We faced this exact question from an installer last year. They had a composite pipe project and needed a valve that worked without soldering or threading. The answer shaped our recommendation.

Yes, the IFAN 121UC valve is specifically designed for press or crimp connection methods, not for threaded or solvent-weld joints. It supports industry-standard systems for PEX-Al-PEX composite pipes, creating a reliable, mechanical seal by compressing a dedicated sleeve or ring around the pipe and onto the valve’s integral fittings.

This compatibility makes installation fast and reliable. However, using it correctly requires understanding the specific systems and tools involved. Let’s dive into the details to ensure a perfect connection every time.

Which Specific Press or Crimp Connection Systems Does the 121UC Valve Support?

Choosing the wrong system leads to leaks and frustration. We learned this by testing valves across different manufacturer protocols.

The 121UC valve supports standardized press connection systems that use a stainless steel sleeve, such as those compatible with Viega ProPress, IBP Pressfit, or similar generic press fittings for multilayer composite pipes. For crimp connections, it is designed for systems that use a copper or brass crimp ring, similar to those used for standard PEX-A or PEX-B piping but sized for the composite pipe’s outer diameter.

Understanding Press vs. Crimp Systems

First, it’s important to know the difference between “press” and “crimp,” as the tools and parts are not interchangeable.

Press Connection Systems: These use a stainless steel press sleeve and a powered pressing tool. The tool has wide jaws that deform the sleeve uniformly around the pipe and the valve’s fitting. This method is very fast and consistent.

- Common Brand Examples: Viega ProPress, IBP Pressfit, Geberit Mapress.

- Key Point: The 121UC valve’s fittings have grooves and dimensions that match the inner profile of these standard press sleeves. When the sleeve is pressed, it locks mechanically into these grooves.

Crimp Connection Systems: These use a copper or brass crimp ring and a hand-held or powered crimping tool. The ring is placed over the pipe, and the tool squeezes it to create the seal.

- Common Standard: PEX crimp ring standards, but adapted for the larger outer diameter of composite pipe.

- Key Point: The 121UC valve works with this method because its fitting has a raised shoulder or barb. The crimp ring compresses the pipe material tightly against this shoulder.

Compatibility Table for Installers

The table below helps clarify which components work with the 121UC valve.

| Connection Method | Required Ring/Sleeve | Required Tool Type | Notes for 121UC Valve |

|---|---|---|---|

| Press (e.g., ProPress) | Standard Stainless Steel Press Sleeve for composite pipe. | Electric or Battery-Powered Press Jaws (e.g., Jaw “B” or “V”). | Most common method. Ensure sleeve size matches the valve’s port size (e.g., 1/2″, 3/4″). |

| Crimp (PEX-style) | Extra-Wide Copper Crimp Ring for composite pipe OD. | Manual Crimping Tool or Cinch Tool. | Double-check ring size is for composite, not regular PEX. A go/no-go gauge is essential. |

Practical Advice: Always confirm with your supplier. Tell them, “I need press sleeves/crimp rings for PEX-Al-PEX composite pipe to connect to a 121UC valve.” Do not use components meant for copper pipe or plain PEX pipe, as the dimensions are different.

Does It Require a Dedicated Pressing Jaw Profile for the Composite Pipe?

Using the wrong jaw can crush the pipe or make a weak connection. We have seen failed installations because of this simple oversight.

Yes, you must use pressing jaws specifically designed for multilayer composite (PEX-Al-PEX) pipes. Jaws made for copper, stainless steel, or plain PEX have a different shape and closing profile. Using the wrong jaws will not apply the correct, even pressure and can damage the aluminum layer, leading to a guaranteed leak.

Why the Jaw Profile is Critical

The pressing tool’s jaws are not universal. Their shape is engineered to deform the stainless steel sleeve perfectly around a specific type of pipe and fitting combination.

A jaw for copper pipe is designed to crush a sleeve onto a hard, unyielding copper tube. If you use it on a composite pipe, the excessive force can distort the internal aluminum layer, potentially cracking it or causing it to separate from the PEX layers. This creates a weak point.

Conversely, a jaw for composite pipe applies the ideal force. It compresses the sleeve enough to:

- Tightly grip the outer PEX layer.

- Press the pipe’s inner lining firmly into the sealing grooves on the 121UC valve’s fitting.

- Create a uniform seal without deforming the internal structure of the pipe.

How to Identify the Correct Jaws

This is simpler than it sounds. Major tool manufacturers like Ridgid, Viega, and Rems make specific jaw sets for composite pipes. They are often clearly labeled:

- “For Multilayer Pipe”

- “For PEX-Al-PEX”

- “Type ML” or “Jaw C”

Actionable Steps:

- Check your tool manual. Look for the jaw chart.

- Look at the jaw itself. It often has a stamped code (like “ML”).

- Ask your supplier. When you buy the 121UC valves, confirm the correct jaw profile for your brand of pipe and press tool.

Do not guess. An incorrect press is a permanent failure; you must cut out the section and start over, wasting the valve and pipe.

How Does the Connection Ensure a Seal with Both PEX and Aluminum Layers?

The genius of this valve lies in how it handles the pipe’s complex structure. A seal that only grips the plastic can fail over time.

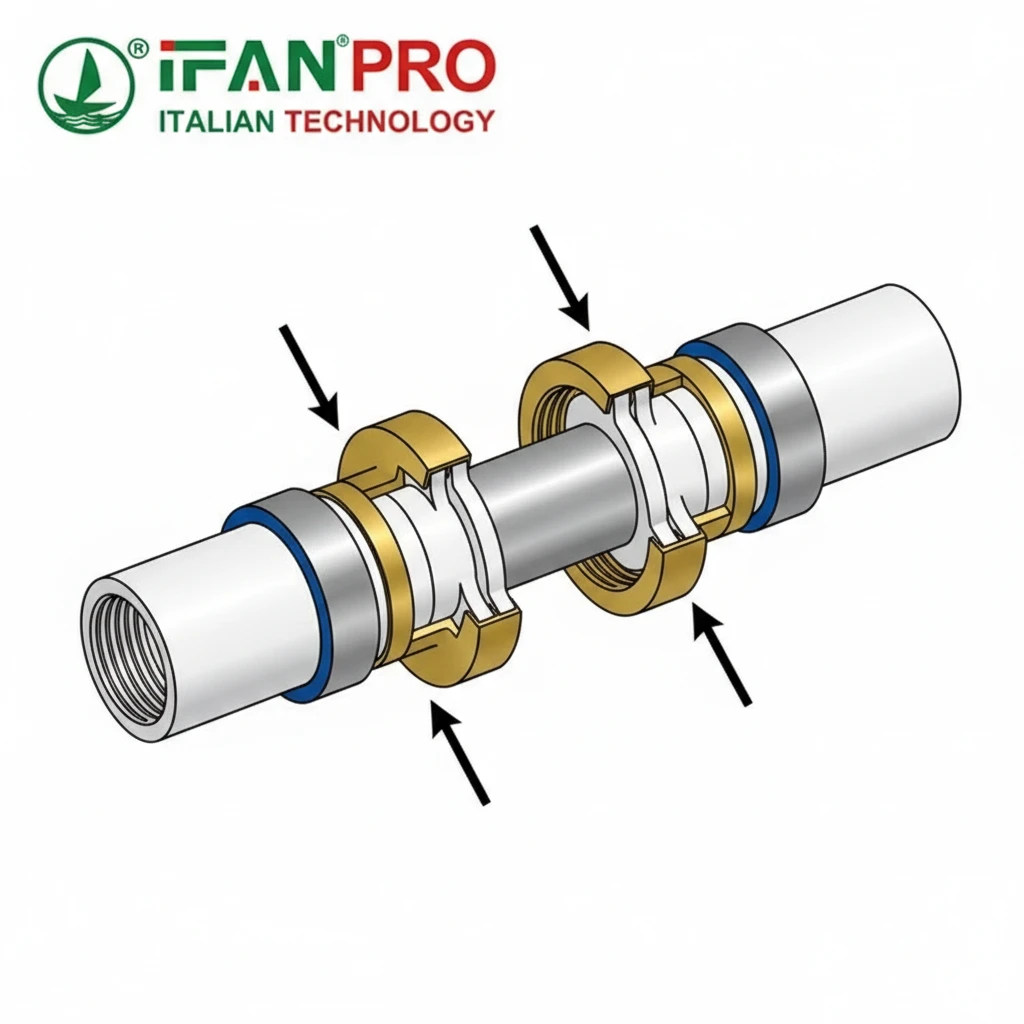

The connection ensures a seal by mechanically locking all pipe layers at once. The pressed or crimped ring compresses the outer PEX layer inward. This forces the pipe’s internal PEX lining to flow into the precise sealing grooves on the valve’s brass fitting, while the trapped aluminum layer provides rigid structural support, preventing the joint from relaxing or leaking.

A Closer Look at the Sealing Action

Let’s break down what happens during a successful press or crimp connection with the 121UC valve.

Step 1: Positioning. You slide the correct press sleeve or crimp ring over the clean, cut end of the composite pipe. Then, you insert the pipe fully into the valve’s fitting until it hits the internal stop.

Step 2: Compression. When you activate the tool, the jaws apply tremendous, even force to the ring/sleeve. This force has two simultaneous effects:

- On the Outer Layer: The stainless steel sleeve bites into the outer PEX, creating a strong mechanical grip that holds the pipe in place.

- On the Inner Layer: The immense pressure squeezes the entire pipe wall. The soft, inner PEX material is forced to cold-flow (like putty) into the specially machined grooves or barbs on the valve’s fitting. This creates multiple sealing points.

Step 3: The Role of the Aluminum Layer. The aluminum layer in the middle is the unsung hero. It is rigid. It does not compress like the PEX. Instead, it acts as a backbone. It transfers the compression force evenly and prevents the PEX layers from creeping or deforming over time, which could loosen the seal. The aluminum ensures the grip is permanent.

Visualizing the Sealing Zones

Think of the sealed connection as having two distinct jobs:

| Sealing Zone | How it Works | Why it’s Important |

|---|---|---|

| Mechanical Grip Zone | The outer sleeve crimps onto the outer PEX layer. | This provides the brute strength to hold the pipe onto the valve against pulling forces. |

| Watertight Seal Zone | The inner PEX is compressed into grooves on the valve fitting. | This creates the actual barrier that stops water from leaking out. The multiple grooves provide backup sealing lines. |

The 121UC valve’s fitting is designed so that the sealing grooves are positioned perfectly to align with the pipe’s inner liner when the pipe is fully inserted. This design, combined with the correct installation, ensures a leak-proof system that handles both hot and cold water pressure.

Can the Same Valve Be Used with Multiple Connection Methods Interchangeably?

This is a common point of confusion. Installers want flexibility, but physics has limits.

No, the same 121UC valve cannot be used interchangeably between press and crimp methods. You must decide on one connection method (press or crimp) before installation and use the corresponding sleeves/rings and tools. A valve prepared for a press sleeve has a different fitting profile than one intended for a crimp ring, and trying to mix components will result in a failed, leaking connection.

Why Interchangeability is Not Possible

While the valve body is the same, the critical connection area is different. Manufacturers design the fitting’s profile to work optimally with one type of compression ring.

- For Press Systems: The fitting has deep, circular grooves. The stainless steel press sleeve is designed to be crushed into these grooves, creating a hard, metal-to-metal locking action.

- For Crimp Systems: The fitting typically has sharp, raised barbs. The softer copper crimp ring compresses the pipe over these barbs, which bite into the inner PEX layer.

If you put a crimp ring on a fitting designed for press, the ring will not seat correctly. The seal will be uneven and weak. Conversely, if you try to press a sleeve onto a barbed fitting, you may not achieve the proper compression, and the sleeve might not lock.

How to Avoid Costly Mistakes

This has real-world consequences. We once troubleshooted a leak where an installer tried to use a generic crimp ring on a valve designed for a press system. The leak was slow but persistent, causing damage before it was found.

Here is a clear guide to follow:

- Order the Correct Valve: Specify your connection method when ordering. Reputable suppliers like IFAN often list valves as “121UC for Press Fit” or “121UC for Crimp.”

- Use a Complete, Matched System: Use the sleeves/rings and tools from the same manufacturer’s ecosystem for your chosen method. Do not mix and match brands unless they are certified as compatible.

- Commit on Site: Before starting work on a job site, confirm all valves and connection parts are for the same method. A quick visual check can save hours of rework.

Conclusion

The 121UC valve is a reliable, time-saving solution for composite pipe systems when used with the correct press or crimp method. For a guaranteed match of valve, sleeve, and technical support, choose the IFAN 121UC valve system for your next project.

Commentaires récents