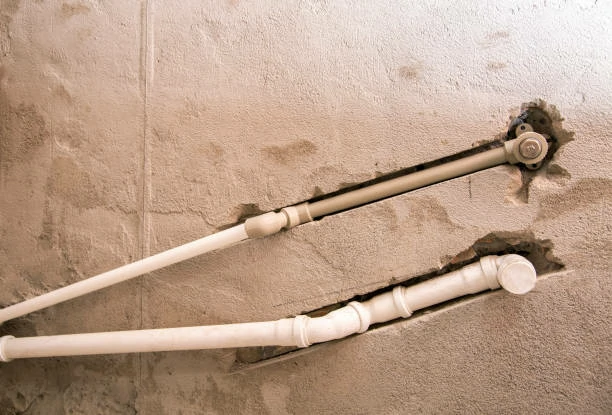

Poor Installation Techniques

One of the most common problems in PPR plumbing arises from poor installation techniques. Incorrect pipe alignment, improper welding, and loose connections can cause leaks or system failures. To prevent this, it is essential to ensure that the installation is done by skilled professionals who follow the correct procedures. For example, using specialized tools to properly weld pipes ensures strong, leak-proof joints. Regular inspections during installation can also identify potential issues early, avoiding future complications.

Inconsistent Water Pressure

Inconsistent water pressure can cause strain on PPR plumbing systems, leading to pipe wear and leaks. This issue often stems from poor design or incorrect pipe sizing. To avoid problems related to water pressure, it is vital to calculate the required pipe diameter based on the expected flow rate and pressure. Installing pressure regulators can also help maintain consistent pressure levels, preventing damage to the pipes. For example, industrial systems should always include pressure control mechanisms to avoid sudden bursts of high pressure.

Thermal Expansion and Contraction

PPR pipes expand and contract with temperature changes. If not accounted for, this can cause pipes to warp, crack, or detach at joints. To prevent these issues, it is necessary to install expansion loops or compensators in areas prone to temperature fluctuations. In hot water systems, leaving adequate space for pipe expansion during installation will prevent long-term damage. For instance, a water heating system should always include thermal expansion buffers to accommodate the pipe’s movement.

Improper Pipe Support

Inadequate pipe support is a frequent problem in PPR plumbing systems. Without proper support, pipes can sag, which puts stress on joints and connections. Over time, this can lead to leaks or even complete system failure. To avoid this, use appropriate pipe clamps and supports at regular intervals to distribute the pipe’s weight evenly. For example, in long horizontal runs, installing clamps every 1.5 meters ensures stability and reduces the risk of sagging.

Exposure to UV Radiation

PPR pipes are not UV-resistant and degrade when exposed to direct sunlight. Prolonged exposure can cause the pipes to become brittle, leading to cracks and leaks. To prevent this, always protect PPR pipes from UV radiation by installing them in shaded areas or using UV-resistant coatings. In outdoor installations, enclosing pipes in protective conduits is also an effective solution. For example, water systems exposed to the sun should be properly shielded to prevent long-term UV damage.

Chemical Resistance Concerns

While PPR pipes are highly resistant to many chemicals, certain substances can degrade them over time. If the wrong type of fluid is transported through the pipes, it can cause internal damage, leading to leaks or pipe failure. To avoid chemical-related issues, always ensure that the PPR material is compatible with the chemicals being transported. For instance, industrial plants that handle aggressive chemicals should check the manufacturer’s guidelines to ensure compatibility with PPR piping.

Freezing and Thawing

In regions with freezing temperatures, PPR pipes are vulnerable to expansion and potential rupture during freeze-thaw cycles. Water that freezes inside the pipes expands, exerting pressure on the walls, which can cause them to crack. To prevent this, ensure that pipes are installed below the frost line in cold regions, or use insulation to protect exposed areas. In addition, drain the system during periods of non-use in cold weather to prevent freezing. For example, outdoor irrigation systems should be winterized to avoid freezing damage.

Regular Maintenance and Inspections

Neglecting routine maintenance is a common cause of long-term issues in PPR plumbing systems. Even though PPR is durable, regular inspections can help identify potential problems before they become serious. Implementing a maintenance schedule that includes checking for leaks, monitoring water pressure, and cleaning the system will extend the lifespan of the pipes. For example, commercial buildings should have annual plumbing inspections to ensure that the PPR systems remain in optimal condition.

Conclusion: Proactive Measures for Long-Term Success

By addressing common issues such as poor installation, water pressure inconsistencies, and thermal expansion, you can significantly reduce the chances of system failure in PPR plumbing. Taking preventive measures, like ensuring proper installation and regular maintenance, will maximize the efficiency and lifespan of your PPR plumbing system. By investing in quality components and following best practices, both residential and industrial users can enjoy the durability and benefits that PPR plumbing offers.

| Best PPR plumbing Manufacturers | ||

| Companies | Headquarter/Location | Year Founded |

| IFAN | ZHEJIANG,CHINA | 1993 |

| RAKtherm | UAE | 1963 |

| REHAU | Muri bei Bern, Switzerland | 1948 |

| POLOPLAST | Leonding, Austria | 1954 |

| ERA | ZHEJIANG,CHINA | 1983 |

| LESSO | GUANGDONG,CHINA | 1986 |

The IFAN PPR piping system adheres to international standards, including ISO 15874 series, EN 15874 series, ASTM F2389, DIN 8077/8078, GB/T 18742 series, and NBR 15884.

Connect

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interest in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments