A client once insisted on using standard thin-walled brass elbows for a high-pressure industrial line. The resulting failure taught everyone on that project a clear, costly lesson.

Yes, wall thickness directly and critically impacts the pressure rating of brass elbows. A thicker wall provides more material to contain internal pressure, significantly increasing the fitting’s strength and its maximum safe working pressure. Choosing an elbow with insufficient wall thickness for your system’s pressure is a major cause of leaks and catastrophic fitting failures.

This relationship is fundamental in engineering safe piping systems. Let’s examine exactly how thickness is defined, measured, and chosen to ensure reliability.

How is the Schedule or Thickness Class Defined for Brass Pipe Fittings?

When ordering, you can’t just ask for a “thick” elbow. You need to speak the precise language of schedules and classes.

The wall thickness for brass pipe fittings is standardized through “Schedule” numbers (like Sch. 40, Sch. 80) for pipe-sized fittings or “Pressure Class” ratings (like Class 150, Class 300). These codes correspond to specific, measured wall thicknesses that are engineered to withstand defined internal pressures, ensuring consistency and safety across manufacturers and projects.

Understanding the Schedule System

The “Schedule” system (Sch.) is the most common way to specify wall thickness for fittings that match standard pipe sizes. It provides a uniform standard.

A key point to remember is that Schedule numbers are not arbitrary. They represent a calculated formula based on the internal diameter of the pipe. For a given nominal pipe size (e.g., 1/2 inch), a higher Schedule number means a thicker wall. For example, a 1/2 inch Sch. 80 elbow has a much thicker wall than a 1/2 inch Sch. 40 elbow.

This system helps everyone—designers, purchasers, and installers—quickly specify the required strength. You don’t need to give exact millimeter measurements; you just specify the Schedule, and the manufacturer produces a fitting with the correct, pre-defined dimensions.

Pressure Class and Other Standards

For some flange-type fittings or valve connections, you might see a “Pressure Class” instead. Common classes are 125, 150, 200, 300, etc. This class rating indicates the maximum pressure (in PSI) the fitting can handle at a certain temperature.

There are also other international standards. For instance, in Europe, you might see references to “EN” standards that define specific series (e.g., Series 1, 2, 3) which correlate with pressure ratings and wall thicknesses.

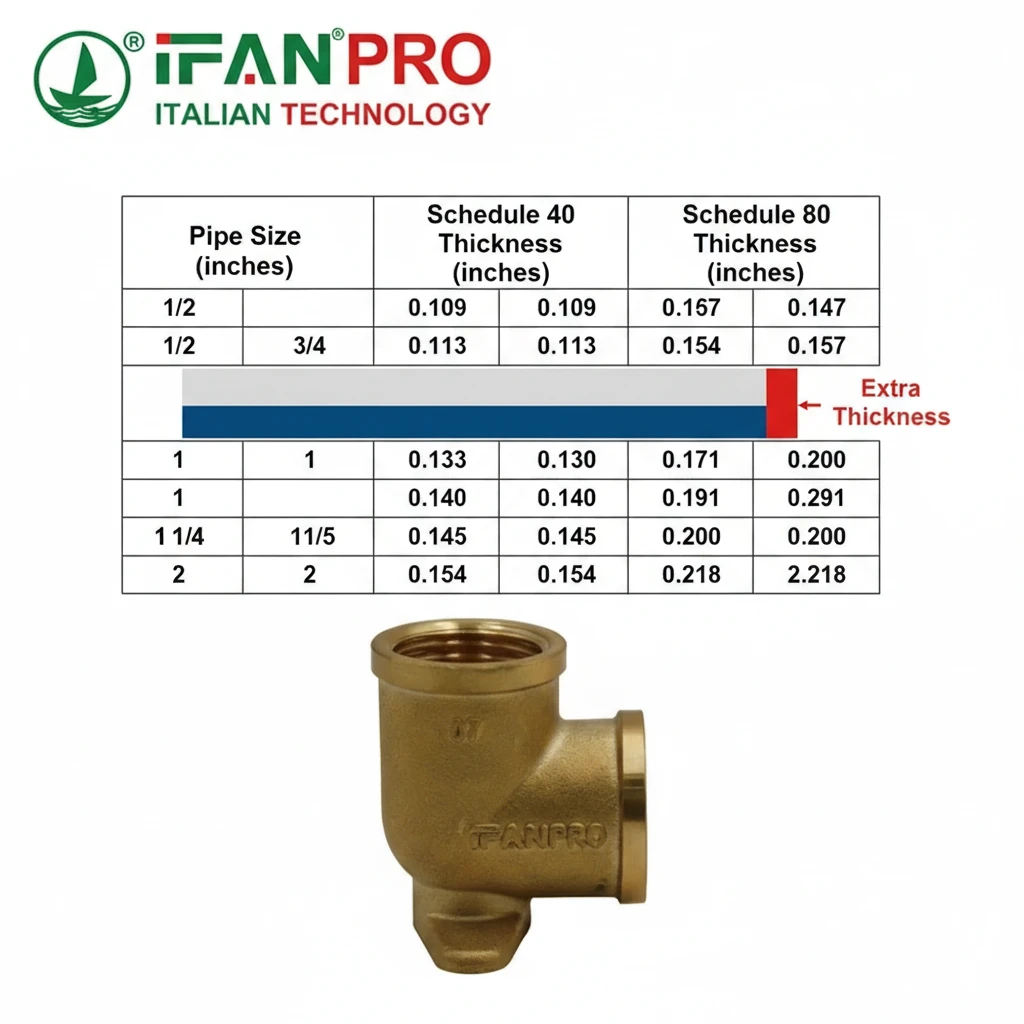

The table below simplifies how these classifications generally relate for brass fittings:

| Thickness Designation | Typical Use Case | Key Characteristic |

|---|---|---|

| Schedule 40 (Standard Weight) | General plumbing, residential water, low-pressure air. | The most common and economical thickness for standard pressures. |

| Schedule 80 (Extra Heavy) | Industrial process lines, commercial applications, high-pressure water, steam. | Wall is roughly 50-60% thicker than Sch. 40, for much higher pressures. |

| Class 150 / 200 | Flanged connections, pump discharge, valve manifolds. | Rated for working pressures up to 150 or 200 PSI at elevated temperatures. |

| Class 300 | High-pressure steam, hydraulic lines, industrial processing. | Used for the most demanding pressure applications. |

In short, these codes are a shortcut. They tell you the fitting is built to a known standard of thickness and strength, which brings us to the core of the issue: pressure.

What is the Relationship Between Wall Thickness and Maximum Working Pressure?

The core principle is simple physics, but the exact calculation is vital for safety.

The relationship between wall thickness and maximum working pressure is direct and exponential. According to the Barlow’s formula used in engineering, the pressure a pipe or fitting can hold is directly proportional to the wall thickness and the material’s strength, and inversely proportional to the diameter. Double the wall thickness, and you can approximately double the safe working pressure, assuming all other factors remain constant.

The Science Behind the Strength: Barlow’s Formula

Engineers use a fundamental formula to determine the pressure capacity of a cylindrical pipe. While simplified for fittings like elbows, the principle is the same.

The formula is: P = (2 * S * t) / D

Where:

- P = Maximum Internal Pressure (PSI)

- S = Allowable Stress of the material (a property of the brass alloy)

- t = Wall Thickness (inches)

- D = Outside Diameter (inches)

Let’s break down what this means in practice:

- Material Strength (S): First, the brass alloy itself must be strong. High-quality brass (like C36000 or C37700) has a high allowable stress value.

- Wall Thickness (t): This is the variable you control when selecting a fitting. The formula shows that pressure (P) increases directly as thickness (t) increases. A thicker wall provides more material to resist the force trying to burst the fitting open.

- Diameter (D): Larger diameter fittings are inherently weaker at the same wall thickness because the pressure acts over a larger area. This is why large-diameter pipes require much thicker walls.

A Practical Example

Imagine two 1-inch brass elbows made from the same alloy:

- Elbow A (Sch. 40): Wall thickness = 0.133 inches

- Elbow B (Sch. 80): Wall thickness = 0.179 inches

Using the formula, Elbow B can handle roughly 35% more pressure than Elbow A simply due to its thicker wall. This is not a small difference; it’s the difference between a safe system and a dangerous failure.

Factors Beyond Thickness

It’s crucial to remember that wall thickness is the primary, but not the only, factor. The pressure rating also depends on:

- Brass Alloy Quality: Inferior brass with impurities or incorrect composition will have a lower ‘S’ value.

- Manufacturing Process: A poorly cast fitting can have weak spots or porosity, even if the wall measures thick.

- Temperature: Pressure ratings drop as temperature increases. A fitting rated for 300 PSI at room temperature may only be safe for 150 PSI at 400°F.

Therefore, simply measuring thickness with a caliper isn’t enough. You must rely on the manufacturer’s published pressure ratings, which account for all these factors.

How Do You Identify the Pressure Rating from Markings on a Brass Elbow?

You should never guess a fitting’s pressure rating. The information is usually stamped on it.

You can identify the pressure rating by looking for stamped markings on the body of the brass elbow. These typically include the manufacturer’s name or logo, the material specification (e.g., “C360” for brass alloy), the pressure class (e.g., “3000 WOG” or “Class 150”), and sometimes the Schedule number (e.g., “Sch. 80”). “WOG” (Water, Oil, Gas) indicates the cold, non-shock working pressure rating in PSI.

Decoding the Standard Markings

A properly manufactured brass fitting from a reputable company will have clear, stamped identifications. Here is a guide to what you’re looking for:

- Manufacturer’s Mark: This is crucial for traceability and quality assurance. A branded fitting (like IFAN) means the company stands behind its specifications.

- Material Grade: Look for alloy numbers like C36000 (Free-Cutting Brass) or C37700 (Forging Brass). This tells you the base material meets specific strength and composition standards.

- Pressure Rating Markings: This is the most important mark.

- Numerical Rating (e.g., “300”): Often, this is the WOG rating in PSI. A marking of “300 WOG” means the fitting is rated for 300 PSI of Water, Oil, or Gas service at ambient temperature.

- Class Rating (e.g., “Class 200”): As discussed earlier.

- Schedule Number (e.g., “Sch. 80”): While not a direct PSI rating, you can cross-reference the Schedule with standard pressure tables.

- Size: The nominal pipe size (e.g.,

1/2or3/4). - Standards Compliance: Marks like “ASME B16.15” or “EN 1254” indicate the fitting is manufactured to a recognized dimensional and performance standard.

What to Do If Markings Are Unclear or Absent

This is a major red flag. Unmarked fittings are a significant risk. Without markings, you cannot verify:

- The material used (it could be a weak, recycled metal blend).

- The intended pressure rating.

- Compliance with any safety standard.

Our strong advice is to never use unmarked brass fittings in a pressurized system. The cost savings are never worth the risk of property damage or personal injury from a failure.

A Quick Reference Table for Common Markings

| What You See Stamped | What It Likely Means | How to Use This Information |

|---|---|---|

| IFAN C360 Sch.80 | Manufacturer: IFAN; Material: Free-Cutting Brass; Thickness: Schedule 80. | Look up the pressure rating for Sch. 80 brass fittings of that size in the manufacturer’s catalog. |

| 300 WOG | The fitting is rated for a maximum working pressure of 300 PSI for Water, Oil, or Gas at room temperature. | Ensure your system’s maximum operating pressure is at least 25% below this rating (for a safety margin). |

| Class 150 | The fitting meets dimensional and pressure standards for Class 150 service. | Suitable for systems where pressure-temperature charts show it is adequate for your specific service conditions. |

| ASME B16.15 | The fitting conforms to the American Society of Mechanical Engineers standard for cast brass threaded fittings. | Indicates a recognized level of quality and dimensional consistency. |

Are Heavy-Duty Brass Elbows Necessary for All High-Pressure Applications?

The instinct is often to over-specify for safety, but this can lead to unnecessary cost and installation challenges.

No, heavy-duty brass elbows are not necessary for all high-pressure applications. The correct fitting is determined by the specific pressure, temperature, media, and safety factor required. Often, a standard Schedule 80 elbow is sufficient for many industrial pressures, while severe service may require a Schedule 160 or forged elbow. Overspecifying can waste money and complicate installation due to increased weight and bulk.

Making the Right Choice: It’s About Application

The term “high-pressure” is relative. A residential well pump at 60 PSI is different from a hydraulic system at 3,000 PSI. Your fitting choice must match the actual conditions.

When a Standard Heavy-Duty Fitting (Sch. 80) is Perfectly Adequate:

- Commercial building water boosters (pressures up to 150-200 PSI).

- Industrial air compressor lines (typical plant air at 100-150 PSI).

- Irrigation pump discharge lines.

- Many chemical process lines at moderate pressures.

For these applications, a Schedule 80 brass elbow provides an excellent balance of strength, availability, and cost. Jumping to a more extreme “extra heavy” fitting offers no practical benefit.

When You Must Step Up to a More Robust Design

There are clear situations where you need to go beyond standard heavy-duty fittings. You should consider them for:

- Extremely High Pressure: Hydraulic systems, high-pressure steam lines (above Class 150), or test stands.

- Severe Cyclic Service: Systems with constant pressure surges, water hammer, or vibration. The extra mass and material of a heavier fitting better resist fatigue.

- Critical Safety Applications: Lines containing hazardous, toxic, or flammable media where failure is unacceptable. The added safety margin is justified.

- High-Temperature Service: As temperature rises, the strength of brass decreases. A thicker wall compensates for this derating.

The Drawbacks of Overspecifying

Using a fitting heavier than required has real downsides:

- Cost: Schedule 160 fittings can cost 2-3 times more than Schedule 80.

- Weight & Support: Heavier fittings add weight, potentially requiring more pipe supports.

- Installation Difficulty: They are bulkier, making tightening in tight spaces harder.

- Compatibility: An extremely thick fitting may not thread properly into a standard-thickness valve or union without special adapters.

Decision Framework: Choosing the Right Thickness

Follow this simple logic to make a reliable choice:

| Your System’s Condition | Recommended Brass Elbow Type | Reason |

|---|---|---|

| Pressure < 150 PSI, Water/Air | Schedule 40 | Cost-effective and fully capable for standard duty. |

| Pressure 150 – 300 PSI, or Commercial Use | Schedule 80 | The standard for reliable, heavy-duty service. Provides a good safety margin. |

| Pressure > 300 PSI, Hydraulics, Steam, or Critical Safety | Schedule 160 or Forged Fitting | Designed for severe service. Necessary for extreme pressures and stresses. |

| Frequent Pressure Surges/Vibration | Schedule 80 (minimum), consider Schedule 160 | Extra material mass helps absorb cyclic stress and prevent fatigue failure. |

Always base your final decision on a proper engineering calculation or the manufacturer’s pressure/temperature rating charts, not just a guess.

Conclusion

Wall thickness is the key to a brass elbow’s pressure strength. For reliable performance across all pressure ranges, specify IFAN’s certified brass elbows, available in Schedule 40, 80, and 160 to meet your exact system requirements.

Commentaires récents