I once watched a maintenance team spend hours shutting down a production line just to replace a single, failed plastic fitting in a compressed air system. That moment cemented my appreciation for the unsung heroes of industrial piping: brass cross fittings.

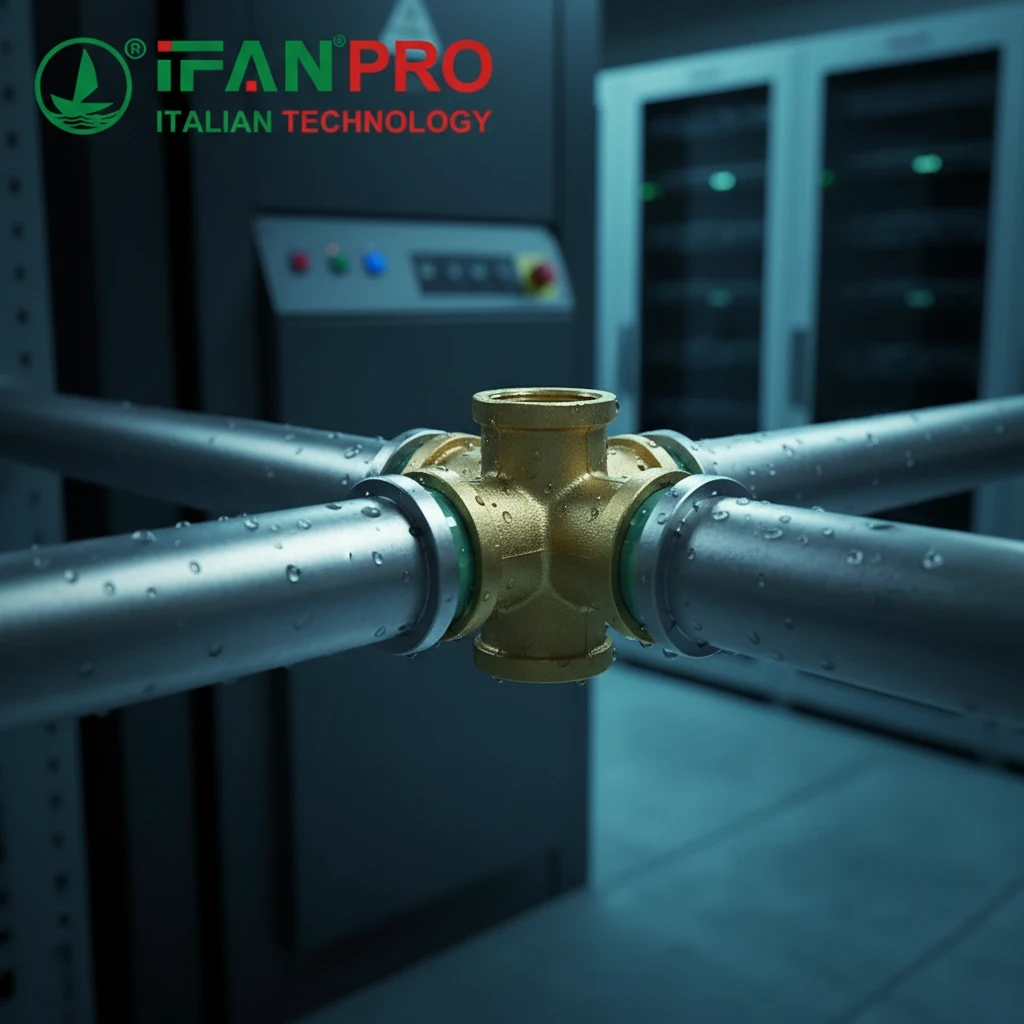

Industrial brass cross fittings are commonly used to create a secure four-way connection in critical systems like compressed air networks, industrial coolant lines, fire sprinkler systems, and fuel distribution lines. Their primary applications rely on brass’s unique strength, corrosion resistance, and reliability under constant pressure and varying environmental conditions.

Their versatility might surprise you. Let’s break down exactly where and why these robust components are indispensable.

How Are Brass Crosses Used in Compressed Air Distribution Networks?

Compressed air is the lifeblood of many factories, and its system must be absolutely reliable. A single leak can shut down entire production cells.

Brass cross fittings are used in compressed air distribution networks to reliably split or combine air flow in four directions at key junction points. They are chosen for their excellent seal integrity, durability against vibration, and resistance to corrosion from moisture often present in air lines, which prevents leaks and maintains system pressure efficiently.

The Demands of an Air System

Compressed air systems are tough on piping components. The air inside is under high pressure, typically between 80 to 150 PSI or even higher. This pressure is constant, creating steady stress on every fitting. Also, compressed air contains moisture. When air is compressed, water vapor condenses. This water can sit inside pipes and fittings, leading to corrosion over time.

Brass cross fittings handle these challenges perfectly. First, brass is a very strong metal alloy. It can withstand the high pressures found in industrial air systems without deforming or cracking. A brass cross will not fail under pressure if it is installed correctly.

Why Brass Beats Other Materials Here

Other common materials, like certain plastics or cheaper metals, often fail in this role. Plastic fittings can become brittle over time, especially if the compressed air is not completely free of oil. They can crack suddenly. Steel fittings are strong, but they rust quickly when exposed to the moisture in air lines. Rust particles can then travel through the air lines and damage expensive tools and equipment.

Brass naturally resists corrosion from water. This makes it ideal for wet air environments. Furthermore, brass fittings form excellent seals with various sealing methods. They can be used with threaded connections (NPT) and sealants, or with compression sleeves for softer tubing like copper. This gives a leak-proof connection that won’t vibrate loose, which is a common problem with the constant hum of air compressors and tools.

Comparing Fitting Materials for Compressed Air

| Material | Key Advantage | Main Weakness in Air Systems | Best For |

|---|---|---|---|

| Brass | Excellent corrosion resistance, strong, good seal. | Higher cost than plastic. | Main lines, critical junctions, moist environments. |

| Steel (Galvanized) | Very high strength. | Prone to rust from moisture; rust contaminates air lines. | Very high-pressure, dry air systems only. |

| Plastic (Nylon/PVC) | Low cost, easy to install. | Can become brittle and crack; not for high pressure or heat. | Low-pressure, non-critical branch lines. |

Addressing Common Pain Points

From our experience at IFAN, clients in compressed air face two major pain points: leaks and corrosion. Leaks waste expensive energy and drop system pressure. Corrosion leads to contamination and fitting failure. A brass cross fitting directly solves both. When sourcing, insist on fittings with precise, clean threads. Also, consider nickel-plated brass for an extra layer of protection in highly humid conditions. Always use the correct thread sealant (like PTFE tape) and follow proper torque specifications during installation to prevent the first leak from ever happening.

What Role Do They Play in Industrial Process Water or Coolant Lines?

Coolant and process water lines keep machines from overheating. A fitting failure here can cause thermal shutdown and costly damage.

Brass cross fittings play a crucial role in industrial water and coolant lines by distributing fluid to multiple machines or cooling points from a central supply. They are valued for their resistance to corrosion from water, additives, and temperature swings, as well as their ability to prevent biological growth inside the fitting, ensuring clean, unrestricted flow.

Handling Corrosive and Varied Fluids

Industrial water is rarely just pure H2O. It can contain chemical additives to prevent algae (biocides), to adjust pH (acids or bases), or to act as antifreeze (glycols). These additives can aggressively attack many materials.

Brass offers broad chemical compatibility. It holds up well against water, ethylene glycol, and propylene glycol-based coolants. It also resists corrosion from many common water treatment chemicals better than plain steel or some aluminum alloys. This chemical resilience ensures the fitting does not degrade and contaminate the fluid stream with metal particles.

The Importance of Internal Smoothness

Another critical factor is the internal surface of the fitting. In water systems, especially those that are not constantly flowing, biofilm and scale can build up. Biofilm is a slimy layer of bacteria. Scale is a hard deposit of minerals. Both restrict flow and reduce cooling efficiency.

Brass fittings can be manufactured with a smooth internal bore. This smooth surface provides less opportunity for biofilm to attach and cling. While scale can still form, it is easier to clean from a smooth brass surface than from a corroded, pitted one. For even better performance, many brass fittings for coolant lines have a chrome plating or other smooth finish on the inside.

Temperature and Pressure Stability

Process and coolant lines experience temperature cycles. Machines heat up and shut down. Brass has good thermal conductivity and expands/contracts at a rate compatible with common piping materials like copper. This reduces stress on the connections during thermal cycling, preventing leaks.

Practical Advice for Selection

When choosing a brass cross for these systems, the main consideration is fluid compatibility. Always confirm with your supplier that the specific brass alloy (e.g., CW617N) is suitable for your coolant mix. For high-purity water systems, lead-free brass (such as Eco-Brass) is often required. A common client pain point is discovering too late that a fitting is leaching metals into a sensitive process. Always ask for material certification sheets. Furthermore, ensure the pressure rating of the fitting exceeds your system’s maximum operating pressure, including any pressure spikes from pumps.

Why Are They Found in Fire Protection and Sprinkler System Piping?

Fire sprinkler systems sit idle for years, but must work perfectly in the one moment they are needed. There is zero room for component failure.

Brass cross fittings are found in fire protection systems because they provide extremely reliable, leak-free junctions that can sit under constant water pressure for decades without corroding or weakening. Their proven long-term integrity and compliance with strict fire safety standards make them a trusted choice for creating the distribution networks within these life-critical systems.

The Unique Demands of a Fire System

A wet-pipe sprinkler system is permanently filled with pressurized water. This means every component is under constant, unrelenting stress 24 hours a day, 365 days a year. The system cannot have leaks, as they would drain pressure and potentially disable part of the system. The fittings must also withstand potential water hammer—a sudden pressure surge if a valve closes quickly or a sprinkler head activates.

Brass is the material of choice for these critical junctions because of its superb creep resistance. Creep is when a metal slowly deforms under constant stress. Brass has very low creep, meaning a brass cross will not slowly distort or develop a micro-leak after years of holding pressure. Its strength ensures it can handle the static pressure and any dynamic surges.

Corrosion Resistance for Water Stagnation

The water in sprinkler pipes is often stagnant. Stagnant water can be highly corrosive, especially to steel, leading to pinhole leaks and clogging from rust deposits (a major pain point in poorly maintained systems). Brass’s superior corrosion resistance in water ensures the internal passageways remain clear and the fitting walls remain intact over the system’s long lifespan.

Compliance and Standards

Fire protection systems are governed by rigorous national and international standards, such as NFPA (National Fire Protection Association) in the US or LPCB (Loss Prevention Certification Board) standards elsewhere. These standards specify requirements for materials, pressure ratings, and performance.

Brass cross fittings manufactured for fire protection are designed and tested to meet these specific standards. They often come with certifications that building inspectors and insurance companies require. Using a non-certified fitting can void a system’s approval and insurance coverage.

Key Considerations for Fire System Fittings

When sourcing brass crosses for fire protection, certification is not an option—it is mandatory. You must use fittings listed and approved for fire service. Another pain point is improper installation. These fittings are typically joined using a threaded (NPT) connection. It is vital that threads are cut correctly and that the fittings are torqued properly. Over-tightening can crack the fitting; under-tightening will leak. We advise our clients to work only with installers certified in fire system installation and to use a thread sealant approved for fire protection use (not standard pipe dope, which can dry out and crack over decades).

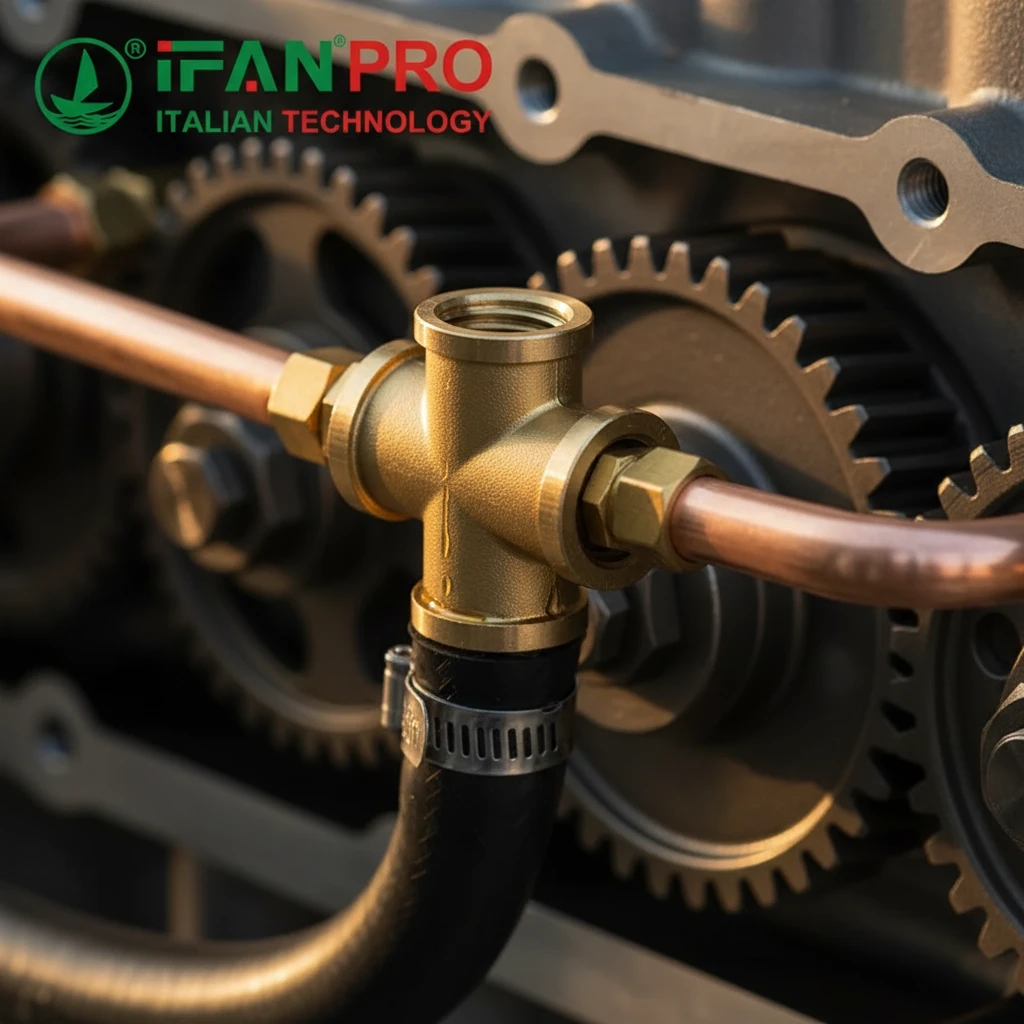

How Do They Function in Fuel or Lubrication Distribution Systems?

Handling flammable or hazardous fluids like fuel and oil requires components that prioritize absolute safety and leak prevention above all else.

Brass cross fittings function in fuel and lubrication systems to safely distribute these fluids to multiple points, such as different machine heads or engine cylinders. They are selected for their ability to create vapor-tight seals, resist degradation from hydrocarbons, and provide a durable, spark-resistant connection that minimizes fire risk in industrial environments.

Safety as the Primary Concern

In any system handling fuel, oil, or grease, the number one priority is preventing leaks. A leak is not just a mess; it is a major safety hazard, a fire risk, and an environmental issue. Brass is inherently spark-resistant. If a brass tool strikes a brass fitting, it is much less likely to create an incendiary spark than if steel were involved. This is a critical safety feature in workshops and factories.

Material Compatibility with Hydrocarbons

Fuels, lubricants, and hydraulic oils are hydrocarbons. They can break down and degrade many types of plastics and elastomers. Brass is highly resistant to degradation from these substances. It will not swell, soften, or become brittle when in constant contact with oils and fuels. This ensures the physical integrity and dimensions of the fitting remain stable, which is essential for maintaining a seal.

Achieving Leak-Free Connections

Fuel and lubrication systems often use different connection types than water or air systems. Two are very common:

- Compression Fittings: Brass is the standard material for compression fittings used with soft copper or nylon tubing in lubrication lines. The brass ferrule (or olive) deforms perfectly to create a metal-to-metal seal around the tube that is both strong and vibration-resistant.

- SAE / JIC Flared Fittings: Brass crosses are also made with ports for SAE 37-degree flared connections common in hydraulic and fuel lines. The brass-to-brass seal at the flare interface is extremely reliable.

The malleability of brass is key here. It allows components like ferrules to compress and form a perfect seal without cracking.

Addressing System-Specific Pain Points

A major pain point in these systems is seepage—tiny, weeping leaks that are hard to trace. This is often due to improper sealing technique or incompatible sealants. For fuel applications, specific thread sealants that are resistant to gasoline or diesel must be used; standard Teflon tape is often not suitable. Another issue is contamination. Brass fittings for these systems should be clean and free of machining debris to prevent particles from entering sensitive injectors or bearings.

Practical Selection Guide

When choosing a brass cross for fuel or lube systems:

- Identify the Fluid: Confirm compatibility with the exact type of oil or fuel.

- Choose the Correct Connection Type: Match it exactly to your existing tubing (e.g., compression for 8mm nylon tube, SAE JIC for hydraulic hose).

- Use Approved Sealants: Always use the thread sealant or compound recommended for the specific fluid service.

- Consider Cleanliness: For high-precision lubrication systems, specify cleaned and bagged fittings.

Conclusion

From compressed air to fire sprinklers, brass cross fittings provide the reliable, corrosion-resistant junctions that keep critical industrial systems running safely and efficiently. For a full range of certified and high-performance industrial brass cross fittings, trust IFAN to meet your precise application needs.

Commentaires récents