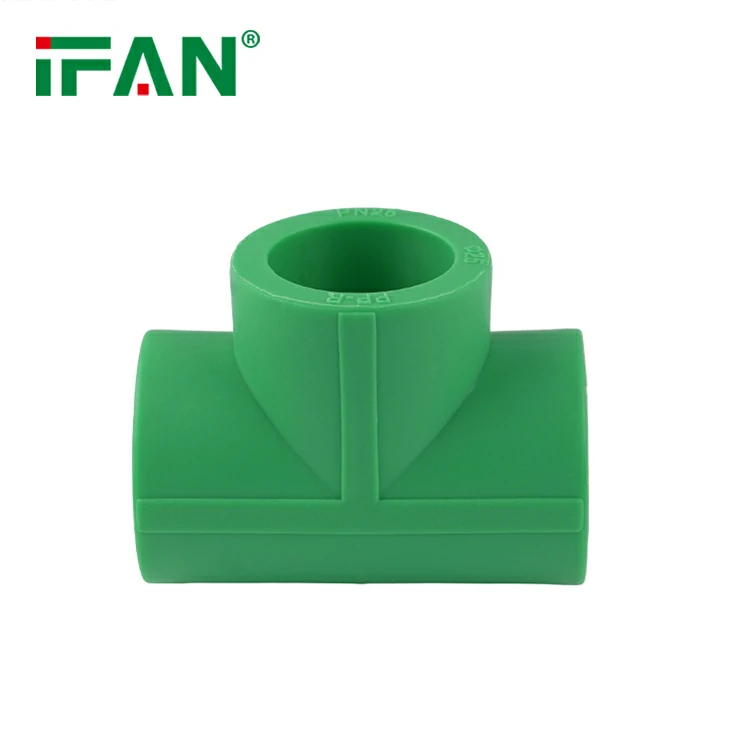

PPR tee fittings form the backbone of modern plumbing systems. These critical components connect three pipe sections at precise angles. Quality matters more than price when selecting these essential fittings.

Understanding PPR Tee Fitting Basics

PPR stands for Polypropylene Random Copolymer. This thermoplastic material offers exceptional durability and chemical resistance. Tee fittings create branch connections in water supply lines.

The material withstands temperatures up to 95°C continuously. It handles pressures exceeding 2.5 MPa under normal conditions. These specifications make PPR ideal for residential and commercial applications.

Key Quality Indicators

Material Composition

Premium PPR contains high-grade polypropylene compounds. Check for smooth, uniform surfaces without visible impurities. Quality fittings display consistent wall thickness throughout.

Avoid products with rough textures or color variations. These indicate poor raw material quality or manufacturing defects.

Dimensional Accuracy

Precise measurements ensure proper pipe connections. Standard sizes include 20mm, 25mm, 32mm, and larger diameters. Socket depths must match pipe insertion requirements exactly.

Measure fitting dimensions against international standards. ISO 15874 provides comprehensive specifications for PPR systems.

Pressure Ratings

High-quality fittings clearly display pressure classifications. PN10, PN16, and PN20 represent different pressure capabilities. Match your system requirements to fitting specifications.

Never compromise on pressure ratings. Undersized fittings lead to system failures and costly repairs.

Evaluating Manufacturers

Certification Standards

Look for ISO 9001 quality management certification. NSF approval ensures drinking water safety compliance. CE marking indicates European conformity standards adherence.

Request certification documents before making purchases. Reputable manufacturers provide complete documentation readily.

Production Capabilities

Established manufacturers operate advanced injection molding equipment. They maintain strict quality control throughout production processes. Modern facilities ensure consistent product specifications.

Visit manufacturer facilities when possible. Direct inspection reveals production quality and capacity.

Technical Support

Quality manufacturers offer comprehensive technical assistance. They provide installation guidelines and system design support. Professional teams answer technical questions promptly.

Evaluate customer service responsiveness before committing to suppliers.

Purchasing Considerations

Quantity Requirements

Bulk orders typically offer better pricing structures. Calculate total project needs including spare components. Consider future expansion requirements in quantity planning.

Minimum order quantities vary between suppliers. Factor shipping costs into total purchase expenses.

Delivery Timeframes

Standard products ship within 7-15 business days. Custom specifications require additional manufacturing time. Plan project schedules around delivery expectations.

Confirm delivery dates in writing before finalizing orders.

Warranty Terms

Quality manufacturers provide 15-50 year product warranties. Warranty coverage includes material defects and manufacturing flaws. Understand warranty claim procedures thoroughly.

Document installation dates and conditions for warranty protection.

Testing and Verification

Visual Inspection

Examine fittings for surface defects upon delivery. Check socket depths and thread specifications. Verify dimensional accuracy using precision measuring tools.

Return defective products immediately to avoid installation delays.

Pressure Testing

Conduct hydrostatic pressure tests before system commissioning. Test at 1.5 times working pressure for 24 hours minimum. Monitor for leaks or deformation carefully.

Failed tests indicate fitting quality issues or installation problems.

Common Purchasing Mistakes

Price-Only Decisions

Cheap fittings often use inferior materials or manufacturing processes. Initial savings disappear through premature failures and replacements. Quality fittings provide decades of reliable service.

Calculate total lifecycle costs including maintenance and replacement expenses.

Inadequate Specifications

Vague product descriptions lead to compatibility issues. Specify exact dimensions, pressure ratings, and material grades. Detailed specifications prevent costly ordering mistakes.

Create comprehensive specification sheets for all project components.

Insufficient Quality Verification

Skipping quality checks increases project risks significantly. Implement incoming inspection procedures for all deliveries. Verify critical dimensions and visual quality standards.

Installation Considerations

Quality fittings require proper installation techniques. Use appropriate fusion welding temperatures and timing. Maintain clean work environments during assembly.

Follow manufacturer installation guidelines precisely. Proper installation maximizes fitting performance and longevity.

Conclusion

High-quality PPR tee fittings ensure reliable plumbing system performance. Focus on material quality, dimensional accuracy, and manufacturer reputation. Proper selection and installation provide decades of trouble-free operation.

Invest in quality components from established manufacturers. Your plumbing system’s reliability depends on these critical connection points.

Commentaires récents