I once saw a PVC valve shatter under unexpected pressure surge, flooding a pump room. That moment taught me that material choice is critical, not just convenient.

A standard PVC pump valve can handle moderate pressure, but it is generally not suitable for truly high-pressure flow applications. Its maximum working pressure decreases significantly with temperature, and it risks sudden brittle failure under pressure spikes or sustained high stress, making it a safety concern in demanding systems.

If you are considering PVC for a pressure application, understanding its precise limits is crucial. Let’s break down the key factors that determine if a PVC valve is the right choice for your system.

What is the Maximum Pressure Rating for a Standard PVC Pump Valve?

Many assume a valve is a valve, but material dictates strength. I frequently review system schematics where this oversight creates risk.

The maximum pressure rating for a standard Schedule 80 PVC pump valve is typically between 150 to 200 PSI at room temperature (73°F / 23°C). However, this rating is for water only and drops sharply as the fluid temperature increases. Always check the manufacturer’s specific rating stamped on the valve body, as it is the legal limit.

Understanding Pressure Ratings

The pressure number on a valve isn’t just a suggestion; it’s a critical safety threshold. For PVC valves, this rating, often called the “maximum working pressure,” is determined through standardized tests. It indicates the maximum continuous pressure the valve can safely withstand without deforming or failing.

It’s vital to know that this rating is not static. It applies under very specific conditions: primarily, a fluid temperature of 73°F (23°C). The moment you introduce hotter water or chemicals, the material weakens. Also, this rating is for non-shock, steady pressure. Systems with water hammer (rapid pressure surges from pumps starting/stopping or quick-closing valves) create instantaneous pressures that can far exceed the working rating and cause immediate failure.

Key Factors Influencing the Real-World Limit

Several factors make the printed rating an ideal maximum, not a guaranteed performance level.

- Schedule/Class: PVC pipes and valves come in different wall thicknesses. Schedule 40 is common but thinner. Schedule 80 has a thicker wall and a higher pressure rating. Never mix a Schedule 80 valve with Schedule 40 piping in a high-pressure line, as the pipe will fail first.

- Chemical Compatibility: The pressure rating is based on water. If your fluid is a chemical, solvent, or oil, it can attack the PVC, causing it to become brittle and lose strength long before it reaches its rated pressure. Always consult chemical resistance charts.

- Age and UV Exposure: PVC becomes more brittle over time, especially if exposed to sunlight. An old PVC valve will not handle pressure as well as a new one.

- Installation Stress: Overtightening or misalignment during installation can create stress points (called “notch effects”) that dramatically lower the pressure at which a crack can start.

Common PVC Valve Pressure Ratings (Water @ 73°F / 23°C)

This table gives a general overview, but you must verify with your specific product data sheet.

| Valve Type & Material | Typical Schedule | Maximum Working Pressure (Approx.) | Best For |

|---|---|---|---|

| PVC Ball Valve | Schedule 80 | 150 – 200 PSI | Low to moderate pressure water, irrigation, drainage. |

| PVC True Union Ball Valve | Schedule 80 | 150 PSI | Systems requiring frequent disassembly for maintenance. |

| PVC Diaphragm Valve | Schedule 80 | 150 PSI | Slurries or fluids with particulates where sealing is key. |

| CPVC Ball Valve | Schedule 80 | 100 PSI @ 180°F | Hot water applications up to 180°F, but at lower pressure. |

In summary, while 150-200 PSI might sound high, it is the best-case scenario for cool water. For a truly high-pressure system (commonly considered 300 PSI and above), PVC is operating at its absolute limit and presents a significant risk.

Why Does Temperature Affect the Pressure Capacity of PVC Pump Valves?

A client learned this the hard way after a PVC valve failed on a sun-heated outdoor line. The pressure was fine, but the summer heat weakened the material.

Temperature directly affects the pressure capacity of PVC valves because PVC is a thermoplastic. As it gets hotter, the material softens and loses its structural strength (tensile strength and modulus of elasticity). This means the same valve that holds 200 PSI at room temperature may safely hold only 100 PSI or less at 120°F.

The Science of Thermoplastic Materials

PVC, like all plastics, is a polymer with long chains of molecules. At room temperature, these chains are relatively rigid and locked in place, giving the material its strength. When you add heat, you add energy. This energy causes the polymer chains to vibrate more and move more freely. Think of it like a hard wax candle versus a soft, warm candle. The warm wax is the same material but is much weaker and can deform easily.

This property is fundamental to thermoplastics. It allows them to be melted and molded (which is how valves are made), but it also means their performance is permanently tied to their operating temperature. Unlike metals, which retain most of their strength until very high temperatures, PVC’s strength curve drops steadily from the moment the temperature rises above room level.

Practical Consequences for System Design

This relationship is not linear, and it is not minor. It is a drastic reduction that system designers must calculate.

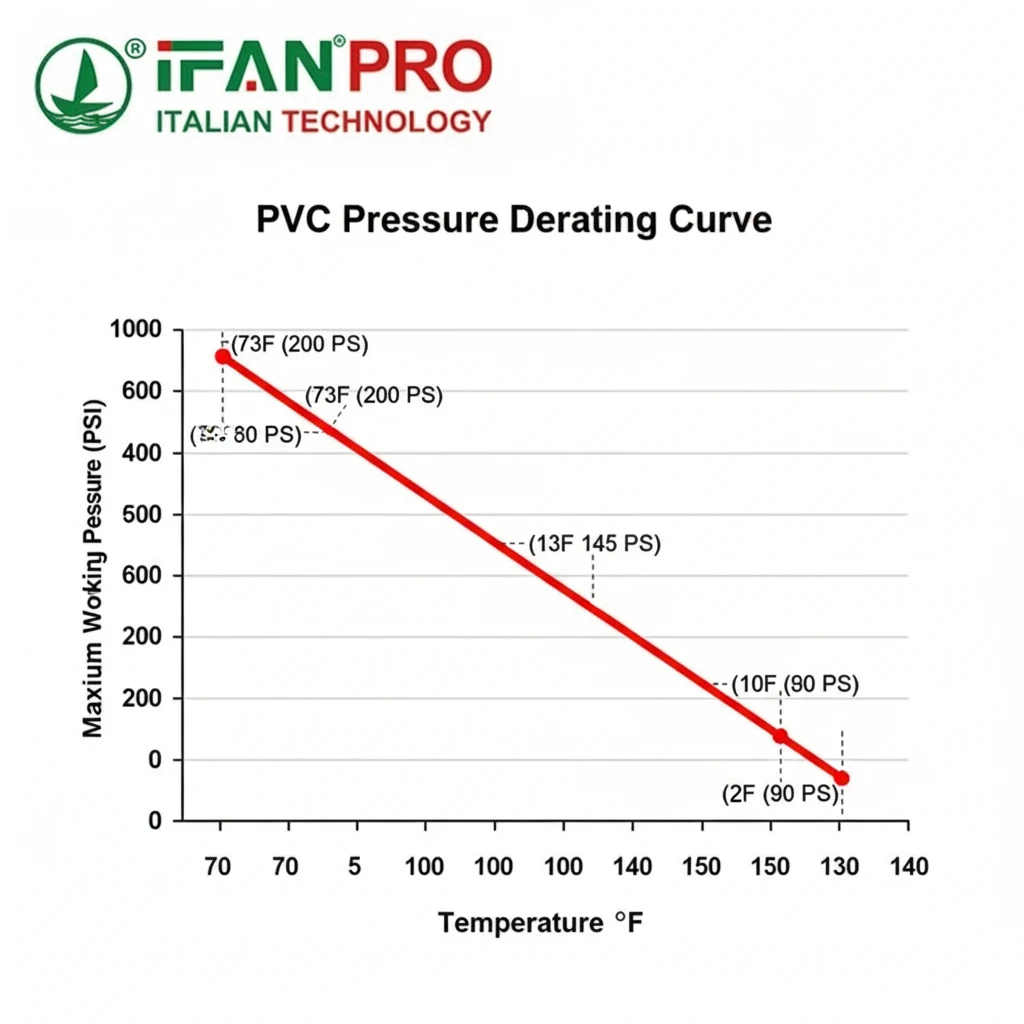

For example, a Schedule 80 PVC valve might have a pressure rating of 200 PSI at 73°F. If the fluid inside is 110°F (a common temperature for solar thermal loops or some industrial processes), its pressure rating might be derated by 50% or more. The manufacturer provides a derating chart or factor that you must apply. Ignoring this is the number one cause of premature PVC valve failure in non-cold water applications.

Temperature Derating Table for PVC (Example)

The numbers below are illustrative. You must use the chart from your valve’s manufacturer.

| Fluid Temperature | Approximate Pressure Derating Factor | Effective Max Pressure for a 200 PSI @ 73°F Valve |

|---|---|---|

| 73°F (23°C) | 1.00 | 200 PSI |

| 90°F (32°C) | 0.80 | 160 PSI |

| 110°F (43°C) | 0.62 | 124 PSI |

| 130°F (54°C) | 0.50 | 100 PSI |

| 140°F (60°C) | 0.40 | 80 PSI |

Important Note: Most standard PVC is not recommended for use above 140°F. CPVC, a chlorinated cousin, can handle higher temperatures (up to 200°F) but at proportionally lower pressures. For any system with variable or high temperature, this temperature-pressure relationship makes metal valves a far more stable and predictable choice.

What Are the Risks of Using PVC Valves in High-Pressure Water Systems?

Choosing the wrong valve to save cost can lead to catastrophic failure. I’ve documented failures that caused costly downtime and safety hazards.

The primary risks of using PVC valves in high-pressure systems are sudden brittle fracture (catastrophic shattering), failure from pressure surges (water hammer), and creep deformation over time. These failures can cause flooding, equipment damage, personal injury, and significant production or operational downtime.

Catastrophic Brittle Fracture

This is the most dangerous risk. Unlike ductile materials like brass or steel that may leak, bulge, or tear under extreme over-pressure, PVC typically fails in a brittle manner. This means it can crack and shatter explosively, sending sharp plastic shrapnel flying at high speed. The valve doesn’t just leak; it disintegrates. This poses an immediate physical safety threat to anyone nearby and can sever electrical lines or damage other equipment.

Vulnerability to Pressure Surges

Every water system experiences transient pressure spikes, known as water hammer. These occur when a pump starts or stops suddenly, or when a valve closes too quickly. The kinetic energy of the moving water converts into a pressure wave that travels through the pipes. In a metal system, the components can often absorb this shock. A PVC valve, already operating near its pressure limit, may not. The surge pressure can exceed the valve’s burst pressure in an instant, causing it to fail even though the “normal” system pressure is within spec. This is why PVC is rarely allowed in systems with fast-acting solenoid valves or frequent pump cycling.

Long-Term Creep and Stress Cracking

Even if a PVC valve survives the initial installation and handles steady pressure, it is susceptible to “creep.” Creep is the slow, permanent deformation of a material under constant stress. A PVC valve body under constant high pressure can slowly stretch and distort over months or years, eventually leading to a leak or failure at a fitting. Combined with environmental stress cracking from sunlight or chemical exposure, this creates a hidden time bomb. The valve might look fine one day and fail the next without an obvious change in system conditions.

Summary of Key Risks

The table below outlines the main dangers and their likely causes.

| Risk | Description | Likely Cause |

|---|---|---|

| Brittle Fracture | Valve shatters explosively. | Pressure exceeding burst rating; physical impact; extreme cold making PVC more brittle. |

| Joint Failure | Valve separates from pipe at threaded or glued connection. | Over-torqueing (threads); improper solvent welding (glue); sustained stress from misalignment. |

| Seal Failure / Leakage | Water leaks from stem or seat. | Deformation of body (creep) distorting seals; temperature cycling degrading seals. |

| Collapse / Deformation | Valve body distorts, impeding operation. | Excessive temperature softening material; sustained pressure causing creep. |

For a high-pressure system, these risks are unacceptable in most industrial, commercial, or critical residential applications (like well pump discharge). The potential cost of failure in terms of safety, water damage, and lost production far outweighs the lower initial cost of a PVC valve.

Which Valve Materials Are Recommended for High-Pressure Flow Applications?

When clients need reliability under pressure, we guide them away from plastic. The right material ensures safety and long-term performance.

For high-pressure flow applications, ductile metals like brass, stainless steel, and carbon steel are strongly recommended. These materials maintain their strength at higher temperatures, resist pressure surges, and fail in a safer, more predictable manner (usually by leaking first, not shattering).

Evaluating Material Properties for Pressure

Selecting a valve material for high pressure is about choosing a combination of strength, ductility, and temperature resistance. Metals excel in all three areas compared to plastics.

- Strength (Pressure Rating): Metals like forged brass or stainless steel have yield strengths that are orders of magnitude higher than PVC. It is common to find brass valves rated for 600 PSI or stainless steel valves rated for 1000+ PSI at ambient temperatures, and their ratings hold much more steadily as temperature increases.

- Ductility (Mode of Failure): This is a critical safety feature. Ductile materials stretch and deform before breaking. If a metal valve is over-pressurized, it will likely first leak at a seal or bulge, giving a visible warning. This allows the system to be shut down safely. PVC’s brittle fracture offers no such warning.

- Temperature Resistance: Metals retain their strength well into the hundreds of degrees Fahrenheit. A stainless steel valve rated for 1000 PSI at room temperature will still be rated for nearly that same pressure at 200°F or higher, making system design calculations much simpler and safer.

Recommended Material Options

Here are the most common and reliable choices, which IFAN supplies for demanding applications:

- Forged Brass Valves: An excellent all-around choice for high-pressure water applications up to around 600 PSI. They are corrosion-resistant for most water types, durable, and offer a good balance of cost and performance. Ideal for industrial water, irrigation booster pumps, and commercial building systems.

- Stainless Steel Valves (304 or 316): The premium choice for high pressure, corrosion, and temperature. SS valves are used in chemical processing, food and beverage, pharmaceuticals, seawater applications, and extreme pressure situations (well over 1000 PSI). Type 316 offers superior chemical resistance compared to 304.

- Carbon Steel Valves (with proper coating): Used in high-pressure steam, oil, and gas applications. They are very strong but susceptible to rust if not protected or used with the correct fluids. Typically found in industrial plant settings.

High-Pressure Valve Material Comparison Guide

Use this table to guide your initial selection.

| Valve Material | Max Pressure Range (Typical) | Max Temperature (Typical) | Key Advantages | Best Applications |

|---|---|---|---|---|

| Forged Brass | Up to 600 PSI | 400°F | Good strength, corrosion resistance, cost-effective. | High-pressure water lines, air compressors, irrigation. |

| Stainless Steel 304 | 1000+ PSI | 800°F | Exceptional strength, excellent corrosion resistance, durable. | Chemical plants, food processing, marine, high-purity water. |

| Stainless Steel 316 | 1000+ PSI | 800°F | Superior to 304 in harsh chemicals/chlorides. | Seawater, bleach solutions, harsh chemical processes. |

| Carbon Steel | 1500+ PSI | 1000°F | Extreme strength, handles high heat. | Steam lines, oil & gas pipelines, high-temperature industrial. |

| PVC (for reference) | 150-200 PSI | 140°F | Low cost, corrosion resistant. | Low-pressure cold water, drainage, non-critical irrigation. |

For any system where pressure regularly exceeds 150 PSI, involves temperature swings, or is critical to operations, investing in a metal valve from a trusted supplier like IFAN is the only prudent choice. We provide a full range of forged brass and stainless steel valves designed and tested specifically for high-pressure duty, ensuring your system’s integrity and safety.

Conclusion

PVC valves have their place in low-pressure, cool water systems, but they are not safe for true high-pressure applications. For reliable high-pressure flow, always choose ductile metal valves. IFAN offers a robust selection of forged brass and stainless steel pump valves designed to handle demanding pressure with complete safety.

Commentaires récents