I once saw a plumbing system fail because of a poorly soldered joint. That moment proved that a simple socket design is the true hero behind a reliable, leak-free brass connection.

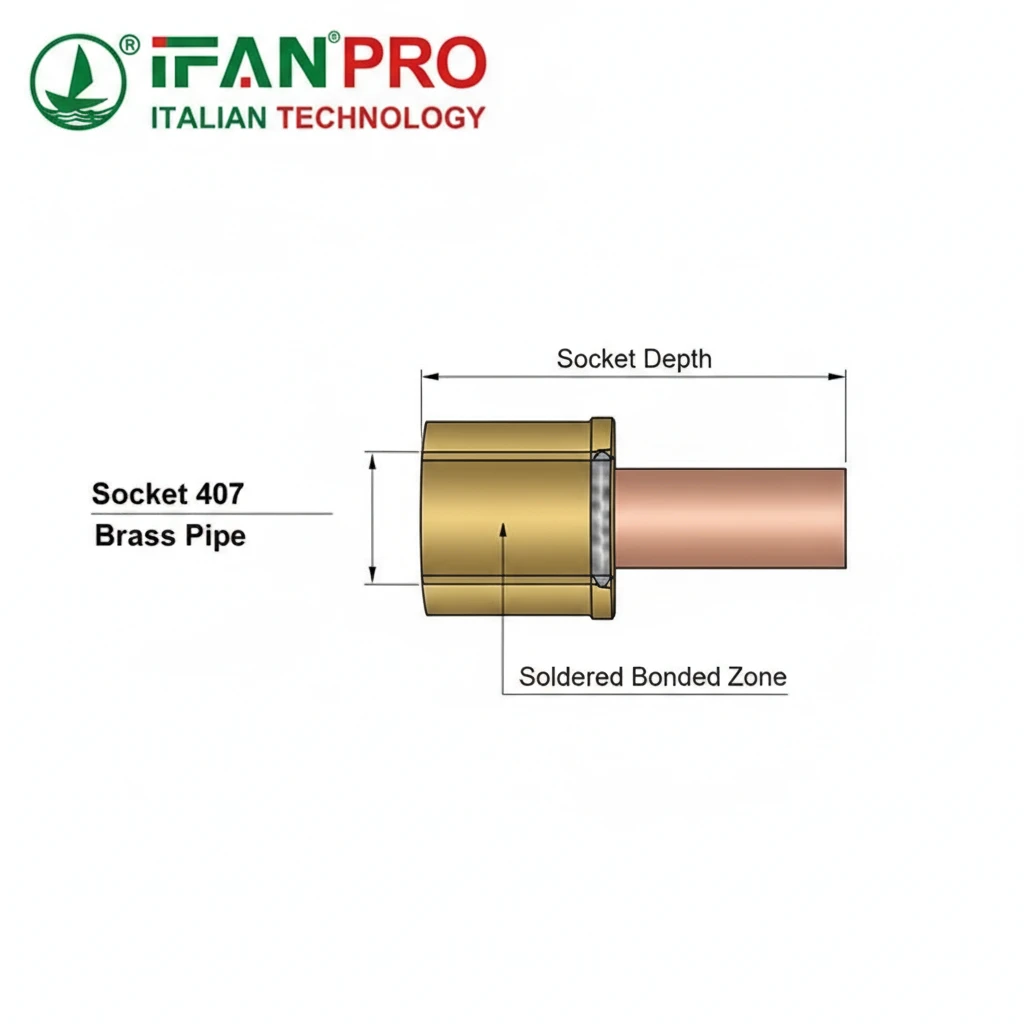

A socket end ensures a leak-proof brass connection by using a precisely engineered cup to hold the pipe. This creates a tight capillary gap that draws molten solder throughout the entire joint when heated. The solder then cools to form a permanent, metallurgical bond that is often stronger than the pipes being joined, completely sealing the connection against leaks.

This method is a cornerstone of professional plumbing. Let’s take a closer look at how each part of this simple yet brilliant system works together to create a perfect seal.

How Does the Capillary Gap in a Socket Fitting Work with Solder?

Many assume a tight fit is best. In reality, the secret lies in the small, intentional space between the pipe and the fitting.

The capillary gap in a socket fitting is a very small, uniform space designed to draw molten solder into the entire joint through capillary action. When heated, the liquid solder is pulled into this narrow gap by surface tension, filling it completely to create a continuous seal around the pipe, much like water soaking into a paper towel.

The Principle of Capillary Action

To understand this, think about how water climbs up a thin straw. This is capillary action. In a soldered joint, the space between the pipe and the inside wall of the socket fitting acts like a network of microscopic straws.

When you heat the fitting with a torch, the solder you touch to the joint’s edge melts. Because the gap is so small and uniform, the molten solder gets pulled in and spreads throughout the entire area between the pipe and the fitting. This happens quickly and evenly.

Why the Gap Size is Critical

The size of this gap is not random. It is carefully engineered.

- If the gap is too wide: Capillary action fails. The solder will not be drawn in; it will just blob and fall out, resulting in a weak, leaky joint.

- If the gap is too narrow: There is no room for the solder to flow. You cannot get enough solder into the joint to form a complete seal.

- The perfect gap: This is just wide enough to allow the solder to be pulled in by capillary force but tight enough to control and distribute it evenly. For most copper and brass plumbing, this ideal gap is between 0.004 and 0.006 inches.

The Role of the Socket in Creating the Gap

The socket itself is machined to create this perfect gap when a standard-sized pipe is inserted. The pipe fits snugly into the “cup,” but the inner diameter of the cup is ever so slightly larger than the outer diameter of the pipe. This precise difference creates the all-important capillary gap.

| Component | Function in Capillary Action |

|---|---|

| Socket (Cup) | Provides a smooth, cylindrical wall to create a uniform gap around the pipe. |

| Pipe End | Must be perfectly round and clean to maintain a consistent gap with the socket wall. |

| Molten Solder | The liquid material pulled through the gap by surface tension forces. |

| Heat | Applied to the fitting, it melts the solder and creates the necessary conditions for capillary flow. |

In summary, the capillary gap is the engineered pathway that allows solder to be distributed perfectly. It turns a manual process into a reliable, physics-driven one. Without this correct gap, creating a consistent leak-proof seal would be nearly impossible.

What Role Does Flux Play in Creating a Metallurgically Bonded Seal?

Applying solder without flux is a common mistake. I’ve seen joints fail because someone skipped this crucial step, thinking it was just grease.

Flux plays three critical roles: it cleans the metal surfaces of oxides, it prevents new oxides from forming during heating, and it helps the molten solder wet and flow onto the metal. This process is essential for the solder to form a true metallurgical bond—where it actually alloys with the surface of the brass—instead of just sticking to it like glue.

Flux as a Chemical Cleaner

First, you must understand that brass and copper quickly form an oxide layer when exposed to air. This thin layer, like rust on steel, prevents solder from bonding to the pure metal underneath. If you try to solder over this oxide, the solder will just bead up and roll off.

Flux is a chemically active paste. When you apply it to the pipe and inside the socket, it dissolves this oxide layer right before soldering. This exposes the perfectly clean, raw metal that is ready to bond.

Flux as a Protective Shield During Heating

Second, heating metal accelerates oxidation. As you heat the fitting with your torch, the fresh, clean metal wants to oxidize again. The flux melts and forms a liquid coating over the metal surface. This coating acts as a protective barrier, shielding the clean metal from the air and preventing new oxides from forming while you work.

Enabling the Metallurgical Bond

This final role is the most important. “Wetting” is the term for when solder spreads out and sticks to a metal surface. For a true bond, the solder must alloy with—or mix into—the top few molecules of the brass.

Flux dramatically reduces the surface tension of the molten solder. This allows it to flow smoothly and wet the entire surface of the clean, hot metal. When this happens, the tin and silver in the solder intermingle with the copper and zinc in the brass, creating a strong, seamless interface. The joint becomes a single, hybrid piece of metal.

What Happens Without Flux?

To see why flux is non-negotiable, look at this comparison:

| Scenario | Process | Result |

|---|---|---|

| Soldering WITH Flux | 1. Flux cleans oxides. 2. Flux shields metal during heat. 3. Solder wets and alloys with metal. | A strong, continuous metallurgical bond. The joint is integral and leak-proof. |

| Soldering WITHOUT Flux | 1. Oxide layer remains. 2. Heating creates more oxides. 3. Solder cannot wet the surface. | A weak mechanical bond. The solder just sits on top of the oxide, prone to cracking and leaking. |

In practice, using a high-quality flux, like the type IFAN includes with its professional-grade fittings, is as important as using good solder. It ensures the chemical part of the bonding process is successful, guaranteeing a permanent seal.

Why Is the Socket Depth Designed for Optimal Solder Distribution and Strength?

A deeper socket isn’t just for safety; it’s a fundamental part of the joint’s engineering. A shallow socket is a weak point waiting to happen.

The socket depth is specifically designed to provide enough surface area for the solder to create a strong mechanical bond and enough volume to absorb stress. The correct depth ensures solder is drawn completely through the joint, forming a solid ring of metal that can handle pressure, temperature changes, and physical strain without failing.

The Relationship Between Depth and Strength

Think of the soldered joint like a weld. The strength of a weld depends on the length of the weld seam. In a socket joint, the “seam” is the cylindrical area where the pipe and fitting overlap. A deeper socket means a longer overlap, which means a larger bonded area. This larger area distributes any force—like water pressure or bending stress—over more square inches, making the joint much stronger and more resistant to failure.

How Depth Guides Solder Distribution

The capillary action we discussed needs a channel to work. The socket depth defines the length of that channel. A properly designed depth ensures that when solder is drawn in from one end, it has enough space to travel and fill the entire gap uniformly.

- Too Shallow: Solder may fill the gap but won’t have enough bonded area to be strong. It can also easily be pushed out by thermal expansion.

- Optimally Deep: Solder is pulled through the full length of the socket, creating a complete, solid filler metal ring from the front to the back of the joint.

- Excessively Deep: While not common in standard fittings, too much depth can make it hard to heat the back of the joint evenly, potentially leaving a void.

Standards and Stress Absorption

Industry standards (like ASME/ANSI) specify minimum socket depths for different pipe diameters. Reputable manufacturers like IFAN adhere to or exceed these standards. The depth also provides a buffer zone. When the pipe expands from hot water or contracts from cold, the joint experiences stress. The deeper soldered column acts as a flexible, yet solid, cushion that absorbs these micro-movements without cracking.

Socket Depth Standards by Pipe Size

The table below shows typical minimum requirements for solder-joint fittings. IFAN fittings meet or exceed these specifications.

| Nominal Pipe Size (inches) | Minimum Socket Depth (inches) | Purpose of the Design |

|---|---|---|

| 1/2″ | 0.375″ | Provides sufficient bonded area for standard household water pressure. |

| 3/4″ | 0.4375″ | Increased depth to handle higher flow rates and pressure in main lines. |

| 1″ | 0.500″ | Designed for greater mechanical strength and stress absorption. |

In short, the socket depth is a calculated dimension. It ensures there is enough “glue” (the solder) in the right place to create a bond that is not just leak-tight, but also mechanically robust for the long term. Choosing fittings with the correct, standardized socket depth is a basic but critical step for a reliable plumbing system.

How Does This Method Create a Joint Stronger Than the Pipe Itself?

It sounds like an exaggeration, but it’s a proven fact. The weakest point in a soldered system should never be the joint itself.

The soldered joint becomes stronger than the pipe because the fused area—where the solder alloys with both the pipe and fitting—forms a continuous, thickened ring of metal. This ring has a higher tensile and shear strength than the thin wall of the pipe tubing. When pressure is applied, the pipe will distort or burst before the soldered joint fails.

Understanding the Composite Structure

After a perfect soldering job, the joint is no longer just a pipe inside a fitting held by adhesive. It becomes a single, composite structure. The solder doesn’t just fill a gap; it metallurgically bonds with the brass of the fitting and the copper (or brass) of the pipe, creating a new hybrid material at the interface.

This bonded zone is now thicker and more substantial than the wall of the pipe. Imagine reinforcing a paper tube by wrapping several layers of tape around it; the taped section becomes the strongest part.

The Science of Failure Points

Materials fail under stress at their weakest point. In a pipe system, stress comes from internal water pressure, which tries to push the pipe walls outward (hoop stress). The thin wall of a standard Type L copper pipe is the most vulnerable part.

In a pressure test, the force will cause the pipe wall to expand and eventually burst long before it can break the thick, reinforced ring of the soldered joint. The joint effectively becomes a localized reinforcement.

Comparison of Strength in Different Scenarios

Let’s look at how different connection methods compare under various types of stress:

| Stress Type | Soldered Socket Joint | Threaded Joint | Mechanical Compression Joint |

|---|---|---|---|

| Tensile (Pulling Apart) | Very High. Failure occurs in pipe. | Low. Can unthread under vibration. | Medium. Relies on friction and rubber seals. |

| Shear (Sideways Force) | Very High. Bonded metal resists. | Low. Threads can strip. | Medium to Low. Can shift if over-tightened or under-tightened. |

| Internal Pressure | Very High. Burst point is in pipe. | Medium. Can leak at threads before pipe bursts. | Medium. Seal can extrude under very high pressure. |

| Thermal Cycling | Excellent. Expands and contracts as one unit. | Poor. Different expansion rates can loosen threads. | Fair. O-rings can harden and fail over time. |

Real-World Implications for Reliability

This principle is why professional plumbing codes trust soldered joints. It means the system’s integrity doesn’t depend on rubber seals that can dry out or plastic parts that can creep. It relies on a permanent metal bond.

For you, the builder or homeowner, this means the installed system is incredibly forgiving and reliable. Even if the system experiences a pressure surge or freeze, the joints are the last place you should expect a failure. This is the ultimate goal of using the socket-and-solder method: to make the connection points disappear as potential weaknesses in the system.

Conclusion

The socket-end design uses precise engineering, chemistry, and physics to create a permanent, leak-proof seal that outperforms the pipe. For reliable, precision-machined brass fittings that ensure perfect joints every time, trust IFAN’s pre-fluxed solder-joint fittings and accessories.

Commentaires récents