I’ve seen metal valves in city water lines fail from rust, causing expensive emergencies. This firsthand experience shows why materials matter for public infrastructure.

PVC ball valves are used in municipal water systems primarily for their exceptional corrosion resistance, reliable sealing for flow control, and significant long-term cost savings. They provide a durable, maintenance-free solution that ensures consistent water delivery and system integrity over decades, which is critical for public utilities.

Let’s examine the specific reasons that make PVC ball valves a smart, foundational choice for modern water networks.

Why is PVC Corrosion Resistance Crucial for Municipal Water System Durability?

Municipal systems can’t afford constant repairs. Corrosion is the silent enemy of metal pipes and valves, but PVC offers a permanent solution.

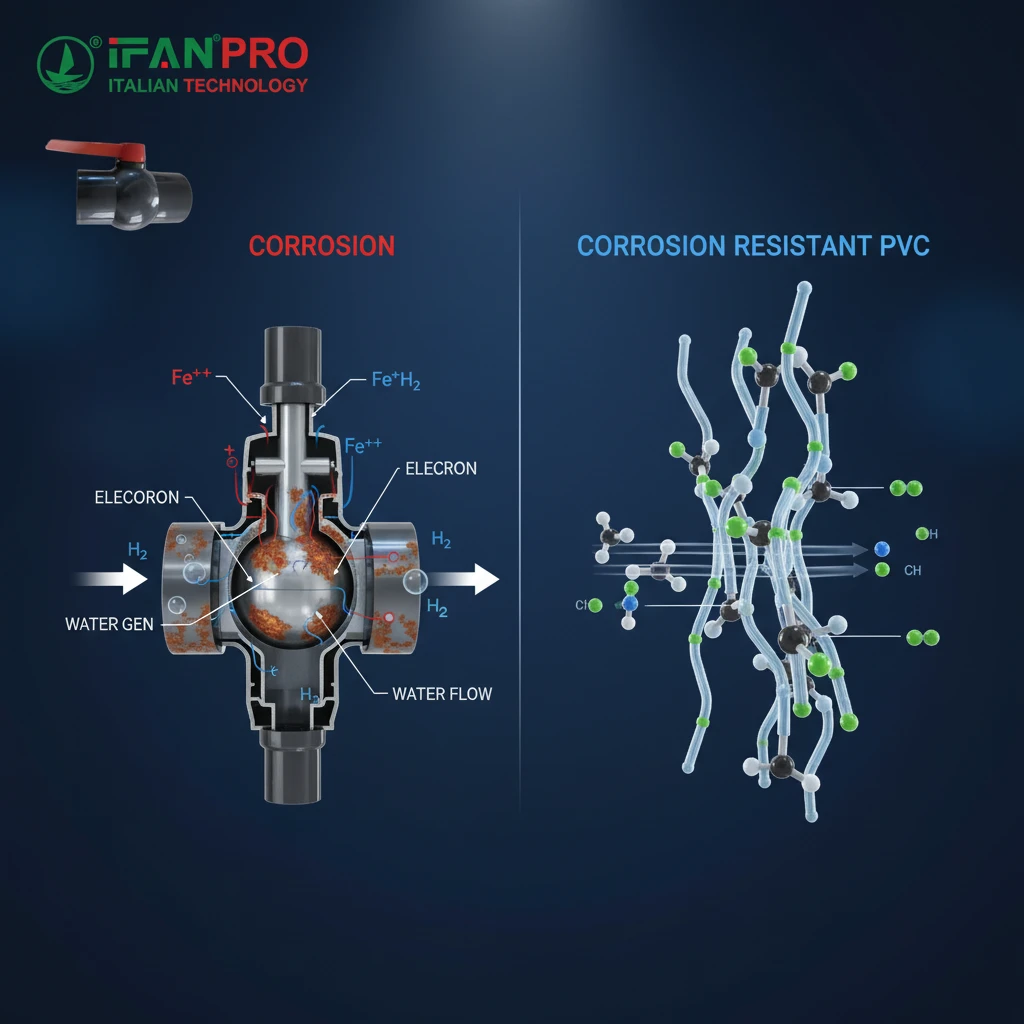

PVC’s corrosion resistance is crucial because municipal water and soil environments often contain chemicals and minerals that aggressively rust metal. PVC is inert, meaning it does not react with these elements, eliminating rust-based failures, preserving water quality, and ensuring the valve’s structural integrity for over 50 years without degradation.

The High Cost of Corrosion

For a city or town, a water system failure is a major crisis. It can mean service disruptions, costly emergency repairs, and wasted treated water. The main cause of these failures is often corrosion. Unlike iron or brass, PVC (Polyvinyl Chloride) is a thermoplastic that is completely immune to electrochemical corrosion (rust) and highly resistant to chemical corrosion.

Water in municipal systems isn’t always neutral. It can be slightly acidic or alkaline. It contains dissolved chlorine for disinfection and various minerals. Over time, these elements eat away at metal valves from the inside. Soil conditions around buried valves can also be highly corrosive. PVC valves, however, do not react with these substances. This means the valve wall thickness and strength remain constant year after year.

How Corrosion Affects Different Materials

Let’s look at what happens to different valve materials in a typical municipal setting:

| Valve Material | Reaction in Water/Soil | Long-Term Result |

|---|---|---|

| PVC | No chemical reaction. | Maintains original strength and dimensions. No rust scale. |

| Ductile Iron | Gradual rust (oxidation). | Wall thinning, reduced strength, rust particles in water. |

| Brass | Can dezincify in certain waters. | Weakens, becomes porous and prone to cracking. |

Benefits for Water Quality and Maintenance

This resistance directly translates to two major benefits:

- Water Purity: Corroding metal valves can leach metals like iron, lead, or copper into the water, affecting taste, color, and safety. PVC contributes no contaminants, keeping the water clean as it passes through.

- Zero Corrosion Maintenance: Municipal crews spend countless hours and budget replacing corroded valves. A PVC valve installed today won’t need replacement due to rust in the future. This allows maintenance teams to focus on other tasks, making the entire system more efficient and predictable.

In short, choosing PVC for corrosion resistance isn’t just about making the valve last longer; it’s about building a more reliable, safer, and more manageable water system for the entire community. It removes a major variable—material decay—from the equation of public utility management.

How Do PVC Ball Valves Ensure Reliable Flow Control in Water Networks?

A valve that leaks or sticks is useless. Municipalities need absolute reliability, and the design of PVC ball valves delivers it.

PVC ball valves ensure reliable flow control through their simple, quarter-turn design. A rotating ball with a through-port allows for full, unobstructed flow when open and provides a tight, drop-tight seal when closed. The PTFE (Teflon) seats create a reliable seal against the smooth PVC ball, ensuring no leaks even after thousands of cycles.

The Simplicity of the Ball Valve Design

Reliability in engineering often comes from simplicity. The ball valve is a perfect example. Its core mechanism is a ball with a hole drilled through it. When the handle is turned 90 degrees, the hole aligns with the pipe for full flow. Another 90-degree turn rotates the solid side of the ball into the path, blocking flow completely. This simple action is far more reliable than the multiple turns required for gate valves or the complex mechanics of butterfly valves.

For municipal workers in trenches or pump houses, this simplicity is key. They can quickly see if a valve is open or closed by the handle position. Operation is fast and requires less effort, which is crucial during an emergency shutdown.

The Key to Leak-Free Sealing

The sealing performance is what makes a ball valve truly reliable. The ball rotates between two flexible seals, typically made of PTFE. These seats gently press against the perfectly smooth surface of the PVC ball.

- In the closed position, the system water pressure itself helps push the seats tighter against the ball, enhancing the seal. This design makes it virtually impossible for water to leak past when closed.

- The smooth PVC ball does not corrode or pit. A corroded metal ball would quickly damage the soft seats, causing leaks. The non-stick property of PVC also prevents mineral deposits from building up on the ball, which could prevent a tight seal.

Comparison of Valve Types for Municipal Use

| Valve Type | Sealing Mechanism | Reliability Concern in Water Systems |

|---|---|---|

| PVC Ball Valve | PTFE seats seal against a smooth polymer ball. | Excellent. Resists scaling and corrosion; consistent seal. |

| Metal Gate Valve | A wedge presses against metal seats. | Can corrode open or shut; seats wear; may leak over time. |

| Butterfly Valve | A disc compresses a rubber liner against the valve body. | The rubber liner can degrade or extrude; disc shaft can leak. |

Performance in Daily and Emergency Use

This reliability is tested in two main scenarios. First, in daily operation for system isolation during repairs, a PVC ball valve will shut off flow completely every time. Second, and most importantly, during a major line break, crews can depend on these valves to isolate the damaged section quickly and effectively, minimizing water loss and service impact.

The combination of a corrosion-free body, a smooth rotating ball, and durable seals makes the PVC ball valve a fundamentally reliable component. It performs the same way on its first use as it will on its thousandth, giving municipal engineers and operators a dependable tool for managing their water network.

What Makes PVC Ball Valves Cost-Effective for Large-Scale Municipal Projects?

City budgets are tight. Every dollar must deliver long-term value, and PVC ball valves excel at providing a low total cost of ownership.

PVC ball valves are cost-effective for municipal projects due to low initial purchase price, fast and easy installation requiring less labor, and near-zero maintenance costs over their 50+ year lifespan. When you account for the avoided costs of corrosion repairs, valve replacements, and water loss, PVC offers the lowest total cost of ownership compared to metal alternatives.

Analyzing the Total Cost of Ownership

For a large-scale municipal project involving thousands of valves, the decision cannot be based on sticker price alone. Project managers must consider the Total Cost of Ownership (TCO), which includes purchase, installation, operation, maintenance, and replacement over the asset’s life.

PVC ball valves have a clear advantage in almost every category. First, the raw material and manufacturing cost for PVC is significantly lower than for ductile iron, brass, or stainless steel valves. This upfront saving is immediately apparent.

Installation and Labor Savings

The savings continue during installation. PVC valves are much lighter than metal ones. A crew can handle and install them without heavy machinery. The joining method—solvent cementing—is quick, clean, and requires less skilled labor compared to welding, threading, or flanging metal valves. This translates directly into lower labor costs and faster project completion times. For a project spanning miles of pipeline, these time and labor savings are enormous.

The Biggest Savings: Maintenance and Longevity

However, the most dramatic cost savings occur after installation, during the decades of operation.

- No Corrosion Maintenance: As established, PVC does not rust. A municipality will never spend money sandblasting, painting, or replacing a PVC valve due to external corrosion.

- Reduced Operational Costs: The smooth bore and excellent flow characteristics of a full-port PVC ball valve reduce pumping energy costs compared to more restrictive valve types.

- Longevity and Avoided Replacement: A properly installed PVC valve in a municipal system has a service life expectation of 50-100 years. Metal valves, especially in corrosive environments, may require multiple replacements within that same period. The cost of digging up a street, shutting off water, and replacing a failed valve can be 10-20 times the cost of the valve itself.

Total Cost of Ownership Comparison (Per Valve, 50-Year Period)

| Cost Category | PVC Ball Valve | Ductile Iron Ball Valve |

|---|---|---|

| Initial Purchase Price | $ | $$ |

| Installation Labor & Equipment | $ | $$ |

| Rust Prevention / Painting | $0 | $$ |

| Replacement Due to Corrosion | 0 times | 1-2 times (est.) |

| Total Cost (Estimate) | $$ | $$$$ |

The table shows that while the initial price difference might be modest, the long-term cost divergence is massive. By choosing PVC, municipalities invest in predictable, low-maintenance infrastructure. They free up future budgets for other critical needs instead of repeatedly funding the same corrosion repairs. This long-term financial predictability is the true definition of cost-effectiveness for public works.

Why are PVC Valves Preferred Over Metal in Corrosive Water Conditions?

Some water is just tough on metal. In these challenging conditions, PVC isn’t just an alternative; it’s the only sensible choice.

PVC valves are preferred over metal in corrosive water conditions because they are chemically inert. They do not deteriorate in acidic water, aggressive soils, or water with high chlorine or mineral content. This eliminates valve failures, prevents water contamination from metal leaching, and ensures system reliability where metal valves would rapidly degrade.

Defining “Corrosive Water Conditions”

Not all water is the same. Several common conditions in municipal water systems create a highly corrosive environment for metals:

- Low pH (Acidic Water): Water from certain sources or affected by environmental factors can be acidic. This aggressively attacks metal, accelerating rust and dezincification.

- High Chlorine/Chloramine: Used for disinfection, these chemicals are highly oxidizing and accelerate the corrosion of iron and steel.

- Soft, Aggressive Water: Soft water with low mineral content is actually more corrosive to metal pipes and valves as it seeks to dissolve minerals.

- Stray Electrical Currents: In areas with poor grounding, stray currents in the soil can cause extremely rapid electrolytic corrosion of buried metal valves.

PVC as the Inert Solution

In all these scenarios, PVC remains completely stable. Its polymer structure does not conduct electricity and does not participate in electrochemical or acid-base reactions. It is a passive barrier. This means the valve’s performance—its ability to open, close, and seal—is completely unaffected by the chemistry of the water flowing through it or the soil surrounding it.

Material Performance in Specific Corrosive Scenarios

| Corrosive Condition | Effect on Metal Valves | Performance of PVC Valves |

|---|---|---|

| Acidic Water (Low pH) | Rapid internal corrosion, wall thinning, failure. | No effect. Material integrity remains unchanged. |

| High Chlorine Disinfection | Accelerated oxidation (rust) and pitting. | No effect. PVC is resistant to strong oxidizers. |

| Brackish or Saltwater Intrusion | Severe galvanic and pitting corrosion. | Excellent resistance. Widely used in marine applications. |

| Electrolytic Corrosion | Can corrode through a wall in months. | Immune. Non-conductive material. |

Case Study: Avoiding Recurring Failures

Consider a municipal well field with slightly acidic water. A town installs brass valves. Within 5-7 years, the valves begin to fail from dezincification—they become porous, crumble, and leak. The town replaces them with expensive stainless steel valves. These last longer but eventually suffer from pitting corrosion. Each replacement costs thousands in parts and labor.

The permanent solution is to install PVC valves. Once installed, the material compatibility issue is solved forever. The maintenance log for that well field no longer has recurring entries for “valve replacement due to corrosion.” This transforms a chronic, predictable expense into a closed, one-time cost.

For engineers designing systems in known corrosive areas, PVC valves are not merely a preference; they are a risk-mitigation strategy. They specify PVC to ensure the system’s longevity and to guarantee that the water delivered to homes remains free of corrosion byproducts, regardless of the source water’s challenging chemistry.

Conclusion

PVC ball valves offer unmatched corrosion resistance, reliable operation, and long-term cost savings for municipal water systems. For durable, certified PVC ball valves that meet the demands of public utilities, specify IFAN for your next infrastructure project.

Commentaires récents