I once saw a plumber’s frustration trying to connect a new PEX line to an old copper system with a jumble of mismatched parts. That moment perfectly showed the problem a brass conversion fitting solves.

A brass conversion fitting connects different pipe types by having two distinct ends, each designed for a specific material. One end might have threads for metal pipes, while the other is smooth for soldering or has barbs for plastic tubing. A single fitting securely bridges the gap, creating a reliable, leak-free connection between incompatible systems.

This simple yet brilliant component is a toolbox essential. Let’s break down exactly how it works and why it’s so valuable.

How Do Integrated Ends Connect to Both Plastic and Metal Pipe Systems?

The core challenge is joining two different worlds: the rigid, threaded world of metal and the flexible, smooth world of plastic. A conversion fitting is the diplomat that speaks both languages.

The integrated ends of a brass conversion fitting connect to different systems by using material-specific connection methods on each side. The metal-compatible end typically uses male (MPT) or female (FPT) threaded connections, or a smooth cup for soldering. The plastic-compatible end uses push-to-connect sockets, compression rings, or barbed inserts, creating a perfect seal for each material type.

The Design Philosophy of Dual-Ended Fittings

A brass conversion fitting doesn’t try to be a universal connector. Instead, it is designed from the start as a hybrid. Each end is engineered with the optimal geometry and sealing mechanism for its target pipe material. Brass is the ideal material for this job because it is strong, corrosion-resistant, and easy to machine into precise shapes.

Connection Methods for Metal Pipes

On the metal-compatible side, you will typically find one of these common connection types:

- Threaded (NPT): This is the most common method. The fitting will have either external (male) or internal (female) tapered threads. You simply screw it onto the corresponding threaded iron, steel, or brass pipe. The threads deform slightly as they tighten, creating a metal-to-metal seal that is often reinforced with thread sealant tape or pipe dope.

- Solder (Sweat) Cup: For connecting to copper pipes without threads, one end of the fitting is a smooth, cup-shaped socket. The plumber cleans the copper pipe, applies flux, inserts it into the cup, and heats the joint with a torch while applying solder. The solder is drawn into the gap by capillary action, creating a permanent, monolithic metal bond.

Connection Methods for Plastic Pipes

On the plastic-compatible side, the methods are designed to grip and seal without damaging the softer pipe material:

- Push-to-Connect (John Guest style): This end has a collet with sharp teeth inside a release collar. You simply push the plastic pipe (like PEX or polyethylene) straight in. The teeth grip the pipe firmly to prevent pull-out, while an internal O-ring creates a watertight seal. To disconnect, you push the collar down to retract the teeth.

- Compression: This end has a threaded nut, a compression ring (ferrule), and a seat. You slide the nut and ring onto the plastic or soft copper tube, insert the tube into the fitting, and tighten the nut. This squeezes the ring against the tube and the fitting body, forming a tight seal.

- Barbed: This end has a series of ridged “barbs.” You push a flexible plastic or rubber tube (like vinyl or reinforced hose) over the barbs. The ridges prevent the tube from slipping off under pressure, and a hose clamp is usually added over the tube for extra security.

Choosing the Right End Combination

The table below shows common combinations found in a single brass conversion fitting:

| Metal Pipe End | Plastic Pipe End | Typical Use Case |

|---|---|---|

| Female Threads (FIPT) | Push-to-Connect | Connecting a threaded steel pipe to a PEX water line. |

| Male Threads (MIPT) | Compression | Connecting from a brass valve outlet to a soft copper or plastic tubing. |

| Solder Cup | Barbed Insert | Connecting a soldered copper line to a vinyl hose for an appliance. |

By combining these proven methods into one solid brass body, the fitting ensures a correct and reliable transition, eliminating guesswork and weak points.

What Types of Connections Does a Single Conversion Fitting Provide?

A single fitting can solve many common problems. Its value lies in its versatility, acting as a Swiss Army knife for plumbing connections.

A single brass conversion fitting provides a direct, one-piece transition between two specific connection standards. Common types include Threaded-to-PEX, Threaded-to-Compression, Solder-to-Threaded, and Push-Fit-to-Barbed connections. Each type is designed for a particular installation scenario involving different pipe materials or sizes.

The Range of Direct Transitions

Think of a conversion fitting as a dedicated translator for two specific languages. It is not a universal adapter but a precise tool. The “type” of connection it provides is defined by the combination on each end. This specialization is what makes it more reliable than a stack of separate adapters.

Here are the most prevalent types you will encounter:

- Thread-to-Tube (Push/Compression): This is a superstar for repairs and retrofits. One end has NPT threads (male or female) to connect to an existing galvanized, brass, or PVC-threaded port on a valve, tank, or older pipe. The other end is a push-to-connect or compression outlet, allowing you to run a new, flexible PEX or soft copper line directly from an old system.

- Solder-to-Thread: This fitting is crucial when adding a modern threaded fixture to a traditional copper plumbing system. You solder the cup end onto the copper line, and now you have a sturdy threaded port to attach a shower head, supply line, or valve.

- Thread-to-Thread (Adapter): While often just called an adapter, this is a conversion fitting when the thread standards differ. For example, it can connect a female iron pipe thread (FIPT) to a male garden hose thread (GHT), bridging household plumbing with outdoor hose bibs.

- Barbed-to-Thread: This type is common in appliances and low-pressure applications. The threaded end connects to a pump or metal fixture, while the barbed end accepts a flexible vinyl or rubber hose, secured with a clamp.

Addressing Specific Installation Scenarios

Each fitting type solves a specific puzzle. For example, if you are installing a new water heater with threaded inlets into a house with soldered copper lines, you need a “Male Thread x Solder Cup” fitting. You solder the copper pipe into the cup, and then screw the male threads into the heater’s tank.

Similarly, connecting a stainless steel kitchen sink faucet (which often has compression-style supply nuts) to rigid copper supply stops requires a “Compression x Solder Cup” fitting. The variety exists because there are many such specific scenarios in plumbing.

Key Advantages of Single-Piece Design

The fact that these two different connection methods are forged into a single, solid piece of brass is what provides the key benefits:

- Strength: The joint between the two different connection types is permanent and machined from one block, making it far stronger than two separate pieces screwed together.

- Leak Reduction: It eliminates one potential leak point that would exist if you used two separate adapters joined in the middle.

- Space Saving: A single, compact fitting fits into tight spaces where stacking multiple adapters would not.

Why Does It Create a Secure Bridge Between Incompatible Piping Materials?

Security is the top priority. A leak at a connection point can cause major damage. The conversion fitting’s design focuses on creating a trustworthy, permanent bridge.

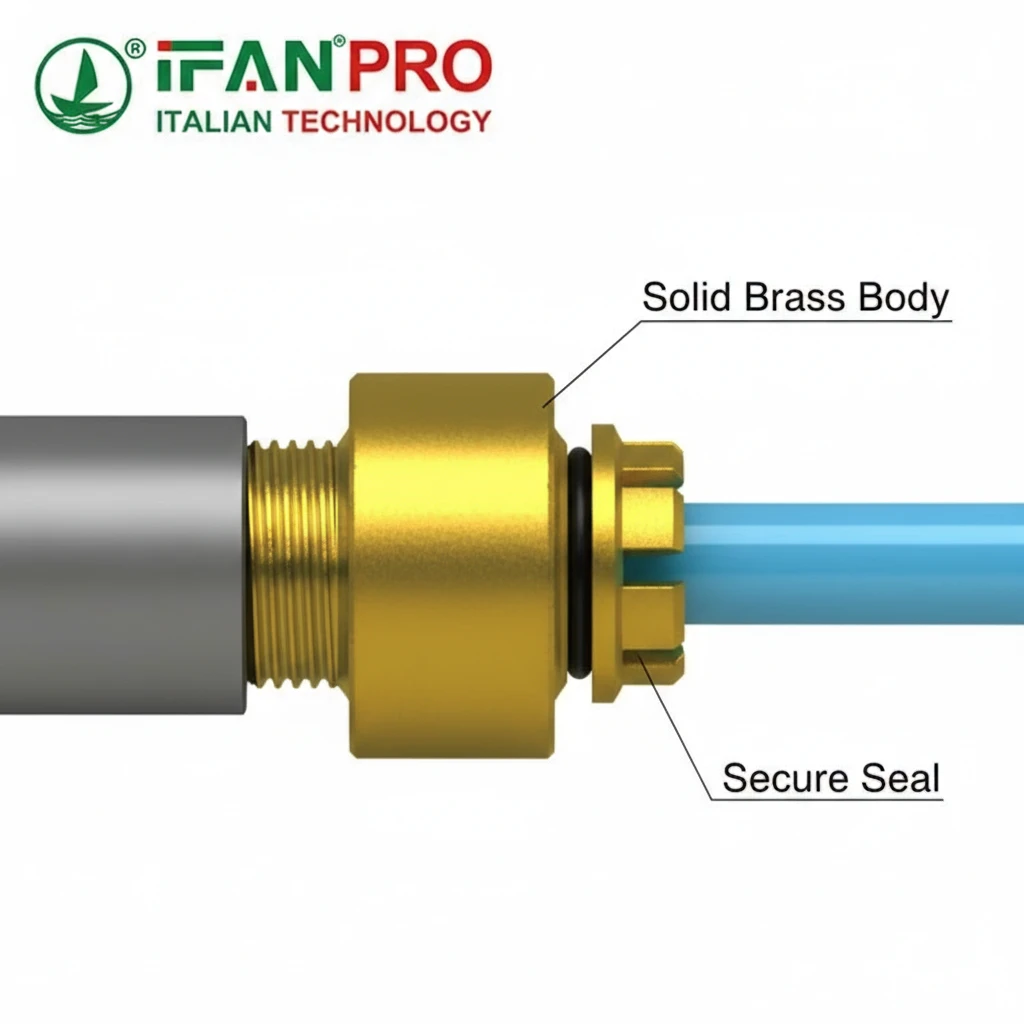

It creates a secure bridge because brass is a rigid, dimensionally stable material that can be precision-machined. This allows each end to maintain the exact tolerances required for its specific sealing method (threads, O-rings, compression). The solid body prevents flexing and stress, ensuring the seal on one side does not compromise the seal on the other.

The Problem of Material Incompatibility

Different pipe materials expand, contract, and react to pressure in different ways. For example, plastic pipes like PEX can expand slightly under pressure and are flexible. Metal pipes are rigid. If you try to connect them with an improper method, the different behaviors can loosen connections, crack seals, and cause leaks over time.

How Brass Provides the Solution

Brass is the perfect mediator for three main reasons:

- Rigidity and Strength: Brass is much stronger than the plastic pipes it connects to and is comparable in strength to many metals. This strength means the fitting will not warp, bend, or crack under normal water pressure or from the tightening force applied during installation. It provides a stable anchor point for both sides of the connection.

- Machinability and Precision: Brass can be machined to extremely precise tolerances. This precision is critical. The threads must be cut perfectly to seal with tape or dope. The inner diameter of a push-fit socket must be exact to allow the O-ring to seal correctly. A compression seat must be perfectly angled to compress the ferrule evenly. This precision, built into one piece, guarantees a proper seal on both ends.

- Corrosion Resistance: Brass resists corrosion from water and from contact with both dissimilar metals (like steel) and plastics. This prevents the fitting itself from degrading and becoming the weak link in the system.

Ensuring a Lasting Seal

The security comes from correctly transferring the sealing force. Let’s compare two ends:

- On the threaded metal end, the seal is created by the deformation of thread sealant and the metal-on-metal contact as the threads are tightened into the fitting body. The brass body is thick enough to withstand this torque without splitting.

- On the push-fit plastic end, the seal is created by an O-ring being compressed against the inner wall of the fitting’s socket. The brass socket does not deform, providing a constant, smooth surface for the O-ring to seal against for decades.

Because the fitting is one solid piece, the force applied to install the metal pipe does not distort the plastic-compatible socket, and vice-versa. Each sealing system works independently but is supported by the same robust foundation.

Comparison of Connection Security

| Connection Type | Primary Sealing Mechanism | How Brass Fitting Ensures Security |

|---|---|---|

| Threaded (Metal) | Deformation of thread sealant in tapered threads. | Provides strong, precise threads that won’t strip, with a thick wall to handle torque. |

| Push-Fit (Plastic) | Compression of an EPDM or Nitrile O-ring. | Machines a perfectly smooth, consistent inner bore for the O-ring to seal against. |

| Compression | Metal ferrule compressed onto the tube. | Provides a precisely angled seat that uniformly compresses the ferrule for a 360-degree seal. |

How Does This Design Eliminate the Need for Multiple Separate Adapters?

In plumbing, every extra joint is a potential future leak. The beauty of the conversion fitting is its elegant simplicity that reduces complexity.

The design eliminates multiple adapters by combining two different connection interfaces into a single, monolithic unit. Instead of needing a separate adapter for each transition (e.g., brass nipple + plastic adapter), one fitting does the job directly. This reduces potential leak points, saves installation space, and often lowers the total cost of parts and labor.

The “Adapter Stack” Problem

Before these dedicated conversion fittings were common, plumbers had to create their own solutions. To connect a threaded iron pipe to a PEX line, they might have used:

- A brass nipple screwed into the iron pipe.

- A threaded-to-barbed plastic adapter screwed onto the nipple.

- A hose clamp to secure the PEX to the barb.

This stack of parts creates several problems. First, it introduces three separate seal points that could leak: the iron-to-nipple threads, the nipple-to-adapter threads, and the barb-to-PEX clamp connection. Second, it takes up more physical space, which can be a critical issue in tight cabinets or walls. Third, it requires more labor time to assemble and tighten multiple components correctly.

The Efficiency of an Integrated Design

A single “Female Iron Pipe Thread x PEX Barb” brass fitting solves this in one step. It is installed directly: the threaded end screws onto the iron pipe, and the PEX tube is pushed onto the barb and clamped. This transformation is clear in the table below:

Comparison: Old Method vs. Modern Conversion Fitting

| Aspect | Using Multiple Separate Adapters | Using a Single Brass Conversion Fitting |

|---|---|---|

| Number of Parts | 3 or more (nipple, adapter, clamp). | 1 (the fitting) plus a clamp. |

| Potential Leak Points | 3 or more (each threaded joint, clamp connection). | 2 (the main threads, the clamp connection). |

| Installation Time | Longer; requires assembling and sealing multiple threaded joints. | Shorter; one threaded connection and one tube attachment. |

| Space Required | Greater, due to the length of the nipple and adapter. | Compact, as the transition happens within the fitting’s short body. |

| System Rigidity | Less rigid; multiple joints can wiggle or stress. | More rigid; a single solid piece provides a stable connection. |

| Cost Implication | Higher total cost for multiple parts and more labor time. | Lower total cost with one part and faster installation. |

Real-World Impact on Reliability and Cost

By eliminating the intermediate joints, you dramatically increase the system’s long-term reliability. Fewer threads mean fewer places for sealant to fail over years of thermal cycling and vibration. For the installer, it means carrying fewer individual SKUs in their truck inventory. For the homeowner or project manager, it results in a cleaner, more professional-looking installation that is easier to understand and maintain in the future.

In essence, the brass conversion fitting embodies the principle of “less is more.” Fewer parts, fewer leaks, less space, and less time—all adding up to a more secure and cost-effective solution.

Conclusion

Brass conversion fittings provide a simple, strong, and smart solution for connecting different plumbing materials. For a reliable selection of precision-machined brass conversion fittings, trust IFAN to bridge your piping needs.

Commentaires récents