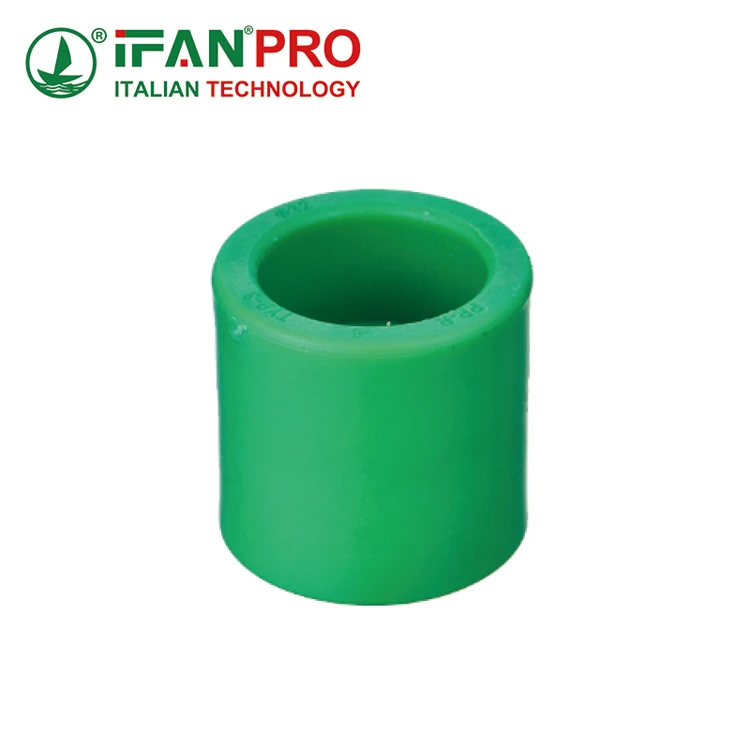

Product Name: PPR Pipe Fittings

Material: Korea Hyosung Raw Material

Color: Green/White/Yellow/Gray/Blue/Customized

Size: 20-110mm

Package: Opp Bag+Carton Or Customized

Connection: Welding

Guarantee Time: 50 Years

Delivery Port: Ningbo,Yiwu,Shanghai

Sample: Contact us for a free sample

Catégorie PPR Pipe And Fittings (Green)

Tags ppr fitting, ppr pipe fitting, ppr plumbing fitting

Prodcuts Description

Image des produits

Graphiques des produits

Prodcuts Description

| Size | M/Bag |

| S20 | 700 |

| S25 | 500 |

| S32 | 250 |

Excellent Chemical Resistance

Another significant advantage of PPR pipe fittings is their excellent chemical resistance. They do not react with most chemicals, ensuring the purity and safety of the water being transported. This chemical resistance makes PPR fittings suitable for a variety of applications where chemical exposure is a concern, such as in industrial settings.Non-Toxic and Safe

PPR pipe fittings are made from non-toxic materials that do not leach harmful chemicals into the water supply. This makes them a safe choice for potable water systems. Additionally, the non-reactive nature of PPR ensures that the water remains uncontaminated and safe for consumption, which is crucial for residential and commercial applications.Installation Methods of PPR Pipe Fittings

Preparation of Materials and Tools

Before beginning the installation of PPR pipe fittings, it is crucial to prepare all necessary materials and tools. This includes the PPR pipes and fittings, a pipe cutter, a marker, a measuring tape, and a fusion welding machine. Ensuring that all tools and materials are readily available will streamline the installation process and prevent unnecessary delays.Measuring and Cutting the Pipes

Accurate measurement is essential for a successful installation. Measure the length of PPR pipe needed for your project using a measuring tape and mark the cutting points with a marker. Use a pipe cutter to make clean, straight cuts at the marked points. Properly cut pipes ensure a snug fit and prevent potential leaks.Fusion Welding of Fittings

The most common method for joining PPR pipes and fittings is fusion welding. This process involves heating the ends of the pipe and the fitting using a fusion welding machine until they reach a molten state. Then, quickly and carefully join the heated ends together, ensuring they align correctly. Hold them in place until they cool and fuse, forming a strong, leak-proof bond.Inspection and Testing

After completing the installation, it is essential to inspect all joints and connections to ensure they are secure and leak-free. Turn on the water supply and check for any signs of leaks or weak connections. Testing the system under normal operating conditions will help identify any issues that need to be addressed before the system goes into full operation.Tips and Best Practices for Installing PPR Pipe Fittings

Ensuring Clean and Dry Surfaces

For optimal fusion welding results, it is crucial to ensure that the surfaces to be joined are clean and dry. Any dirt, moisture, or debris can compromise the quality of the weld and lead to leaks or weak connections. Use a clean cloth to wipe the ends of the pipes and fittings before heating them.Proper Heating Time

During fusion welding, it is important to heat the PPR pipes and fittings for the correct amount of time. Overheating or underheating can result in poor joint quality. Follow the manufacturer’s guidelines for heating times based on the size and thickness of the pipes and fittings being used.Consistent Pressure

When joining the heated pipes and fittings, apply consistent pressure to ensure a uniform bond. Uneven pressure can cause weak spots in the joint, increasing the risk of leaks. Holding the pipes and fittings firmly in place until they have completely fused will create a strong and reliable connection.Regular Maintenance and Inspection

Even though PPR pipe fittings are durable and long-lasting, regular maintenance and inspection can help ensure the longevity of the plumbing system. Periodically check for any signs of wear, leaks, or damage and address any issues promptly to maintain the integrity of the system.Conclusion

PPR pipe fittings offer numerous advantages, including exceptional durability, excellent chemical resistance, and safety for potable water systems. The installation of PPR pipe fittings, primarily through fusion welding, ensures a secure and reliable plumbing system. By following proper installation methods and best practices, homeowners, contractors, and industry professionals can achieve efficient and long-lasting plumbing solutions tailored to their specific needs.Contact

With 30 years of experience, IFAN is a specialist manufacturer specializing in the production of high quality plastic fittings, fittings and valves. Our products cover copper valves, PPR valves and various fitting and fittingxs to meet different customer needs. No matter what your needs are for plumbing or valves, IFAN offers a wide range of cost-effective products to support your project. Below is our contact information, this is our Whatsapp: + 86 19857948982,Email:[email protected]

Image des produits

Graphiques des produits