A client’s irrigation project was failing because their old valves choked the water flow. This frustrating problem is exactly why understanding valve design is critical for any system’s performance.

A large PVC ball valve ensures maximum flow primarily through its full-port design, where the internal bore matches the pipe diameter exactly. This creates a straight, unobstructed path for fluid, minimizing turbulence and resistance. Combined with a smooth PVC interior and proper sizing, it allows the system to achieve its highest possible flow rate with minimal pressure loss.

To get the most from your pipeline system, you need to understand how a valve’s design impacts flow. So, let’s break down the key features that make a large PVC ball valve the best choice for maximum flow.

What is a Full-Port Design in Large PVC Ball Valves for Maximum Flow?

I’ve seen many systems underperform simply because someone chose a standard valve instead of a full-port one. Actually, the difference is not just on paper; it’s visible in system output.

A full-port (or full-bore) design in a large PVC ball valve means the hole through the ball and the valve ports are the same diameter as the connecting pipeline. This creates a completely straight, uninterrupted passage for the fluid, removing any constriction that would slow down the flow, which is the essential feature for achieving maximum flow capacity.

The Core Principle of Full-Port Design

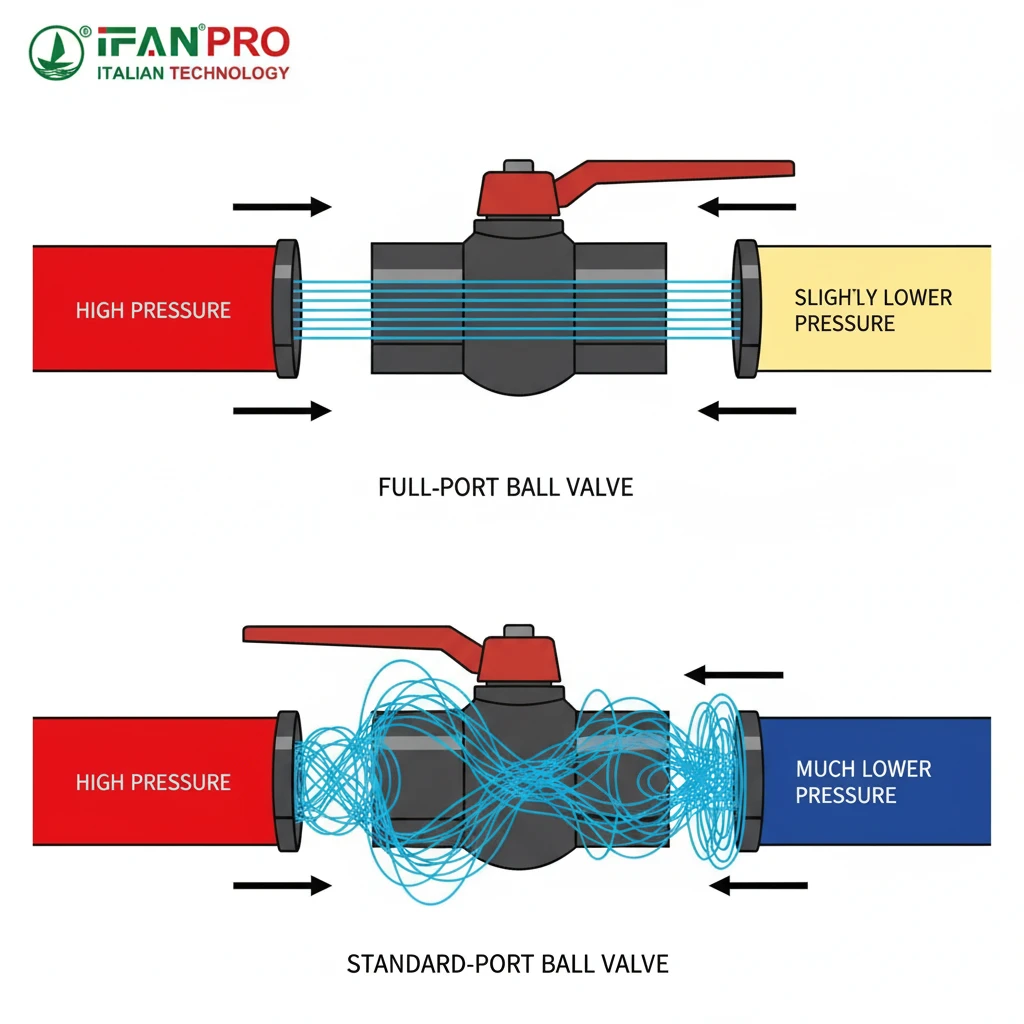

Think of your pipeline as a highway. A valve is like a tunnel on that highway. For example, a standard port valve is a narrow tunnel that forces all cars to slow down and squeeze through. In contrast, a full-port valve is a tunnel that’s just as wide as the highway, so traffic can keep moving at full speed.

In technical terms, the “port” refers to the opening at the inlet and outlet of the valve, and the “bore” is the hole through the ball. In a full-port valve, these three diameters—pipe, port, and bore—are all equal. Therefore, this alignment is what eliminates the bottleneck.

Why This Matters for Your System

The main benefit is minimizing pressure drop. Pressure drop is the loss of water pressure or pumping force as fluid moves through a restriction. Specifically, every constriction causes friction and turbulence, making your pump work harder to push the same amount of fluid. Since a full-port valve has virtually no constriction, the pressure drop across the valve is extremely low. As a result, you maintain more useful pressure throughout the rest of your system.

Another key advantage is for system maintenance. The full-bore opening allows for the easy passage of “pigs” or cleaning devices used to scour the inside of pipelines. This is crucial in industrial or municipal applications where keeping pipes clean is essential.

Full-Port vs. Standard-Port: A Direct Comparison

The table below shows the clear operational differences between the two main designs.

| Feature | Full-Port (Full-Bore) Ball Valve | Standard-Port (Reduced-Bore) Ball Valve |

|---|---|---|

| Bore Diameter | Same as the pipe diameter (e.g., 2″ valve has a 2″ bore). | Typically one pipe size smaller than the valve size (e.g., a 2″ valve has a ~1.5″ bore). |

| Flow Capacity | Maximum possible flow. Minimizes pressure drop (often less than 1 psi). | Reduced flow. Creates a noticeable pressure drop due to the constriction. |

| Primary Use Case | Critical for applications requiring max flow, pigging, or minimal pressure loss (e.g., main supply lines, pump discharge). | Suitable for applications where some flow restriction is acceptable and cost is a bigger factor (e.g., branch lines, isolation points). |

| Cost & Size | More expensive and physically larger/heavier due to more material. | Less expensive and more compact. |

Making the Right Choice

So, when do you absolutely need a full-port design? First, choose it for your main supply lines and pump discharge outlets. Also, use it anywhere the system design demands the highest possible flow with the least energy loss. While it costs more upfront, it saves money on pumping energy over time and ensures your system performs as designed. For this reason, at IFAN, we always specify full-port designs for our large PVC ball valves intended for maximum flow applications. This ensures our clients get the performance their systems require.

How Does the Bore Size of a PVC Ball Valve Affect System Flow Rate?

Selecting the wrong bore size is a common and costly mistake. It’s like putting a narrow straw in a large drink—you just can’t get the volume you need.

The bore size of a PVC ball valve directly controls the system flow rate by determining the cross-sectional area available for fluid to pass. A larger bore offers less resistance, allowing a higher volume of fluid to pass per minute. Conversely, a smaller bore restricts this area, increasing fluid velocity and friction, which significantly reduces the total flow rate and increases pressure drop.

Understanding the Relationship

The connection between bore size and flow isn’t just intuitive; it’s mathematical. The flow rate (Q) through a pipe or valve is governed by principles like Bernoulli’s equation. However, a simpler way to think about it is through the cross-sectional area.

The area of a circle (which is the bore) is calculated as πr². This means if you double the bore diameter, you quadruple the available flow area. For example:

- A 2-inch bore has an area of about 3.14 square inches.

- A 4-inch bore has an area of about 12.56 square inches.

This four-times-larger area allows much more fluid to flow through at the same pressure. On the other hand, even a small reduction in bore size creates a surprisingly large reduction in potential flow area, creating a major bottleneck.

The Consequences of a Restricted Bore

When fluid encounters a smaller bore, several things happen that hurt your system. First, increased velocity occurs. The fluid must speed up to squeeze through the smaller opening, and this higher velocity creates more friction against the valve walls. Next, it causes turbulence. The sudden change in diameter causes chaotic, swirling flow patterns (turbulence), which wastes energy. Furthermore, there is a cavitation risk. In liquid systems, if the pressure drops too low due to this restriction, the liquid can vaporize into bubbles that then violently collapse, damaging the valve and pipe walls. Finally, it leads to a higher pump load. Your pump must work significantly harder to overcome this added restriction, leading to higher energy bills and potential pump wear.

Practical Impact on System Design

Let’s look at a practical scenario. Imagine you’re designing a water transfer system that needs to move 500 gallons per minute (GPM). You use a 6-inch pipeline. If you install a standard-port 6-inch ball valve with a bore of only 5 inches, you have created an immediate restriction. Consequently, your pump now has to generate extra pressure just to force the required flow through that valve. As a result, you may need a larger, more expensive pump to achieve your target flow, and you’ll pay for that extra energy forever.

Bore Size Selection Guide

Use this table as a starting point for understanding how bore choice impacts flow. The exact numbers depend on pressure and fluid type, but the relative difference is clear.

| Nominal Valve Size | Typical Full-Port Bore Diameter | Typical Standard-Port Bore Diameter | Approximate Relative Flow Capacity (Full-Port = 100%) |

|---|---|---|---|

| 2 inches | 2.0 inches | ~1.5 inches | 100% vs. ~56% |

| 4 inches | 4.0 inches | ~3.0 inches | 100% vs. ~56% |

| 6 inches | 6.0 inches | ~5.0 inches | 100% vs. ~69% |

| 8 inches | 8.0 inches | ~6.0 inches | 100% vs. ~56% |

The key takeaway is never to assume a valve’s size matches its bore. Instead, always check the manufacturer’s specifications for the actual bore diameter. For maximum flow, insist on a full-port, full-bore design where the bore matches the pipe ID. Therefore, at IFAN, our large PVC ball valves for high-flow applications are always specified with true full-port dimensions. This ensures the bore size never becomes the weak link in your system.

Why Does a Large PVC Ball Valve Minimize Pressure Drop in Pipelines?

Pressure drop silently steals energy and money. I’ve diagnosed systems where pumps were wrongly blamed, when the culprit was actually high-pressure-drop valves.

A large PVC ball valve minimizes pressure drop by offering a smooth, straight flow path that matches the pipe diameter (full-port design). The inherent smoothness of the PVC material and the valve’s unobstructed open state reduce friction and turbulent disturbances to a minimum, allowing fluid to pass through with very little loss of energy or pressure.

What is Pressure Drop and Why is it Bad?

Pressure drop (ΔP) is the difference in pressure between two points in a system. In a pipeline, it’s the energy lost to friction as fluid moves. Every fitting, elbow, and valve causes some pressure drop. While some drop is inevitable, excessive drop is a design flaw with real consequences:

- Reduced Flow Rate: Lower pressure at the outlet means less force to move fluid, reducing overall flow.

- Higher Energy Costs: Pumps and compressors must work harder to overcome the drop, using more electricity.

- Cavitation: In liquids, a severe local pressure drop can cause vapor bubbles to form and implode, causing noise, vibration, and physical damage to pipes and equipment.

- Poor System Performance: Sprinklers won’t spray far enough, tools won’t operate correctly, and processes may slow down.

Key Design Features That Reduce Drop

A well-designed large PVC ball valve attacks the causes of pressure drop on three fronts:

1. Minimal Flow Obstruction (Full-Port Design):

This is the most important factor. As discussed, a full-port valve has no narrowing. The flow path is straight and consistent. The primary formula for pressure drop in a straight section is related to friction. However, a sudden contraction and expansion (like in a reduced-bore valve) adds a separate, often larger, “minor loss” component. Importantly, a full-port valve eliminates this minor loss component entirely.

2. Superior Surface Smoothness:

PVC has a very low Hazen-Williams roughness coefficient (typically around C=150). This means the interior surface is hydraulically smooth, creating much less frictional resistance to flow compared to metals like steel or even other plastics. Additionally, the smooth ball and body lining further ensure minimal turbulence.

3. Efficient Open Geometry:

When fully open, the ball’s bore aligns perfectly with the pipe. As a result, the fluid doesn’t have to change direction, go around corners, or through labyrinths like in gate or globe valves. Instead, it experiences a single, clean, straight-through journey.

Comparing Valve Types for Pressure Drop

Not all valves are created equal. In fact, the design fundamentally affects how much pressure is lost.

| Valve Type | Typical Flow Path When Open | Relative Pressure Drop (for same size) | Reason |

|---|---|---|---|

| Full-Port Ball Valve | Straight, full-diameter tube. | Very Low | No obstruction, smooth path. |

| Globe Valve | S-shaped, tortuous path. | Very High | Fluid must change direction multiple times. |

| Gate Valve | Gate retracts fully, but flow path is not perfectly aligned. | Low (but higher than full-port ball) | Some turbulence around the gate seat. |

| Standard-Port Ball Valve | Straight but narrowed path. | Medium to High | Constriction causes acceleration and turbulence. |

The Economic Impact of Low Pressure Drop

Choosing a low ΔP valve like a full-port PVC ball valve is an investment in efficiency. For a constantly running pump system, even a 2-3 psi reduction in pressure drop can translate into hundreds of dollars in annual energy savings. More importantly, it ensures your system’s design pressure is available where it’s needed—at the point of use. For this purpose, IFAN’s large PVC ball valves are engineered with these principles. They provide the low-pressure-drop performance required for efficient large-scale water, chemical, and industrial systems.

How Do You Select the Correct Large PVC Ball Valve for Maximum Flow Capacity?

Choosing the right valve is more than picking a size. Actually, it’s a process that matches valve specs to your system’s needs to unlock full performance.

To select the correct large PVC ball valve for maximum flow, first ensure it’s a true full-port (full-bore) design where the bore diameter matches your pipe’s inner diameter. Then, verify the valve’s pressure rating exceeds your system’s maximum operating pressure, confirm the PVC material is compatible with your fluid, and choose an appropriate actuation method (manual or automated) based on operational needs.

Step 1: Determine Size and Confirm Full-Port Design

This is the most critical step for flow. First, match the valve’s nominal size to your pipe size (e.g., 6-inch pipe needs a 6-inch valve). Do not stop here. Next, you must obtain the manufacturer’s specification sheet and confirm the actual bore diameter. It must be listed as “Full Port” or “Full Bore” and the bore measurement should equal the inner diameter of your schedule pipe. In short, never assume; always verify.

Step 2: Check Pressure and Temperature Ratings

The valve must withstand your system’s conditions. Specifically, PVC valves have a maximum pressure rating (like 150 psi) that decreases as temperature rises. Therefore, your system’s maximum operating pressure must be below the valve’s rating at your fluid’s temperature. Also, include a safety factor. Additionally, consider potential water hammer (pressure surges) and choose a valve with a sufficient safety margin.

Step 3: Verify Chemical and Fluid Compatibility

While PVC is excellent for water, acids, bases, and many chemicals, it is not universal. Consequently, you must check that your specific fluid (including any cleaning agents) is compatible with PVC material. Consult chemical resistance charts. For instance, PVC is not suitable for concentrated solvents, hot aromatic hydrocarbons, or certain concentrated oxidizing acids.

Step 4: Choose the Right End Connections

The valve must connect properly to your pipeline. For large PVC valves, the most common types are:

- Socket (Slip) Ends: For solvent cement welding to PVC pipe. This creates a permanent, leak-free joint.

- Threaded Ends: For screwing onto threaded pipe (less common for large sizes due to sealing challenges).

- Flanged Ends: For bolting between pipe flanges with a gasket. This is essential for large industrial systems where valves may need future removal for service.

Step 5: Consider Actuation and Operation

How will you open and close the valve? Here are your main options:

- Manual Lever: Simple, reliable, and cost-effective for valves that are operated infrequently. Ensure the lever has enough clearance to rotate 90 degrees.

- Gear Operator: A must for large valves (typically 4-inch and above). It reduces the effort needed to turn the valve, making operation safer and easier.

- Electric/Pneumatic Actuator: For automated, remote, or frequent operation. This is essential for process control systems.

Key Selection Criteria Checklist Table

Finally, use this table as a final checklist before purchasing.

| Selection Criteria | What to Look For | Why It Matters for Max Flow |

|---|---|---|

| Bore Type | Full-Port / Full-Bore designation confirmed on spec sheet. | Ensures no flow restriction, enabling maximum capacity. |

| Size | Nominal size matches pipe. Bore diameter matches pipe ID. | Correct sizing is fundamental to system design. |

| Pressure Rating | Valve’s PN or psi rating > max system pressure + safety factor. | Prevents valve failure under pressure, ensures safety. |

| Temperature Rating | Valve’s max fluid temp rating > your operating temperature. | PVC strength decreases with heat; prevents deformation. |

| Material Compatibility | PVC (Type I, II, or CPVC) is listed as suitable for your fluid. | Prevents valve degradation, leaks, and fluid contamination. |

| End Connection | Compatible with your pipeline (Socket, Flanged, Threaded). | Ensures a secure, leak-free installation. |

| Operation Method | Suitable for your needs (Lever, Gear, Actuator). | Ensures the valve is practical and safe to use. |

By following this disciplined selection process, you move beyond guesswork. Ultimately, you ensure the valve is an integral, high-performance component of your system, not a hidden bottleneck. For applications demanding reliable, maximum flow, IFAN’s range of full-port, heavy-duty large PVC ball valves are manufactured to precise specifications. They offer the verified bore dimensions, robust pressure ratings, and chemical resistance needed for demanding industrial and municipal applications.

Conclusion

For maximum flow, always choose a true full-port PVC ball valve sized correctly for your system. Therefore, for reliable, high-performance valves that deliver on this promise, specify IFAN’s professional-grade large PVC ball valves.

Commentaires récents