I once inspected a failed heating system where corrosion had clogged the radiators. The culprit was not the famous PEX-AL-PEX pipe, but a standard valve that let oxygen seep in.

Yes, a valve designed for PEX-AL-PEX systems must and can prevent oxygen diffusion. It does this by incorporating a continuous metal layer or a specialized oxygen-barrier seal at the connection point, ensuring the pipe’s built-in aluminum barrier is not compromised. This design is critical to protect the entire heating system from corrosive damage.

So, a quality pipe alone is not enough. The valve is a decisive link. Let’s explore why this is so important and how the right valve design seals the deal.

Why is Oxygen Barrier Integrity Critical for the Entire Heating System?

A single weak point can undermine the entire system. I see this too often: clients invest in premium oxygen-barrier pipe but connect it with generic fittings.

Oxygen barrier integrity is critical because even tiny amounts of oxygen diffusing into a closed-loop heating system cause rapid corrosion of ferrous metals (like in boilers, pumps, and radiators). This leads to sludge buildup, reduced efficiency, component failure, and ultimately, costly system breakdowns.

The Destructive Role of Oxygen in Water

Think of a closed-loop heating system like a human body, and oxygen in the water like a poison. The system contains steel, iron, and cast iron components. When oxygen dissolves in the warm water, it reacts with these metals to form iron oxide—rust.

This process happens continuously if oxygen is present. First, the rust particles circulate and start to clog narrow passages in pumps, heat exchangers, and modern, efficient radiators. This is the “sludge” that plumbers often find. The system must work harder to pump water, using more energy.

Next, the corrosion itself eats away at metal parts. Over time, this can cause pinhole leaks in radiators or damage the boiler’s heat exchanger. The result is a loss of pressure, a need for constant water top-ups, and finally, complete failure. Repairing this is very expensive and disruptive.

The High Cost of a Failed Barrier

The table below shows the consequences of a compromised oxygen barrier at different system points:

| System Component | Consequence of Oxygen Ingress | Resulting Problem |

|---|---|---|

| Boiler (Heat Exchanger) | Internal corrosion and pitting. | Loss of efficiency, leaks, need for early replacement. |

| Circulation Pump | Bearing and impeller corrosion. | Seizure, loud operation, pump failure. |

| Radiators / Underfloor Heating Manifolds | Internal rust buildup and clogging. | Cold spots, reduced heat output, imbalance in the system. |

| Overall System | Black, magnetic sludge circulating everywhere. | Reduced flow, higher energy bills, frequent maintenance. |

Using an oxygen-diffusion resistant pipe (like PEX-AL-PEX) is the first and most important step. However, if the valve you connect to that pipe is just a standard brass fitting, it creates a major weak point. Oxygen can diffuse directly through the valve body or, more commonly, through the seal between the valve and the pipe. Therefore, the valve must be part of the barrier strategy, not a hole in it.

How Does the Valve Connection Maintain the Pipe’s Built-in Oxygen Barrier?

The connection point is the battleground. A standard compression fitting crushes the pipe’s layers, potentially breaking the aluminum barrier.

A compatible valve maintains the oxygen barrier by using a connection method that preserves the pipe’s aluminum layer continuity. For PEX-AL-PEX, this is typically achieved with a press-fit or a specialized compression sleeve that grips the pipe without rupturing the inner aluminum core, ensuring the metallic diffusion barrier remains intact all the way to the valve port.

Understanding the Pipe’s Structure

First, you must understand what you are protecting. PEX-AL-PEX pipe has five layers: an inner PEX tube, an adhesive, a central aluminum tube, another adhesive, and an outer PEX layer. The thin, central aluminum layer is the hero—it is completely impermeable to oxygen.

The goal of any connection is to keep this aluminum tube as a continuous, unbroken shield. If you pierce, crack, or excessively deform it at the connection, you create a direct path for oxygen to enter the water stream.

Connection Methods: Good vs. Bad

Not all valve connections treat the pipe the same way.

The Problematic Method: Generic Compression Fittings

Many standard brass compression fittings use a sharp ferrule (olive ring) that bites into the pipe when tightened. This can cut or severely distort the aluminum layer, breaking the barrier. The seal is made further out on the pipe, but the damage is already done. Oxygen can diffuse through the PEX layers at the point of the break.

The Correct Method: Press-Fit or Barrier-Compression Fittings

The correct valves for PEX-AL-PEX use a different approach:

- Press-Fit Systems: A special tool presses a stainless-steel sleeve evenly around the pipe and onto the valve socket. This creates a uniform, high-pressure seal over the pipe’s layers without cutting. The aluminum layer deforms slightly but remains continuous. The metal-to-metal contact between the pipe’s aluminum and the valve’s brass body can further hinder diffusion.

- Specialized Compression Fittings: These use a wider, smoother compression ring or sleeve designed to apply pressure evenly. Their geometry is calculated to seal securely without compromising the critical aluminum core.

The key principle is controlled deformation. The connection must be strong and watertight, but it must also protect the integrity of the central metal layer. A valve designed for this purpose will clearly state it is compatible with “oxygen-barrier PEX-AL-PEX” or “multi-layer pipe.”

Are There Specific Gaskets or Seals That Block Oxygen at the Valve Joint?

The valve body and pipe connection are only part of the solution. The static seals inside the valve itself are equally important.

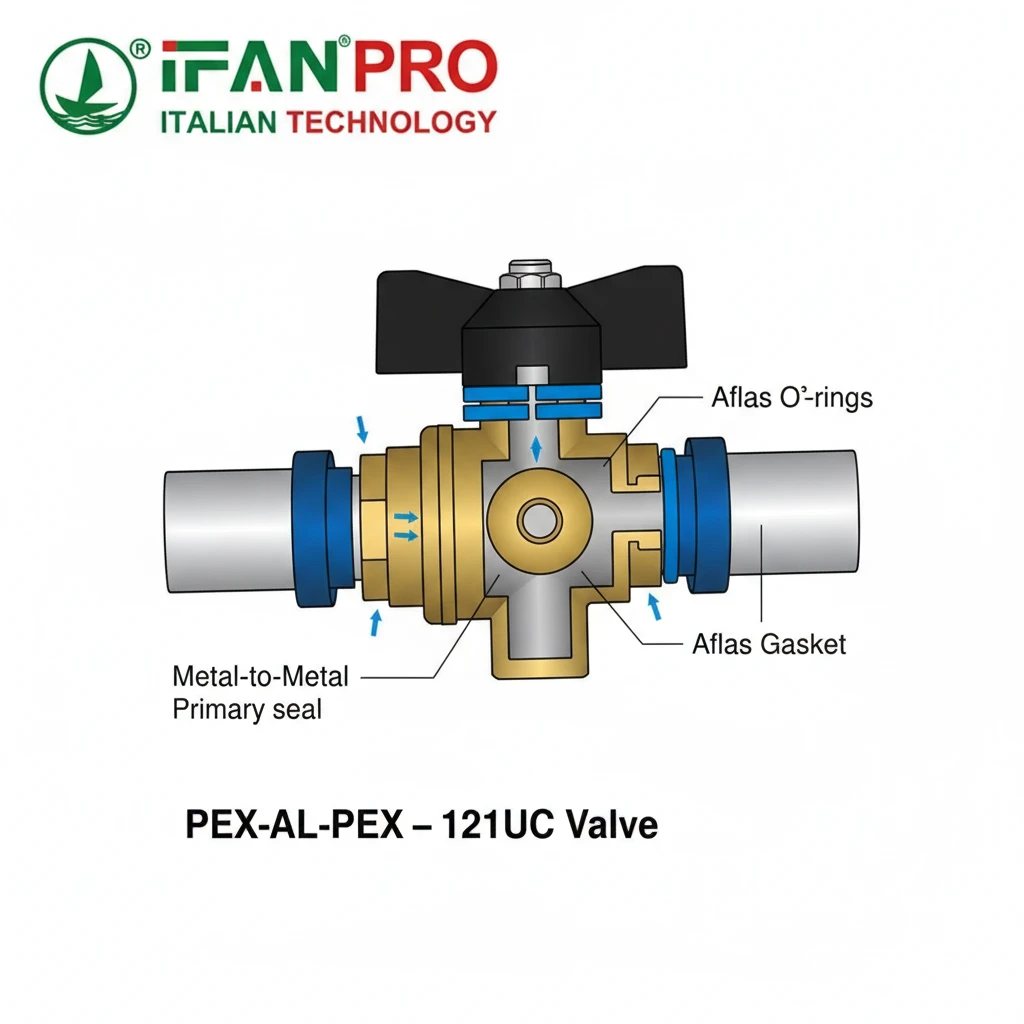

Yes, specific gaskets and seals are crucial. While standard rubber seals (like EPDM) are water-tight, they are somewhat permeable to gases. High-end valves for oxygen-sensitive systems may use specialized low-permeability seals made from materials like Aflas or specially compounded EPDM, and they employ metal-to-metal sealing faces in critical areas to block oxygen effectively.

The Two Sealing Challenges Inside a Valve

A valve must seal in two ways: dynamically (at the moving stem) and statically (between its body and ports). Oxygen can try to diffuse through both.

- Static Body Seals (Gaskets/O-rings): These seal the joints where the valve body is assembled or connects to the pipe. Standard nitrile or EPDM rubber is excellent for water but can allow tiny amounts of gas to permeate over years. For maximum protection, look for valves that use:

- Metal-to-Metal Sealing: Some press-fit valve designs have the pipe’s aluminum layer pressed directly against a precision machined brass seat, creating a primary metallic barrier.

- Low-Permeability Elastomers: Seals made from materials like Aflas (TFE/P) or specially formulated EPDM have significantly lower gas permeability rates. A quality manufacturer will specify this.

- Dynamic Stem Seal (The Biggest Challenge): This is where the valve handle turns. It’s the most likely path for oxygen from the outside air to enter. A standard packing gland or O-ring here is not enough. The best designs use:

- Multiple Seal Barriers: Several stacked seals or a combination of a primary seal and a secondary dust/wiper seal.

- Diaphragm or Bellows Seals: In advanced “packless” valve designs, a flexible metal diaphragm or bellows completely separates the water chamber from the moving stem and the outside air. This is the gold standard for absolute oxygen barrier integrity at the valve.

What to Look For in a Specification

Don’t guess. Ask for the technical data. A valve suitable for a demanding PEX-AL-PEX system should have clear specifications regarding its sealing technology and its oxygen permeability rating, often tied to a certification like DIN 4726 (which we will discuss next).

The table below compares seal types and their effectiveness:

| Seal Location & Type | Oxygen Barrier Capability | Typical Use Case |

|---|---|---|

| Standard EPDM O-ring | Good for water, moderate for gas. May allow slow diffusion. | General plumbing, non-critical heating loops. |

| Low-Permeability Compound (e.g., Aflas) | Very Good. Specifically designed to reduce gas transmission. | Quality oxygen-barrier systems. |

| Metal-to-Metal Contact (Pipe to Valve) | Excellent. Creates a direct, impermeable metallic barrier. | Press-fit connections on multilayer pipe. |

| Diaphragm/Bellows Stem Seal | Outstanding. Physically eliminates a diffusion path. | High-end systems where zero leakage is critical. |

How is the Valve’s Oxygen Permeability Tested and Certified?

Anyone can claim their valve “helps prevent” diffusion. Trust comes from independent, standardized proof.

The valve’s oxygen permeability is tested in certified laboratories according to strict international standards, primarily DIN 4726 (European) or ASTM F2023 (International). These tests measure the extremely low rate of oxygen diffusion through the assembled valve over time at elevated temperatures. Products passing these tests receive official certification, which is your guarantee of performance.

The Rigorous Test Procedure

Testing is not simple. It simulates years of service in a matter of weeks. Here is how it generally works:

- Sample Preparation: Technicians assemble valves onto standard lengths of oxygen-barrier PEX-AL-PEX pipe as they would be in the field.

- Test Environment: They place the assembled samples in a controlled environment, often with the pipe immersed in water and the valve exposed to air (or vice-versa), at an elevated temperature (e.g., 40°C or 60°C) to accelerate diffusion.

- Measurement: They use sensitive instruments to measure the tiny amount of oxygen that passes through the entire assembly—pipe, connection, and valve—over a long period (e.g., 16 weeks).

- Calculation: The results are calculated as a diffusion rate, typically in milligrams per liter per day (mg/(l·d)).

Understanding the Key Standards

Two major standards define the acceptable limits:

- DIN 4726 “Thermal diffusion tightness”: This is the leading European standard. It is very stringent. It requires the complete system (pipe + fitting) to have an oxygen permeability of less than 0.10 mg/(l·d). This is an extremely low number, effectively blocking oxygen ingress.

- ASTM F2023 “Standard Test Method for Evaluating the Oxygen Barrier Characteristics of Multilayer Pipe”: This international standard provides the test method. Project specifications will then state the maximum allowable diffusion rate based on this test, often aligning with the DIN 4726 limit.

The Importance of the Certificate

A responsible manufacturer like IFAN will have its valves tested as part of a complete system with PEX-AL-PEX pipe. They will hold a valid test report from an accredited lab (like TÜV, KIWA, or IAPMO). This report is your proof.

Practical Advice: When sourcing valves, do not just accept a verbal claim. Ask for the official test certificate that shows the valve model, the pipe used, and the measured oxygen permeability value. Ensure it meets the DIN 4726 requirement of <0.10 mg/(l·d) for the assembled system.

Conclusion

The right valve design is essential to lock oxygen out of your PEX-AL-PEX heating system. For guaranteed barrier integrity, insist on certified components like IFAN’s oxygen-barrier valves and press-fit system.

Commentaires récents