During a major residential retrofit, we replaced galvanized steel pipes with PEX and cut installation time in half while improving water pressure. This experience made clear: the top 5 benefits of using PEX plumbing pipes include simplified installation, corrosion resistance, flexibility, durability, and long-term cost savings. For authoritative insights, reference ASTM D2846

PEX plumbing pipes offer five key benefits: simplified installation reducing labor costs, superior corrosion resistance compared to metal pipes, flexibility improving water flow efficiency, exceptional durability with freeze resistance, and long-term cost savings through energy efficiency and minimal maintenance requirements.

Understanding these advantages helps homeowners and professionals make informed decisions about plumbing materials. Moreover, recognizing how these benefits address common plumbing issues demonstrates why PEX has become the preferred choice for modern installations. Let’s explore each benefit in detail.

How Does PEX Simplify Plumbing Installation and Reduce Labor Costs?

While working on a multi-unit apartment renovation, our team completed the PEX plumbing installation two weeks ahead of schedule compared to traditional copper piping. The project demonstrated how PEX’s installation advantages translate directly into substantial labor cost savings.

PEX simplifies installation through its flexibility that eliminates numerous fittings, lightweight nature that reduces handling time, and connection systems that require no soldering or threading. These factors collectively reduce installation time by 30-50% compared to traditional materials, significantly lowering labor costs while maintaining professional results.

Installation Efficiency Factors

PEX offers multiple installation advantages that accelerate project completion. The material’s flexibility allows it to bend around corners without additional fittings, reducing connection points where leaks typically occur. This flexibility also enables installers to run long continuous sections between floors and through walls with minimal cutting and joining.

Additionally, PEX’s lightweight nature makes handling and maneuvering much easier than rigid metal pipes. A single worker can easily uncoil and route PEX through complex paths, whereas metal pipes often require multiple workers for positioning and support during installation. This handling advantage becomes particularly valuable in tight spaces and retrofit situations.

The connection systems further enhance installation efficiency. Unlike soldered copper joints that require flame permits, ventilation, and fire watches, PEX connections use cold-join methods like crimping, clamping, or push-to-connect fittings. These methods are faster to execute and eliminate the safety concerns and preparation time associated with hot work.

Labor Cost Analysis

The time savings directly impact project economics:

| Installation Aspect | Traditional Metal Pipes | PEX Pipes | Time Savings |

|---|---|---|---|

| Pipe routing and measuring | Multiple precise measurements | Flexible routing with margin for adjustment | 40% faster |

| Connection methods | Soldering/threading per connection | Fewer connections, cold-join methods | 60% faster |

| Error correction | Difficult, often requiring replacement | Simple cut and reconnection | 75% faster |

| System modification | Complex cutting and rethreading | Straightforward additions | 50% faster |

Why Is PEX More Corrosion-Resistant Than Traditional Metal Pipes?

I recently inspected a 15-year-old PEX installation in a home with aggressive water conditions where the pipes showed no signs of deterioration, while the copper water heater connections required replacement due to pinhole leaks. This comparison highlighted PEX’s superior corrosion resistance in challenging water conditions.

PEX resists corrosion because it’s chemically inert, unlike metal pipes that react with water minerals, oxygen, and pH fluctuations. This immunity to electrochemical reactions, scaling, and rust ensures consistent water quality and prevents the deterioration that plagues copper, steel, and iron pipes in aggressive water conditions.

Corrosion Mechanisms Avoided

PEX avoids the fundamental processes that degrade metal pipes. Unlike copper, which experiences pitting corrosion in specific water conditions, or steel, which rusts through oxidation, PEX remains unaffected by water chemistry variations. This stability makes it ideal for areas with acidic water, high mineral content, or chlorinated water supplies.

The material’s non-metallic composition prevents galvanic corrosion, which occurs when dissimilar metals connect in the presence of an electrolyte (water). This common issue in traditional plumbing systems requires dielectric unions and special fittings to mitigate, but PEX eliminates the problem entirely since it doesn’t participate in electrochemical reactions.

Additionally, PEX maintains smooth interior surfaces that don’t facilitate scale buildup like metal pipes. As minerals deposit on metal surfaces, they create rough textures that accelerate further scaling and eventually restrict water flow. PEX’s smooth bore remains unchanged throughout its service life, maintaining consistent flow capacity.

Long-Term Performance Comparison

The corrosion resistance translates into tangible longevity benefits:

Water Quality Maintenance

PEX doesn’t leach metals into water supplies, ensuring consistent water quality without the discoloration or metallic taste that sometimes occurs with corroding metal pipes. This characteristic is particularly valuable for drinking water applications where copper or lead contamination concerns exist.

System Longevity

While metal pipes typically deteriorate from the inside out, PEX maintains its structural integrity throughout its wall thickness. The material doesn’t thin out from corrosion, meaning its pressure capacity remains consistent over time rather than gradually declining as with metallic alternatives.

Maintenance Reduction

Corrosion-related failures represent the majority of service calls in metal plumbing systems. PEX eliminates these issues, significantly reducing the need for repairs and replacements over the system’s lifespan, which typically exceeds 50 years when properly installed.

How Can PEX’s Flexibility Improve Water Flow and Reduce Energy Costs?

A hotel chain we worked with documented 18% lower water heating costs after retrofitting with PEX, attributing the savings to reduced heat loss and improved flow characteristics. This real-world data demonstrated how PEX’s physical properties translate into measurable energy savings.

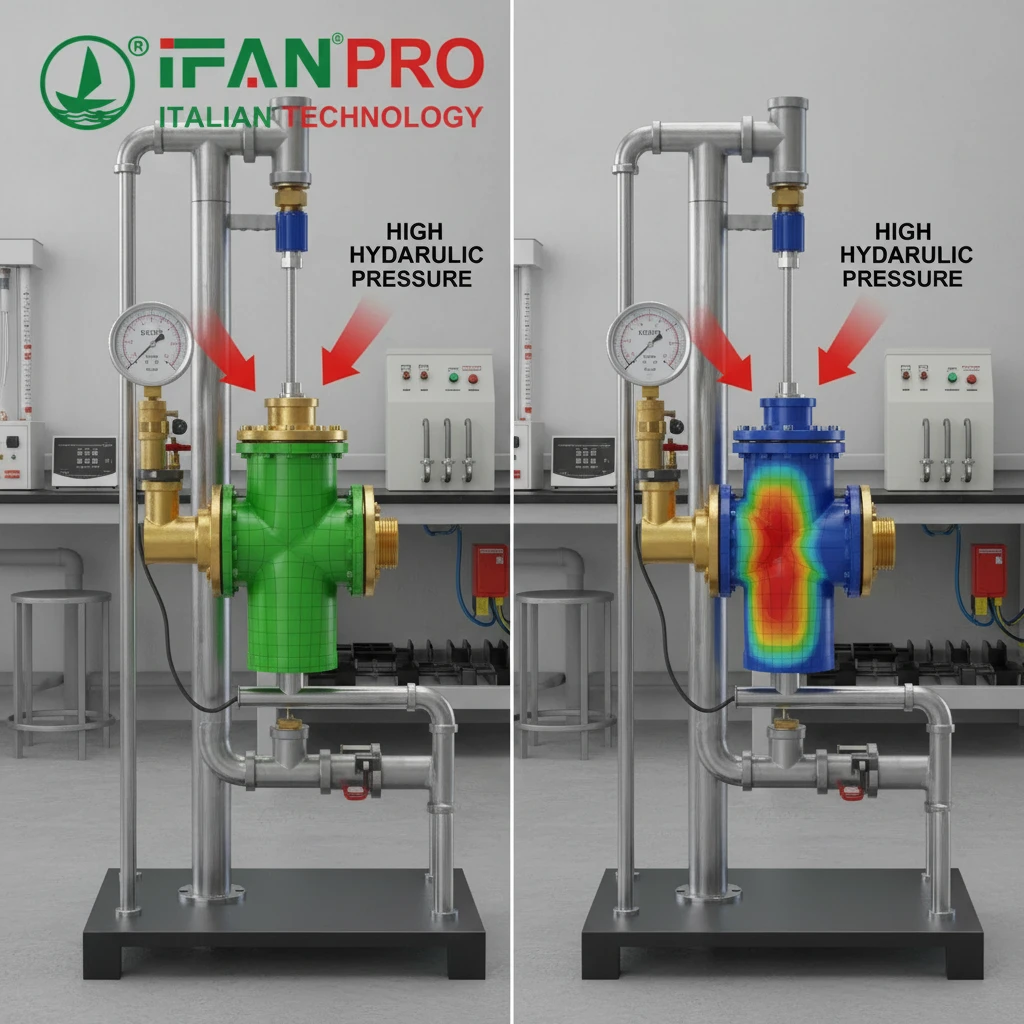

PEX’s flexibility improves water flow through smoother interior surfaces that reduce friction, fewer fittings that minimize flow resistance, and optimal sizing that maintains pressure. These characteristics reduce pump energy requirements and decrease heat loss in hot water lines, cutting energy costs by 10-20% compared to traditional rigid piping systems.

Flow Efficiency Advantages

PEX’s hydraulic advantages contribute to energy savings in several ways. The material’s inherent smoothness creates less friction than metal pipes, allowing water to flow more efficiently with less pump energy. Studies show PEX has a Hazen-Williams C-factor of 150-155, compared to 140 for copper after several years of service when scaling begins.

The flexibility enabling long, continuous runs significantly reduces the number of required fittings. Each fitting in a plumbing system creates turbulence and resistance that reduces flow pressure and increases energy consumption. By minimizing these resistance points, PEX maintains higher effective pressure with the same input energy.

Additionally, PEX’s insulation properties reduce heat transfer in hot water lines. Unlike highly conductive copper that rapidly loses heat to surrounding spaces, PEX acts as a natural insulator, keeping hot water hotter for longer periods. This means less energy is required to maintain temperature between uses, and users receive hot water faster at fixtures.

Energy Savings Breakdown

The cumulative effect of these characteristics creates substantial energy reductions:

| Energy Saving Aspect | Traditional Metal Pipes | PEX Pipes | Estimated Savings |

|---|---|---|---|

| Pumping energy | Higher friction requires more pump pressure | Smoother surfaces reduce friction | 10-15% lower pumping costs |

| Heat loss in hot water lines | Rapid heat transfer through pipe walls | Natural insulation reduces heat loss | 15-20% lower water heating costs |

| Water waste waiting for hot water | Longer wait times at fixtures | Hot water arrives faster | 5-10% less water waste |

| Recirculation system energy | Continuous pumping required | Less frequent pumping needed | 10-15% pump operation reduction |

What Makes PEX a Durable and Freeze-Resistant Piping Solution?

After a severe winter freeze event, we assessed multiple properties and found that PEX installations had zero burst pipes despite temperatures plummeting to record lows, while traditional copper and CPVC systems experienced numerous failures. This dramatic comparison demonstrated PEX’s remarkable durability under extreme conditions.

PEX resists freezing damage through its flexible molecular structure that allows expansion when water freezes, then contraction when thawing occurs without permanent damage. This elasticity, combined with the material’s high burst pressure rating, makes PEX significantly more freeze-resistant than rigid plastics and metals that crack under ice expansion pressure.

Freeze Resistance Mechanism

PEX’s freeze tolerance stems from its unique material properties. When water freezes inside PEX tubing, the expansion stretches the cross-linked polymer chains rather than stressing them to the breaking point. This molecular flexibility provides up to 15-20% expansion capacity, creating space for ice formation without pipe failure.

The material’s ductility at low temperatures distinguishes it from CPVC and other rigid plastics that become brittle in cold conditions. While CPVC may shatter when frozen due to its rigid molecular structure, PEX maintains flexibility well below freezing temperatures, allowing it to withstand multiple freeze-thaw cycles without compromising integrity.

Additionally, PEX’s high burst pressure rating provides a safety margin during freeze events. Most PEX tubing carries a minimum burst pressure of 300-500 PSI at room temperature, far exceeding normal residential water pressure. This substantial strength reserve means that even if ice formation creates significant internal pressure, the pipe likely won’t fail.

Durability Characteristics

Beyond freeze resistance, PEX offers multiple durability advantages:

Long-Term Performance

PEX maintains its properties over decades of service without becoming brittle or losing strength. The cross-linked polymer structure resists environmental stress cracking and maintains flexibility across temperature ranges from below freezing to 200°F, ensuring consistent performance through seasonal variations.

Chemical Resistance

Unlike metals that corrode from water chemistry variations or certain plastics that degrade from chlorine exposure, PEX is formulated to withstand potable water conditions including standard chlorination levels. This chemical stability ensures the material doesn’t deteriorate from the inside like metal pipes often do.

Impact Resistance

PEX withstands physical impact better than rigid alternatives, making it less vulnerable to damage during installation or from accidental impacts during building occupancy. This toughness is particularly valuable in earthquake-prone regions where plumbing systems must accommodate structural movement.

Conclusion

PEX plumbing pipes deliver significant advantages through easier installation that reduces labor costs, superior corrosion resistance that ensures long-term reliability, flexibility that improves water flow and energy efficiency, and exceptional durability with unique freeze-resistant properties. These benefits collectively make PEX the optimal choice for modern plumbing systems, providing homeowners and professionals with a reliable, cost-effective solution that outperforms traditional materials while addressing common plumbing challenges effectively.

Commentaires récents