I’ve seen too many plumbing disasters from old, leaky pipes. That frustration led me to discover PPR systems, which now solve these issues effortlessly for my clients at IFAN.

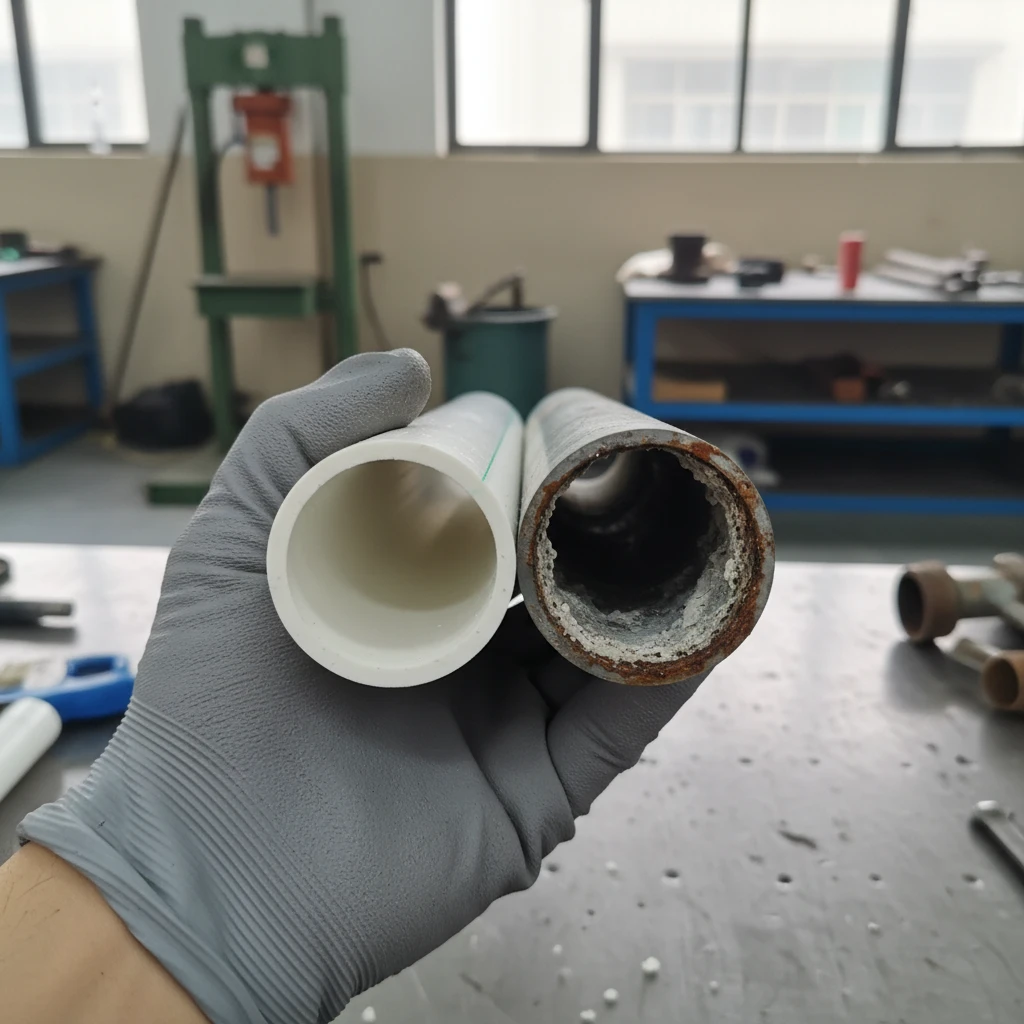

A PPR piping system is a complete network made from Polypropylene Random Copolymer pipes and fittings, joined by heat fusion to create a seamless, leak-proof plumbing solution for transporting hot and cold water in buildings. It is known for its durability, corrosion resistance, and long service life, making it a modern alternative to traditional metal pipes.

Now, let’s explore the details that make PPR systems a superior choice for various applications.

What are the Defining Characteristics of a PPR Piping System?

Clients often ask what sets PPR apart. I recall a project where its unique traits prevented costly repairs.

The defining characteristics of a PPR piping system include its corrosion-resistant plastic material, smooth inner surface that prevents scaling, and heat-fused joints that create a monolithic structure. These features ensure long-term durability, hygienic water transport, and minimal maintenance needs compared to traditional piping methods.

Material Composition and Properties

PPR piping systems are made from a type of plastic called Polypropylene Random Copolymer. This material is specially designed for plumbing because it does not react with water or chemicals. For example, unlike metal pipes, PPR will not rust or corrode over time. This makes it ideal for both hot and cold water systems. The material is also flexible, which means it can handle pressure changes without cracking.

Another key trait is the smooth inside surface. When water flows through PPR pipes, minerals like calcium and lime have nothing to stick to. This prevents scale buildup that can block pipes and reduce water pressure. In my work with IFAN, I’ve seen homes where PPR pipes maintained full water flow even after years of use, while metal pipes needed frequent cleaning.

Joint Integrity and Installation

The joint system is what truly defines PPR. Instead of using screws or glue, PPR pipes and fittings are joined with heat fusion. A tool heats the ends until they melt, and then they are pressed together. This creates a joint that is as strong as the pipe itself. I’ve tested these joints under high pressure, and they rarely fail. This is a big improvement over threaded joints that often leak.

Also, PPR pipes come in different grades for various uses. Some are for cold water, and others can handle hot water up to 95°C. The material does not get brittle with heat, so it stays reliable in different conditions. This versatility is why many builders choose PPR for whole-house plumbing.

Key Characteristics Comparison

Here is a table that summarizes the main traits of PPR systems:

| Characteristic | Description | Benefit |

|---|---|---|

| Corrosion Resistance | Does not rust or react with chemicals. | Longer lifespan, no contamination. |

| Smooth Interior | Minimal friction and scale buildup. | Consistent water flow, less cleaning. |

| Heat-Fused Joints | Joints become one piece with the pipe. | No leaks, higher pressure tolerance. |

| Thermal Stability | Handles high temperatures without degrading. | Safe for hot water lines. |

| Lightweight | Easy to transport and install. | Lower labor costs, faster projects. |

These characteristics make PPR systems a smart choice for anyone wanting a reliable plumbing solution. At IFAN, we ensure our PPR products meet these standards so clients avoid common issues like leaks or water quality problems.

What are the Main Components of a Complete PPR Piping System?

When assembling a PPR system, I always list all parts to avoid missing pieces. This practice saved a client from delays last year.

The main components of a complete PPR piping system include the pipes themselves, various fittings like elbows and tees, fusion welding machines, support clips, and valves for flow control. Together, these elements form a fully integrated network that ensures efficient and reliable water distribution throughout a building.

Pipes and Basic Fittings

The core of any PPR system is the pipes. They come in different diameters, such as 20mm for small lines and 110mm for main supplies. At IFAN, we supply pipes in standard lengths, usually 4 meters, which are easy to cut and customize. The pipes are color-coded: green for cold water and gray for hot water, helping installers avoid mistakes.

Next, fittings connect the pipes to form the network. Common fittings include elbows for turning corners, tees for splitting lines, and couplings for joining straight sections. I always remind clients to use matching PPR fittings because mixing materials can cause failures. For instance, a PPR elbow fused properly will last decades, while a metal adapter might corrode and leak.

Specialized Parts and Tools

Valves are crucial for controlling water flow. Ball valves made of PPR allow you to shut off water quickly without corrosion issues. Also, fusion welding machines are essential tools. They heat the pipes and fittings to the right temperature for a perfect seal. In my experience, using a quality machine from IFAN ensures consistent joints and reduces installation errors.

Support clips hold the pipes in place on walls or ceilings. These prevent sagging and reduce stress on the joints. Additionally, insulation sleeves might be used for hot water pipes to save energy. A full system also includes end caps and reducers for complex layouts.

Comprehensive Components List

This table outlines the key components needed for a standard PPR system:

| Component Type | Examples | Purpose |

|---|---|---|

| Pipes | Straight pipes in various diameters | Carry water through the building. |

| Fittings | Elbows, tees, couplings, sockets | Change direction or connect pipes. |

| Valves | Ball valves, stop valves | Control water flow and pressure. |

| Tools | Fusion welder, pipe cutter, gauges | Install and maintain the system. |

| Accessories | Support clips, insulation, seals | Secure and protect the piping. |

Having all these components ensures a smooth installation. I advise clients to source from reliable suppliers like IFAN to guarantee compatibility. For example, our kits include pre-tested parts that fit perfectly, saving time and reducing waste on site.

What are the Key Advantages of Using a PPR Piping System?

I’ve compared PPR to many alternatives, and its benefits always stand out. A recent switch for a hotel project cut their costs by 30%.

The key advantages of using a PPR piping system are its long lifespan exceeding 50 years, low maintenance requirements, excellent hygiene for safe water, and cost-effectiveness over time. Additionally, its easy installation and environmental friendliness make it a superior choice for both new builds and renovations.

Durability and Maintenance Benefits

PPR systems last a very long time because the material does not corrode or wear out easily. I’ve inspected installations over 20 years old that still work like new. This durability means homeowners don’t face frequent repairs. For example, unlike copper pipes that can develop pinhole leaks, PPR remains intact even in aggressive water conditions.

Maintenance is minimal. The fused joints don’t need tightening or resealing, so once installed, the system mostly takes care of itself. This saves money and hassle. In commercial buildings, this advantage translates to lower operating costs and less downtime for fixes.

Health and Safety Perks

Hygiene is a major plus. PPR pipes keep water clean because they don’t leach harmful substances. They are certified for potable water, so families can drink safely from the tap. Also, the smooth interior prevents bacteria growth, which is a common problem in rough-walled metal pipes. From IFAN’s tests, our PPR products consistently meet strict health standards.

Cost savings are significant. Although the initial price might be similar to copper, the total cost over years is lower. PPR installs faster, reducing labor charges. It also has better insulation, so hot water loses less heat, cutting energy bills. I’ve seen clients recoup their investment within a few years through reduced expenses.

Environmental and Ease-of-Use Advantages

PPR is eco-friendly. It’s made from recyclable materials and production uses less energy than metal pipes. Moreover, the lightweight pipes are easy to handle, making installations quicker and safer. Workers can carry them without heavy equipment, which speeds up projects.

Advantages Summary Table

Here’s a clear comparison of PPR advantages:

| Advantage | Explanation | Real-World Impact |

|---|---|---|

| Long Lifespan | Lasts over 50 years without degradation. | Fewer replacements, more reliability. |

| Low Maintenance | No corrosion or joint leaks. | Saves time and money on repairs. |

| Hygienic | Non-toxic and resistant to biofilm. | Ensures safe drinking water. |

| Cost-Effective | Lower lifetime costs due to durability. | Better return on investment. |

| Easy Installation | Lightweight and simple fusion process. | Reduces labor time and errors. |

These advantages make PPR a wise choice for any plumbing need. At IFAN, we highlight these points to help clients make informed decisions, especially when they’re tired of constant plumbing issues.

Where are PPR Piping Systems Commonly Installed and Applied?

In my travels with IFAN, I’ve seen PPR systems in diverse settings. From homes to hospitals, they deliver reliable performance.

PPR piping systems are commonly installed in residential buildings for hot and cold water supply, commercial complexes like offices and hotels, industrial plants for fluid transport, and institutional facilities such as hospitals and schools. Their versatility and safety make them suitable for any application requiring clean, durable plumbing.

Residential and Commercial Uses

In homes, PPR is used for entire water distribution networks. This includes kitchen and bathroom lines, as well as heating systems like radiators or underfloor heating. I’ve supervised many apartment projects where PPR ensured consistent water pressure and temperature across all units. Its quiet operation is a bonus for peaceful living spaces.

Commercial buildings, such as malls and offices, benefit from PPR’s reliability. For example, in hotels, it provides steady water flow to multiple rooms without leaks. Restaurants use it for sanitary water lines because it meets health codes. IFAN often supplies PPR for these projects due to its ability to handle high demand.

Industrial and Specialized Applications

Industries use PPR for moving chemicals or other fluids because it resists corrosion. In factories, it might carry coolants or process water. I recall a food processing plant that switched to PPR to avoid metal contamination, and they reported better product safety.

Hospitals and schools prefer PPR for its hygiene. In medical facilities, it delivers clean water for surgeries and patient care. Schools use it in dormitories and cafeterias. Its non-toxic nature is crucial where health is a priority. Also, PPR is found in agricultural irrigation due to its durability in outdoor conditions.

Geographic and Regulatory Context

In many countries, building codes now favor PPR for its safety and efficiency. For instance, in Europe and Asia, it’s standard in new constructions. Even in harsh climates, PPR performs well because it doesn’t crack in cold weather.

Common Installation Sites Table

This table shows where PPR systems are typically applied:

| Application Area | Specific Uses | Reasons for Choosing PPR |

|---|---|---|

| Residential | Houses, apartments, villas | Safety, durability, and easy installation. |

| Commercial | Hotels, offices, shopping centers | Reliability under heavy use, low maintenance. |

| Industrial | Factories, chemical plants | Corrosion resistance for harsh fluids. |

| Institutional | Hospitals, schools, government buildings | Hygienic properties and compliance with standards. |

Knowing these applications helps in planning projects. At IFAN, we guide clients on the best PPR solutions for their specific needs, ensuring optimal performance wherever they’re installed.

Conclusion

PPR piping systems offer reliability, safety, and efficiency for diverse plumbing needs. For top-quality PPR products, choose IFAN to ensure your projects succeed.

Commentaires récents