I once had a client whose irrigation system kept failing because standard float valves couldn’t withstand their pump’s pressure. This taught me that not all valves are created equal.

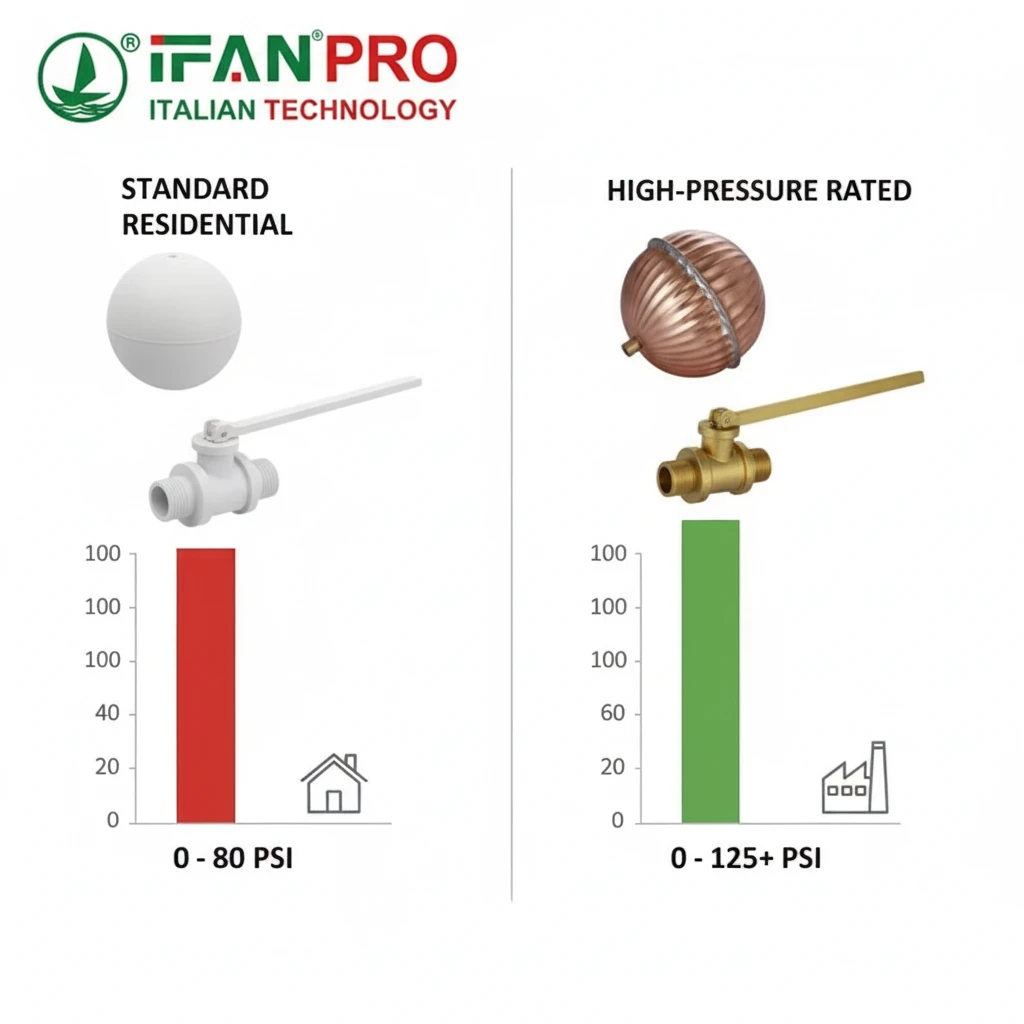

A standard residential float valve often cannot handle high-pressure inlets, but specialized high-pressure float valves are designed specifically for this task. The ability to handle pressure depends on the valve’s maximum pressure rating (PSI or Bar), the strength of its internal seals and springs, and the robustness of its construction materials.

Let’s explore the key factors that determine if a float valve is suitable for your high-pressure application.

What is the Maximum Pressure Rating for Standard Residential Float Valves?

Many people assume a valve is a valve. I’ve seen this mistake lead to frequent leaks and replacements in systems with powerful pumps.

The maximum pressure rating for most standard residential float valves, commonly made of plastic or basic brass, is relatively low, typically between 50 PSI (3.4 Bar) and 80 PSI (5.5 Bar). These valves are designed for the consistent, moderate pressure found in typical municipal water supply lines or low-pressure tanks.

Understanding Pressure Ratings

First, you need to know what a pressure rating means. It is the highest water pressure the valve’s body and internal parts are designed to handle safely and continuously. Going above this rating risks immediate failure or a much shorter lifespan. Think of it like a speed limit for water inside the valve.

Standard valves you find at a local hardware store are built for common household use. Their main job is to reliably shut off water in a toilet tank or a small animal watering trough when the float rises. The pressure in these settings is usually stable and controlled.

Why Standard Valves Have Limits

These valves have several design features that limit their pressure capacity:

- Material Strength: Many are made from molded plastics like PVC or polypropylene, which can crack or deform under high, sustained pressure.

- Seal Design: They use simple rubber or silicone washers as seals. High pressure can force water past these seals, causing a constant drip or leak, even when the valve is supposed to be closed.

- Spring Tension: The internal spring that helps close the valve is often light. A strong surge of high-pressure water can overpower this spring, preventing the valve from closing fully or causing it to chatter and wear out quickly.

Typical Application Pressures

It helps to compare standard valve ratings with real-world water pressures.

| Water Source / Application | Typical Pressure Range | Suitable for Standard Float Valve? |

|---|---|---|

| City Mains Supply | 40 – 80 PSI | Yes, at the lower end. |

| Home Well Pump | 40 – 60 PSI | Yes, generally safe. |

| Low-Pressure Storage Tank | 10 – 30 PSI | Yes, ideal. |

| High-Pressure Irrigation Pump | 80 – 120+ PSI | No, risk of failure. |

| Industrial Water Line | 100+ PSI | No, will likely fail. |

The Key Takeaway

If your water source involves a pump, a pressure booster, or comes from a high-elevation storage tank, the inlet pressure likely exceeds the safe zone for a standard float valve. Assuming a standard valve will work is a common and costly mistake. You must first measure or know your system’s maximum operating pressure, then choose a valve rated well above that number for safety and durability.

How Do Reinforced Seals and Stronger Springs Handle High Inlet Pressure?

When pressure increases, the weak points of a standard valve become obvious. Upgrading internal components is the solution.

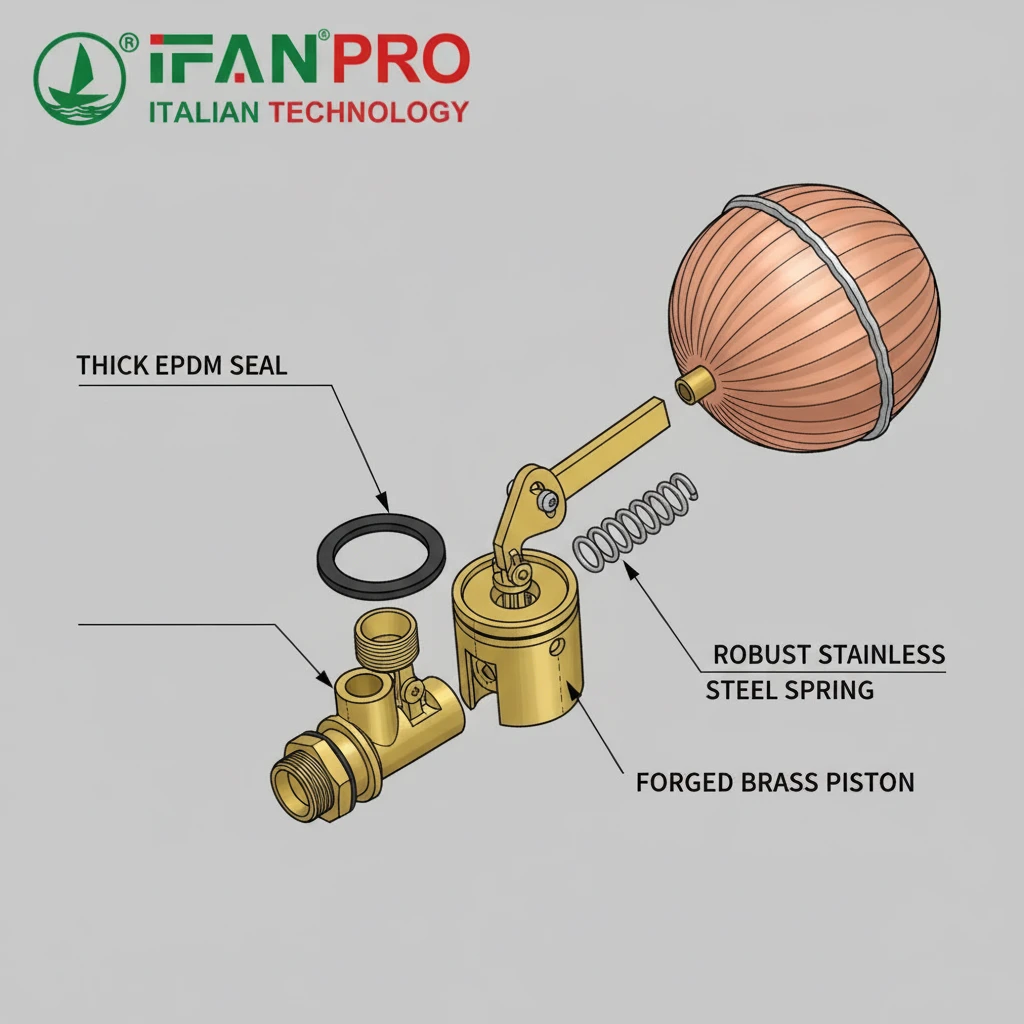

Reinforced seals and stronger springs handle high inlet pressure by creating a much tighter seal and providing greater closing force. Heavy-duty seals, often made of EPDM or Viton, resist deformation, while robust springs ensure the valve piston shuts firmly and instantly against the high-pressure water stream, preventing leaks and water hammer.

The Role of High-Pressure Seals

In a valve, the seal is the gatekeeper. Under high pressure, water aggressively tries to find any path to escape.

- Material Upgrade: Standard seals may use basic nitrile rubber. High-pressure valves use engineered elastomers like EPDM (excellent for hot and cold water) or Viton (superior for chemicals and high temperatures). These materials are denser and more resistant to “extrusion,” which is when high-pressure water forces the seal to deform and squeeze into gaps.

- Design Upgrade: The seal’s shape is also crucial. High-pressure seals often have a more complex profile—sometimes with multiple lips or a reinforced backbone—to maintain their shape under extreme force. They are designed to create a perfect, wide contact area with the valve seat, leaving no microscopic path for water.

The Critical Function of Stronger Springs

The spring is the muscle that slams the gate shut. Here’s how a stronger spring makes a difference:

- Positive Shut-Off: When the float rises, it needs to overcome the water pressure pushing against the piston or plunger trying to open it. A light spring can be overwhelmed, causing the valve to not close completely, leading to constant overflowing or running water. A heavy-duty spring provides the necessary force to seat the piston firmly into the seal, even against 100+ PSI of pushing force from the inlet side.

- Reduced Water Hammer: Water hammer is the shockwave caused when flowing water stops suddenly. A weak valve may close slowly or flutter, which can actually make water hammer worse. A strong spring enables a faster, more decisive closure. While this can create a pressure surge, it is often managed better with the valve’s overall robust design and is preferable to a leaky, never-fully-closed valve.

- Durability: A stronger spring is made from thicker-gauge, high-grade stainless steel to resist fatigue. Constant cycling under high pressure will quickly wear out a light spring, leading to failure.

How These Components Work Together

Think of it like closing a heavy door in a strong wind. A flimsy seal is like a thin weatherstrip, and a weak spring is like a light door closer. The wind (high water pressure) will whistle through the gaps and may even blow the door back open. A high-pressure valve uses a thick, gasketed seal and a heavy-duty door closer to slam and hold the door tightly shut, regardless of the wind.

For a buyer, this means: When selecting a valve for high pressure, you must look beyond the material of the valve body. Check the product specifications for the seal material and ask about the spring mechanism. Phrases like “heavy-duty seals,” “forged brass internals,” and “high-tension spring” are key indicators of a valve built to handle the stress.

What Specific High-Pressure Float Valve Models Are Available on the Market?

The market offers solutions, but knowing the categories helps you choose wisely. From our experience, clients often buy the wrong type.

Specific high-pressure float valve models available include Heavy-Duty Brass Valves, Industrial Forged Body Valves, and Pilot-Operated Valves. Brass valves handle up to 125 PSI, forged bodies suit extreme conditions up to 250 PSI, and pilot-operated valves use water pressure itself to assist closing, making them ideal for very high-pressure systems above 150 PSI.

Category 1: Heavy-Duty Brass Float Valves

These are the most common upgrade from standard plastic valves. They are a good fit for high-pressure residential and commercial applications.

- Construction: Made from solid brass with a chrome or other corrosion-resistant finish. The internal piston is also brass or stainless steel.

- Pressure Rating: Typically rated for pressures up to 125 PSI (8.6 Bar) or sometimes higher.

- Seals & Springs: Equipped with EPDM or Viton seals and a robust stainless steel spring.

- Best For: High-pressure well systems, booster pump outlets, commercial livestock watering, and larger pressurized storage tanks.

- Advantage: Excellent balance of durability, pressure handling, and cost. They are widely available and easier to install than more complex models.

Category 2: Industrial Forged Body Float Valves

When brass isn’t strong enough, forged valves step in. These are the heavyweights.

- Construction: The main body is forged from brass or stainless steel, making it incredibly dense and strong. All components are heavy-duty.

- Pressure Rating: Can handle very high pressures, often up to 250 PSI (17 Bar) or more.

- Seals & Springs: Use the highest grade seals (Viton is common) and extremely powerful springs.

- Best For: Industrial applications, manufacturing plants, high-pressure wash down systems, and large-scale agricultural irrigation supply tanks.

- Advantage: Maximum durability and pressure tolerance. They are built to last for decades in harsh conditions.

Category 3: Pilot-Operated Float Valves

This is a different and highly effective technology for extreme pressures. We recommend these for our clients with the most demanding systems.

- How It Works: It uses a two-stage process. A small pilot valve, controlled by the float, opens or closes a diaphragm chamber. The water pressure from the inlet then acts on this diaphragm to open or close the main valve port. This means the float only needs to control a tiny flow of water, not fight the main pressure directly.

- Pressure Rating: Excellently suited for systems with 150 PSI to over 300 PSI.

- Best For: Very high-pressure municipal water inlets, large industrial water towers, and any situation where the pressure would make a standard direct-acting valve chatter, leak, or fail quickly.

- Advantage: Provides smooth, reliable operation under extreme pressure with minimal strain on the float mechanism. It offers the best performance for high-high-pressure applications.

Model Comparison Table

| Valve Type | Typical Max Pressure | Best For | Key Feature | Relative Cost |

|---|---|---|---|---|

| Standard Plastic/Brass | 50-80 PSI | Residential toilets, low-pressure tanks | Low cost, easy to find | $ |

| Heavy-Duty Brass | 125 PSI | High-pressure wells, booster pumps, farms | Excellent durability for price | $$ |

| Industrial Forged | 250+ PSI | Factories, industrial processes | Maximum strength & longevity | $$$ |

| Pilot-Operated | 300+ PSI | Municipal, high-pressure industrial | Best performance at extreme pressure | $$$$ |

Choosing the right model requires matching your system’s maximum pressure to a valve rated comfortably higher. Always include a safety margin.

What Happens If Water Pressure Exceeds the Valve’s Designed Capacity?

Ignoring the pressure rating is the biggest mistake you can make. The consequences are predictable and often destructive.

If water pressure exceeds the valve’s designed capacity, it will lead to valve failure. This failure manifests as persistent leaking, catastrophic bursting, or improper operation like constant water flow. This results in water waste, potential flooding damage, and the inability to control the water level in the tank or reservoir.

Stage 1: Leakage and Inefficiency

This is the most common immediate symptom. The excessive pressure attacks the weakest points.

- Seal Blow-Out: The high-pressure water forces its way past the seals. You will see a constant drip or stream from the valve outlet even when the tank is full and the float is up. The seal may become permanently deformed.

- Failed Shut-Off: The pressure overpowers the closing spring. The valve never fully closes, causing the tank to overflow continuously. The valve may make a chattering or whistling sound as it struggles to close.

- Result: You waste a significant amount of water and energy (if the water is pumped). The system cannot maintain its intended water level.

Stage 2: Physical Damage and Catastrophic Failure

If the over-pressure condition continues or is severe, physical damage occurs.

- Body Cracking: For plastic valves, the body itself can crack or split open, especially at threaded connection points. This leads to a major, uncontrolled leak.

- Component Fatigue: The float arm may bend or break. The internal piston can warp. The threads can strip. The valve becomes inoperable.

- Burst Failure: In the worst-case scenario, the valve body catastrophically fails, releasing the full flow and pressure of the inlet line into the room or equipment area. This can cause extensive water damage in minutes.

The Domino Effect on Your System

A failing float valve doesn’t operate in isolation. It causes other problems:

- Pump Damage: If the valve is leaking or won’t shut off, the pump (if present) may cycle on and off rapidly or run continuously, leading to premature pump burnout.

- Water Hammer Escalation: A valve damaged by high pressure often closes erratically, worsening water hammer shocks that can damage other pipes, fittings, and appliances in your plumbing system.

- Loss of System Control: The entire purpose of the valve—to automatically maintain a water level—is lost. You risk dry running a tank or flooding an area.

How to Prevent This Situation

The solution is always prevention through proper selection and system management.

| Problem Cause | Preventive Action |

|---|---|

| Unknown System Pressure | Install a pressure gauge at the valve inlet to know your exact pressure. |

| Pressure Surges/Spikes | Install a pressure relief valve or an expansion tank upstream to absorb shocks. |

| Choosing the Wrong Valve | Always select a valve with a pressure rating at least 1.5 times your system’s maximum operating pressure. |

| Faulty Pressure Regulator | If your system has a regulator, check and maintain it regularly. |

Exceeding the pressure rating is a sure path to failure. It is not a matter of “maybe” but “when.” Investing in a correctly rated valve from the start is far cheaper than dealing with water damage, wasted resources, and emergency repairs.

Conclusion

Choosing a float valve that matches your water pressure is critical for a reliable, leak-free system. For robust, high-pressure float valves you can trust, explore the durable options available from IFAN.

Commentaires récents