I once visited a commercial building where the constant rattling of pipes in the walls was a major complaint. The solution, as we proved, was not replacing the pipes but securing them correctly with the right clips.

Yes, PVC pipe clips can effectively prevent vibration and noise when selected and installed correctly. They dampen vibrations from water flow and pumps, prevent pipes from knocking against surfaces, and reduce the transmission of sound through the structure, making them a key component for a quiet plumbing system.

Many people focus on the pipes themselves, but the supports are just as important. Let’s look at how the right PVC clips solve common noise problems.

How Effective Are PVC Pipe Clips at Reducing Plumbing Vibration and Noise?

Loud bangs and humming pipes are frustrating. Clients often think it’s a pipe defect, but usually, it’s a support issue.

PVC pipe clips are very effective at reducing plumbing noise because the PVC material naturally absorbs and dampens sound vibrations. They hold the pipe snugly to prevent movement that causes knocking, and their design stops vibrations from traveling into the building’s structure, which is where noise amplifies.

The Source of Plumbing Noise

To understand how clips work, we first need to know where the noise comes from. There are two main types:

- Vibration Noise: This is a humming or buzzing sound. It comes from the sudden start/stop of water (water hammer) or from pumps and appliances. The vibration travels along the pipe.

- Impact Noise: This is a banging or rattling sound. It happens when a loose pipe swings and hits a stud, joist, or wall.

If a pipe is not held firmly, these vibrations and movements turn into audible noise. A rigid metal clip might stop the pipe from swinging, but it can actually transfer vibration into the wall, making the sound worse elsewhere.

How PVC Clips Work as a Solution

PVC clips are effective because they act as a dampener, not just a clamp. Here’s the process:

- Snug Fit: A well-designed PVC clip holds the pipe with a precise fit. This eliminates the space needed for the pipe to move and bang against surfaces.

- Material Absorption: PVC is a polymer that has inherent vibration-dampening properties. When vibration travels down the pipe, the PVC clip absorbs some of that energy, converting it into a tiny amount of heat instead of letting it pass into the building frame.

- Breaking the Sound Path: By isolating the pipe from the structural wood or concrete, the clip “breaks” the path that sound uses to travel and amplify. This is called acoustic isolation.

Real-World Effectiveness Scenario

Consider a high-rise apartment building. Water pumps start frequently, sending pressure surges (water hammer) through the pipes. With poor metal supports, the whole wall on each floor might hum. By switching to properly spaced PVC clips, the vibration is contained within the pipe and absorbed at each clip. The result is a dramatic reduction in transmitted noise between apartments.

| Noise Type | Cause | How PVC Clips Help |

|---|---|---|

| Water Hammer Bang | Sudden valve closure sending shockwave. | Absorbs shock, prevents pipe from jerking and hitting the wall. |

| Vibration Hum | Pump or appliance operation. | Dampens the vibrational energy along the pipe’s length. |

| Rattling | Loose pipe in a large hole or bracket. | Provides a snug, full-circumference grip to eliminate movement. |

In short, their effectiveness comes from a combination of precise fit and the material’s natural sound-dampening quality.

What Design Features Make PVC Clips Good for Noise Prevention in Pipes?

Not all PVC clips are the same. From our audits, we see that design details make a huge difference in performance.

The best PVC clips for noise prevention have a full circular grip, integrated rubber or EPDM lining, wide mounting bases, and are made from high-density, UV-stabilized PVC. These features work together to grip the pipe tightly, add an extra layer of vibration absorption, and ensure a secure, long-lasting hold.

Critical Design Elements for Quiet Operation

When selecting clips for noise control, you must look at these specific features:

1. The Grip Design:

The simplest clip is a “J” or saddle style that doesn’t fully surround the pipe. For noise control, a full-circle design or a clip with a locking top is mandatory. This ensures the pipe is held evenly on all sides, preventing any point of contact where knocking can occur.

2. The Lining Material:

This is often the most important feature. High-quality clips have a soft rubber or EPDM lining bonded to the inside of the PVC.

- Function: This lining creates a cushion between the hard pipe and the hard clip. It is the primary layer that absorbs vibration.

- Benefit: It allows for a tight hold without over-compressing plastic pipes (which can creak) and accommodates slight thermal expansion/contraction without squeaking.

3. The Clip Material & Build:

- High-Density PVC: The PVC itself must be high-quality to avoid becoming brittle and cracking, which would create new rattles.

- UV Stabilization: For clips in exposed areas, UV stabilization prevents degradation from sunlight, maintaining their grip and damping properties for years.

- Wide Mounting Base: A broad base with multiple screw holes distributes force and prevents the clip from loosening or twisting over time, which would compromise its hold.

Comparison of Clip Designs

The table below shows why design choices matter for the final result.

| Clip Design Feature | Benefit for Noise Reduction | Potential Problem if Missing |

|---|---|---|

| Full Circle with Lock | Even pressure, no pipe movement. | Pipe can lift out or vibrate within a “J” saddle. |

| Integrated Rubber Lining | Excellent vibration isolation and damping. | Hard PVC-on-PVC contact can transmit sound and cause creaking. |

| Wide, Reinforced Base | Prevents clip loosening from structural vibration. | Clip can become loose, becoming a noise source itself. |

| Correct Inner Diameter | Snug fit for specific pipe size (e.g., 20mm, 25mm). | A clip too large allows movement; too small stresses the pipe. |

4. Specialized Types:

For extreme noise sensitivity, look for:

- Double-Socket Clips: These hold two pipes separately, preventing them from touching and creating transfer noise.

- Cushioned Hanger Straps: For larger pipes, a PVC-coated metal strap with a thick rubber cushion offers superior support and isolation.

The right design turns a simple piece of plastic into a precise acoustic tool.

How Do You Install PVC Pipe Clips Correctly to Maximize Vibration Control?

Even the best clip will fail if installed poorly. We’ve fixed many noisy systems just by re-installing clips the right way.

To install PVC pipe clips correctly, you must follow three rules: use the right spacing, secure them to a solid substrate, and ensure the pipe is centered and snug but not over-tightened. Correct spacing prevents pipe sag and swing, which are major causes of vibration and impact noise.

The Golden Rules of Installation

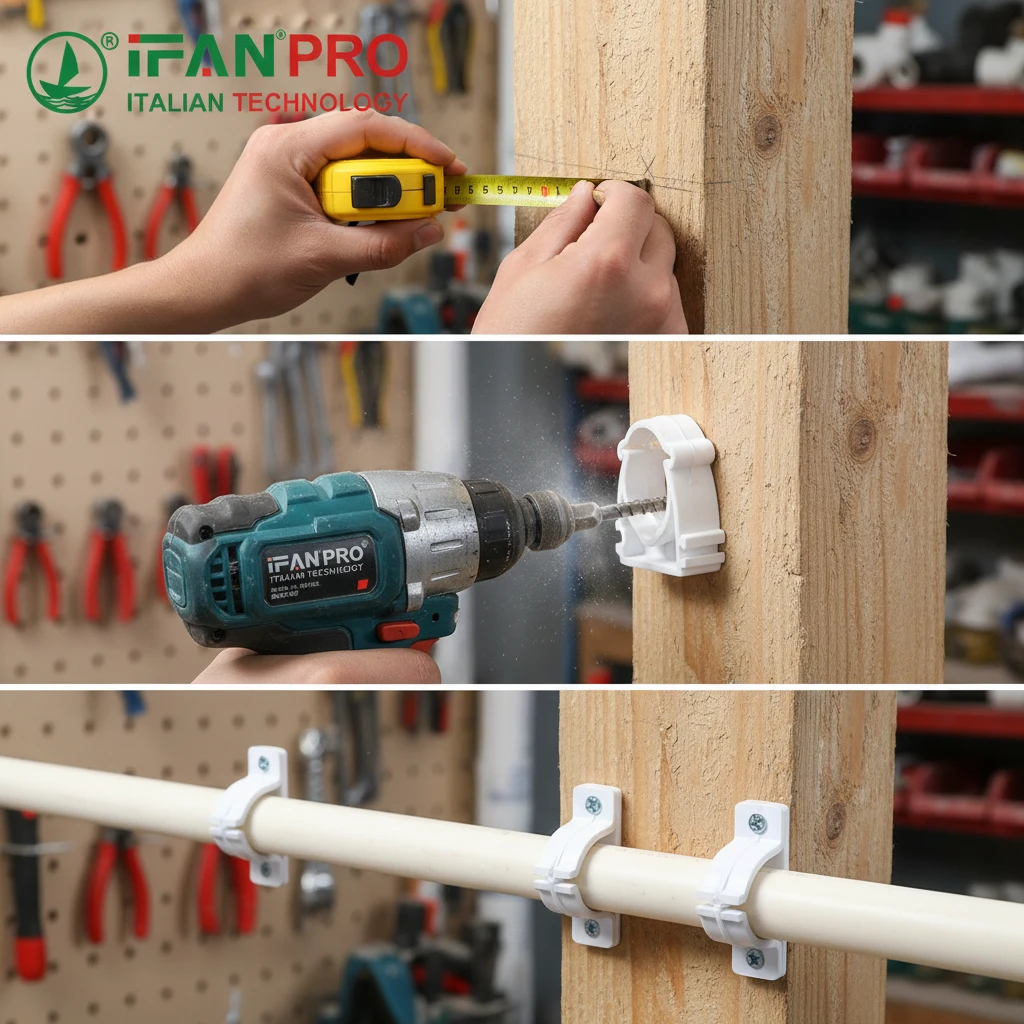

A perfect installation is methodical. Here is a step-by-step guide based on best practices:

Step 1: Planning and Spacing

This is the most commonly ignored step. Clips must be close enough together to support the pipe’s weight and prevent it from sagging or bending between supports.

- Horizontal Pipes: Space clips every 0.5 to 1 meter, depending on the pipe material and diameter. Heavier pipes (like water-filled iron) need closer spacing.

- Vertical Pipes: Space clips at every floor level or at intervals of 1.5 to 2 meters.

- Key Points: Always place a clip within 15cm of any joint, valve, or fitting. These are points of stress and potential movement.

Step 2: Mounting Surface Preparation

The clip must be fixed to something absolutely solid.

- Do Not: Attach directly to drywall, plaster, or thin paneling. The clip and pipe will vibrate the entire sheet.

- Do: Anchor directly into wooden studs, joists, concrete, or solid masonry. Use the correct screw or anchor for the material.

Step 3: Fitting the Pipe

- Insert the Pipe: Place the pipe into the lower part of the clip. For full-circle clips, you may need to snap the top half on.

- Tightening: If the clip has a screw or locking mechanism, tighten it until the pipe is held firmly. Do not overtighten. You should not be deforming the pipe. The goal is to eliminate movement, not to crush the pipe. If the clip has a rubber lining, stop when you feel consistent resistance.

Common Installation Mistakes and Fixes

Many noise problems arise from simple errors. Here is a table of common mistakes we find during site audits.

| Installation Mistake | Resulting Problem | How to Fix It |

|---|---|---|

| Clips spaced too far apart | Pipe sags and vibrates like a guitar string between points. | Add more clips at the correct spacing. |

| Clip attached to weak surface | Whole mounting surface vibrates, amplifying noise. | Relocate clip to a stud or use a backing plate to bridge to solid structure. |

| Pipe pinched or over-tightened | Stress on pipe, potential creaking, and flow restriction. | Loosen clip and re-tighten snugly without force. |

| Using wrong clip size | Pipe is loose (rattles) or strained (cracks). | Remove and replace with the correct nominal size clip. |

| Forgetting clips near fixtures | Water hammer causes pipe to jump at the unsecured end. | Install a clip within 15cm of the valve or tap. |

Final Check: After installation, gently try to move the pipe up, down, and side-to-side at each clip. There should be no movement. Also, tap the pipe lightly near the clip; you should hear a dull thud, not a hollow rattle. Following these steps ensures the clips perform their vibration control job as intended.

How Do PVC Clips Compare to Metal or Rubber Clips for Noise Reduction?

Choosing the right material is crucial. Each type has its place, but for overall noise control, PVC often offers the best balance.

PVC clips generally provide better noise reduction than basic metal clips and are more durable and cost-effective than all-rubber clips. They combine the rigidity needed for support with inherent damping properties, whereas metal transmits vibration and rubber can degrade over time.

Material Showdown: Pros and Cons

To make the right choice, you need to compare the core materials directly.

1. Metal Clips (Galvanized Steel, Stainless Steel)

- Pros: Extremely strong, durable, fire-resistant, good for high-temperature or heavy industrial pipes.

- Cons for Noise: They are excellent conductors of vibration and sound. A metal clip will firmly hold a vibrating pipe but will efficiently transfer that vibration into the wall, often making noise worse. They can also creak as metals expand/contract at different rates.

2. Rubber Clips (All-Rubber or Neoprene)

- Pros: Superior vibration isolation. They are the best at absorbing high-frequency vibrations and preventing sound transmission.

- Cons: They lack inherent rigidity. Over time, rubber can harden, crack, or sag under constant load, especially in UV light. They often require a metal backing for support, adding cost and complexity.

3. PVC Clips (Often with Rubber Lining)

- Pros: This is the hybrid solution. The PVC body provides rigid support and durability, resisting corrosion and UV light. The integrated rubber lining provides excellent vibration damping. They are lightweight, easy to install, and cost-effective.

- Cons: Not suitable for extremely high-temperature applications (e.g., steam lines). The plastic can become brittle in extreme, sustained cold.

Decision Guide: Which Clip to Use Where?

The best choice depends on your specific priority: pure strength, pure noise isolation, or the best balance.

| Application / Priority | Recommended Clip Type | Key Reason |

|---|---|---|

| Residential Plumbing (Noise-Sensitive) | PVC Clip with Rubber Lining | Best balance of damping, support, cost, and ease of installation. |

| Industrial, High-Temp, or Heavy Pipes | Metal Clip | Strength and heat resistance are the top priorities. |

| Extreme Vibration Isolation (e.g., Data Center AC) | Isolated Rubber Hanger | Maximum damping is critical; cost is secondary. |

| Outdoor or UV-Exposed Pipes | UV-Stabilized PVC Clip | Resists environmental degradation better than rubber. |

| Fire Protection Sprinkler Lines | Listed Metal Clips | Building codes often require metal for fire integrity. |

The Verdict from Experience

In most residential and commercial building projects, where controlling cost, ensuring longevity, and minimizing noise are all important, PVC clips with a soft lining are the most practical and effective choice. They solve the core problem of metal (noise transmission) and the core weakness of rubber (lack of support and durability). For the IFAN team, specifying the right clip material is part of our project management service, ensuring the entire system performs as quietly as intended.

Conclusion

Properly chosen and installed PVC pipe clips are a highly effective solution for preventing plumbing vibration and noise. For durable, well-designed clips that ensure a quiet system, ask about the IFAN PVC pipe clip and support series for your next project.

Commentaires récents