I once reviewed a mining site where misaligned pipe fittings caused constant slurry leaks and weekly shutdowns. The chaos made the answer to this question very clear to me.

Yes, custom HDPE elbows with integrated seats are highly cost-effective for mining. While their initial price is higher, they deliver massive savings by drastically reducing downtime, minimizing abrasive wear, and slashing installation labor. This makes them a smarter long-term investment compared to standard fittings for abrasive slurry applications.

If you’re managing a mining project, you know that every hour of downtime costs thousands. Let’s break down exactly how custom HDPE elbows save you money where it matters most.

How Does Reduced Downtime from Precise Alignment Lower Total Mining Project Costs?

Unexpected pipeline stops are a project manager’s worst nightmare. I’ve seen mines lose a full day’s production from a single failed fitting.

Precise alignment in custom elbows eliminates stress points and leaks, directly reducing unplanned downtime. This keeps slurry pumping continuously, protecting your revenue stream and avoiding the high costs of emergency repairs and production delays that cripple project budgets.

The True Cost of Misalignment

In mining, time is directly connected to money. A standard elbow might fit, but if it’s not perfectly aligned, it creates problems. Think of it like a bent straw – it creates weak spots. In a pipeline carrying abrasive sand, rocks, and water (slurry), these weak spots fail fast.

First, misalignment causes uneven wear. The slurry hits one side of the pipe much harder, wearing it out quickly and causing leaks. A leak means you must stop the whole system. Stopping the system means no material is being moved. No material movement means lost production. For a large mine, this can cost tens of thousands of dollars per hour.

Second, leaks create safety and environmental hazards. Spilled slurry can damage equipment and require expensive cleanup. This adds more cost and more downtime.

How Customization Solves This

A custom HDPE elbow is made to fit your exact pipeline layout. The manufacturer, like IFAN, uses your system’s drawings to create an elbow where the connection points (the seats) are at the perfect angle. This is called a “mitered elbow” or “custom fabricated elbow.”

When you weld this custom piece into your pipeline, everything lines up perfectly. There is no extra stress on the pipe. The slurry flows smoothly around the bend. This smooth flow reduces wear and tear dramatically. Because there is no weak spot, the chance of a sudden leak or blowout becomes very small.

Financial Impact: Downtime vs. Customization

Let’s compare the costs. The table below shows a simple scenario.

| Cost Item | System with Standard Fittings | System with Custom Elbows |

|---|---|---|

| Initial Fitting Cost | Lower | Higher |

| Estimated Unplanned Stops/Yr | 5-10 times | 1-2 times |

| Downtime Cost (@ $15,000/hr) | $75,000 – $150,000 | $15,000 – $30,000 |

| Emergency Repair & Cleanup | High | Very Low |

| Total Annual Risk Cost | Very High | Low |

As you can see, paying more upfront for a custom elbow buys you predictability. It protects you from the massive, unpredictable costs of downtime. This is the most direct way custom parts save money.

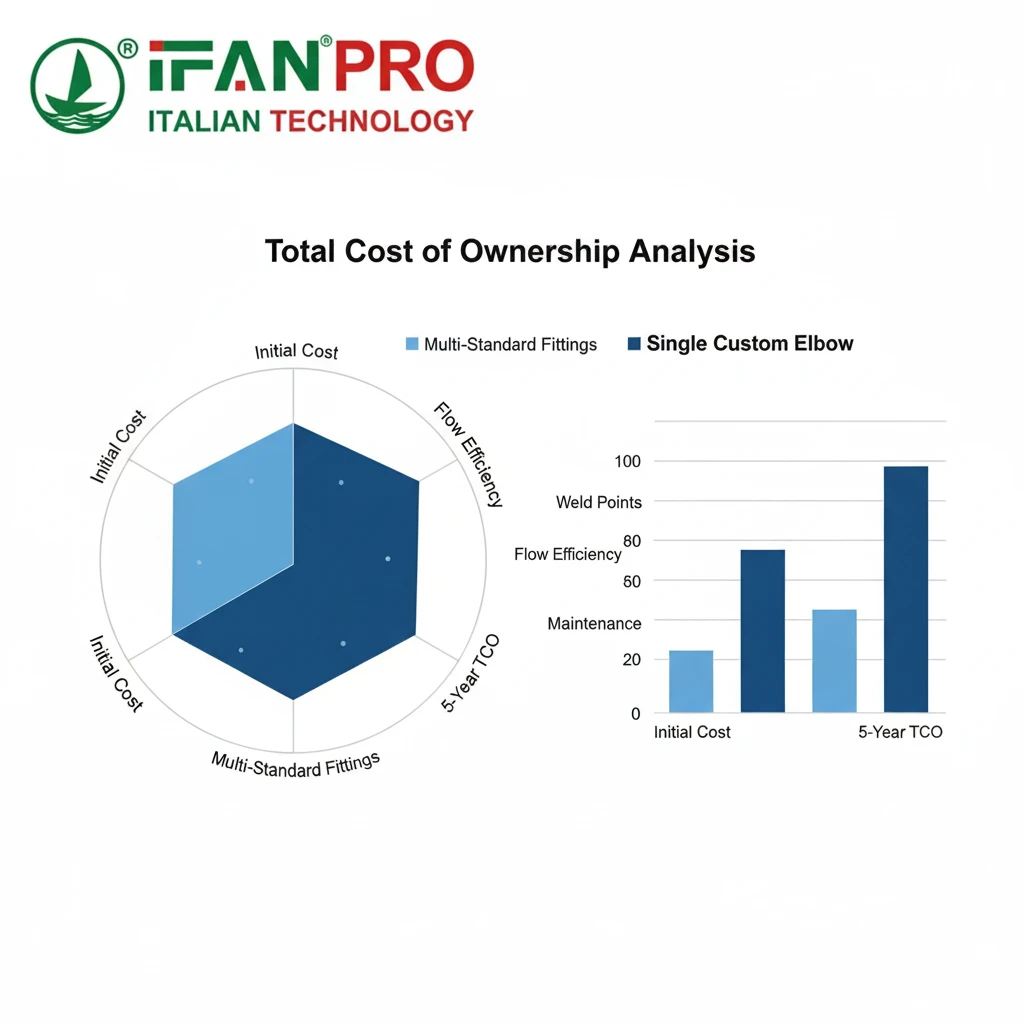

What is the Cost-Benefit Analysis of Custom Elbows Versus Multiple Standard Fittings?

Engineers sometimes try to build a custom angle using several standard pieces. This seems cheaper but creates a hidden trap.

Using multiple standard fittings to create an angle is a false economy. It introduces more leak points, increases friction and wear, and requires more supports and labor. A single, seamless custom elbow has fewer welds, better flow, and lower long-term maintenance costs, offering a superior return on investment despite a higher initial price.

The Problem with “Field Fabrication”

To avoid ordering a custom 45-degree elbow, a site might use two 22.5-degree standard elbows or a 90-degree elbow with a short pipe. This is called field fabrication. Let’s analyze why this is often a bad deal.

More Failure Points: Each connection between fittings is a welded joint. Every weld is a potential future leak. One custom elbow needs two welds (one at each end). A setup using two standard elbows needs three welds. More welds mean a higher statistical chance of failure.

Poor Hydraulics: Slurry flowing through multiple bends or a sharper bend experiences more turbulence and friction. This requires more pumping power (increasing energy costs) and accelerates wear on all the fittings involved. A single, smooth custom bend guides the slurry more efficiently.

Extra Materials and Labor: Multiple fittings need extra supports to hold them in place. They also take longer for the welder to measure, align, and weld. This increases both material and labor costs during installation.

Side-by-Side Cost Analysis

The real cost-benefit becomes clear over a 3-year period. Let’s assume we need a specific 60-degree bend in a 20-inch slurry line.

| Cost Factor | Solution A: Multiple Standard Fittings | Solution B: One Custom Elbow |

|---|---|---|

| Initial Parts Cost | $2,800 | $4,500 |

| Installation Labor & Supports | $1,500 | $800 |

| Total Initial Cost | $4,300 | $5,300 |

| Estimated Maintenance (3 yrs) | High (3+ welds to inspect/fix) | Low (2 welds) |

| Energy Cost (3 yrs – Turbulence) | Higher | Lower |

| Risk of Failure | Higher | Lower |

| Total 3-Year Projected Cost | $6,500+ | ~$5,800 |

The table shows that while the custom elbow costs $1,000 more on day one, it saves money within the project’s life. The savings come from lower energy use, almost zero maintenance, and no downtime from failures. The custom part pays for itself.

How Does Extended Service Life in Abrasive Flow Reduce Replacement Frequency and Cost?

Abrasive wear is the main reason mining pipes fail. Replacing pipe sections deep in a system is incredibly expensive and disruptive.

Custom HDPE elbows extend service life by allowing for optimized design with uniform wall thickness and smooth flow paths. This prevents localized wear “hot spots,” ensuring the entire fitting wears evenly. This can double or triple the time between replacements, directly cutting material and installation costs.

Understanding Abrasive Wear

Slurry is like liquid sandpaper. When it hits a pipe wall, especially at a bend, it slowly scrapes material away. In a standard elbow, the wear is not even. The slurry particles tend to concentrate and hit the same spot on the outer curve of the bend over and over. This creates a thin spot that fails long before the rest of the fitting is worn out.

When this happens, you must replace the entire elbow. To do this, you need to:

- Shut down the production line.

- Cut out the old elbow.

- Weld in a new one.

- Wait for the weld to cool.

- Restart the system.

This process is a major cost, not just for the new part, but for the lost production time.

The Custom Design Advantage

A custom-fabricated elbow can be designed to combat this. Here’s how:

Controlled Wall Thickness: Manufacturers can make the outer curve of the bend thicker than the rest. This is called “abrasion resistance design.” The extra material is placed exactly where the wear will be worst. This means the elbow wears down evenly over its entire surface, maximizing the use of all the material you paid for.

Optimized Geometry: The bend radius can be customized. A longer, gentler radius bend (where possible) reduces the force with which slurry impacts the wall, further slowing down wear.

Superior Material Consistency: Reputable manufacturers use premium, high-density HDPE resin with consistent properties throughout the fitting. This ensures uniform wear resistance, unlike some standard fittings which might have weak spots.

Replacement Cycle Comparison

Longer service life means fewer replacements. Fewer replacements mean lower long-term costs.

| Scenario | Standard Elbow | Custom-Designed HDPE Elbow |

|---|---|---|

| Typical Replacement Interval | 12-18 months | 36-60 months |

| Replacement Cost (Part + Labor + Downtime) | $10,000 per event | $10,000 per event |

| Cost over 5 Years | $30,000 – $40,000 (3 replacements) | $10,000 (1 replacement) |

The math is simple. By tripling the service life, the custom elbow saves you the cost of two full replacement cycles over five years. This saving alone is usually much greater than the initial price difference.

Can Custom Elbows Lower Installation Labor Costs Through Easier and Faster Alignment?

Labor is a huge part of any installation budget. Watching crews struggle for hours to force misaligned pipes together is a waste of money.

Yes, custom elbows significantly lower installation labor costs. Their precise, pre-fabricated design allows for “fit-and-weld” installation. This eliminates hours of manual measuring, cutting, and forcing pipes into alignment, reducing skilled labor time by up to 50% on complex bends and ensuring a right-first-time result.

The Traditional Installation Struggle

Installing a network of standard fittings to make a non-standard angle is a puzzle. The crew must:

- Take precise measurements in the field.

- Calculate cuts and angles.

- Cut pipes to length.

- Use clamps, jacks, and force to pull pipe ends into alignment with the fittings.

- Hold everything in place while welding.

Steps 4 and 5 are time-consuming and physically demanding. Misalignment during welding can lead to weak joints that fail later, causing rework.

The Custom Elbow Installation Process

With a custom elbow, the hard work is done in the factory. The part arrives with the exact angle and connection points your design requires.

The installation becomes simple:

- Fit: Place the custom elbow between the two pipe ends. It should fit snugly with minimal gap.

- Align: Minor adjustments are needed because the part is made to fit.

- Weld: Proceed with the standard butt-fusion or electrofusion welding process.

This “fit-and-weld” approach is faster, easier, and less stressful for the installation team. It reduces the risk of human error.

Labor Time and Cost Savings

The time saved translates directly into lower costs. Consider a complex 30-degree lateral connection in a tight space.

| Task | Standard Fitting Method | Custom Elbow Method |

|---|---|---|

| Measurement & Layout | 2-3 hours | 30 minutes (verification only) |

| Cutting & Preparation | 2 hours | 1 hour |

| Alignment & Fit-Up | 4-5 hours (difficult) | 1-2 hours (simple) |

| Welding & Cooling | 3 hours | 3 hours |

| Total Estimated Labor | 11-13 hours | 5.5 – 6.5 hours |

| Labor Cost (@ $100/hr) | $1,100 – $1,300 | $550 – $650 |

As shown, the custom elbow can cut the labor for that single joint almost in half. Across an entire project with dozens of custom bends, the savings in labor costs can easily surpass the entire additional cost of the custom parts themselves.

Conclusion

Custom HDPE elbows are a strategic investment that reduces total mining project costs through less downtime, longer life, and easier installation. For reliable, precision-engineered custom HDPE fittings, partner with IFAN for your most demanding slurry applications.

Commentaires récents