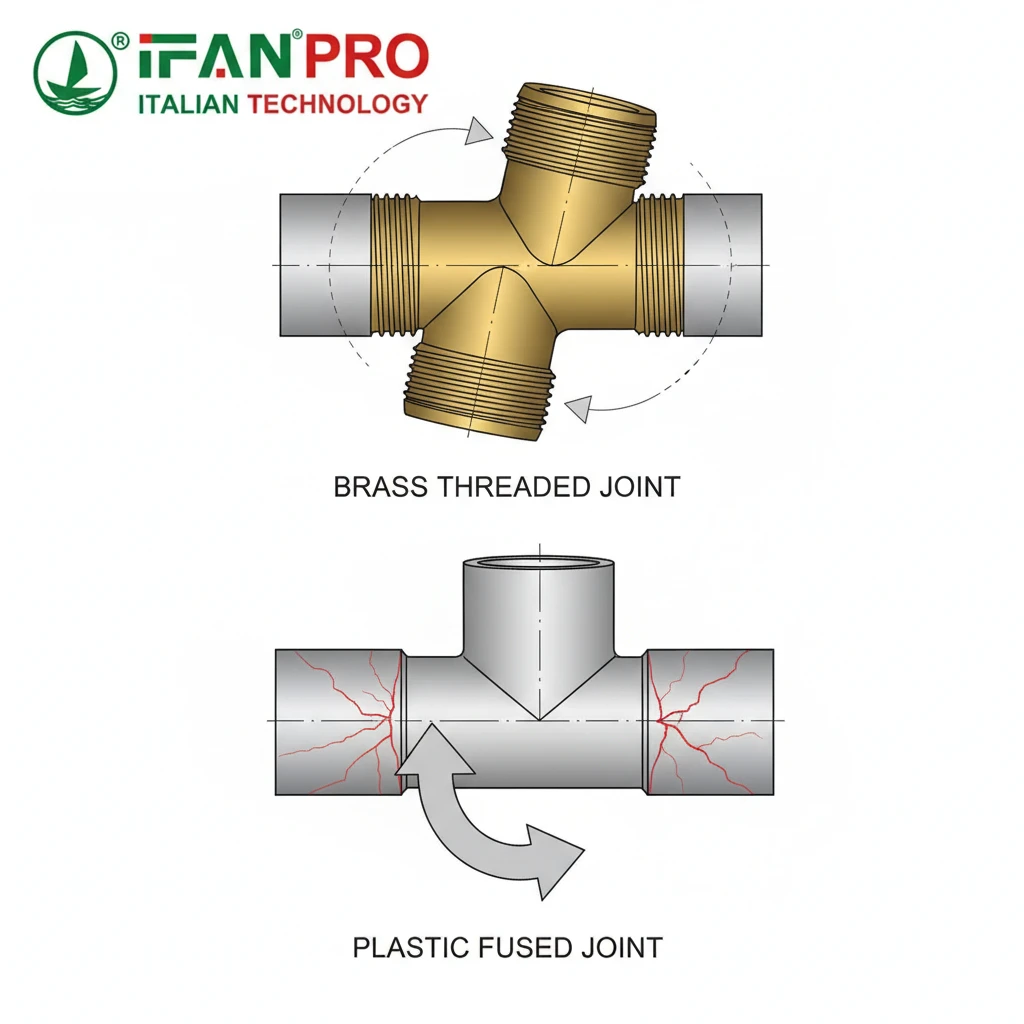

Yes, threaded brass joints can accommodate minor movement better than fused plastic joints. The threaded connection, especially when using sealants like thread tape or paste, has a small degree of inherent flexibility and can tolerate tiny angular deflections without leaking. A heat-fused plastic joint is monolithic and rigid, so any ground movement transfers direct stress to the pipe wall, leading to cracks.

The Flexibility of a Threaded Connection

A threaded joint is not a single, solid piece of material. It is a mechanical connection. The threads themselves have minute gaps and spaces filled with sealant. When the surrounding soil shifts and applies bending force to the pipeline, a threaded brass elbow can experience a very slight rotation or angular deflection at the joint. The sealant within the threads can compress and adjust slightly to this movement while maintaining a seal. This micro-flexibility acts as a shock absorber.

Furthermore, the ductility of brass allows the entire fitting to bend slightly without the threads stripping or failing. The system has a tiny amount of “give.”

The Rigidity of a Fused Plastic Joint

In contrast, a solvent-welded or heat-fused plastic joint is designed to be perfect and permanent. The goal is to make the pipe and fitting into one continuous, homogeneous piece of plastic. This is excellent for a static, stable environment because it eliminates the joint as a leak point.

However, in unstable ground, this rigidity becomes a liability. The soil moves, but the fused joint cannot. Since the joint won’t flex, the stress must go somewhere. It transfers directly into the pipe wall right next to the joint—the very place where the plastic has been thermally stressed during fusion. This often results in a crack forming in the pipe adjacent to the fitting, a common and frustrating failure mode.

Practical Implication for Installation

This difference impacts installation philosophy. With brass, the threaded system allows for minor adjustments during backfilling and can settle with the soil. With fused plastic, you must ensure perfect, undisturbed bed and support to prevent any future stress on the rigid joints—a condition very hard to guarantee over decades in active soil.

What is the Long-Term Reliability of Buried Brass Versus Plastic Fittings?

Clients ask, “Will this last 20 years?” For buried applications, the long-term outlook for brass is consistently more predictable.

The long-term reliability of buried brass fittings is superior to plastic in active soil conditions. Brass does not degrade from UV exposure, is highly resistant to corrosion in most soils, and maintains its mechanical properties for decades. Plastic can become brittle from long-term chemical exposure, oxidation, and environmental stress cracking, leading to unpredictable failures.

Material Degradation Over Time

All materials age. The key is how they age and how it affects performance underground.

Brass Aging Factors:

The primary long-term concern for brass is dezincification—a form of corrosion where zinc leaches out, leaving a porous copper structure. However, modern dezincification-resistant (DZR) brass alloys, like those specified in standard CW602N, are specifically designed to combat this. When specified correctly, DZR brass provides exceptional corrosion resistance for 50+ years in most soil types. Its strength does not diminish with time.

Plastic Aging Factors:

Plastics are susceptible to several degradation mechanisms:

- Environmental Stress Cracking (ESC): This is a major issue. Chemicals in the soil (even traces from fertilizers, oils, or certain soils) can interact with the plastic under stress, causing brittle cracks to form spontaneously over time.

- Oxidation & UV Degradation: While buried, UV is not an issue. However, oxidation from soil chemicals and temperature cycling can make the plastic brittle over decades.

- Creep Rupture: Under the constant pressure of soil, plastic can slowly thin and weaken until it eventually ruptures, a failure mode not seen in metals under normal burial stresses.

Comparing Lifecycle and Failure Modes

The failure modes differ significantly. Brass typically fails predictably through gradual wall thinning from corrosion if the environment is extreme. Plastic failure is often sudden and brittle—a catastrophic crack with little warning.

| Long-Term Factor | Brass (DZR Grade) | Plastic (PP-R/PVC) |

|---|---|---|

| Corrosion/Decomposition | Highly resistant in most soils; specified alloys prevent dezincification. | Resistant to rust but susceptible to chemical attack and Environmental Stress Cracking (ESC). |

| Aging Effect on Strength | Mechanical properties remain stable over time. | Can become brittle due to oxidation and polymer chain breakdown. |

| Predictability of Failure | Failure is usually gradual and predictable through inspection. | Failure is often sudden, brittle, and without obvious prior signs. |

| Effect of Temperature Cycles | Minimal impact on material integrity. | Repeated expansion/contraction can fatigue the material, especially at joints. |

For a “fit and forget” underground installation in an area with any risk of movement, brass provides a much higher confidence level for a multi-decade service life.

Conclusion

For stability in unstable ground, choose brass. Its strength, flexibility, and proven longevity prevent costly failures. For reliable DZR brass fittings engineered for buried applications, contact IFAN for your project specifications.

Commentaires récents