We received a frantic call from a client whose system leaked after a valve replacement. The issue? A mismatched valve. This cemented the importance of choosing the right component, like a dedicated PPR ball valve.

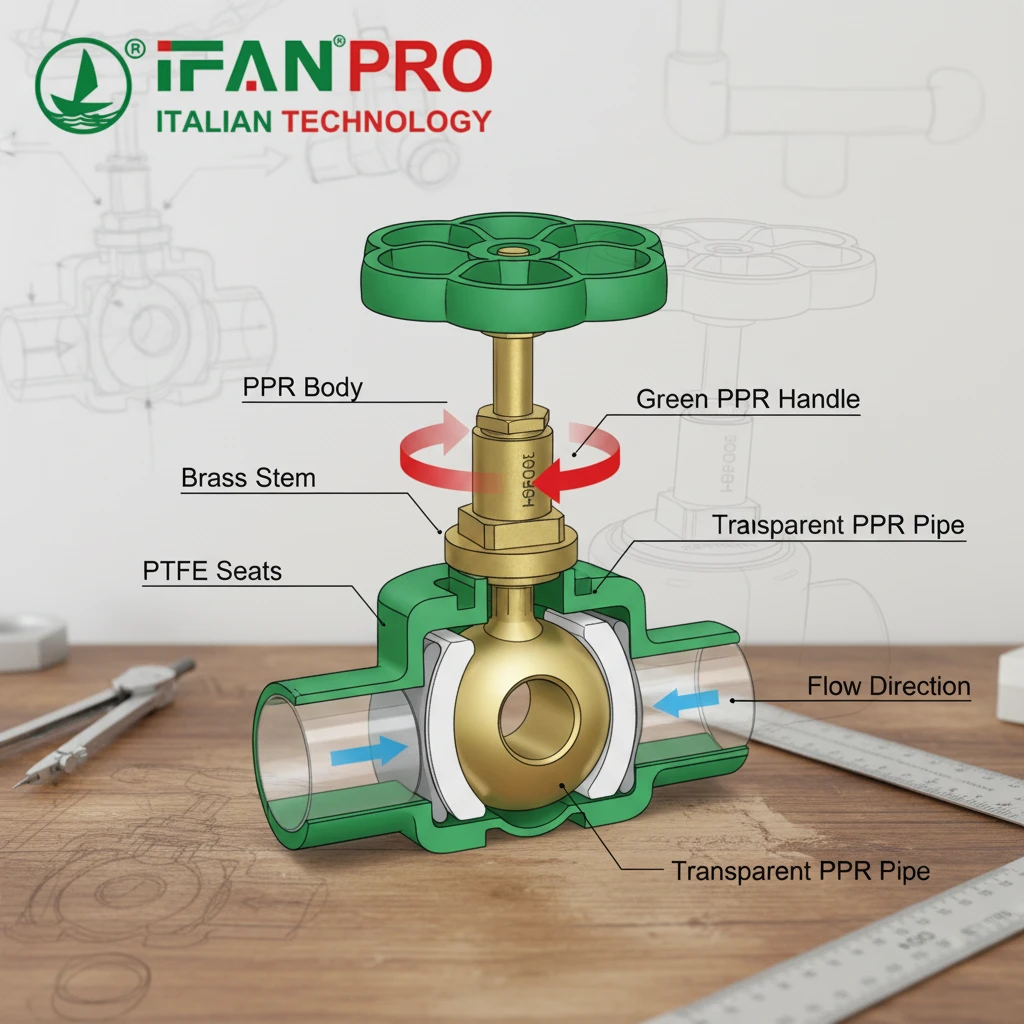

A water ball valve with a PPR connection is a quarter-turn valve that controls flow using a rotating ball with a hole. It seals via tight compression between the ball and durable seats (often PTFE), while the PPR ends are permanently fused to the piping system using heat, creating a monolithic, leak-proof joint at the connection points.

This simple yet reliable component is crucial for any PPR system. Let’s break down how it works, how to install it, and why it’s the preferred choice.

How Does a Water Ball Valve with PPR Connection Operate and Seal?

A client once thought all valves were the same, until a generic valve failed. The integrated design of a true PPR ball valve makes all the difference.

This valve operates by turning its handle 90 degrees, which rotates an internal ball with a through-hole to start or stop flow. It seals tightly because the ball presses against flexible polymer seats (like PTFE) within the valve body, while the PPR socket ends are thermally fused to the pipes, preventing leaks at the system connections.

Understanding the Core Mechanism

The operation is brilliantly simple. Inside the valve body is a chamber containing a ball (the “ball” in ball valve). This ball has a hole drilled straight through its center. When you turn the handle so that the hole aligns with the pipe direction, water flows freely. When you turn the handle 90 degrees (a quarter-turn), the solid side of the ball blocks the pipe, stopping the flow completely.

This on/off action is much faster and more reliable than multiple-turn valves like gate valves. You get immediate, full flow or immediate, full shutoff.

The Two Critical Sealing Points

A valve must seal in two places: internally to stop water from passing through the ball, and externally where it connects to the pipes.

1. Internal Seal (Ball to Seat):

The ball does not seal directly against the metal or plastic body. Instead, it seals against rings called “seats,” typically made from a resilient material like PTFE (Teflon). These seats are held in place behind the ball. When the valve is closed, system pressure helps push the ball slightly against the downstream seat, creating a very tight seal. This design provides excellent leak-tight closure for water.

2. External Seal (Valve to Piping System):

This is where the PPR connection is key. A true PPR ball valve has molded PPR sockets (female ends) on both sides. You don’t use threads or separate adapters. You directly heat-fuse the PPR pipe into these sockets, exactly like joining two pipes. The plastic from the pipe and the valve socket melt together, cool, and become one solid piece. This fusion joint is fundamentally leak-proof and is immune to the loosening that can happen with threaded connections over time.

Comparison of Valve Connection Types

Here is why the fused PPR connection is superior for PPR systems.

| Connection Type | How It Works | Risk of Leak at Connection |

|---|---|---|

| PPR Socket Fusion | Pipe and valve socket are heated and fused into one piece. | Extremely Low |

| Threaded (Male/Female) | Pipe thread is screwed into valve thread, often with sealant tape. | Moderate (Can vibrate loose or suffer from thread wear) |

| Compression Fitting | A nut tightens a ferrule onto the pipe. | Moderate (Overtightening can damage pipe; thermal cycling may loosen it) |

In summary, the reliability comes from the combination of a simple, robust quarter-turn mechanism and the permanent, fused PPR connections. This dual-sealing approach is why these valves are trusted for critical shutoff points in residential and commercial plumbing.

What Are the Steps to Install a Ball Valve with PPR Connections Correctly?

We’ve seen leaks start not at the valve itself, but from poor installation practices around it. Following a correct procedure is non-negotiable.

To install it correctly, first plan its position and cut the PPR pipe squarely. Ensure the valve is in the OPEN position. Then, simultaneously heat the valve socket and the pipe end with a fusion welder, join them quickly and hold straight without twisting, and allow a full cool-down time before pressurizing the system.

Pre-Installation Planning and Safety

A successful installation starts before you heat the welder. First, decide the exact location for the valve, ensuring there is enough straight pipe on both sides and that the handle has room to rotate freely. Mark the pipe where you will cut. Crucially, before any cutting, turn the valve handle to the fully OPEN position. Heating and installing a valve while it is closed can trap expanding air inside, distorting the plastic seats.

Gather all tools: a dedicated PPR pipe cutter (for a perfectly square cut), a fusion welder with the right-sized heating heads, a marker, and a measuring tape. Wear protective gloves, as the heating plate and freshly heated plastic are very hot.

The Step-by-Step Fusion Process

Follow these steps precisely for each connection (inlet and outlet side):

- Cut and Prepare the Pipe: Use the PPR cutter. A clean, 90-degree cut is essential for a uniform fusion joint. After cutting, lightly deburr the outer edge of the pipe with a utility knife or deburring tool. Clean the pipe end and the inside of the valve socket from any dust or moisture.

- Heat the Parts: Mount the correct-sized heating heads on the welder. Let it reach the recommended temperature (typically around 260°C / 500°F). With the valve OPEN, insert the pipe end and the valve socket onto the heating heads simultaneously. Push them gently onto the heaters until a small bead of melted plastic forms around the collars.

- Remove and Connect: After the recommended heating time (see the welder/pipe manufacturer’s chart), quickly remove both the pipe and valve from the heater. In one smooth, straight motion, push the pipe fully into the valve socket. Do not twist or turn them. You must align the valve orientation correctly before this step, as you cannot adjust it after joining.

- Hold and Cool: Hold the pipe and valve firmly together, perfectly straight, for the specified cooling time. This allows the melted plastics to solidify completely, forming the bond. Disturbing the joint during this time will weaken it. After this initial hold, you can set it down, but avoid stressing the joint until it has cooled completely to room temperature.

Common Installation Mistakes to Avoid

Here is a table of pitfalls we commonly see and how to avoid them.

| Mistake | Consequence | How to Avoid |

|---|---|---|

| Cutting pipe at an angle | Uneven fusion, leading to a weak joint and potential leak. | Use a dedicated PPR pipe cutter, not a regular saw. |

| Heating with valve closed | Trapped air expands, deforming internal seals. | Always verify valve is OPEN before heating. |

| Twisting during connection | Creates swirls and weak spots in the fused material. | Push straight in; align valve handle direction before joining. |

| Insufficient heating or cooling time | A cold joint (underheated) or a disrupted joint (undercooled) will fail. | Follow the welder manufacturer’s time chart strictly. |

| Applying force to the joint before full cooling | Can crack or misalign the joint while plastic is soft. | Support the valve and pipe so no weight strains the fresh joints. |

Once both sides are fused and fully cooled, you can test the system. Leave the valve open during initial pressure testing to ensure no debris gets caught against the closed ball.

What Are the Benefits of Using Ball Valves in PPR Piping Systems?

A contractor told us his switch to PPR ball valves reduced callbacks for valve issues by over 90%. The benefits are real and measurable.

The benefits include reliable, bubble-tight shutoff, fast quarter-turn operation, minimal maintenance due to no internal lubrication needs, full port design for low flow resistance, and perfect material compatibility as the valve body and PPR sockets are fused into one homogeneous system.

Unmatched Reliability and Control

The primary job of a shutoff valve is to be 100% reliable when you need to stop water. PPR ball valves excel here. The quarter-turn mechanism is simple with few moving parts, meaning there’s less to go wrong compared to multi-turn valves like gate or globe valves. The PTFE seats provide a resilient, water-tight seal against the polished ball, ensuring “bubble-tight” shutoff that doesn’t leak or drip over time.

Operation is also a major benefit. A simple 90-degree turn is all it takes, even in tight spaces. You can instantly see if the valve is open (handle in line with pipe) or closed (handle perpendicular). This is much faster than cranking a wheel handle dozens of times.

Low Maintenance and Efficient Flow

Unlike some older valve types, modern PPR ball valves require zero internal lubrication. Their design is self-contained and non-corrosive. Once installed, they can sit for years and still function perfectly when needed. This “install-and-forget” characteristic is highly valued.

Furthermore, most ball valves for plumbing are “full port” or “full bore.” This means the hole through the ball is the same diameter as the pipe’s inner diameter. When open, it creates virtually no restriction to water flow. This maintains high system pressure and efficiency, unlike reduced-port valves which can create pressure drops.

System Integrity and Compatibility

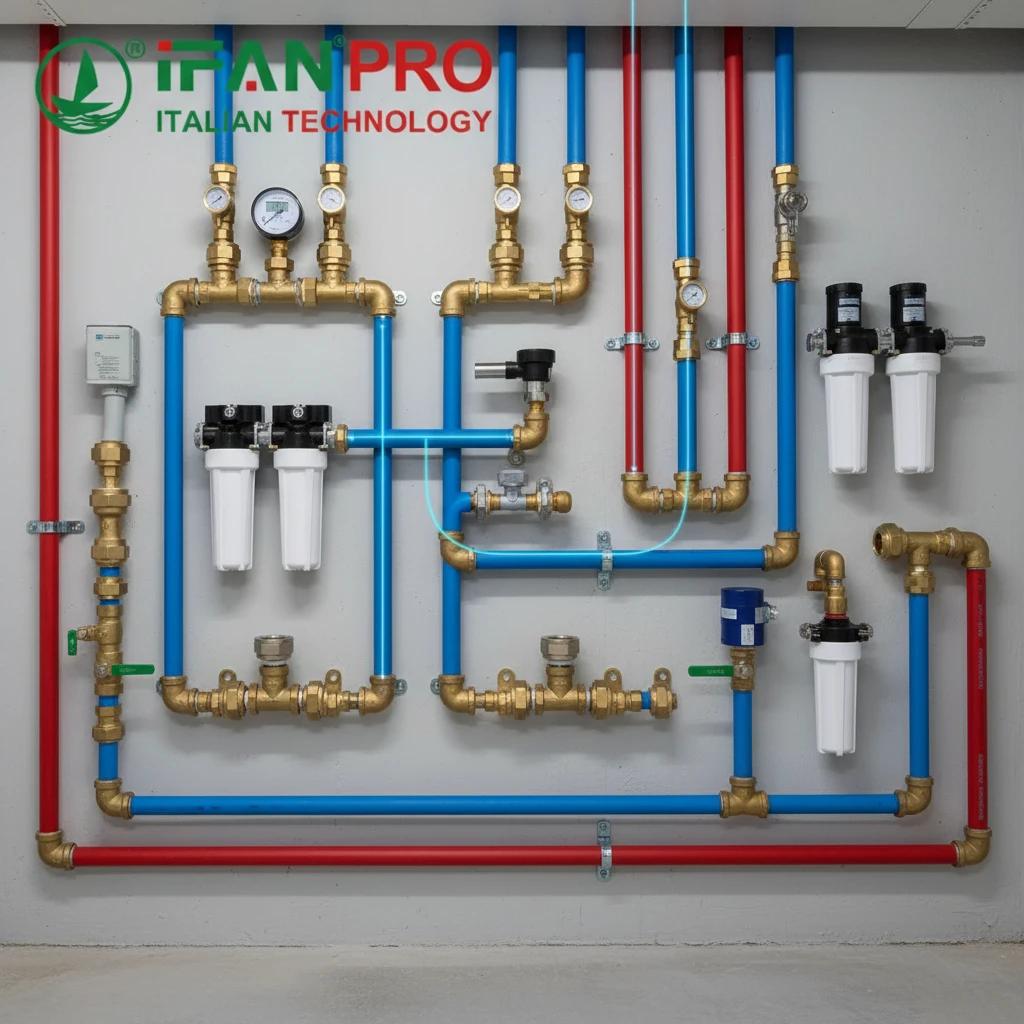

This is the most critical benefit for PPR systems. A valve with molded PPR sockets is made from compatible polypropylene. When you fuse it into the pipeline, you create a homogeneous system.

- Same Thermal Expansion: The valve and pipe expand and contract at the same rate with temperature changes, preventing stress.

- No Galvanic Corrosion: There are no dissimilar metals to corrode (a common problem with brass valves in steel or copper systems).

- Perfect Seal: The fusion joint is permanent and superior to any mechanical seal.

- Certified Safety: The entire assembly, valve included, maintains the drinking water certification of the PPR material.

Benefit Comparison Chart

| Benefit | PPR Ball Valve | Typical Brass Gate Valve |

|---|---|---|

| Operation Speed | Quarter-turn (Fast) | Multi-turn (Slow) |

| Seal Reliability | Bubble-tight seats | Can wear and leak over time |

| Maintenance Needs | None | Stem packing may need adjustment/replacement |

| Flow Resistance | Very Low (Full Port) | Moderate |

| Connection to PPR Pipe | Homogeneous Fusion Joint | Requires a separate threaded adapter |

| Corrosion Resistance | Excellent (Plastic) | Good, but can suffer from dezincification |

In short, using a dedicated PPR ball valve isn’t just adding a component; it’s extending the integrity and performance of the entire PPR system.

How Do You Select the Right PPR Ball Valve Size and Pressure Rating?

Selecting the wrong valve is a common and costly error. We helped a client avoid a system redesign by catching a pressure rating mismatch early.

Select the right size by matching the valve’s nominal diameter (DN) to your PPR pipe’s outer diameter (e.g., DN25 for 25mm pipe). Choose the pressure rating (PN) based on your system’s maximum operating pressure and water temperature, always ensuring the valve’s PN rating meets or exceeds the system’s requirements.

Selecting the Correct Size (Diameter)

Size selection is straightforward but critical. You must match the valve to the pipe size. PPR systems use nominal diameters based on the pipe’s outer diameter.

- Identify Your Pipe Size: Measure the outer diameter (OD) of your existing PPR pipe. Common sizes are 20mm, 25mm, 32mm, 40mm, etc.

- Match the Nominal Diameter (DN): The valve is marked with a DN number (e.g., DN20, DN25). DN20 corresponds to a 20mm outer diameter PPR pipe, DN25 to 25mm, and so on. This is the most important match. A valve that is too small will restrict flow; one that is too large will require reducers and complicate installation.

Important: Do not confuse PPR pipe sizes with iron pipe thread sizes (like 1/2″, 3/4″). They are different systems. Always use the PPR metric DN size.

Understanding and Choosing Pressure Rating (PN)

The Pressure Nominal (PN) rating is a number that indicates the valve’s maximum working pressure at a standard temperature (usually 20°C). Common ratings are PN10, PN16, PN20, and PN25.

Selecting the right PN is a two-step process:

Step 1: Know Your System’s Pressure. What is the maximum sustained pressure in your plumbing system? This is often determined by your pump or street pressure plus any static head from building height. For most residential applications, PN16 or PN20 is standard. For high-rise buildings or industrial applications, PN25 or higher may be needed.

Step 2: Factor in Temperature. The PN rating decreases as water temperature increases. A valve rated PN20 at 20°C will have a lower maximum pressure at 70°C. The manufacturer provides de-rating tables.

Pressure-Temperature Relationship Guide

The table below shows a general example of how pressure rating changes with temperature. Always consult the specific manufacturer’s data for your valve.

| Valve PN Rating | Max Working Pressure at 20°C | Approx. Max Working Pressure at 60°C* | Typical Application |

|---|---|---|---|

| PN10 | 10 bar (145 psi) | ~6 bar (87 psi) | Low-pressure cold water lines. |

| PN16 | 16 bar (232 psi) | ~10 bar (145 psi) | Standard residential hot & cold water. |

| PN20 | 20 bar (290 psi) | ~12.5 bar (181 psi) | Residential & commercial systems, higher pressure. |

| PN25 | 25 bar (363 psi) | ~16 bar (232 psi) | High-pressure mains, industrial applications. |

| *Values are approximate for illustration. |

Final Selection Checklist

Use this simple list when choosing your valve:

- [ ] Diameter: Valve DN matches PPR pipe OD (e.g., DN25 for 25mm pipe).

- [ ] Pressure Rating: Valve PN rating is suitable for your system’s maximum pressure and temperature (e.g., PN16 or PN20 for most homes).

- [ ] Material & Certification: Valve is made from approved PPR material and has relevant drinking water certifications (e.g., NSF/ANSI 61).

- [ ] Connection Type: Valve has PPR socket ends for direct fusion (not threaded ends).

- [ ] Operation: Handle type (lever or butterfly) is suitable for the space and intended use.

By following this method, you ensure the valve will perform safely and reliably for the life of your piping system.

Conclusion

Choosing and installing the correct PPR ball valve ensures reliable control and long-term system integrity. For guaranteed quality and performance, specify IFAN‘s range of certified PPR ball valves for your next project.

Commentaires récents