In my years at IFAN, I’ve seen too many projects stall because of one small detail: mismatched threads. A fitting that seemed perfect would arrive, only to fail to screw onto the existing pipes, causing delays and frustration.

Yes, high-quality brass cross fittings are commonly available in major global threading standards like NPT, BSPP, and BSPT. The key is to work with a supplier who explicitly offers this choice and understands the critical differences between these standards to prevent costly assembly failures in your fluid systems.

Navigating thread standards can be confusing, but it’s essential for a leak-free system. Let’s break down exactly what you need to know and ask for.

Can You Find Brass Cross Fittings with NPT, BSPP, or BSPT Threads?

A client once ordered “standard” fittings from a generic supplier, assuming they would fit. They didn’t. The resulting leak caused a shutdown.

Absolutely. Reputable manufacturers and suppliers like IFAN stock and produce brass cross fittings in NPT (American), BSPP (British Parallel), and BSPT (British Tapered) threads. Availability in a specific standard and size depends on the supplier’s focus and inventory, so always confirm before ordering.

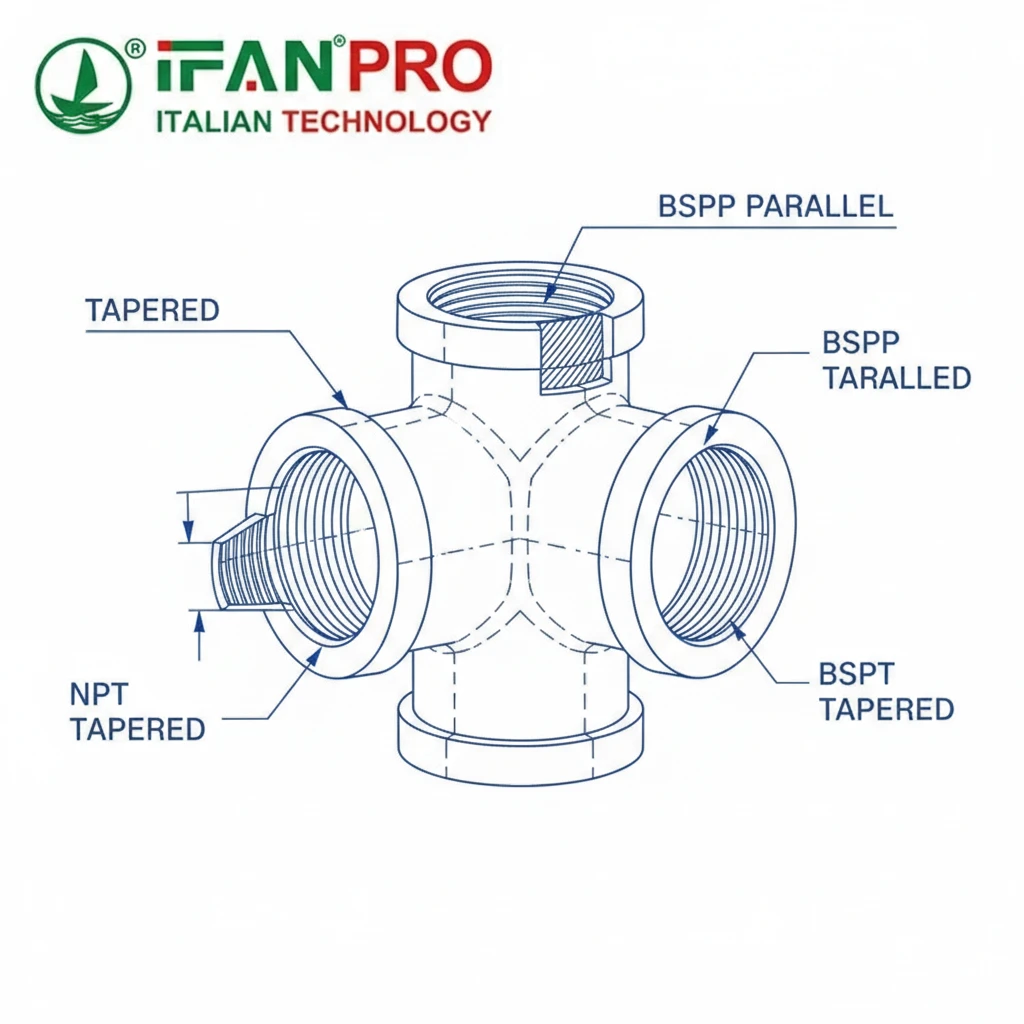

Understanding the Three Major Thread Standards

The short answer is yes, you can find them. But the real question is: which one do you need, and how do you make sure you get the right one? Let’s look at what each standard means.

First, NPT (National Pipe Taper). This is the most common standard in the United States, Canada, and some regions of South America. The key feature is that the threads themselves are tapered, both on the male and female parts. As you screw them together, the threads wedge tightly, forming a seal through metal-to-metal contact. You almost always need to use a sealant tape or compound with NPT threads to ensure a leak-proof seal.

Second, BSPP (British Standard Pipe Parallel), also known as G-type threads. This is the dominant standard in Europe, Asia, Australia, and much of the world outside the Americas. The threads are parallel (straight), not tapered. The seal is not made by the threads jamming together. Instead, it is made by compressing a washer or an O-ring against a flat shoulder at the base of the female thread. This is a critical difference.

Third, BSPT (British Standard Pipe Tapered). This standard is also used internationally, though less commonly than BSPP. As the name suggests, the threads are tapered, similar to NPT. However, the thread angle and pitch (the distance between threads) are different from NPT. NPT and BSPT fittings are not compatible. Forcing them together will damage the threads and will not create a proper seal.

A Quick Comparison Guide

This table shows the core differences at a glance:

| Thread Standard | Region of Use | Thread Form | Sealing Method | Key Compatibility Note |

|---|---|---|---|---|

| NPT | Americas | Tapered | Thread engagement + Sealant (e.g., Teflon tape) | Do not mix with BSPT. |

| BSPP (G) | Europe, Asia, Int’l | Parallel | Washer/O-ring on a shoulder | Parallel threads require a sealing washer. |

| BSPT (R) | International | Tapered | Thread engagement + Sealant | Do not mix with NPT. |

When sourcing brass cross fittings, your supplier must know these differences. A professional supplier will ask you for your thread standard. If they don’t ask, it’s a major red flag. At IFAN, we inventory crosses in all these standards because we serve global markets from Russia to the Middle East to the Americas, and we know that assuming one standard fits all is a recipe for project failure.

How Do You Specify the Required Thread Standard When Ordering?

Clear communication is the only way to avoid mistakes. I ask clients to provide a simple, standardized specification.

To specify the thread standard, you must state it clearly in your purchase order or drawing. Use the full acronym (e.g., BSPP, NPT) and include the port size for each leg of the cross. Providing a sample, a drawing, or even a clear photo of the thread can prevent costly misunderstandings with your supplier.

Creating a Clear and Unmistakable Order

Specifying your thread requirement isn’t complicated, but it must be precise. Vague terms like “standard thread” or “metric thread” are useless and will lead to errors. Here is a step-by-step guide on how to communicate your needs effectively.

Step 1: Use the Correct Naming Convention. Always use the official acronym. Don’t say “British thread”; say BSPP or BSPT. Don’t say “American thread”; say NPT. This removes the first layer of ambiguity.

Step 2: Specify Size for Every Port. A cross has four ports. You must specify the size and thread standard for each one. A common way to note this is in the product description. For example:

- “Brass Cross, 1/2″ NPT all ports.”

- “Brass Cross, 1″ BSPP x 1″ BSPP x 3/4″ BSPP x 3/4″ BSPP.” (This describes two different port sizes).

- “Brass Cross, 3/4″ BSPT (F) x 1/2″ BSPT (M) x 1/2″ NPT (F) x 3/8″ NPT (M).” (This mixes standards and port types, which must be very clearly detailed).

Step 3: Provide Visual or Physical Aids. If you are ever unsure, or if the project is critical, send more information.

- A Technical Drawing: This is the best option. A simple sketch with each port labeled with size and standard (e.g., “Port A: 3/4″-14 NPT”) is invaluable.

- A Photo with Calipers: Take a clear photo of a sample fitting or the pipe you need to connect to. Place a digital caliper showing the thread’s major diameter (the outer diameter of the male thread) in the photo.

- Send a Sample: If you have an old fitting that works, you can mail it to your supplier. They can then match the thread exactly. This is common practice for complex or legacy projects.

Essential Information for Your Purchase Order

Your PO line item should look structured, not like a sentence. Here is a good format:

| Item | Description | Qty |

|---|---|---|

| 1 | Brass Pipe Cross, Inch | 50 |

| – Thread Standard: NPT | ||

| – Port 1 & 2: 1/2″ Female | ||

| – Port 3 & 4: 3/8″ Female | ||

| – Material: CW617N Brass | ||

| – Seal Type: Requires thread sealant |

By providing information in this clear, tabular, and unambiguous way, you give your supplier no room for error. A good supplier will review this with you and confirm the details. This step of double-checking specifications is a core part of the service IFAN provides to prevent exactly these kinds of sourcing errors.

Are Reducing Crosses Available with Different Port Sizes and Threads?

A recent project needed a cross to connect two different pipe lines and a gauge. Only a reducing cross with mixed threads could solve it.

Yes, reducing crosses with different port sizes and threads are available. They are called “reducing crosses” or “unequal crosses.” You can find them with combinations of different port sizes, and it is also possible to have different thread standards on different ports, though this is a custom manufacturing service offered by specialized suppliers.

The Utility of Reducing and Combination Crosses

A standard cross has four ports of the same size. A reducing cross has at least one port that is a different size. This is essential for system design where you need to branch off a main line to a smaller secondary line, or combine flows from lines of different diameters into one common header.

The availability depends on the complexity. Common reducing combinations are often kept in stock by larger suppliers. For example, a 1″ x 1″ x 3/4″ x 3/4″ cross (where two opposite ports are one size and the other two are a smaller size) is a standard item. More complex mixes, like a 1″ x 3/4″ x 1/2″ x 1/2″ cross, are less common and may need to be custom-made.

Taking it Further: Mixing Thread Standards

The most complex, yet highly valuable, type is the cross with different thread standards on its ports. This is a true hybrid fitting. Imagine a system where you have:

- A main supply line from an American-made pump with NPT threads.

- Branch lines to European-made equipment with BSPP threads.

- A connection for an Asian-made pressure sensor with BSPT threads.

Instead of using multiple adapters (which add cost, potential leak points, and bulk), you can have a single custom brass cross manufactured with the exact thread standards on each port. This simplifies assembly, improves reliability, and creates a cleaner, more professional installation.

Process for Sourcing Custom Reducing Crosses

If you need a reducing cross with mixed threads, follow this process:

- Create a Detailed Diagram: Draw the cross. Label each port (A, B, C, D). For each port, specify the required thread standard (NPT, BSPP, BSPT), the size (e.g., 1/2″, 3/4″), and the gender (Male or Female).

- Request a Quotation: Send this diagram to potential suppliers. Ask specifically if they offer custom threading services.

- Ask About Lead Time and MOQ: Custom fittings are not off-the-shelf items. They will have a longer lead time for production and often a Minimum Order Quantity (MOQ). A supplier like IFAN, with strong factory partnerships, can efficiently manage this custom manufacturing process.

- Request a Sample: For a large project, it is wise to pay for a single prototype sample to verify all threads and dimensions before ordering the full batch.

This capability to provide custom, problem-solving fittings is what separates a basic parts seller from a true supply chain partner. It turns a sourcing challenge into a system advantage.

What Should You Check to Ensure Thread Compatibility in an International Project?

We managed a project for a plant in the Middle East with equipment from the US, Germany, and Japan. Thread compatibility was the first item on our checklist.

To ensure thread compatibility, you must first audit all connection points in the system to document the exact thread standard, size, and gender. Then, standardize your Bill of Materials (BOM) using this data and source all fittings from a single, knowledgeable supplier who can provide consistent, correctly specified parts and verify compatibility before shipment.

Conducting a Pre-Procurement Thread Audit

An international project is a minefield of potential thread mismatches. Rushing to order fittings without a plan is the biggest mistake you can make. Here is a practical checklist to follow.

Step 1: Audit Every Connection. Before you order a single fitting, you need a complete map. This means checking every piece of equipment, every valve, and every pipe end. Create a spreadsheet. For each connection point, record:

- Equipment/Item Name: (e.g., “Pump A outlet”, “Tank B drain valve”)

- Thread Standard: (Verify NPT, BSPP, or BSPT. Use a thread gauge if necessary).

- Size: (Measure the major diameter with calipers).

- Gender: (Male or Female).

- Photos/Drawing Reference: (A visual record is crucial).

Step 2: Standardize Your BOM. With the audit complete, you will see the mix of standards you have to deal with. Now, decide on the fitting strategy. Will you use adapters to convert everything to one primary standard? Or will you order custom fittings with mixed threads, as discussed earlier? List every fitting you need (elbows, tees, crosses, couplings) in your Bill of Materials, using the clear specification method from the previous section.

Partnering with the Right Supplier

Your choice of supplier is critical. You need more than a catalog; you need a consultant.

- Choose a Supplier with Global Knowledge: They must understand NPT, BSPP, and BSPT intimately. They should ask you clarifying questions about your application.

- Leverage Their Inspection Service: A good supplier will offer quality control that includes verifying threads. At IFAN, part of our pre-shipment inspection involves checking thread standards with master gauges (Go/No-Go gauges). We can provide a report confirming that the threads are to the specified standard.

- Order a Compatibility Sample Kit: Before mass production, ask the supplier to make a small batch of sample fittings (or even a single set of your most complex crosses). You can use these to test-fit them on your actual equipment during a factory acceptance test (FAT) or site visit. This final physical check eliminates all remaining risk.

International Project Thread Compatibility Checklist

Use this table as a guide to manage the process:

| Phase | Action Item | Responsible Party | Verification Method |

|---|---|---|---|

| Design | Document all equipment thread specs from vendor manuals. | Project Engineer | Review equipment datasheets. |

| Audit | Physically measure and record threads on received equipment. | Site Engineer | Use thread pitch gauges and calipers. |

| Sourcing | Issue a unified BOM with full thread specs to supplier. | Procurement Manager | Supplier to acknowledge and confirm specs. |

| Quality | Request thread inspection report from supplier. | Quality Manager | Review Go/No-Go gauge results. |

| Testing | Conduct a fit-check with sample fittings before shipment. | Site Team | Physically screw samples onto equipment. |

By following this disciplined approach, you turn thread compatibility from a hidden risk into a managed, verified part of your project plan. It prevents last-minute scrambling for adapters, avoids damaging expensive equipment, and keeps your project on schedule.

Conclusion

Ensuring the correct thread standard—NPT, BSPP, or BSPT—is crucial for a leak-free system. For reliable brass crosses in any standard, contact IFAN for expert sourcing and guaranteed compatibility.

Commentaires récents