Through years of installing and maintaining both residential and commercial plumbing systems, I’ve tested PEX performance across various temperature conditions. While PEX offers numerous advantages for hot water distribution, understanding its temperature limitations is crucial for system design and long-term reliability. Modern PEX formulations have significantly improved high-temperature capabilities, but strategic planning remains essential for optimal performance.

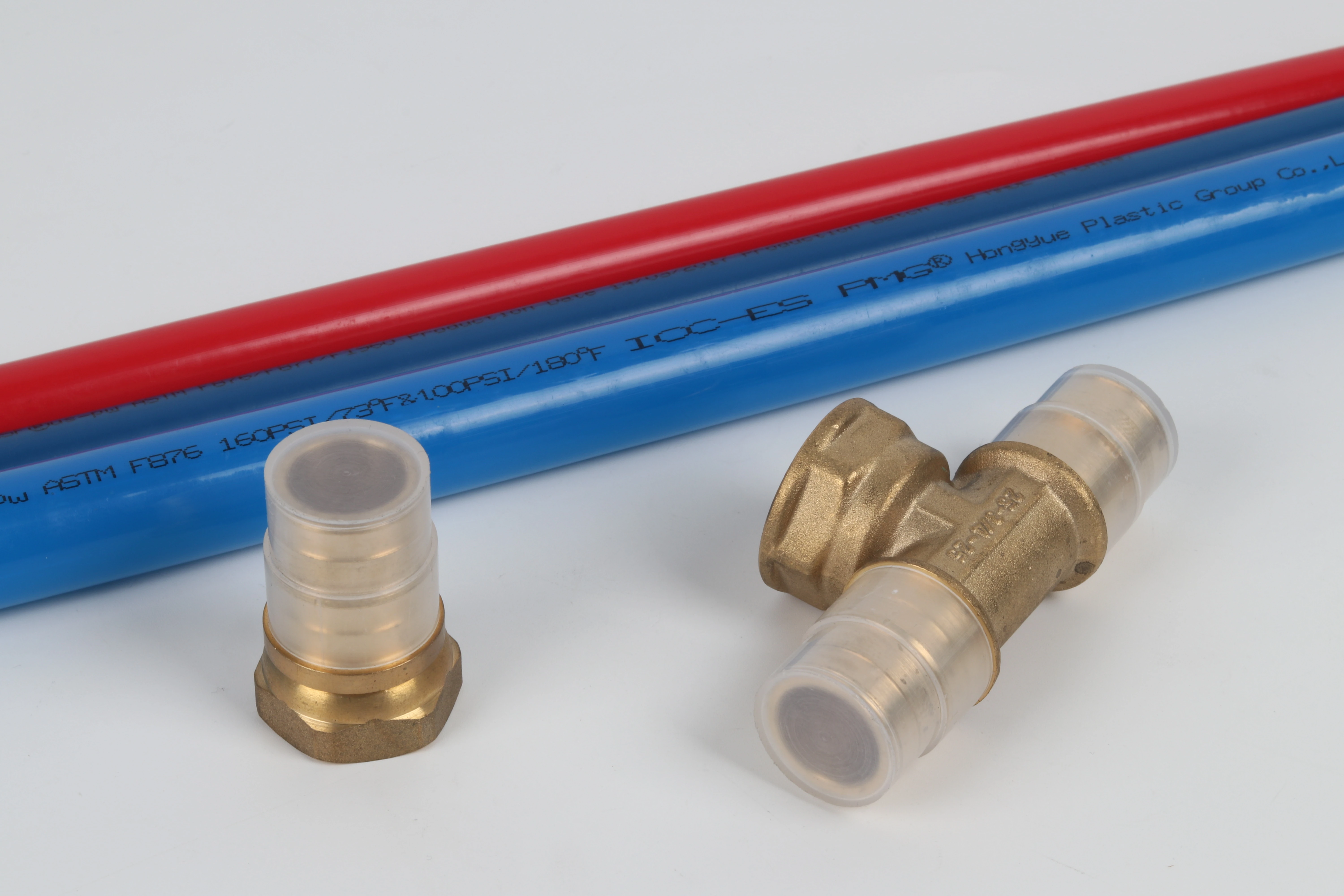

PEX pipes can safely handle typical residential hot water temperatures up to 140°F (60°C) continuously, with most products rated for intermittent exposure to 180°F (82°C) and maximum short-term tolerance of 200°F (93°C). These temperature capabilities comfortably cover normal domestic hot water requirements while maintaining material integrity and drinking water safety when properly selected and installed.

PEX’s temperature performance varies by type and formulation, making proper selection critical for high-temperature applications. Understanding these parameters ensures systems deliver reliable performance while maintaining safety margins.

What is the maximum temperature rating for PEX in potable water systems?

PEX temperature ratings follow standardized classifications that establish safe operating parameters for potable water applications.

Most PEX products carry maximum continuous temperature ratings of 180°F (82°C) with 100 PSI pressure, decreasing to 140°F (60°C) at 80 PSI for extended service life. These ratings incorporate safety factors that account for material degradation over time, with higher temperatures requiring reduced pressure to maintain 50-year service life expectations.

Temperature ratings represent careful balancing of material capabilities, safety factors, and long-term performance expectations established through extensive testing.

Standard Temperature Classifications

PEX temperature capabilities follow established pressure-temperature relationships:

- 73°F (23°C): 160 PSI maximum operating pressure

- 140°F (60°C): 100 PSI maximum operating pressure

- 180°F (82°C): 80 PSI maximum operating pressure

- 200°F (93°C): 50-65 PSI for intermittent exposure only

These ratings ensure PEX maintains hydrostatic strength while accounting for accelerated oxidative degradation at elevated temperatures. The pressure derating at higher temperatures compensates for reduced material strength and increased permeability.

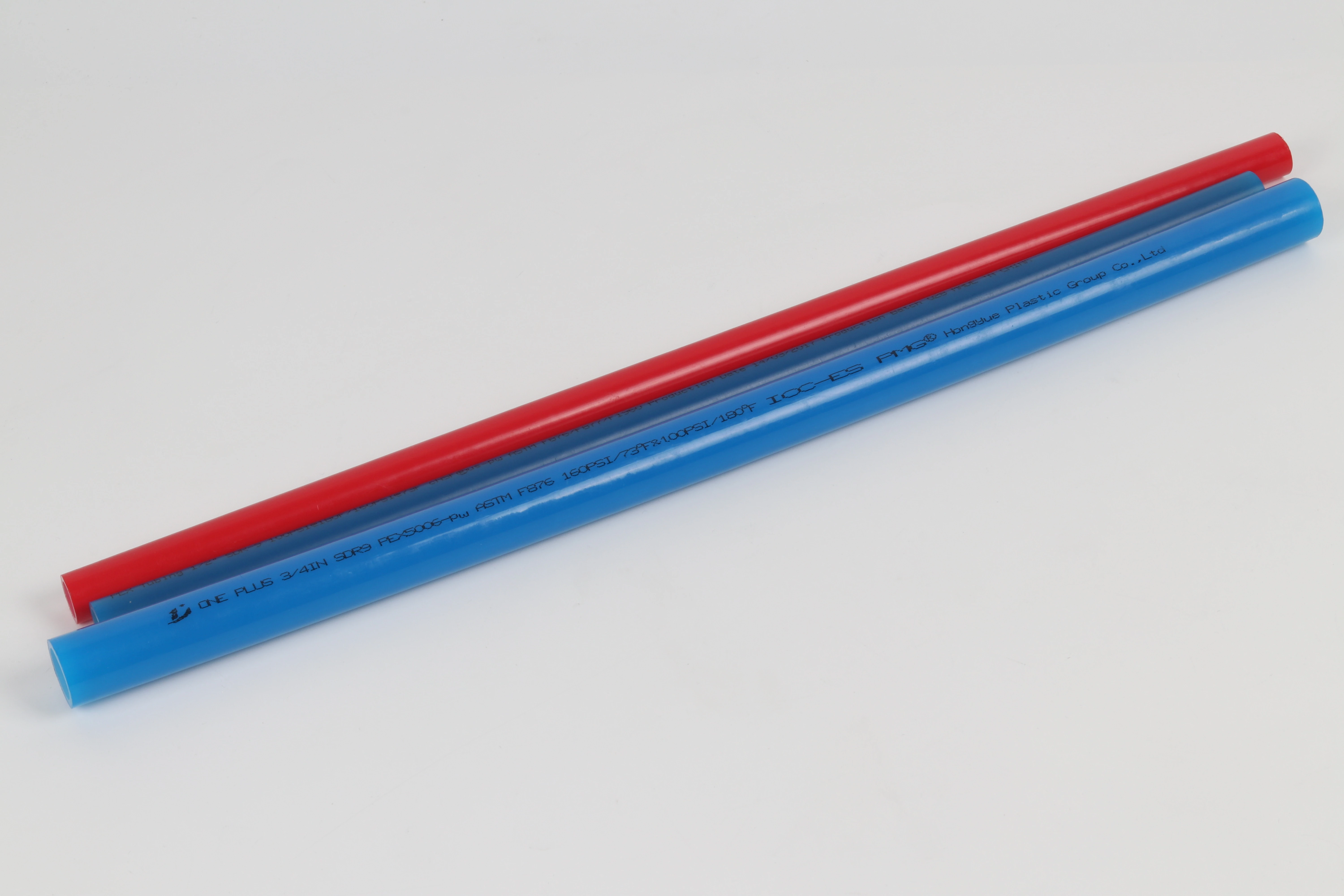

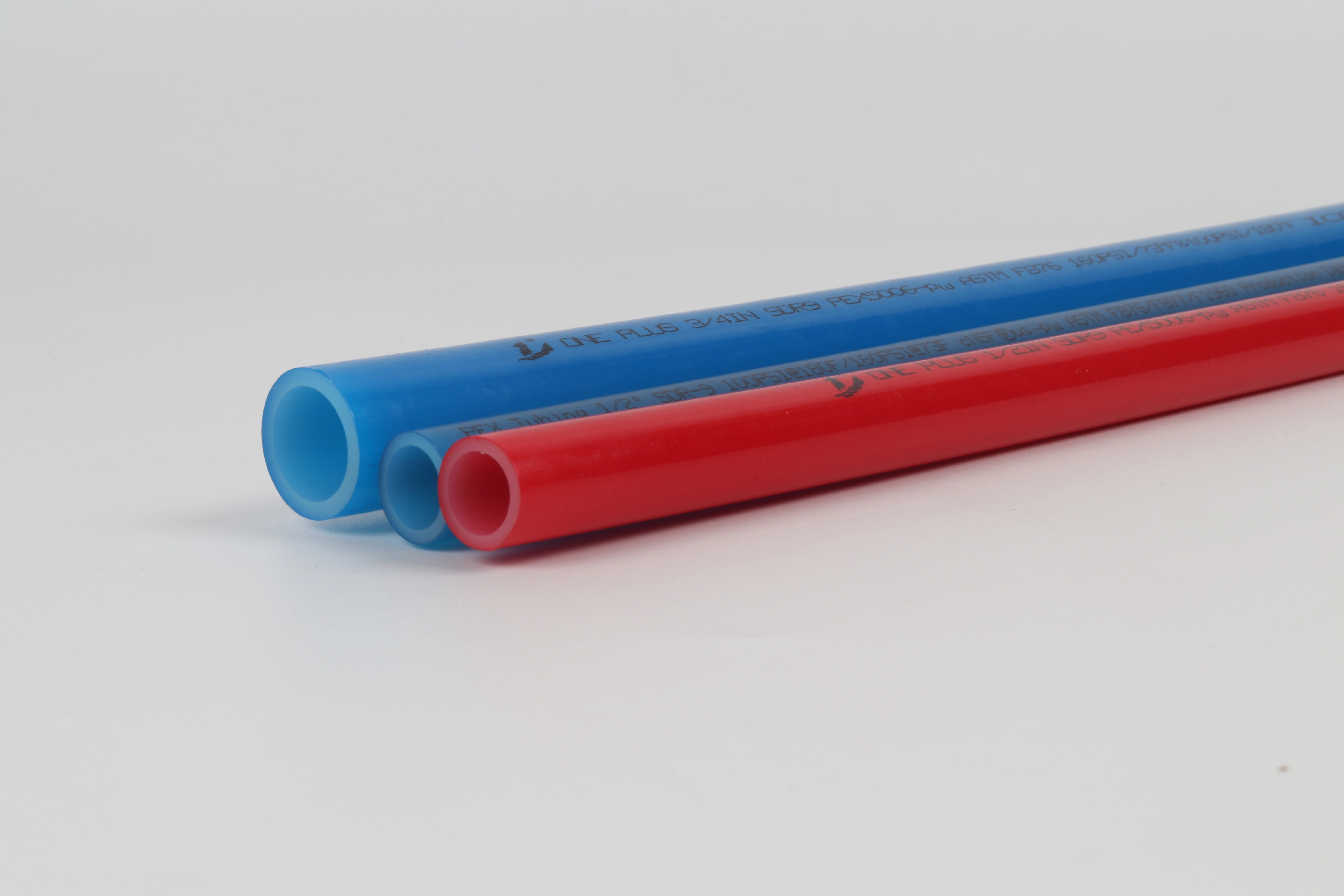

Temperature Limitations by PEX Type

Different PEX manufacturing methods yield varying temperature performance:

- PEX-A typically offers the best high-temperature performance due to uniform cross-linking

- PEX-B provides reliable performance with slightly lower temperature tolerance

- PEX-C may have more conservative ratings depending on manufacturing quality

Most residential hot water systems operate between 120-140°F (49-60°C), well within PEX capabilities. However, applications near water heaters or in recirculating systems may approach upper limits, requiring careful planning and potentially different materials for critical high-temperature sections.

Table: PEX Temperature-Pressure Ratings

| Temperature | Maximum Pressure | Typical Application | Service Life Impact |

|---|---|---|---|

| 73°F (23°C) | 160 PSI | Cold water supply | Minimal degradation |

| 140°F (60°C) | 100 PSI | Standard hot water | Normal 50-year life |

| 180°F (82°C) | 80 PSI | High-temp applications | Reduced service life |

| 200°F (93°C) | 50-65 PSI | Intermittent exposure only | Significant life reduction |

Application-Specific Considerations

Temperature requirements vary by application:

- Residential potable water: Typically 120-140°F (49-60°C)

- Commercial kitchens: May require 180°F (82°C) for sanitation

- Hydronic heating: Typically 100-140°F (38-60°C) for radiant systems

- Snow melt: 100-140°F (38-60°C) depending on system design

Understanding these application-specific requirements ensures proper PEX selection and prevents temperature-related performance issues.

How does PEX maintain material stability with recurring hot water exposure?

PEX’s cross-linked molecular structure provides inherent thermal stability that withstands repeated hot water exposure through multiple protective mechanisms.

PEX maintains material stability through antioxidant additives that retard oxidative degradation, a cross-linked molecular structure that resists polymer chain scission, and manufacturing processes that ensure uniform material properties. These elements work together to prevent brittleness, cracking, and loss of pressure capacity during prolonged hot water service.

The science behind PEX’s thermal stability involves sophisticated material engineering that prevents common failure modes in plastic piping systems.

Antioxidant Protection Systems

PEX formulations incorporate complex antioxidant packages that:

- Scavenge free radicals generated during thermal exposure

- Decompose hydroperoxides that accelerate degradation

- Synergistically work with other stabilizers for enhanced protection

- Migrate slowly to the material surface as antioxidants deplete

These systems typically provide protection for decades under normal operating conditions, though extremely high temperatures or aggressive water conditions can accelerate antioxidant depletion.

Molecular Structure Integrity

The cross-linked polyethylene structure provides inherent advantages:

- Three-dimensional network prevents polymer chain slippage

- Covalent bonds maintain structural integrity at elevated temperatures

- Reduced crystallinity compared to non-crosslinked polyethylene minimizes stress points

- Uniform material properties prevent localized weak spots

This molecular stability allows PEX to withstand the thermal cycling typical in domestic hot water systems, where temperatures fluctuate daily as systems heat, cool, and reheat.

Table: PEX Thermal Degradation Protection Mechanisms

| Protection Method | Function | Effectiveness | Limitations |

|---|---|---|---|

| Antioxidant Additives | Free radical scavenging | Excellent for normal conditions | Depletes over time |

| Cross-linked Structure | Prevents chain mobility | Superior thermal stability | Manufacturing dependent |

| Stabilizer Packages | Multiple protection mechanisms | Enhanced service life | Cost and complexity |

| Material Purity | Reduces degradation catalysts | Improved longevity | Raw material cost |

Long-Term Performance Factors

Several factors influence PEX’s long-term thermal performance:

- Water chemistry affects antioxidant depletion rates

- Oxygen concentration in water accelerates oxidation

- System pressure combined with temperature creates synergistic stress

- Installation quality impacts localized stress concentrations

Proper system design that maintains temperatures within recommended parameters maximizes PEX service life while maintaining safety margins.

What certifications verify PEX safety for high-temperature drinking water?

Multiple certification programs specifically evaluate PEX performance and safety under high-temperature conditions relevant to drinking water applications.

NSF/ANSI 61 and NSF-pw certifications verify PEX safety for high-temperature drinking water through extraction testing at elevated temperatures, long-term hydrostatic strength testing, and material stability evaluation. These certifications ensure that PEX doesn’t leach harmful substances and maintains structural integrity when exposed to hot water conditions.

Certification processes employ rigorous testing protocols that simulate decades of service in compressed timeframes, providing assurance of long-term safety and performance.

NSF/ANSI 61 Temperature Testing

This certification includes specific high-temperature evaluation:

- Elevated temperature extraction using 60°C water for accelerated migration

- Taste and odor assessment after hot water exposure

- Material analysis following thermal aging

- Multiple water conditions simulating different water chemistries

Products passing these tests demonstrate that they don’t leach contaminants at levels that could pose health risks, even under elevated temperature conditions typical in hot water systems.

Specialized High-Temperature Certifications

Beyond basic drinking water safety, several certifications address high-temperature performance:

- NSF-pw includes enhanced testing for potable water applications

- IAPMO PS certifications for specific temperature classes

- UL temperature ratings for continuous and intermittent exposure

- Regional certifications with temperature-specific requirements

These specialized certifications provide additional assurance for applications where temperatures approach PEX’s upper limits or where regulatory requirements demand specific verification.

Table: PEX High-Temperature Certification Requirements

| Certification | Temperature Testing | Safety Verification | Performance Requirements |

|---|---|---|---|

| NSF/ANSI 61 | 60°C extraction testing | Leaching potential | Material safety only |

| NSF-pw | Enhanced temperature testing | Chlorine resistance at temperature | Comprehensive performance |

| ASTM F876 | Pressure-temperature rating | Hydrostatic strength | Mechanical performance |

| Regional Standards | Varies by region | Local requirements | Market-specific compliance |

Certification Maintenance and Verification

Maintaining certification requires ongoing compliance:

- Annual surveillance audits of manufacturing processes

- Regular retesting to verify consistent performance

- Batch testing for critical performance characteristics

- Documentation review of material sourcing and formulations

This ongoing verification ensures that manufacturing consistency maintains the safety profile established during initial certification, particularly important for high-temperature applications where material variations can significantly impact performance.

How does PEX performance compare to copper in high-temperature applications?

PEX and copper offer different advantages in high-temperature applications, with material selection depending on specific temperature requirements, water chemistry, and installation considerations.

Copper maintains superior maximum temperature tolerance (400°F+/204°C+) but suffers from scaling, corrosion, and higher installation costs, while PEX offers excellent corrosion resistance, lower installation costs, and sufficient temperature capability for most residential applications up to 180°F (82°C) with proper pressure derating.

The choice between PEX and copper involves balancing temperature requirements, water quality considerations, installation factors, and long-term performance expectations.

Temperature Capability Comparison

Copper’s fundamental advantage lies in its much higher temperature tolerance:

- Copper: Withstands temperatures exceeding 400°F (204°C) without degradation

- PEX: Limited to 180°F (82°C) continuous, 200°F (93°C) intermittent

This difference makes copper preferable for applications near high-temperature heat sources or where temperature excursions might occur. However, most residential and commercial hot water systems operate well within PEX’s temperature capabilities.

Long-Term Performance Factors

Each material faces different degradation mechanisms at elevated temperatures:

- Copper experiences scaling, corrosion, and erosion at high temperatures

- PEX undergoes oxidative degradation and reduced hydrostatic strength

Water chemistry significantly impacts performance:

- Aggressive water accelerates copper corrosion but doesn’t affect PEX

- Hard water causes copper scaling but doesn’t impact PEX

- High chlorine affects both materials but through different mechanisms

Table: PEX vs Copper High-Temperature Performance

| Performance Factor | PEX Advantages | Copper Advantages | Application Considerations |

|---|---|---|---|

| Maximum Temperature | Adequate for most applications | Superior for high-temperature uses | Copper for extreme temperatures |

| Corrosion Resistance | Excellent in all water conditions | Vulnerable to aggressive water | PEX for problem water |

| Scale Formation | No scaling regardless of water hardness | Significant scaling in hard water | PEX reduces maintenance |

| Installation Cost | 30-50% lower installed cost | Higher material and labor costs | PEX more economical |

| Freeze Protection | Excellent expansion capability | Poor, typically bursts when frozen | PEX for cold climates |

Application-Specific Recommendations

Based on temperature requirements and application needs:

Choose PEX for:

- Standard residential hot water systems (120-140°F/49-60°C)

- Areas with aggressive or hard water conditions

- Budget-conscious projects with standard temperature needs

- Retrofits where installation access is limited

Choose Copper for:

- Commercial applications requiring very high temperatures

- Locations with potential temperature excursions above 180°F (82°C)

- Exposed installations where UV resistance is needed

- Historical restoration matching existing systems

System Design Considerations

Hybrid approaches often provide optimal solutions:

- PEX for distribution with copper near heat sources

- Temperature-limiting devices to protect PEX systems

- Proper insulation to maintain temperatures and improve efficiency

- Expansion compensation in long PEX runs for thermal movement

These approaches leverage each material’s advantages while mitigating limitations, creating systems that deliver reliable performance across temperature ranges.

Conclusion

PEX pipes capably handle high-temperature drinking water needs within their specified temperature ratings, providing safe, reliable performance for most residential and commercial applications. The material’s temperature limitations require careful system design and proper pressure derating, but its corrosion resistance, scaling immunity, and installation advantages make it an excellent choice for typical hot water systems. Certification to NSF/ANSI 61 and other relevant standards verifies PEX safety for high-temperature drinking water applications, while understanding performance differences with copper enables optimal material selection based on specific project requirements. By respecting temperature limitations, implementing proper system design, and selecting certified products, PEX delivers decades of reliable service in hot water applications while maintaining drinking water safety and system performance.

Commentaires récents