We received an urgent call from a plant manager. His new smart valves couldn’t talk to the rest of the system, halting a major upgrade. This highlighted the critical question of protocol compatibility.

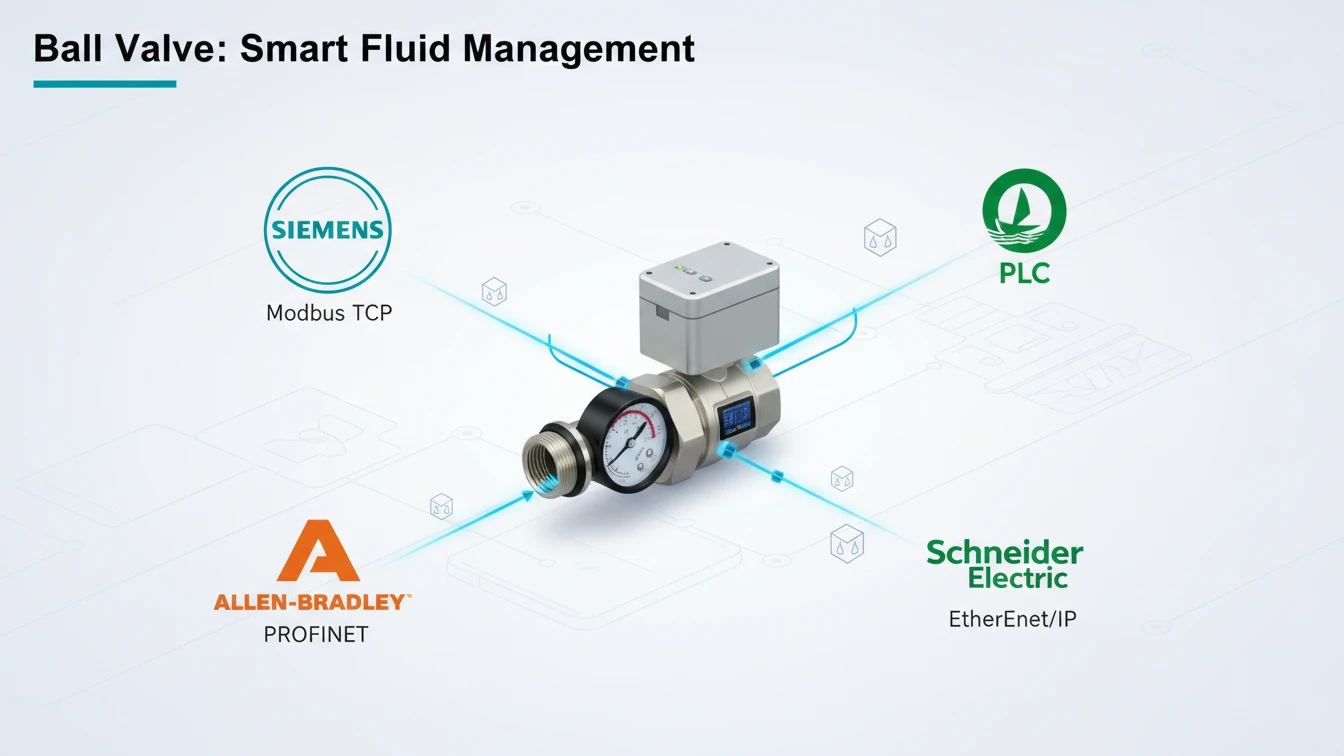

Yes, modern smart ball valves are designed to be compatible with major industrial protocols. Leading valves support communication standards like Modbus RTU/TCP, PROFINET, EtherNet/IP, and PROFIBUS-DP. This compatibility allows them to exchange data and receive commands directly within a plant’s existing control architecture, turning them from simple switches into intelligent system components.

Understanding which protocols a valve supports is the first step to a successful automation project. Let’s break down why this matters so much.

Which Common Industrial Protocols Do Smart Ball Valves Support?

Choosing a valve without checking its protocol is like buying a plug for the wrong outlet. We’ve seen projects stall for this exact reason.

Smart ball valves commonly support key industrial protocols such as Modbus (serial and TCP), PROFINET, EtherNet/IP, and PROFIBUS. This range covers most network needs, from simple serial connections in small plants to high-speed Ethernet-based systems in large facilities, ensuring broad applicability across different industries and control system ages.

The Foundation of Communication

Industrial protocols are the specific languages that devices use to talk to each other and to control systems like PLCs (Programmable Logic Controllers). A smart ball valve’s compatibility list determines where and how easily it can be used.

First, let’s look at the most common protocols you’ll encounter. These are often divided into two groups: fieldbus (older, serial-based) and Industrial Ethernet (newer, network-based).

Key Protocol Breakdown

Here is a table explaining the most common protocols smart valves support:

| Protocol | Type | Key Characteristic | Typical Use Case |

|---|---|---|---|

| Modbus RTU | Serial Fieldbus | Simple, robust, uses RS-485 wiring. A universal standard. | Connecting a few valves to a PLC in a cost-sensitive or legacy system. |

| Modbus TCP | Industrial Ethernet | Modbus messages sent over standard Ethernet networks. | Integrating valves into plant-wide IT/OT networks for data collection. |

| PROFINET | Industrial Ethernet | High-speed, deterministic data exchange. Popular with Siemens PLCs. | High-performance automation lines where timing is critical. |

| EtherNet/IP | Industrial Ethernet | Uses standard Ethernet with CIP protocol. Popular with Allen-Bradley (Rockwell) PLCs. | North American automotive, packaging, and other discrete manufacturing. |

| PROFIBUS-DP | Serial Fieldbus | High-speed serial communication for field devices. | Legacy factory automation systems, especially in Europe. |

Making the Right Choice

For most new installations, Industrial Ethernet protocols (PROFINET, EtherNet/IP) are the future. They offer faster data transfer and easier integration with higher-level systems. However, many plants still operate on reliable fieldbus systems like Modbus RTU or PROFIBUS.

Therefore, a versatile smart ball valve will often support multiple protocols. Some advanced valves even have dual ports or switchable protocol settings. This flexibility is crucial. It means you can use the same valve model in different parts of your factory, even if those areas use different control systems. Our advice is to always match the valve’s protocol to your existing PLC and network infrastructure. Don’t force a new protocol into an old system unless you are planning a full network upgrade.

How Does Protocol Compatibility Ensure Seamless System Integration?

Integration headaches are a major project cost. Compatible protocols act as a universal translator, eliminating these headaches.

Protocol compatibility ensures seamless integration by allowing the smart ball valve to connect directly to the central Programmable Logic Controller (PLC) or Distributed Control System (DCS). This direct connection enables real-time data exchange—like valve position, torque, and diagnostics—and control within the same software environment used for pumps, motors, and sensors, creating a unified control loop.

The Role of the Control System

Seamless integration means the valve becomes a natural, easily managed part of your larger control system. Without the right protocol, engineers need to use clumsy workarounds like additional gateways or standalone controllers, which add cost, complexity, and points of failure.

When a smart ball valve speaks the native language of your PLC, the integration process is straightforward. The control engineer simply adds the valve as a new device node in the control software (e.g., TIA Portal for Siemens, Studio 5000 for Rockwell). The valve’s data points—its “tags”—are then available just like any other I/O point.

Streamlining Data Flow and Control

This direct connection enables two critical functions:

- Real-Time Control and Monitoring: The PLC can command the valve to open or close based on process logic (e.g., “close valve V101 if tank level is high”). Simultaneously, it receives instant confirmation of the valve’s position and status. You can see on the HMI (Human-Machine Interface) if the valve is open, closed, stuck, or in motion.

- Advanced Diagnostics Integration: Smart valves provide more than just on/off signals. They can report conditions like excessive torque (hinting at wear or blockage), cycle count, and internal temperature. With native protocol compatibility, these diagnostic alarms are sent directly to the control system. This allows for predictive maintenance alerts, reducing unplanned downtime.

Integration Without Compatibility vs. With Compatibility

The table below contrasts the two scenarios:

| Aspect | Integration WITHOUT Protocol Compatibility | Integration WITH Protocol Compatibility |

|---|---|---|

| Connection Path | Valve -> Gateway/Converter -> PLC (Complex, multi-device). | Valve -> PLC (Direct, single connection). |

| Engineering Effort | High. Requires configuring the valve, the gateway, and the PLC separately. | Low. Valve is configured as a device within the PLC’s own engineering tool. |

| Data Accessibility | Limited, often slow. Diagnostics may be trapped in a separate app. | Full, real-time. All data is available in the central SCADA/HMI system. |

| Reliability | Lower. More components and connections increase potential failure points. | Higher. Simpler architecture with fewer potential failures. |

| Total Cost | Higher (hardware + extra engineering time). | Lower. |

In short, protocol compatibility removes barriers. It makes the smart valve a true “plug-and-play” component within your industrial network, saving significant time and money during installation and throughout the valve’s operational life.

Can the Valve Communicate in Multi-Vendor Industrial Environments?

Plants rarely have only one brand of equipment. A valve that only talks to one brand creates islands of automation, which is a problem we often help solve.

Yes, a well-designed smart ball valve can communicate in multi-vendor environments by supporting open or widely adopted industry-standard protocols. Protocols like Modbus TCP and EtherNet/IP are vendor-neutral, allowing a valve from one manufacturer to seamlessly exchange data with PLCs, HMIs, and sensors from many other manufacturers on the same network.

The Challenge of Proprietary Systems

Historically, some automation vendors used proprietary protocols to lock customers into their ecosystem. This made adding a third-party device, like a smart valve, difficult and expensive. Today, the industry strongly favors open standards to ensure interoperability—the ability of different brands to work together.

A multi-vendor environment is the reality. You might have Siemens PLCs on one line, Allen-Bradley on another, and a Schneider electric motor control center. Your smart valve needs to fit into this mosaic.

The Power of Open Standards

The key to multi-vendor communication is the use of open, non-proprietary protocols. Modbus is the classic example of an open, royalty-free standard. Any manufacturer can implement it. If your valve and your PLC both support Modbus TCP over Ethernet, they can communicate regardless of who made them.

Similarly, EtherNet/IP is an open standard managed by the ODVA consortium. While strongly associated with Rockwell, it is not proprietary. Many vendors, including Siemens, Omron, and others, make devices that communicate via EtherNet/IP. This is why choosing a smart valve that supports these universal protocols is an insurance policy against vendor lock-in.

Strategy for Multi-Vendor Success

Here is a practical approach to ensure success:

- Map Your Network: Before selecting a valve, identify the primary protocol used in the area of your plant where it will be installed. Is it a PROFINET segment? An EtherNet/IP zone?

- Choose the Bridge Protocol: If you need a valve to communicate between systems, select a model that supports both relevant protocols, or one that supports a neutral protocol like Modbus TCP that can be accessed by most major PLCs.

- Verify Interoperability: Don’t just check the protocol name. Look for specific statements about interoperability testing or certifications from the valve manufacturer. For example, a valve with “EtherNet/IP Conformance Tested” certification from ODVA is guaranteed to work in that network.

Protocol Openness and Vendor Neutrality

| Protocol | Open Standard? | Primary Vendor Association | Multi-Vendor Friendly? |

|---|---|---|---|

| Modbus TCP/RTU | Yes | None (Schneider originally but open). | Excellent. The universal translator of industry. |

| EtherNet/IP | Yes (ODVA) | Allen-Bradley / Rockwell. | High. Widely adopted by many brands. |

| PROFINET | Yes (PI) | Siemens. | Good. Many third-party devices support it. |

| PROFIBUS | Yes (PI) | Siemens. | Fair. Common but requires specific profiles. |

| DeviceNet | Yes (ODVA) | Allen-Bradley / Rockwell. | Fair. Legacy system, but multi-vendor. |

By prioritizing valves that support these open standards, you maintain flexibility. You are not forced to buy all your automation components from a single supplier, fostering competition and potentially lowering costs for future expansions.

Why Is Open Protocol Support Important for Future System Expansions?

Factories evolve. The valve you install today should not become a roadblock to tomorrow’s upgrade. We emphasize this point in every project plan.

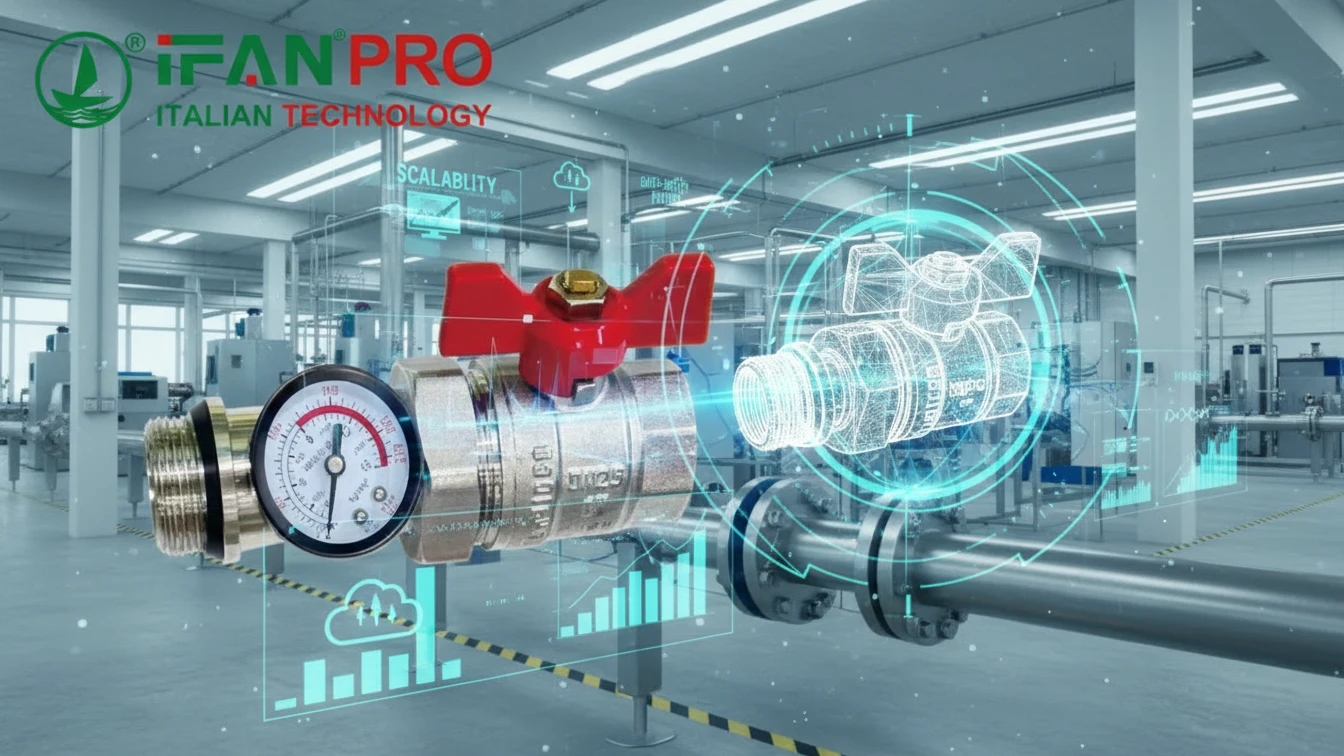

Open protocol support is crucial for future expansion because it prevents vendor lock-in and ensures the valves can communicate with next-generation control systems. It provides the flexibility to upgrade PLCs, add new sensors, or integrate with Industrial IoT platforms without the need to replace the entire valve infrastructure, protecting your long-term investment.

Protecting Your Capital Investment

Industrial valves are durable assets expected to last 15-20 years or more. Control systems and IT infrastructure, however, may be upgraded every 5-10 years. If your smart valves only support a proprietary or obsolete protocol, they become orphaned devices during a system refresh. This forces a terrible choice: delay the necessary upgrade of your control system or rip out and replace perfectly good, functional valves.

Open protocol support future-proofs your investment. It decouples the lifecycle of your field devices (the valves) from the lifecycle of your control hardware and software.

Enabling Technology Migration

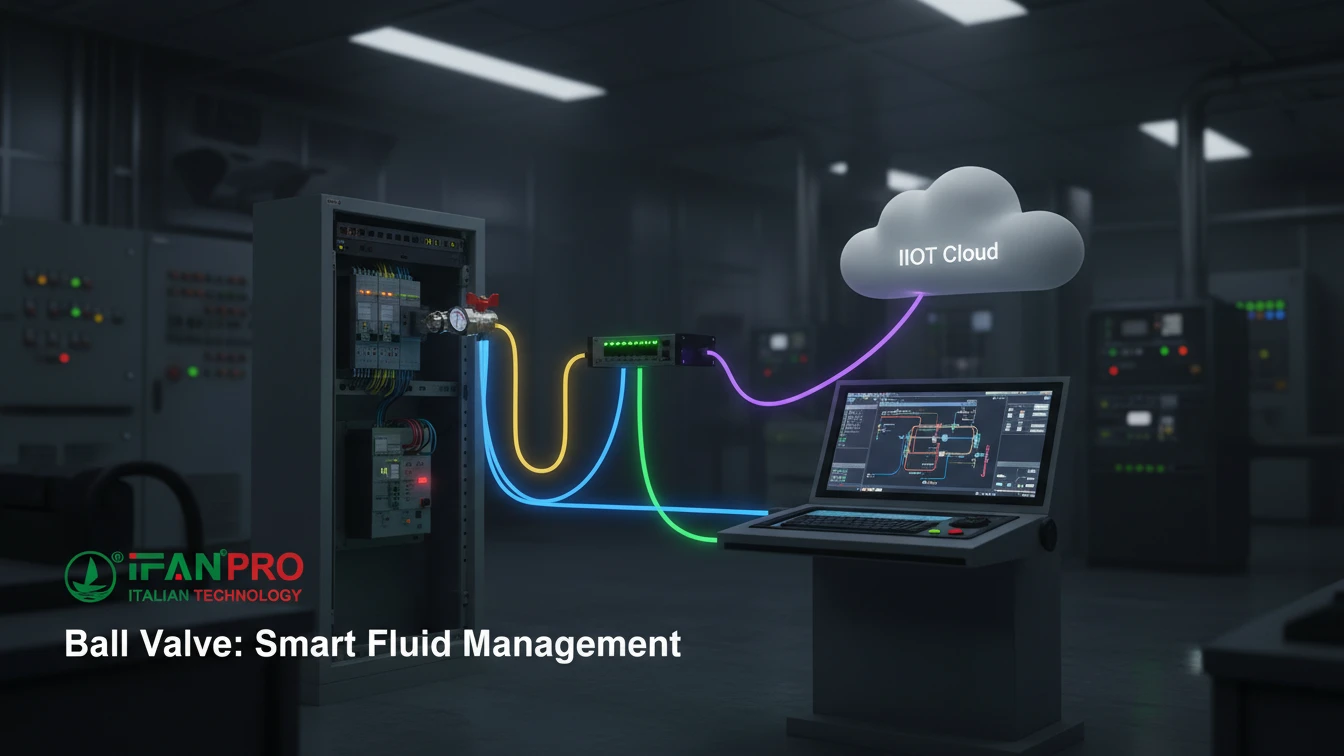

Future expansions often involve adopting new technologies. Today, this might mean connecting devices to a cloud-based IIoT (Industrial Internet of Things) platform for advanced analytics.

Here’s how open protocols facilitate this:

- Easier Control System Upgrades: When you replace an old PLC with a new one, the new system will almost certainly support standard protocols like Modbus TCP or EtherNet/IP. If your valves already use these protocols, re-integrating them is a simple reconfiguration task, not a rewiring and replacement project.

- Simplified IIoT/Industry 4.0 Integration: Open, Ethernet-based protocols (Modbus TCP, OPC UA) are the gateway to IIoT. Data from these valves can be easily collected by an edge gateway or directly by a SCADA system and then forwarded to higher-level analytics software. A proprietary, closed protocol would require expensive middleware to translate the data.

The Cost of Closed vs. Open Protocols Over Time

The financial impact becomes clear over a long period:

| Project Phase | System with Closed/Proprietary Valves | System with Open Protocol Valves |

|---|---|---|

| Initial Purchase | Possibly lower valve cost. | Possibly slightly higher valve cost. |

| First 5-7 Years | Works well within the original system. | Works well within the original system. |

| At System Upgrade | High Cost. Must replace valves or use costly protocol converters. | Low Cost. Valves reconnect to new system easily. |

| Adding IIoT Analytics | Difficult & Costly. Requires custom drivers/gateways. | Straightforward. Data is already in an accessible format. |

| Total 15-Year Cost | Very High (initial + replacement/converter costs). | Lower (initial cost only, full asset utilization). |

Practical Advice for Planning

Always specify smart valves that support established, non-proprietary communication standards. Even if you are using a primarily Siemens (PROFINET) shop today, choosing a valve that also speaks Modbus TCP gives you an escape route. It ensures that no matter how your control strategy evolves—whether toward a different primary vendor or toward a data-centric IIoT architecture—your valve assets remain valuable, connected, and productive.

Conclusion

Smart ball valve compatibility with open industrial protocols is essential for seamless integration, multi-vendor operation, and long-term system flexibility. For future-proof, protocol-versatile smart ball valves, explore the range of solutions from IFAN.

Commentaires récents