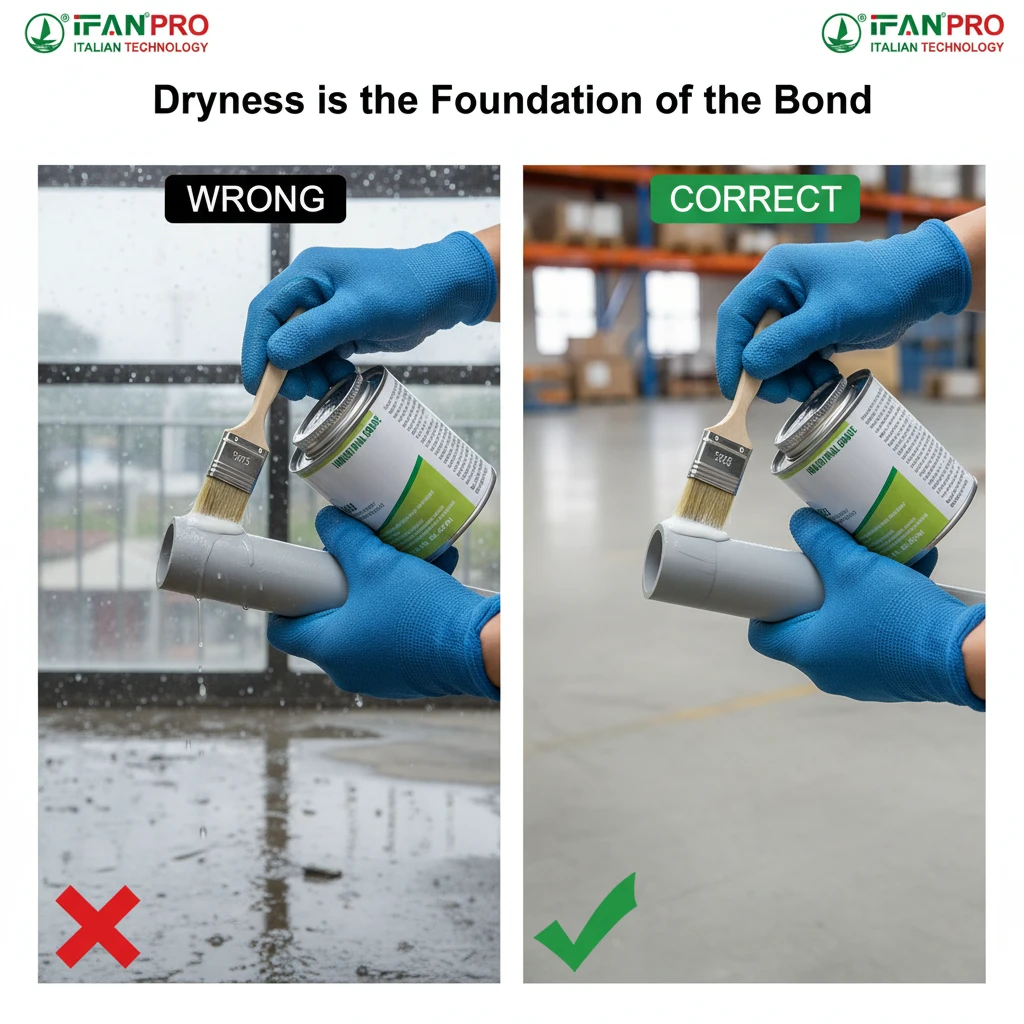

I once saw a newly installed PVC drain line fail a pressure test because of a few unseen water droplets. The leak was tiny, but the rework cost was huge. This taught me the critical, non-negotiable rule: PVC must be bone dry.

PVC pipes must be dry before gluing because PVC cement works by chemically melting and fusing the plastic surfaces together. Moisture creates a barrier that stops this chemical reaction, resulting in a weak, incomplete bond that is prone to leaks and failure under pressure, compromising the entire plumbing system’s integrity.

Sticking to this simple rule separates a professional, lasting installation from a future headache. Let’s break down exactly why moisture is the enemy of a good PVC joint.

How Does Moisture Prevent PVC Cement from Creating a Strong Chemical Weld?

Many think glue just “sticks” pipes together. In reality, it’s a welding process, and water stops it cold.

Moisture prevents a strong chemical weld because PVC cement is a solvent, not an adhesive. It must dissolve the PVC surfaces to fuse them. Water acts as a physical and chemical barrier, diluting the solvent and preventing it from properly softening the plastic, which leads to a brittle, grainy joint that lacks strength.

The Science of Solvent Welding

To understand why dryness is key, you must first understand how PVC “glue” actually works. It’s more accurate to call it “solvent cement.”

The process is not about sticking two things together with a sticky middle layer. Instead, the cement is a powerful chemical solvent. When you apply it to the pipe and fitting, it temporarily dissolves the top layer of the PVC plastic, turning it into a softened, gel-like state.

When you quickly push the pipe into the fitting and give it a quarter turn, you are mixing these two liquefied surfaces together. As the solvent evaporates, the PVC molecules from the pipe and fitting re-harden as one single, continuous piece of plastic. This is called a homogenous fused joint.

How Water Interferes with the Process

Now, imagine there is water present on the pipe or inside the fitting. Here’s what happens step-by-step:

- Barrier Creation: Water forms a microscopic layer between the PVC cement and the plastic surface. The solvent cannot reach the PVC to begin dissolving it.

- Dilution: The water mixes with and dilutes the solvent cement. A diluted solvent is less effective and works much more slowly.

- Premature Evaporation: Water can cause the volatile solvents in the cement to evaporate too quickly or unevenly, before they have time to properly soften the PVC.

- Poor Fusion: Instead of a clean, deep melt, you get a shallow, incomplete reaction. The PVC surfaces don’t fully integrate.

The result is a joint that looks okay on the outside but has a weak, grainy, or chalky structure on the inside. It hasn’t formed a true molecular bond.

Visualizing the Difference: A Good Joint vs. a Bad Joint

| Characteristic | A Proper, Dry Joint | A Moist, Poor Joint |

|---|---|---|

| Bond Type | Chemical weld (monolithic fusion) | Mechanical hold (like a weak glue) |

| Internal Structure | Smooth, continuous plastic | Grainy, chalky, or layered |

| Strength | As strong as the pipe itself | Significantly weaker |

| Failure Point | Pipe will break before the joint | Joint will fail (crack or leak) under stress |

In short, water prevents the necessary chemical reaction from occurring. You don’t get a weld; you get a faulty stick that is destined to fail.

What Problems Can Occur If You Glue PVC Pipes in Humid or Wet Conditions?

Ignoring the dry rule doesn’t just create a weak joint; it creates multiple points of failure that can show up immediately or years later.

Gluing PVC in wet conditions causes immediate problems like visible leaks and failed pressure tests, and long-term issues like chronic slow leaks, joint cracks from stress, and contamination from mold or bacteria growing in the incomplete bond, leading to system failure and costly repairs.

Immediate and Obvious Problems

The consequences of gluing wet PVC aren’t always hidden. Often, they show up right away, during testing or initial use.

- Failed Pressure Test: This is the most common immediate sign. When you pressurize the system with air or water to check for leaks, a joint made in damp conditions will often weep or spray. This means you must cut out the entire faulty section and start over, wasting time and materials.

- Visible Leaks at the Joint: Even without a formal test, you might see water dripping from a freshly made joint as soon as you turn on the water. This is a clear sign of a non-bond.

- Cloudy or Bubbled Cement Ring: A proper joint shows a clear, continuous bead of cement around the pipe entry point. A joint compromised by moisture might show a cloudy, whitish, or bubbled ring, indicating poor curing and air/water entrapment.

Long-Term, Hidden Failures

Some problems take months or years to appear, making them more dangerous and expensive.

- Chronic Slow Leaks: A joint might hold initially but develop a very slow leak over time. This water can damage building structures, insulation, and drywall before it’s ever noticed.

- Stress Cracking: A weak joint cannot handle the normal stresses in a plumbing system—water hammer (pressure surges), thermal expansion/contraction from hot water, or minor soil movement. It will crack at the joint line, causing a catastrophic rupture.

- Biological Contamination: In drain, waste, and vent (DWV) systems, an incomplete bond can leave microscopic gaps. These gaps can trap organic matter, becoming a breeding ground for bacteria and mold. This leads to odors and potential health hazards.

Risk Comparison Table

| Condition | Short-Term Risk (Within 1 year) | Long-Term Risk (1-10 years) | Repair Complexity & Cost |

|---|---|---|---|

| Slightly Damp Surface | May pass initial test; possible weep. | High chance of stress crack or slow leak. | Moderate (localized repair). |

| Wet or Soaking Pipe | Immediate test failure and visible leak. | Total joint failure likely. | High (section replacement, possible water damage). |

| High Humidity (>60%) | Slow curing, possible test failure. | Increased brittleness, risk of crack. | Moderate to High. |

The bottom line is simple: the problems caused by moisture are guaranteed. They might be instant or delayed, but they will happen, turning a simple plumbing job into a recurring repair nightmare.

What Are the Correct Steps to Ensure PVC Pipes Are Completely Dry Before Gluing?

Professional results come from a meticulous process, not luck. Here is the fail-proof method we use and recommend.

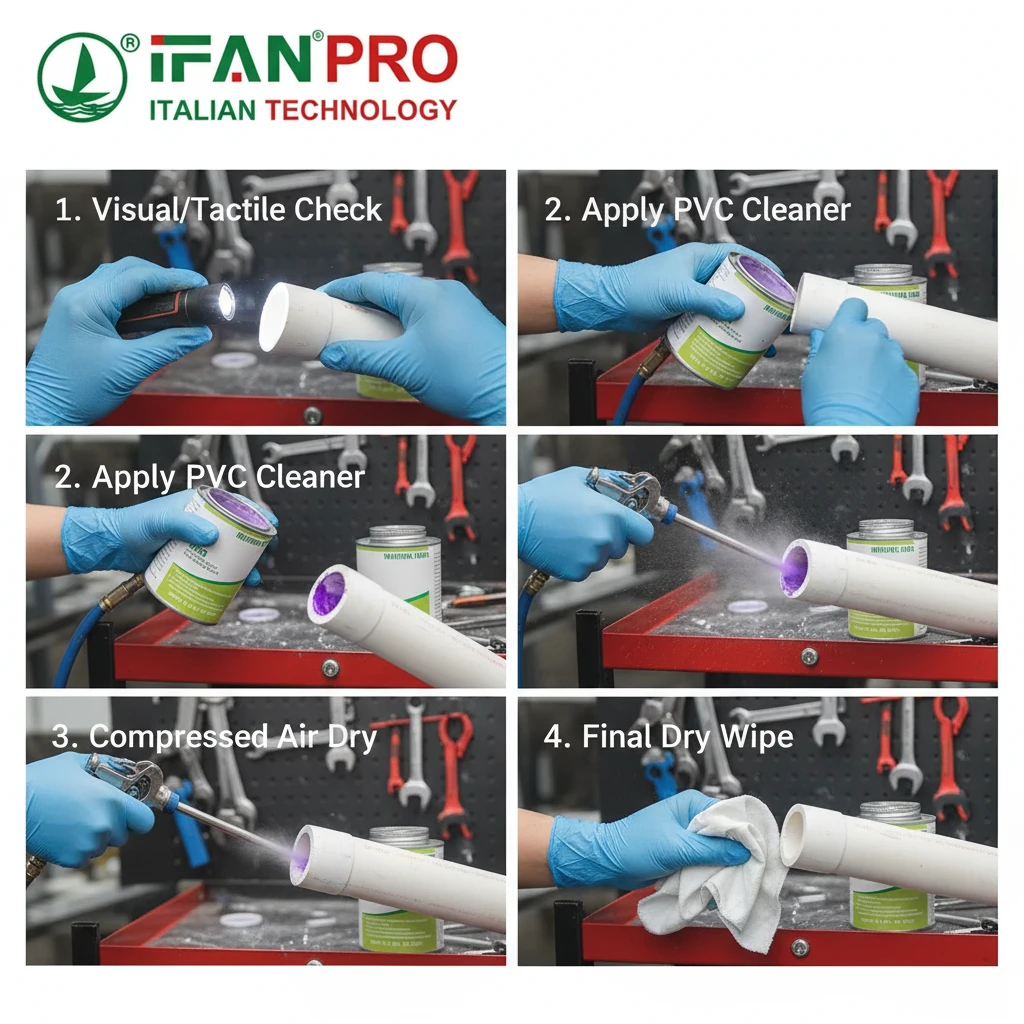

To ensure PVC pipes are completely dry, follow these steps: cut and deburr the pipe, clean both surfaces with PVC cleaner, visually inspect for water, use compressed air or a dry cloth to remove moisture, and allow sufficient time in a low-humidity environment. Never assume a pipe is dry—always verify.

The Step-by-Step Drying Protocol

A strong joint starts long before the cement comes out of the can. Follow this sequence every single time.

Step 1: Preparation and Cutting

First, ensure your work area is as dry as possible. Avoid working in rain, heavy dew, or direct sunlight that can cause condensation. Use a sharp PVC cutter or fine-tooth saw for a clean, square cut. After cutting, use a deburring tool or sandpaper to remove the plastic ridge (burr) from the inside and outside of the pipe. This burr can trap moisture and prevent a proper seal.

Step 2: The Essential Cleaning

This is the most skipped but critical step. Use a dedicated PVC cleaner/primer (often purple in color). Its job is not to glue, but to:

- Remove surface dirt, grease, and the plastic “glaze.”

- It evaporates any residual surface moisture.

- It slightly softens the surface, preparing it for the cement.

Apply it to the outside of the pipe and the inside of the fitting with the applicant brush. It will dry in seconds. If the surface was wet, you will see the cleaner streak or bead—this tells you it’s working.

Step 3: Active Drying Methods

After cleaning, take active measures:

- Compressed Air: This is the best method. Blow out the inside of the fitting and across the pipe end. It forces out droplets hiding in the pipe bell or socket.

- Dry, Lint-Free Rag: Push a clean rag into the fitting and twist it. Wipe the pipe end thoroughly. Use multiple rags if they become damp.

- Time: In cool or humid weather, simply wait a few extra minutes after cleaning to let any last traces evaporate.

Step 4: The Final Check

Right before applying cement, do a visual and tactile check. Look inside the fitting for a shiny sheen (indicating water). Run your finger along the pipe surface—it should feel perfectly dry and slightly rough from the cleaner, not cool or slick.

Tools for Ensuring a Dry Joint

| Tool | Purpose | Pro Tip |

|---|---|---|

| PVC Cleaner/Primer | Removes contaminants and surface moisture. | Always use it, even on new pipes. The color confirms coverage. |

| Compressed Air Canister | Blows out trapped water from fittings and pipe ends. | Essential for repairs where draining the line completely is hard. |

| Clean, Dry Rags | Wipes away standing water and moisture. | Keep a large bundle in a sealed bag to ensure they stay dry. |

| Moisture Meter (Advanced) | Gives a digital readout of surface moisture. | Useful in extremely humid climates for critical applications. |

Remember, “dry to the touch” is the minimum standard. For pressure systems, “bone dry” is the only standard. Rushing this process is the number one cause of joint failure in the field.

Do Professional Plumbing Codes Require Dry Conditions for PVC Pipe Solvent Welding?

This isn’t just a good tip—it’s the law of proper plumbing. Building codes formalize this critical requirement.

Yes, all major professional plumbing codes explicitly require dry conditions for PVC solvent welding. Codes like the International Plumbing Code (IPC) and manufacturer instructions mandate that surfaces be clean, dry, and free of moisture before applying solvent cement to ensure a reliable, code-compliant joint that passes inspection.

Code Language and Interpretation

Plumbing codes exist to ensure safety, health, and system longevity. The requirements for joining PVC are very clear.

The International Plumbing Code (IPC), which is the basis for most local codes in the US, states the following in its installation standards:

“Joint surfaces shall be clean and dry. Solvent cement shall be applied to all joint surfaces…“

This directive is unambiguous. “Dry” is a precondition alongside “clean.” An inspector has the right to reject work if there is evidence of improper joining, such as water stains on the pipe during assembly or the tell-tale cloudy joint ring caused by moisture.

Manufacturer Instructions as Law

Furthermore, plumbing codes also state that installations must follow the manufacturer’s printed instructions. Every can of reputable PVC solvent cement has dire warnings and clear steps. Here’s a typical excerpt from a major brand’s instructions:

“Surfaces must be dry. Do not use if raining or in damp conditions. Moisture will cause a weak bond leading to joint failure.”

When you use a product, you are legally and practically bound to follow its instructions. Ignoring the “dry” requirement means you are not installing the product as intended by its maker, voiding any warranty and violating code.

Consequences of Non-Compliance

Failing to follow this code requirement has real-world consequences:

- Failed Inspection: The most immediate result. The inspector will see the improper workmanship and will not approve the installation until the faulty joints are replaced.

- Liability: If a joint fails later and causes property damage (e.g., flooding, mold), an investigation can trace it back to improper installation against code. The installer or contractor can be held liable for all damages.

- Voided Warranty: Both the pipe manufacturer and the cement manufacturer will not honor warranty claims for failures linked to incorrect installation, including gluing wet surfaces.

Summary of Key Code-Compliant Practices

| Code Principle | Practical Action | Why It Matters |

|---|---|---|

| Surfaces shall be clean and dry. | Use PVC cleaner & dry with rag/air. | Forms the legal basis for a proper joint. |

| Follow manufacturer’s instructions. | Read and follow the steps on the cement can. | Instructions always specify “DRY” as the first condition. |

| Workmanship must prevent defects. | A wet joint is a known defect. | Protects the health and safety of the building occupants. |

In conclusion, keeping PVC dry isn’t just a best practice from experienced plumbers; it’s a written requirement in the rulebook that governs all professional plumbing work. It is the standard you must meet.

Conclusion

A dry pipe is the foundation of a leak-proof PVC system. For reliable, code-compliant PVC pipes and fittings that perform when it counts, trust IFAN for your project supply needs.

Commentaires récents