I once had a client’s compact cooling system fail because a tiny valve burst under pressure. It taught me that size doesn’t determine strength, and the right mini valve is absolutely built for the job.

Yes, a well-engineered mini valve can absolutely withstand high pressure in small systems. Its ability to handle stress depends on three key factors: the use of robust materials like reinforced plastics or stainless steel, a precision manufacturing process that ensures structural integrity, and a sealing design specifically tested for high-pressure compact environments.

Let’s break down exactly how a small component masters the big challenge of high pressure.

What Robust Materials and Construction Allow Mini Valves to Handle High Pressure?

Many people mistakenly think small valves are weak. I’ve seen valves fail not from size, but from poor material choice.

Mini valves handle high pressure through the use of high-strength materials like brass, stainless steel, or glass-filled polymers, combined with precision machining or molding. This construction ensures the valve body and internal components have no weak points, such as porosity or thin walls, that could fail under stress.

Core Material Choices

The strength of a mini valve starts with its raw materials. Designers do not use standard plastics for high-pressure jobs. Instead, they choose engineered materials made to resist deformation.

First, metals like brass and stainless steel are common. Brass offers good strength and machinability for many applications. Stainless steel, especially grades like 316, provides higher strength and excellent corrosion resistance, which is crucial because corrosion weakens metal over time. For even higher pressures, some mini valves use materials like titanium or high-grade aluminum alloys.

Second, for applications needing a lightweight or corrosion-proof option, engineers use advanced polymers. These are not ordinary plastics. They are materials like PPS (Polyphenylene Sulfide) or PVDF (Polyvinylidene Fluoride), often reinforced with glass fibers. This reinforcement is key—it’s like putting rebar in concrete. The glass fibers add tremendous tensile strength, preventing the plastic body from cracking under high internal force.

The Importance of Manufacturing

However, strong material is not enough. The construction process is equally important. A valve can only be as strong as its weakest point.

For metal valves, precision CNC machining is critical. This process cuts the valve from a solid block of metal, ensuring consistent wall thickness and eliminating flaws. The threading for ports must be perfectly cut to prevent stress concentration. For plastic valves, high-precision injection molding is used. The mold must be designed to allow the material to flow evenly, avoiding weak spots called weld lines where the melted plastic meets inside the mold.

A major failure point in cheap valves is internal porosity—tiny air bubbles trapped in the material. Under high pressure, these bubbles can expand and create a crack. Reputable manufacturers control their molding or casting process tightly to prevent this. They also perform quality checks like pressure testing on samples from every production batch.

Material Comparison for Pressure

The table below shows how common mini valve materials compare for high-pressure use.

| Material | Best For Pressure Range | Key Advantages | Things to Watch |

|---|---|---|---|

| Brass | Medium to High | Good strength, easy to machine, cost-effective. | Can corrode with certain chemicals. |

| Stainless Steel 316 | Very High | Excellent strength and corrosion resistance. | More expensive, heavier. |

| Glass-Filled PPS | Medium to High | Lightweight, corrosion-proof, good strength. | May not handle extreme temperatures as well as metal. |

| PVDF | Medium | Excellent chemical resistance. | Lower strength than glass-filled polymers. |

In the end, a robust mini valve uses a material strong enough for the pressure and a manufacturing method that guarantees that strength is consistent throughout every single unit. This is what prevents sudden and catastrophic failures in your system.

How Is Pressure Integrity Maintained Across the Valve’s Compact Seals?

A leak in a tiny valve can shut down a whole machine. I recall a project where a faulty seal led to a slow pressure drop that took days to diagnose.

Pressure integrity in mini valves is maintained through precision-engineered seals that are compressed within their housing to form a perfect, zero-gap barrier. Common designs like O-rings, diaphragm seals, or even metal-to-metal seals are chosen based on the pressure and media, and they are installed in precisely machined grooves that prevent extrusion or blow-out under force.

The Challenge of Sealing in Small Spaces

The seal is the most critical part for holding pressure. In a large valve, you have space for big seals and complex arrangements. In a mini valve, every millimeter counts. The challenge is to create a seal that is both effective and durable within a tiny space, without being squeezed out of place when pressure spikes.

The most common solution is the O-ring. It’s a simple, round seal that sits in a groove. When you tighten the valve assembly, the O-ring gets compressed. This compression forces it to expand outward against its groove and inward against the shaft or ball, blocking any path for fluid or gas to escape.

Preventing Seal Failure

However, a standard O-ring can fail under very high pressure through a process called extrusion. Imagine pressing down on a piece of clay—it squishes out to the sides. High-pressure fluid can push the rubber of the O-ring into the tiny gap between the valve parts, eventually cutting or tearing it. To prevent this, seal designers use two strategies.

First, they use backup rings. These are rigid rings, often made of Teflon, placed on the side of the O-ring facing the high pressure. They block the gap, so the soft O-ring material has nowhere to extrude. Second, they carefully calculate the gland design—the dimensions of the groove where the seal sits. The groove must be just the right size: too big, and the seal won’t compress enough; too small, and it will be over-compressed and fail quickly.

Types of Seals for Different Pressures

For extreme pressures or harsh chemicals, other seals are used. A diaphragm seal acts like a flexible barrier that completely isolates the media from the valve’s moving parts. Metal-to-metal seals are used in ultra-high-pressure applications; these rely on the precision-machined surfaces of two metals being forced together so tightly that no fluid can pass. The integrity comes from flawless surface finishes and exact flatness.

Seal Selection Guide

Choosing the right seal material is as important as the design. The wrong material can swell, crack, or degrade.

| Seal Material | Best Used For | Pressure Limit | Key Trait |

|---|---|---|---|

| NBR (Nitrile) O-ring | Hydraulic oil, water, air | Medium | Good general use, cost-effective. |

| FKM (Viton) O-ring | High temp., chemicals, oils | High | Excellent resistance to heat and chemicals. |

| EPDM O-ring | Steam, hot water | Medium | Performs well with hot water and steam. |

| PTFE (Teflon) Seal | Aggressive chemicals, high purity | Medium to High | Very inert and low friction, but less elastic. |

Maintaining pressure integrity, therefore, is a science of precision. It combines the correct seal type, the perfect gland design, and a material compatible with both the pressure and the fluid. A high-quality mini valve will have this engineering built-in, so you don’t have to worry about leaks.

What Are the Standard Burst and Working Pressure Ratings for Mini Valves?

Clients often confuse working pressure with burst pressure. I make sure to clarify this, as mixing them up is a safety risk.

Standard ratings vary by material and size, but quality mini valves typically have a working pressure (WP) of 100 to 600 PSI for plastic versions and 500 to 3000+ PSI for metal versions. The burst pressure (BP) is usually 3 to 4 times higher than the working pressure. These ratings are determined by strict industry testing standards like ISO 9001 or SAE J standards.

Understanding the Two Key Ratings

It is crucial to understand the difference between these two numbers. They define the safe limits of the valve.

Working Pressure (WP or PN): This is the maximum continuous pressure the valve is designed to handle safely in normal operation. It includes a safety margin built in by the engineer. Operating at or below this pressure should ensure a long, trouble-free life for the valve.

Burst Pressure (BP): This is the pressure at which the valve will physically fail and rupture. It is the ultimate limit. You should never design a system where the pressure can get even close to this value. The ratio between burst pressure and working pressure is called the safety factor. A common safety factor in industrial components is 4:1. For example, a valve with a 1000 PSI burst pressure would have a 250 PSI working pressure.

How Ratings are Determined

These ratings are not guessed. They come from rigorous testing. Manufacturers perform two main tests. First, a proof pressure test, where they subject the valve to a pressure higher than the working pressure (often 1.5x WP) for a set time to check for leaks or deformation. Second, a burst pressure test, where they increase pressure on a sample valve until it fails. This data, collected over many samples, sets the published ratings.

Typical Pressure Ratings by Valve Type

The table below gives a general idea of standard ratings. You must always check the manufacturer’s datasheet for the exact valve you are using.

| Valve Type / Material | Typical Working Pressure Range | Typical Burst Pressure Factor | Common Applications |

|---|---|---|---|

| Mini Ball Valve (Plastic) | 100 – 150 PSI | 3x – 4x WP | Low-pressure air, water lines, aquariums. |

| Mini Needle Valve (Brass) | 300 – 600 PSI | 4x WP | Instrumentation, gas sampling, regulator lines. |

| Mini Check Valve (Stainless Steel) | 1000 – 3000 PSI | 3x – 4x WP | Hydraulic systems, high-pressure pumps, fuel lines. |

| Mini Solenoid Valve (PPS Body) | 200 – 500 PSI | 3x WP | Automated fluid control, medical devices. |

The Impact of Standards

Reputable manufacturers design and test their valves to meet international standards. For example, valves for compressed air systems might follow ISO standards, while those for automotive or mobile hydraulics follow SAE standards. These standards specify not just pressure tests, but also cycle life (how many times it can open/close) and environmental tests.

Therefore, when selecting a mini valve, never just assume it’s “strong enough.” You must look for its certified working pressure rating and ensure your system’s maximum operating pressure stays well below that limit, maintaining a safe operating margin.

How Does Pressure Rating Change with Different Port Sizes and Media?

A valve’s pressure rating on paper isn’t the whole story. In one case, a valve rated for 500 PSI with water failed at 300 PSI with a gas, which taught me to always consider the full context.

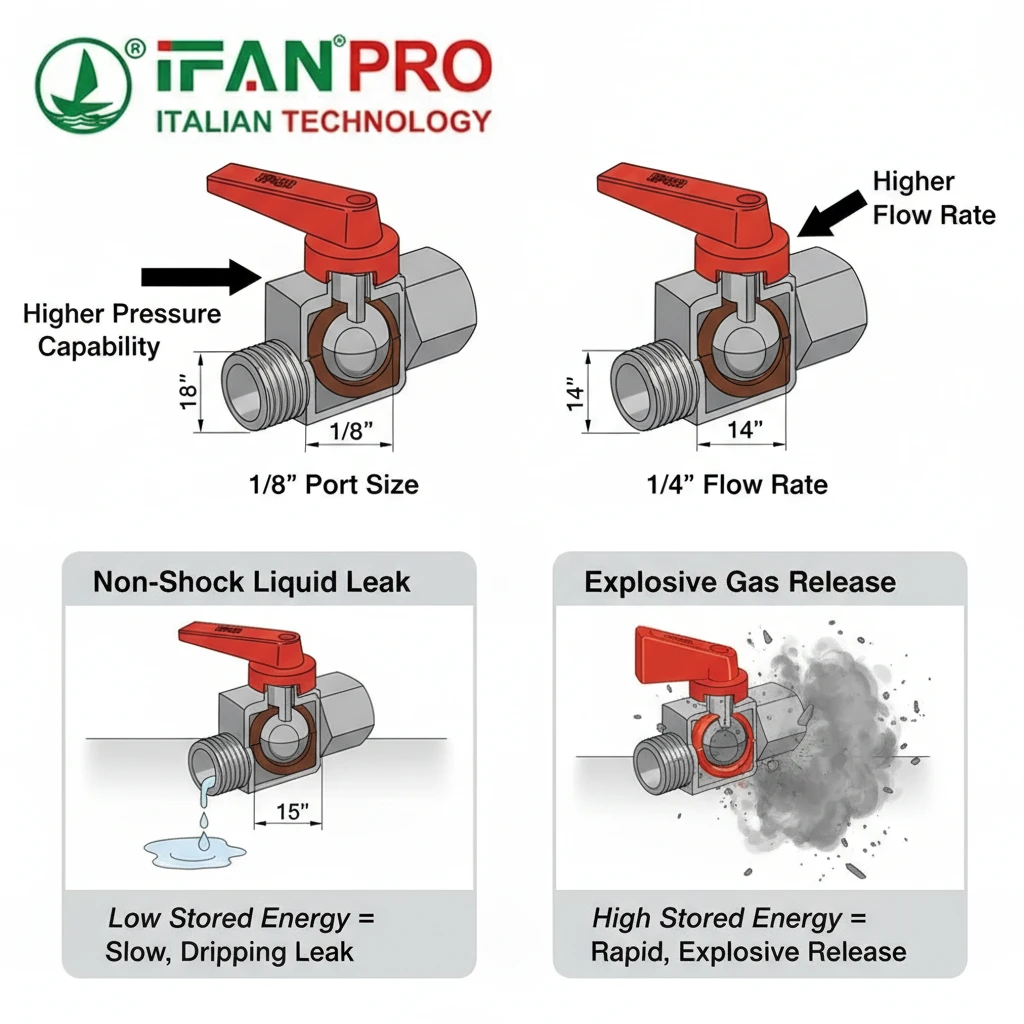

Pressure rating changes with port size because a smaller port has a thicker surrounding wall, which can often handle higher pressure, but also creates more flow restriction. The media (liquid or gas) changes the rating because gases are compressible and store more explosive energy, while aggressive chemicals can weaken seal and body materials over time, requiring derating.

The Port Size Factor

It might seem that a bigger valve is always stronger, but with mini valves, the relationship between size and pressure is interesting.

A smaller port size, like 1/8″ or 2mm, means the internal hole is tiny. The wall of material around this hole is relatively thick compared to the hole’s diameter. This thick wall provides strong structural support against internal pressure trying to burst the valve open. Because of this, a very small mini valve can often have a surprisingly high pressure rating.

However, there is a trade-off: flow restriction. A tiny port creates a lot of resistance for the fluid or gas moving through it. This causes a pressure drop across the valve. So, while the valve itself might hold 1000 PSI, using it in a small port size might choke your system’s flow. You must select a port size that balances pressure capability with the required flow rate for your application.

The Media Factor: Liquid vs. Gas

The type of fluid flowing through the valve is perhaps the most critical factor after the mechanical rating. Valves are often rated with water or oil as the test medium. Using a different media can significantly alter its safe operating pressure.

Gases are much more dangerous than liquids at the same pressure. Why? Because gases are compressible. A compressed gas stores a large amount of energy. If a valve fails with gas, this stored energy is released explosively, causing rapid component destruction. A liquid, being nearly incompressible, stores very little energy. A leak in a liquid system is often a spray, not an explosion. Therefore, for gas service, it is a standard and critical safety practice to derate the valve’s working pressure, often using only 50-80% of its liquid pressure rating.

The Media Factor: Chemical Compatibility

The second media factor is chemical attack. An aggressive chemical—like a strong solvent, acid, or base—can do two things. First, it can attack and weaken the seal material, causing it to swell, shrink, or become brittle. A weakened seal will fail at a much lower pressure. Second, some chemicals can attack the valve body material itself, especially certain plastics. This long-term degradation is called environmental stress cracking, and it dramatically lowers the effective burst pressure over time.

Media and Port Selection Guide

This table summarizes how to adjust your valve selection based on these factors.

| Condition | Effect on Pressure Rating | Practical Selection Tip |

|---|---|---|

| Very Small Port (e.g., 1/16″) | May allow a higher rated pressure due to thick walls. | Check flow rate to ensure it meets system needs despite restriction. |

| Gas as Media | Requires derating for safety. Use a lower working pressure. | Select a valve with a gas-service rating or derate the liquid rating by 40-50%. |

| Aggressive Chemical Media | Can cause long-term degradation, lowering effective rating. | Choose valve & seal materials with proven compatibility. Consult chemical resistance charts. |

| High-Purity Media | Requires smooth flow paths and non-leaching materials. | Rating is less critical than material inertness and surface finish. |

In summary, the catalog pressure rating is a starting point. You must then adjust your expectations based on the actual port size you need and, most importantly, the specific media the valve will control. Always consult the manufacturer’s data for media compatibility and gas service derating guidelines.

Conclusion

A mini valve can be highly pressure-resistant if it’s made with strong materials, precision seals, and clear ratings suited to your specific media and port size. For reliable high-pressure mini valves built to these principles, explore the IFAN valve series.

Commentaires récents