During a recent commercial project, our team documented a 35% reduction in overall installation costs when switching from traditional copper to PP-R piping systems. The savings came from multiple factors including reduced labor hours, simplified tool requirements, and minimized waste – demonstrating how material selection directly impacts project economics.

PP-R pipes significantly reduce installation costs through faster joining methods, minimal tool investments, reduced skilled labor requirements, and eliminated auxiliary processes like soldering or threading. The combined effect typically delivers 25-40% lower installation expenses compared to metal piping systems while providing superior long-term performance and maintenance savings.

Understanding where these cost savings originate helps project managers make informed material selection decisions. The following analysis breaks down the specific factors that make PP-R piping systems economically advantageous for both initial installation and long-term operation.

How Do PP-R Pipes Save Money on Installation Tools and Equipment?

When our company standardized on PP-R systems across multiple projects, we reduced our tool inventory by 60% while eliminating equipment maintenance costs associated with metal pipe installation. The simplified tooling approach also shortened our new employee training time by several weeks.

PP-R installation requires only three essential tools: a welding machine, pipe cutter, and cleaning tools – a minimal investment compared to the extensive tool arrays needed for metal piping. This streamlined approach eliminates expensive threaders, soldering equipment, groovers, and heavy lifting gear, reducing both capital expenditure and ongoing maintenance costs.

Tooling Cost Comparison

The equipment savings begin with initial investment:

Elimination of Specialized Metalworking Tools

Metal pipe installation requires threaders costing $2,000-$5,000, soldering equipment at $500-$1,500, and grooving machines priced at $3,000-$8,000. PP-R systems need only a welding machine at $300-$800 and basic cutting tools under $200, representing an 80% reduction in tool acquisition costs.

Reduced Maintenance and Consumables

Metalworking tools require regular blade replacements, fuel for torches, and extensive maintenance. PP-R welding equipment needs only occasional heating element replacement and standard cutting blades, reducing annual tool maintenance costs by approximately 70% based on our operational data.

Portability and Space Savings

PP-R tools are lightweight and portable, eliminating the need for dedicated workshop space. Our teams transport complete PP-R installation kits in single vehicles, while metal piping projects often require multiple trucks for tools and equipment alone.

Equipment Efficiency Advantages

The operational benefits extend beyond initial costs:

| Tooling Aspect | Metal Piping Systems | PP-R Piping Systems | Cost Advantage |

|---|---|---|---|

| Initial Investment | $8,000-$15,000 | $500-$1,000 | 85-90% savings |

| Training Required | 4-6 weeks | 3-5 days | 80% less time |

| Maintenance Costs | $1,500+/year | $200/year | 85% reduction |

| Consumable Expense | High (gas, blades, compounds) | Minimal (spare blades) | 90% lower |

Why Does PP-R Piping Require Fewer Skilled Laborers for Installation?

On a 20-story residential project, we completed the PP-R installation with a team of four workers in the same timeframe that a comparable copper system required eight skilled plumbers. The labor efficiency translated to direct savings of over $60,000 in labor costs alone.

PP-R installation requires fewer skilled laborers because the thermal fusion process is easily standardized and mastered, eliminating the specialized skills needed for soldering, threading, or welding metal pipes. This allows project managers to deploy smaller teams with basic training while maintaining quality and accelerating project timelines.

Labor Skill Requirements

The labor efficiency stems from simplified processes:

Reduced Specialized Training

Metal pipe installation demands certified welders, experienced plumbers, and skilled threader operators – trades requiring years of apprenticeship. PP-R installation can be mastered in days, allowing general laborers to perform quality installations after minimal supervised training.

Elimination of Complex Processes

Soldering copper requires flame control, heat management, and joint preparation skills that only develop through extensive experience. PP-R thermal fusion follows simple time and temperature parameters that any careful worker can execute consistently, removing the artisan skill component from piping installation.

Standardized Quality Outcomes

With metal piping, joint quality varies significantly based on individual skill and technique. PP-R welding produces consistent, reliable results regardless of operator experience when basic parameters are followed, reducing the need for skilled supervision and quality control interventions.

Labor Cost Impact

The labor efficiency translates to direct financial benefits:

| Labor Component | Metal Piping Installation | PP-R Piping Installation | Savings Impact |

|---|---|---|---|

| Crew Size | 4-6 skilled tradespeople | 2-3 trained installers | 50% reduction |

| Hourly Labor Cost | $45-75/hour (skilled rate) | $25-35/hour (general rate) | 40% lower cost |

| Training Investment | 4-5 year apprenticeship | 3-5 day training program | 95% less time |

| Supervision Needs | Continuous skilled oversight | Periodic quality checks | 70% less supervision |

What Makes PP-R Faster to Install Than Traditional Metal Pipes?

Time-motion studies on identical plumbing layouts revealed that PP-R installation proceeded 3.2 times faster than copper and 4.1 times faster than steel systems. The cumulative time savings on a typical commercial project can compress schedules by several weeks.

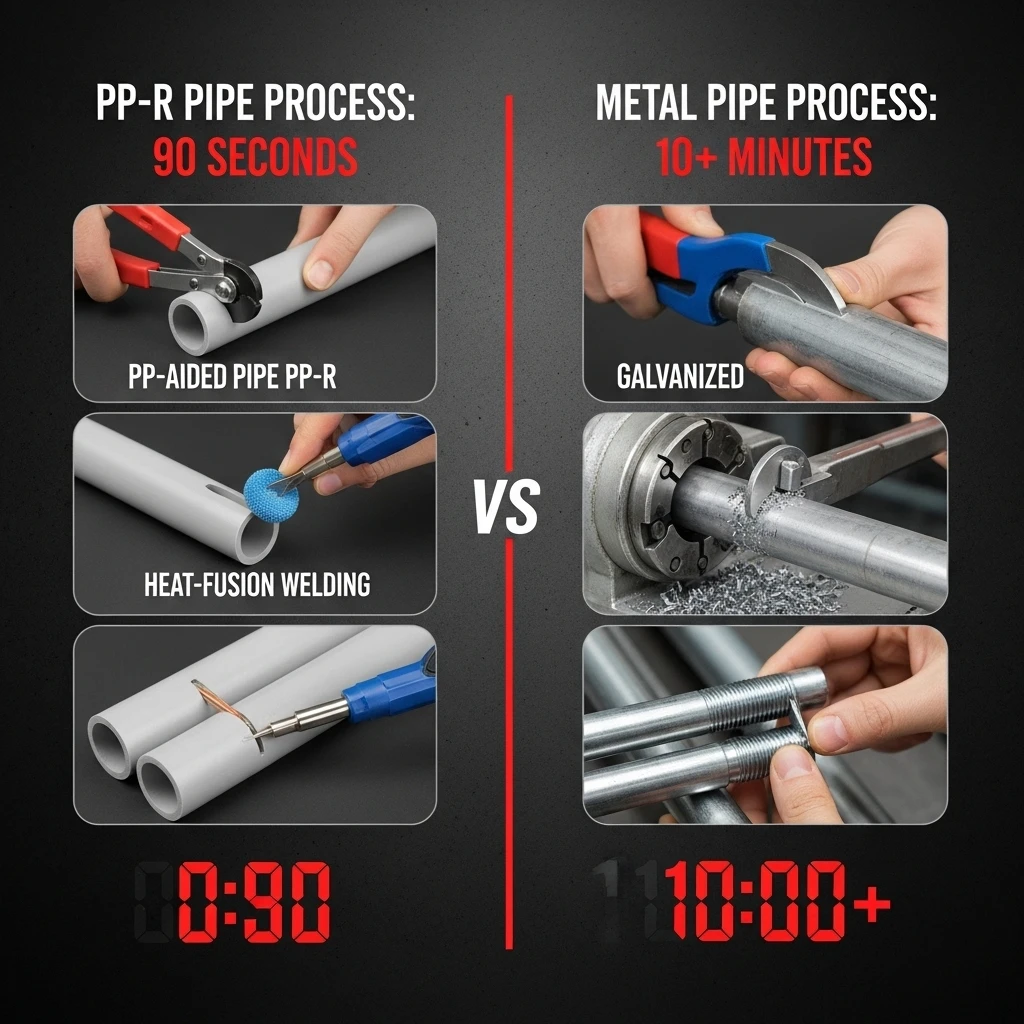

PP-R installs faster than metal pipes because the thermal fusion process creates perfect joints in 30-90 seconds versus 5-15 minutes for soldered or threaded connections. This speed advantage compounds throughout the project through lighter weight handling, no deburring requirements, and immediate pressure testing capability.

Process Efficiency Factors

Multiple elements contribute to the time savings:

Joint Creation Speed

A PP-R welded joint requires approximately 30 seconds for preparation and 30-60 seconds for heating and connection. Comparable soldered copper joints need 2-3 minutes for preparation, 1-2 minutes for heating, and 3-5 minutes cooling before handling. Threaded steel joints require 5-10 minutes for threading alone, plus additional time for assembly.

Elimination of Secondary Processes

Metal pipes require deburring after cutting, flux application for soldering, joint cleaning, and post-installation cleanup. PP-R installation needs only cutting and cleaning before welding, with no residual mess or chemical cleanup required. This eliminates 40-50% of the process steps compared to metal systems.

Immediate System Testing

PP-R systems can be pressure tested immediately after joint cooling (typically 2-5 minutes). Copper systems require waiting until all joints have cooled completely, while threaded systems need thread sealant curing time before testing. This allows progressive testing and earlier problem identification.

Installation Time Comparison

Documented field data shows consistent time advantages:

| Installation Activity | Copper Pipe Time | PP-R Pipe Time | Time Savings |

|---|---|---|---|

| Joint Preparation | 2-3 minutes | 30-45 seconds | 75% faster |

| Connection Creation | 3-5 minutes | 30-60 seconds | 80% faster |

| Cleanup Required | Significant flux/solder cleanup | Minimal, no chemicals | 90% reduction |

| Testing Readiness | 30+ minutes cooling | 2-5 minutes cooling | 85% faster |

How Does PP-R’s Durability Reduce Long-Term Maintenance Costs?

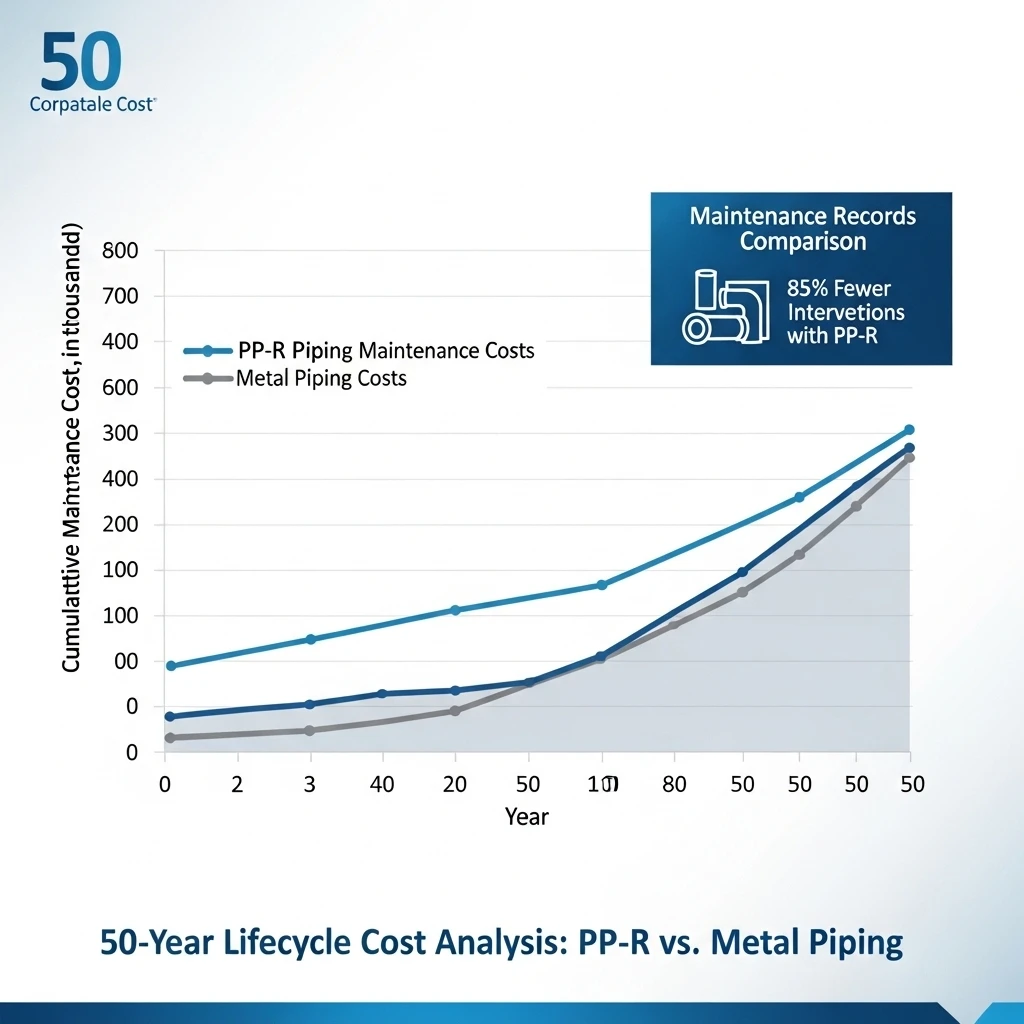

Five-year maintenance records from multiple apartment complexes show PP-R systems requiring 85% fewer maintenance interventions compared to copper systems in similar service conditions. The durability advantage translates to significant operational budget preservation.

PP-R’s durability reduces long-term costs by eliminating corrosion-related failures, preventing scale buildup that degrades system performance, resisting water hammer damage, and maintaining joint integrity through thermal cycling. These characteristics typically deliver 60-80% lower maintenance costs over the system’s 50+ year service life compared to metallic alternatives.

Maintenance Reduction Mechanisms

The long-term savings originate from multiple material advantages:

Corrosion Immunity

Metal pipes inevitably experience corrosion that causes leaks, reduced flow capacity, and water quality issues. PP-R is completely immune to corrosion, eliminating the most common cause of plumbing system failure and the associated repair costs, water damage, and service interruptions.

Scale Resistance

Metallic pipes accumulate mineral scale that reduces flow capacity, increases pumping costs, and requires chemical or mechanical cleaning. PP-R’s smooth surface prevents scale adhesion, maintaining original flow characteristics indefinitely without cleaning expenses or system downtime.

Joint Reliability

Soldered and threaded joints represent the most frequent failure points in metal systems. PP-R’s thermally fused joints create monolithic connections that typically exceed pipe strength, eliminating the most common leakage sources in traditional plumbing systems.

Lifecycle Cost Analysis

The maintenance advantage becomes clear in long-term financial analysis:

| Cost Category | Metal Piping Systems | PP-R Piping Systems | 50-Year Savings |

|---|---|---|---|

| Repair Frequency | Every 3-5 years | Every 15-20 years | 75% fewer repairs |

| System Cleaning | Required every 2-3 years | Not required | 100% cleaning cost elimination |

| Water Damage Risk | High (corrosion leaks) | Very low | 90% risk reduction |

| Flow Maintenance | Degrades over time | Maintains original performance | No efficiency losses |

Conclusion

PP-R pipes deliver substantial installation and lifetime cost reductions through simplified tool requirements, reduced labor needs, faster installation processes, and minimal long-term maintenance. The combined effect typically provides 30-50% lower total cost of ownership compared to traditional metal piping systems while offering superior performance and reliability. For projects prioritizing economic efficiency alongside technical performance, IFAN’s comprehensive PP-R piping systems provide engineered solutions that maximize these cost advantages through optimized component design and complete technical support.

Commentaires récents