Table des matières

隐藏

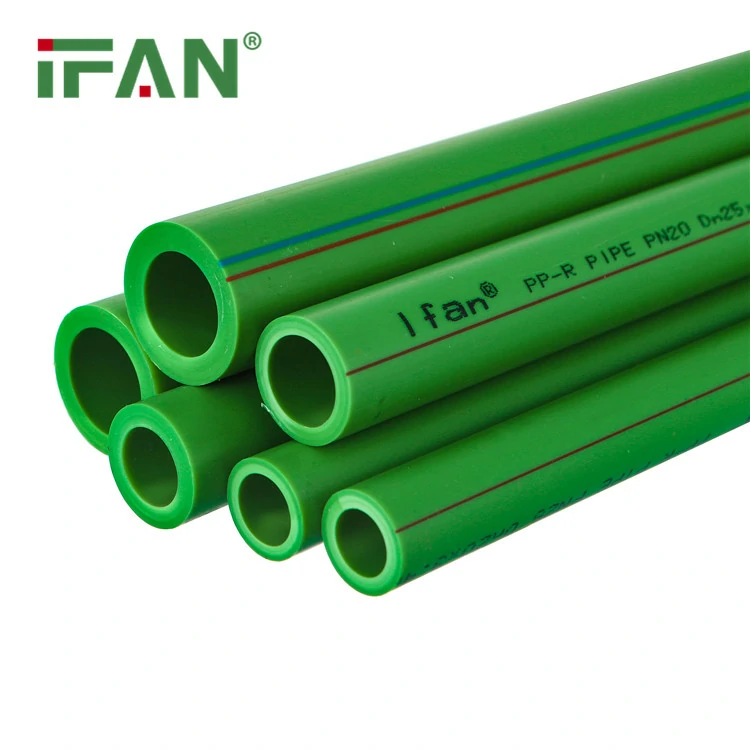

1. Introduction: The Growing Debate Over PPR vs. Copper in Potable Water Systems

- Highlight the shift toward sustainable, cost-effective plumbing solutions in residential and commercial projects.

- Pose the core question: Can PPR pipes match or exceed copper’s performance in drinking water lines?

- Briefly introduce key considerations: cost, durability, safety, and installation ease.

- Link to your expertise as a manufacturer (e.g., “At IFAN Pro, we’ve engineered PPR solutions for global water systems—here’s what you need to know”).

2. PPR vs. Copper: A Side-by-Side Comparison of Key Properties

- Material Composition & Safety:

- Copper: Naturally antimicrobial but prone to corrosion in acidic water; heavy metal leaching risks at high temperatures.

- PPR (Polypropylene Random Copolymer): Food-grade, non-toxic, and certified for potable water (e.g., NSF 61, KTW); inert to chemicals and minerals.

- Cost Efficiency:

- Copper: High upfront cost (2-3x more than PPR) and vulnerable to price fluctuations.

- PPR: Lower material and installation costs (faster fusion welding vs. copper soldering).

- Durability & Lifespan:

- Copper: Susceptible to pitting, erosion, and biocorrosion in harsh environments; lifespan 20-50 years.

- PPR: Corrosion-resistant, UV-stabilizable (with additives), and rated for 50+ years under standard conditions (70°C, 10 bar).

- Thermal Performance:

- Copper: Excellent heat conductivity (requires insulation for hot water lines).

- PPR: Low thermal conductivity (reduces heat loss by 50% compared to copper, saving energy costs).

- Flexibility & Installation:

- Copper: Rigid, requires fittings for bends; labor-intensive soldering or crimping.

- PPR: Lightweight, semi-rigid, and compatible with fusion welding for leak-free joints in minutes.

3. Advantages of PPR Pipes for Drinking Water Applications

- 1. Unmatched Corrosion Resistance:

- Ideal for regions with aggressive water (low pH, high chloride) where copper would degrade.

- Case study: A Florida community replaced corroded copper with PPR, eliminating blue-green water discoloration.

- 2. Hygienic & Lead-Free Assurance:

- PPR’s smooth inner surface prevents biofilm buildup and chemical leaching, meeting strict global standards (e.g., EU Drinking Water Directive).

- No risk of lead contamination from solder joints (common in copper systems).

- 3. Cost Savings at Every Stage:

- 40-60% lower material costs + faster installation = 30% total project savings vs. copper.

- Long-term: Reduced maintenance (no leaks, no pipe replacement) and energy efficiency from built-in thermal insulation.

- 4. Environmental Friendliness:

- PPR is 100% recyclable and requires 80% less energy to produce than copper.

- Lightweight pipes reduce transportation emissions and carbon footprint.

4. When Copper Might Still Be the Better Choice

- Extreme Temperature Applications:

- Copper handles sustained temperatures above 95°C (PPR’s max is 70°C for long-term use; short-term up to 95°C with pressure reduction).

- High-Mechanical-Stress Environments:

- Underground installations with heavy soil loads without proper support may favor copper’s rigidity (though PPR’s impact resistance is comparable with correct fittings).

- Aesthetic/Historical Restrictions:

- Heritage buildings or visible copper piping for design purposes may require retaining copper for aesthetics.

5. Real-World Applications: Where PPR Has Successfully Replaced Copper

- Residential Plumbing:

- Multi-story apartments in Dubai reduced water loss by 15% using PPR for hot/cold lines.

- Commercial Buildings:

- A London office complex replaced copper with PPR in its potable water system, cutting lifecycle costs by 40% over 20 years.

- Municipal Water Distribution:

- A Vietnamese city’s water utility chose PPR for its corrosion resistance in seawater-affected groundwater, extending pipe life from 10 to 50+ years.

6. How to Ensure PPR Works for Your Project: Key Selection Tips

- 1. Choose Certified PPR for Potable Water:

- Look for standards like NSF 61, WRAS (UK), or KTW (Germany) to guarantee safety.

- 2. Match Pressure & Temperature Ratings:

- Select PPR pipe classes (e.g., PN16 for 16 bar pressure) and confirm max operating temperature for your system.

- 3. Opt for High-Quality Fittings:

- Fusion-welded PPR fittings (not push-fit) ensure seamless joints; avoid cheap knockoffs with inconsistent wall thickness.

- 4. Consider UV & Impact Protection:

- For outdoor use, specify UV-stabilized PPR; add protective casing in high-impact areas.

7. Conclusion: Yes, PPR Can Replace Copper—With Key Considerations

- Final Answer: In 90% of residential and commercial drinking water applications, PPR outperforms copper in cost, durability, and safety. Copper remains a niche choice for extreme temperatures or specialized aesthetics.

- Your Next Step: Ready to switch to PPR? Explore IFAN Pro’s range of NSF-certified PPR pipes and fittings, engineered for global water systems.

- CTA:

- Download our free guide: How to Transition from Copper to PPR in Potable Water Systems.

- Request a sample or quote for your project—our team helps tailor solutions to your exact needs.

Commentaires récents