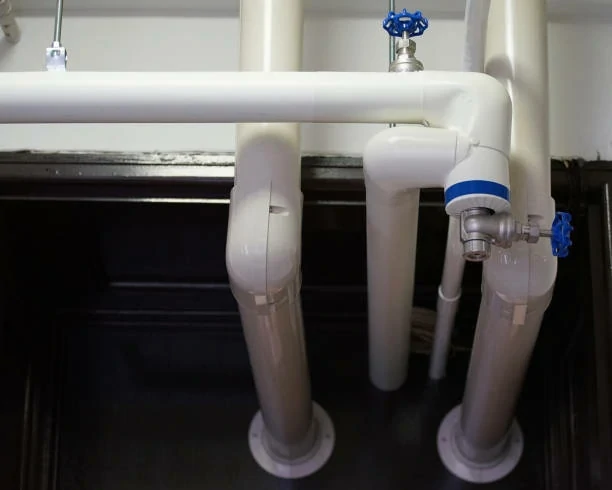

PVC (Polyvinyl Chloride) pipes have become one of the most popular materials in various applications due to their impressive combination of durability, versatility, and cost-effectiveness. Among the critical characteristics that make PVC pipes suitable for a wide range of uses is their compressive strength. This property allows PVC pipes to withstand external pressures and loads without losing structural integrity. In this article, we will explore the concept of compressive strength, its significance in PVC pipes, and why it plays a vital role in the performance of these pipes across different industries.

What Is Compressive Strength?

Compressive strength refers to the ability of a material to resist deformation or failure when subjected to external pressure. When a load presses down on a material, compressive strength determines how much force it can endure before cracking, buckling, or collapsing. For PVC pipes, compressive strength plays a vital role in maintaining the pipe’s integrity when subjected to external loads, such as soil weight, traffic loads, or the pressure exerted by water or other fluids inside the pipe.

Importance of Compressive Strength in PVC Pipes

The compressive strength of PVC pipes impacts their performance and reliability in real-world applications, especially in underground installations. In these installations, PVC pipes must support the weight of surrounding soil and external forces, like passing vehicles. Without sufficient compressive strength, pipes can deform or fail, leading to costly repairs and safety hazards. Compressive strength ensures that PVC pipes perform well under challenging conditions, providing longevity and reliability under significant pressure. Engineers and contractors consider this property when selecting materials, as it affects the pipe’s ability to handle specific loads effectively. This consideration helps ensure that pipes perform reliably over time in various projects.

Factors That Influence the Compressive Strength of PVC Pipes

Several factors contribute to the compressive strength of PVC pipes, and understanding these factors helps ensure that the pipes meet the specific requirements of an application. Here are some key influences:

- Pipe Wall Thickness

The thickness of the PVC pipe walls plays a significant role in determining its compressive strength. Thicker walls provide greater resistance to external pressure, as they distribute the load more effectively across the pipe’s surface. Engineers can specify different wall thicknesses depending on the intended application. For example, pipes used in high-pressure or heavy-load environments typically feature thicker walls to ensure they can handle the increased forces without deformation. - Material Composition

PVC pipes consist of polyvinyl chloride resin combined with various additives that enhance their properties. The composition of the material impacts the compressive strength of the pipe. By adjusting the formulation of PVC, manufacturers can optimize the pipe’s resistance to pressure and other mechanical stresses. Additives that increase flexibility or toughness, for example, can further enhance the compressive strength of the pipe while maintaining other essential qualities, such as durability and corrosion resistance. - Pipe Diameter

The diameter of a PVC pipe also affects its ability to withstand compression. Larger diameter pipes have a greater surface area, meaning they experience more pressure over a broader section. While this can sometimes make larger pipes more susceptible to deformation, engineers can mitigate this risk by using thicker walls or installing the pipes in environments where the external pressure remains within the pipe’s capacity.

Applications That Rely on the Compressive Strength of PVC Pipes

The compressive strength of PVC pipes proves critical in various applications, ensuring that they perform effectively under external pressures and loads. Some of the most common applications where compressive strength plays a key role include:

- Underground Drainage Systems

PVC pipes used in underground drainage systems must resist the pressure exerted by the surrounding soil and any surface loads from vehicles or structures above. The compressive strength of PVC ensures that the pipes maintain their shape and functionality over time, even when buried under heavy loads. This makes them a preferred choice for both residential and municipal drainage applications. - Water Supply Lines

PVC pipes installed in water supply systems need to handle both internal water pressure and any external forces caused by the surrounding environment. Adequate compressive strength ensures that the pipes remain intact and do not collapse or lose their shape under these pressures. Whether used in residential plumbing or large-scale water distribution networks, PVC pipes rely on their compressive strength to deliver water reliably and efficiently. - Sewer Systems

In sewer systems, PVC pipes must withstand the weight of liquid waste and external forces from soil and traffic. The compressive strength of PVC pipes ensures they maintain structural integrity over time, preventing leaks or blockages. This strength helps avoid collapses that could lead to environmental contamination or costly repairs in the system. - Industrial Applications

Industrial facilities often use PVC pipes to transport chemicals, waste, or other materials. These environments may involve high pressures, both from the materials flowing through the pipes and from external forces such as machinery or structural loads. The high compressive strength of PVC makes it an ideal material for these demanding applications, providing a reliable and cost-effective solution.

Testing and Standards for PVC Pipe Compressive Strength

PVC pipes undergo rigorous testing to ensure they meet industry standards for compressive strength. Engineers use various testing methods to assess how well the pipes withstand pressure without failing or deforming. Common tests include:

- Crush Testing: In this test, a controlled force is applied to the PVC pipe, simulating the pressure it might experience in real-world conditions. The test measures the pipe’s resistance to crushing forces and determines its maximum compressive strength.

- Load Testing: This test evaluates the pipe’s ability to handle sustained loads over time. Engineers apply a constant load to the pipe and monitor its performance to ensure it maintains structural integrity without deformation or failure.

Various industry standards, such as those from the American Society for Testing and Materials (ASTM), define the requirements for PVC pipe compressive strength in different applications. These standards help ensure that manufacturers produce pipes capable of withstanding the specific demands of their intended use.

Enhancing Compressive Strength through Installation Practices

While PVC pipes possess high compressive strength, proper installation plays an essential role in optimizing their performance. Factors such as the bedding material used to support the pipe, the depth of the pipe in the ground, and the surrounding soil conditions can all influence the pipe’s ability to withstand external pressures.

By following recommended installation practices, such as providing adequate backfill material and ensuring proper alignment, contractors can enhance the compressive strength of PVC pipes in their systems. This ensures that the pipes remain in optimal condition throughout their service life, even when subjected to significant external forces.

Top PVC Pipe Manufacturers

| Company Name | Location | Years Of Experience | Certificates |

| IFAN | Zhuji, China | 1993 | ISO certification |

| ASC Engineered Solutions | USA | 2019 | ISO certification |

| Patel Precision Works | India | over 21 years | ISO certification |

| RED-WHITE VALVE CORP | USA | 1971 | ISO certification |

| SVF Flow Controls | USA | 1988 | ISO certification |

IFAN international standard for PVC Pipe

IFAN adheres to a wide range of international standards for its products, ensuring high quality and performance. These standards include BS 3505 and BS 4346 from the British Standards Institution; ASTM D1785 SCH40 and SCH80, ASTM D2665, ASTM D2241, ASTM D2729, and ASTM F441/F441M from the American Society for Testing and Materials (ASTM); DIN 8061/8062 from Germany; GB and GB/T 10002 series standards from China; ISO 1452 and EN ISO 1452 from the International Organization for Standardization (ISO); AS/NZS 1477 from Australia and New Zealand; JIS K6741 from Japan; CSA B137.3 from Canada; NSF/ANSI 14 from the United States; and TIS 17-2532/1131-2535 from Thailand. These certifications highlight IFAN’s commitment to meeting global safety and quality requirements across various industries.

Conclusion

The compressive strength of PVC pipes makes them a highly reliable and versatile option in numerous applications, from underground drainage systems to industrial piping networks. This essential property allows PVC pipes to handle heavy loads, resist external pressures, and maintain their structural integrity in a wide range of environments. Understanding the factors that influence compressive strength, along with proper installation techniques, ensures that PVC pipes perform effectively and offer long-lasting value in every application.

Connect

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interest in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments