A client once complained that trace leaks were skewing their lab results. This problem perfectly shows why shut-off reliability in sampling valves is absolutely critical.

Yes, a high-quality mini valve provides extremely reliable shut-off in sampling lines. Its reliability comes from precise sealing technologies, a robust design that prevents clogging, and construction from chemically resistant materials. This combination ensures sample integrity, process safety, and accurate analytical results.

However, not all mini valves perform the same. Let’s examine the specific features that separate a reliable sampling valve from a problematic one.

What Sealing Technology Ensures Leak-Tight Closure in Mini Sampling Valves?

A visible leak is a failure, but a trace leak you cannot see is worse. It can ruin samples and compromise safety.

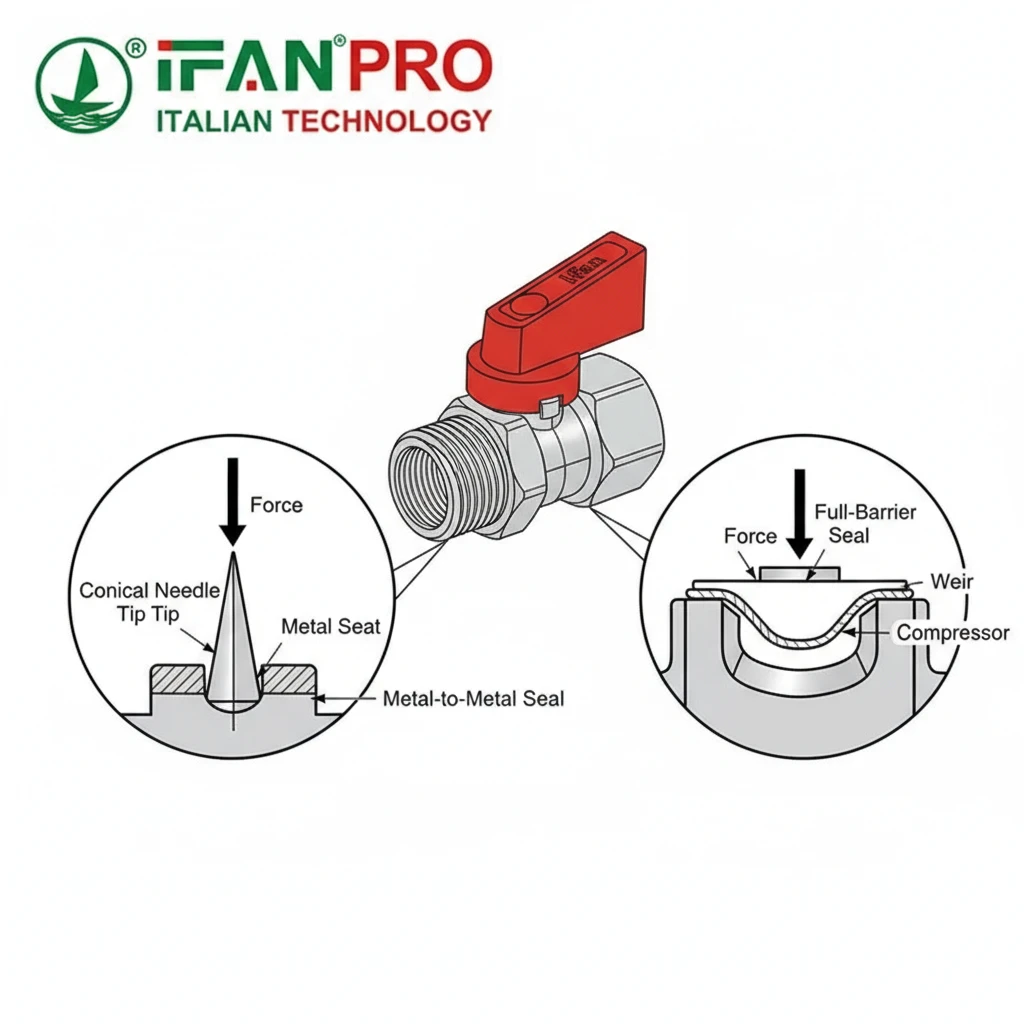

Leak-tight closure in mini sampling valves primarily relies on two sealing technologies. First, precision-machined conical seat designs create a metal-to-metal seal. Second, advanced elastomer or PTFE seals in diaphragm valves provide a compression-based barrier. These methods withstand system pressure and repeated thermal cycling.

The Core Principle of a Good Seal

The main job of any shut-off valve is to create a perfect barrier when closed. For mini valves in sampling, this seal must be exceptionally good. Even a tiny leak can allow atmospheric gases to contaminate a sample or let hazardous process fluid escape. Furthermore, the seal must last through hundreds of open-close cycles without wearing out.

Two main technologies achieve this level of performance in miniature scales suitable for sampling lines.

Needle Valve Conical Seal Design

First, consider the conical seal, which is common in needle valves. In this design, a finely tapered stem descends into a matching conical seat.

- How it works: When you turn the handle, the needle tip screws down and makes precise metal-to-metal contact with the seat. The tapered shape allows for very gradual and fine control over the flow before shut-off.

- The key to reliability: Material quality and design precision determine the reliability. Manufacturers use high-grade stainless steel, sometimes with a hard coating. They machine the angles to extremely tight tolerances so the contact is uniform around the entire seat.

- Advantage: This design is very robust for clean gases and liquids. It offers excellent shut-off and fine flow control in one device.

Diaphragm and Packless Seal Designs

The second major technology uses a flexible barrier to create a seal, which is common in diaphragm or bellows-sealed valves.

- How it works: Instead of the stem directly touching the flow path, a flexible diaphragm or a metallic bellows acts as a barrier. When you turn the handle, the stem pushes the diaphragm down onto a weir or seat, pinching the flow path closed.

- The key to reliability: Here, the integrity and material of the diaphragm or bellows ensure reliability. An advanced elastomer like EPDM or a PTFE diaphragm provides a bubble-tight seal. The biggest advantage is that this design completely separates the stem seal from the process fluid. This separation eliminates the primary path for external leakage.

- Advantage: This design is ideal for hazardous, toxic, or ultra-pure fluids where any stem leakage is unacceptable.

Choosing the Right Seal for Your Application

The table below helps you decide which sealing technology fits your need.

| Application Need | Recommended Seal Type | Key Reason |

|---|---|---|

| General purpose sampling, clean gases/liquids | Precision Needle Valve (Conical) | Robust, good control, cost-effective for non-hazardous duty. |

| Hazardous, toxic, or aggressive chemicals | Diaphragm or Bellows-Sealed Valve | Zero stem leakage, process fluid is fully contained. |

| Ultra-high purity systems (e.g., semiconductor, pharmaceutical) | Diaphragm Valve with PTFE wetted parts | Prevents contamination, offers clean, packless design. |

| High-cycle frequency sampling | Quality Needle Valve with Hardened Tip | Metal seat resists wear from repeated actuation better than soft seals. |

In summary, the reliability of the shut-off comes down to material quality and design precision. A soft seal can offer easier bubble-tight closure, while a hard seal offers superior durability. Therefore, the best choice depends entirely on your specific process fluid and safety requirements.

How Does the Design Minimize Dead Volume for Accurate Sample Integrity?

Dead volume is where old sample fluid hides, contaminating your next reading. It’s the enemy of accuracy.

Mini sampling valve design minimizes dead volume by utilizing straight-through flow paths and reducing internal cavities. Engineers position the sealing point close to the process line. Features like swept interiors and non-rotating stem tips in needle valves prevent fluid from getting trapped in threads or dead pockets.

What is Dead Volume and Why is it a Problem?

Dead volume refers to any space within the valve or fitting where fluid can become trapped and stagnant. When you take a new sample, this old, trapped fluid can mix with the new sample. Consequently, this cross-contamination skews analytical results. For example, it can dilute your sample or introduce contaminants from a previous batch. In precise applications, even a few microliters of dead volume can cause significant errors.

Design Strategies to Reduce Internal Cavities

Valve manufacturers use several intelligent design strategies to tackle this issue head-on.

First, consider the flow path geometry. The best sampling valves use a straight-through design or a smooth, angled bore. This creates a clean channel for fluid to pass through, similar to a tube. It avoids sharp corners or sudden enlargements where fluid can get stuck. Essentially, the goal is to make the valve interior as smooth and continuous as possible.

Second, the sealing mechanism’s location is critical. In a well-designed sampling valve, the point where the seal closes is located right at the entrance to the valve body. This means that when the valve is closed, almost no process fluid remains inside the valve’s internal chambers. As a result, any fluid behind the seat can be purged cleanly.

The Problem of Rotating Stem Tips

A specific issue in simple needle valves is the rotating stem. In a basic design, the stem tip rotates against the seat as it closes. This twisting motion can grind microscopic particles and, more importantly for dead volume, it can trap fluid in the threads of the stem assembly above the seal.

The solution is a non-rotating stem tip design. In this design:

- You turn a handle, which moves a stem up and down.

- The stem’s tip, however, does not rotate. It only moves linearly.

- This prevents the twisting action and eliminates the threaded area above the seal as a place for fluid to be drawn into and trapped.

This design significantly reduces the internal volume that needs purging between samples. Therefore, it leads to faster, cleaner, and more accurate sampling.

Comparing Valve Designs for Dead Volume

| Valve Design Feature | Effect on Dead Volume | Recommendation for Sampling |

|---|---|---|

| Standard Globe Valve | Very High (Large internal chambers) | Avoid for precise sampling. |

| Basic Rotating Stem Needle Valve | Medium (Fluid can enter threads) | Acceptable for some fluids if thoroughly purged. |

| Non-Rotating Stem Tip Needle Valve | Low | Very good for accurate liquid and gas sampling. |

| Diaphragm Valve | Very Low (Swept, straight-through body) | Excellent for high-purity and sensitive sampling. |

To ensure sample integrity, you must select a valve designed with dead volume minimization as a core principle. Specifically, look for terms like “low internal volume,” “swept bore,” “non-rotating stem,” and “straight-through flow path” in the product specifications.

Are They Resistant to Clogging from Particulates in Sampling Applications?

A clogged sampling valve doesn’t just stop working; it stops your entire process for maintenance, costing time and money.

Quality mini sampling valves resist clogging effectively when you choose the correct type. Key features include a smooth, unobstructed flow path and the absence of small internal cavities. Some designs even offer a self-cleaning action where the stem tip wipes the seat during operation.

How Clogging Happens in Valves

In sampling applications, the process fluid often contains small particles, slurries, or viscous materials. These can solidify, crystallize, or simply accumulate inside a valve. Typically, clogging occurs in places where the flow slows down or changes direction abruptly. Once a valve is partially clogged, it affects flow rate, sample accuracy, and eventually shuts completely.

A clogged valve in a sampling line is a major headache. It requires the line to be isolated, the valve to be dismantled, cleaned, and reinstalled. This process is not only labor-intensive but also poses safety risks if the fluid is hazardous.

Design Features that Prevent Particle Build-Up

To prevent this, valve design focuses on maintaining a smooth, fast flow without stagnation points.

The most important feature is a straight or streamlined flow path. Valves with a “full bore” design, where the internal diameter matches the tubing, prevent areas where flow stagnates. Consequently, particles are carried through the valve by the flow rather than settling.

For applications with fine particulates or slurries, diaphragm valves are often superior. Their straight-through body has no sharp corners or small orifices for particles to lodge in. The sealing diaphragm comes down flat against a smooth weir, and when open, it retracts fully, leaving a completely clear passage.

The “Self-Cleaning” Action

Some needle valve designs offer a degree of “self-cleaning.” As the needle stem screws down to close, its tapered tip moves through the orifice. Any soft particles sitting on the seat may shear off or displace by this action. When the valve opens again, the flow can carry these loosened particles away.

However, this is not effective against hardened deposits. It’s more of a preventative feature for soft or fibrous materials.

Material and Surface Finish

The material’s surface finish inside the valve also plays a role. A smooth, polished internal surface offers less friction and fewer microscopic crevices for particles to stick to compared to a rough, machined surface.

Valve Selection Guide for Particulate-Laden Fluids

| Fluid Type | Valve Type Recommendation | Critical Design Features |

|---|---|---|

| Clean Gases & Liquids | Standard Needle Valve | Conical seal, standard finish. |

| Slurries & High-Particulate Fluids | Diaphragm Valve | Straight-through bore, smooth weir, no small cavities. |

| Viscous Fluids (e.g., polymers, oils) | Full-Bore Ball Valve | Large, unobstructed flow path when open. |

| Fibrous Suspensions | Valve with Actuator | Allows for frequent, full-stroke cycling to prevent build-up. |

If your process fluid contains particulates, you must prioritize valve designs that eliminate internal traps. Additionally, regular maintenance cycling can help prevent particles from settling and solidifying in place.

Can They Provide Rapid and Repeatable On-Off Cycling for Sampling?

Manual sampling can be slow. In automated systems, valve speed and consistency directly impact throughput and data quality.

Yes, mini sampling valves designed for sampling duty provide rapid and repeatable cycling. Precision machining and stable sealing materials ensure repeatability. Furthermore, short stem travel and, most effectively, pneumatic or electric actuators enable consistent, fast, and programmable operation.

The Demand for Speed and Consistency

In many modern processes, samples need to be taken frequently—sometimes every few seconds or minutes. For example, this could be for online analyzers or quality control checkpoints. Doing this manually is impractical. Therefore, the valves must open and close quickly and, more importantly, do so in exactly the same way every time.

Repeatability ensures that each sample is taken under identical flow conditions. This is crucial for comparing results over time. If one sample is taken with the valve 30% open and the next at 50% open, the flow rate and fluid shear will differ. This difference can affect the sample’s representativeness.

Engineering for Manual Repeatability

For manual operation, repeatability is built into the valve’s mechanical design.

High-quality needle valves often feature a fine-pitch thread on the stem. This means you need more turns to open or close the valve fully. This design gives the operator very fine control and allows them to return to a specific flow setting reliably. Moreover, the stem and seat materials must be hard and wear-resistant to ensure this precision doesn’t degrade over hundreds of cycles.

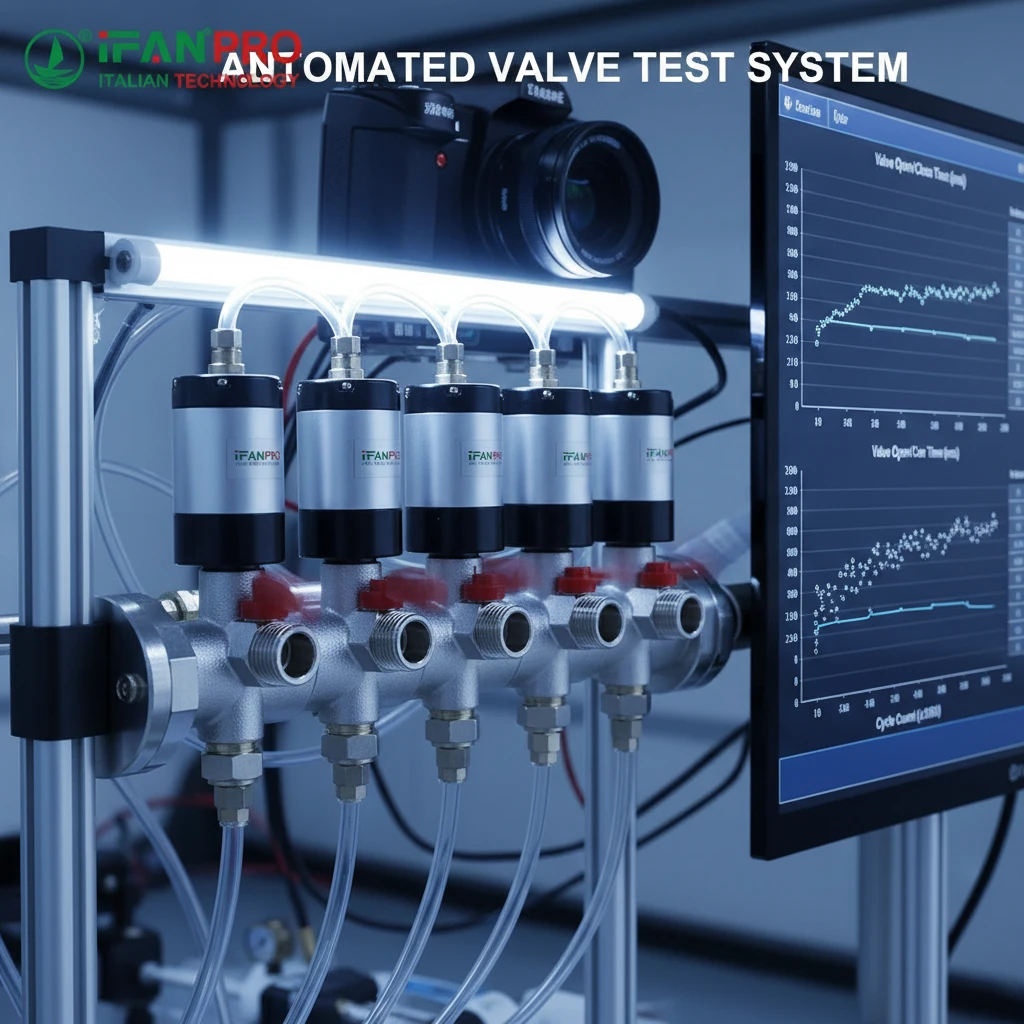

The Ultimate Solution: Actuation

For true speed and guaranteed repeatability, automated actuation is the answer. You can fit a mini valve with a compact pneumatic or electric actuator.

- How it works: The actuator converts energy into precise mechanical motion to turn the valve stem.

- Benefits for Sampling:

- Speed: An actuated valve can open or close in less than a second, far faster than any human operator.

- Consistency: Every cycle is identical. The actuator applies the exact same force and travels the exact same distance every time.

- Integration: You can connect actuated valves to a PLC or timer. This allows for fully automated, timed sampling sequences.

- Safety: Operators can be removed from potentially hazardous sampling points.

Key Factors for High-Cycle Performance

Not every valve is suited for high-frequency cycling. Key factors to consider include:

- Stem/Seat Wear Resistance: Hardened stainless steel or ceramic coatings extend life.

- Robust Stem Seal: The packing or diaphragm must withstand constant movement without leaking.

- Lubrication: Some valves require periodic lubrication of the stem thread, which is not ideal for high-purity applications. Packless designs avoid this issue.

Comparison of Valve Operation Modes

| Operation Mode | Cycling Speed | Repeatability | Best For |

|---|---|---|---|

| Manual (Basic Valve) | Slow | Low to Medium (depends on operator) | Infrequent sampling, low-budget applications. |

| Manual (Precision Metering Valve) | Slow | High | Lab settings, precise manual flow control. |

| Pneumatically Actuated | Very Fast (≤1 sec) | Very High | Frequent, automated sampling in industrial plants. |

| Electrically Actuated | Fast | Very High | Automated systems without compressed air. |

For any application where sampling frequency or consistency is critical, specifying an actuated miniature valve is the most reliable approach. Ultimately, it transforms the valve from a simple shut-off device into a precise component of an automated analytical system.

Conclusion

A reliable mini sampling valve needs a leak-tight seal, low dead volume, clog-resistant design, and consistent cycling. For valves that meet these demands, explore the IFAN range of precision sampling valves.

Commentaires récents