When it comes to reliable plumbing and piping systems, brass fittings elbows stand as one of the most crucial components. Whether you’re a contractor, plumber, or facility manager, understanding how to make the right factory purchase decision for brass fittings elbows can significantly impact your project’s success and longevity.

What Are Brass Fittings Elbows?

Brass fittings elbows are curved pipe connectors manufactured from brass alloy, designed to change the direction of fluid flow in piping systems. These essential components combine the durability of brass with precision engineering to create reliable connections that withstand pressure, temperature variations, and corrosion.

Key Features of Quality Brass Fittings Elbows:

- Corrosion Resistance: Brass naturally resists rust and corrosion

- High Temperature Tolerance: Suitable for both hot and cold applications

- Pressure Rating: Designed to handle various pressure requirements

- Threaded Connections: Provide secure, leak-proof joints

- Multiple Angles: Available in 45°, 90°, and custom angles

Why Choose Factory Direct Purchase for Brass Fittings Elbows?

1. Cost-Effective Solutions

Factory direct purchasing eliminates intermediary markups, allowing you to access premium brass fittings elbows at competitive prices. This approach is particularly beneficial for large-scale projects or businesses requiring consistent supply.

2. Quality Assurance

When you purchase directly from manufacturers like ifanpro, you gain access to:

- Strict Quality Control: Every piece undergoes rigorous testing

- Material Certification: Verified brass composition and grade

- Performance Standards: Compliance with international piping standards

- Batch Consistency: Uniform quality across all products

3. Customization Options

Factory direct relationships enable custom solutions tailored to your specific requirements:

- Custom Angles: Beyond standard 45° and 90° configurations

- Special Dimensions: Tailored to unique project specifications

- Surface Treatments: Various finishes and coatings available

- Pressure Ratings: Engineered for specific operating conditions

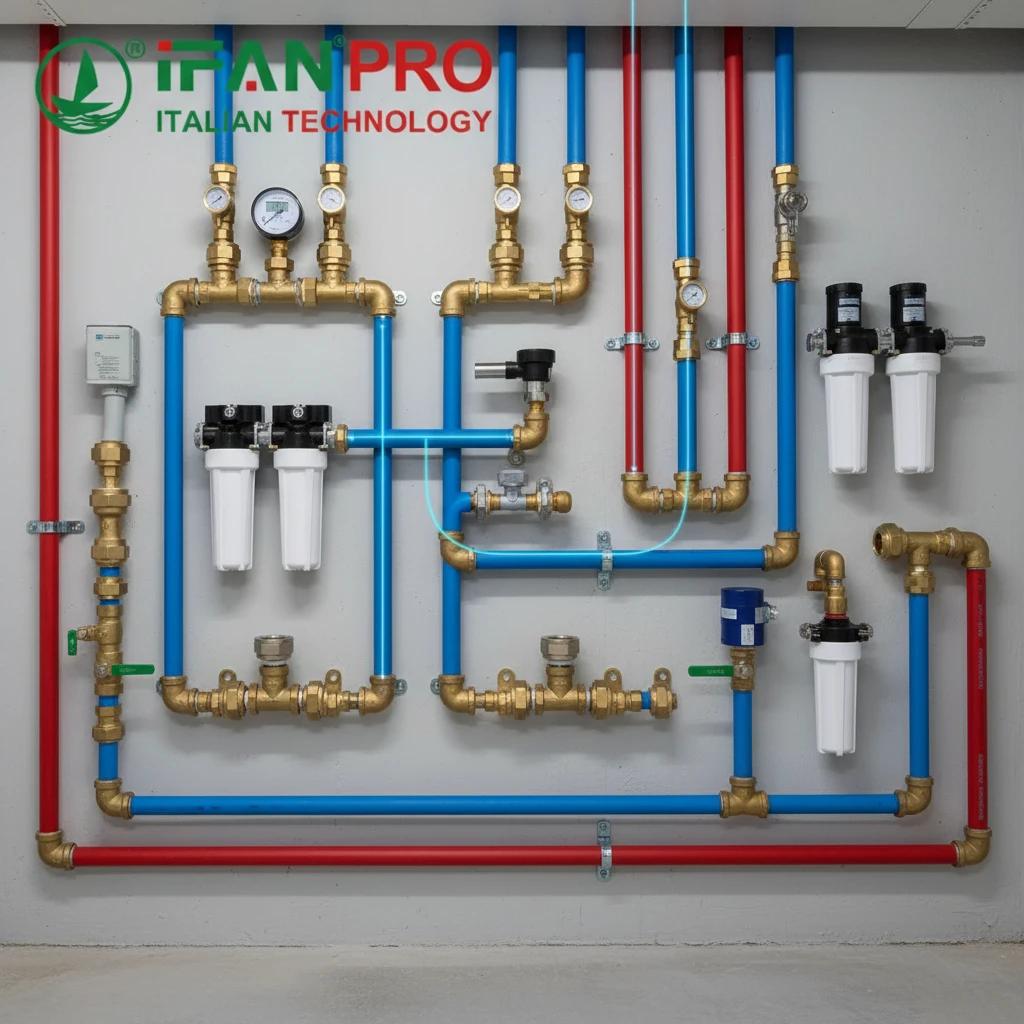

Applications of Brass Fittings Elbows

Residential Plumbing

- Water Supply Lines: Connecting pipes in kitchens and bathrooms

- Heating Systems: Radiator connections and boiler piping

- Gas Lines: Safe natural gas and propane connections

Commercial Applications

- HVAC Systems: Air conditioning and heating installations

- Industrial Processes: Chemical and pharmaceutical piping

- Fire Protection: Sprinkler system connections

Marine and Offshore

- Boat Plumbing: Corrosion-resistant marine applications

- Offshore Platforms: High-pressure, saltwater-resistant connections

Technical Specifications to Consider

Material Composition

High-quality brass fittings elbows typically contain:

- Copper: 60-70% for strength and corrosion resistance

- Zinc: 30-40% for workability and durability

- Lead Content: Compliant with drinking water standards

Pressure and Temperature Ratings

- Working Pressure: Typically 150-300 PSI

- Temperature Range: -20°F to 400°F (-29°C to 204°C)

- Burst Pressure: 4x working pressure minimum

Thread Standards

- NPT (National Pipe Thread): Most common in North America

- BSP (British Standard Pipe): Popular in Europe and Asia

- Metric Threads: For international compatibility

How to Select the Right Brass Fittings Elbow

1. Determine Your Application Requirements

- Fluid Type: Water, gas, oil, or chemicals

- Operating Pressure: Maximum system pressure

- Temperature Range: Expected operating temperatures

- Environmental Conditions: Indoor, outdoor, or marine use

2. Size and Connection Type

- Pipe Diameter: Match your existing piping system

- Thread Type: NPT, BSP, or metric connections

- Elbow Angle: 45°, 90°, or custom angles

3. Quality Standards

Look for certifications such as:

- ANSI/ASME Standards: American National Standards Institute

- ISO Certifications: International Organization for Standardization

- NSF Certification: For potable water applications

Installation Best Practices

Pre-Installation Preparation

- Inspect Components: Check for defects or damage

- Clean Threads: Remove any debris or contamination

- Apply Thread Sealant: Use appropriate sealant for your application

- Plan Layout: Ensure proper alignment and support

Installation Steps

- Hand Tighten: Start connections by hand

- Wrench Tighten: Use appropriate torque specifications

- Pressure Test: Verify connections under operating pressure

- Final Inspection: Check for leaks and proper alignment

Maintenance and Longevity

Regular Inspection

- Visual Checks: Look for signs of corrosion or damage

- Pressure Testing: Periodic system pressure verification

- Thread Condition: Inspect thread integrity

Preventive Maintenance

- Proper Support: Ensure adequate pipe support

- Corrosion Protection: Apply protective coatings when necessary

- System Flushing: Regular cleaning to prevent buildup

Why Choose ifanpro for Your Brass Fittings Elbow Needs?

Manufacturing Excellence

As a leading pipe fitting manufacturer, ifanpro combines advanced production techniques with quality materials to deliver superior brass fittings elbows that meet international standards.

Custom Solutions

Our engineering team works closely with clients to develop custom brass fittings elbows tailored to specific project requirements, ensuring optimal performance and compatibility.

Quality Assurance

Every brass fitting elbow undergoes comprehensive testing including:

- Pressure Testing: Verification of pressure ratings

- Material Analysis: Confirmation of brass composition

- Dimensional Inspection: Precision measurement verification

- Surface Quality: Finish and coating evaluation

Global Supply Chain

With efficient logistics and worldwide shipping capabilities, ifanpro ensures timely delivery of brass fittings elbows to projects around the globe.

Conclusion

Factory direct purchase of brass fittings elbows offers significant advantages in terms of cost, quality, and customization options. By choosing a reputable manufacturer like ifanpro, you ensure access to high-quality components that meet your specific requirements while maintaining competitive pricing.

Commentaires récents