A client once asked me this exact question, fearing their entire water project would fail. The answer is crucial for both safety and compliance.

Yes, a valve can be used in potable water systems, but only if it holds specific certifications for drinking water contact. HDPE female valves, in particular, are an excellent choice when they carry approvals like NSF/ANSI 61, which confirms they do not leach harmful substances into the water, ensuring safety for human consumption.

This is a critical question with serious implications. Let’s break down exactly what makes a valve safe and approved for the water you drink.

Which Certifications Approve HDPE Female Valves for Potable Water Contact?

You cannot just trust a supplier’s word. I always insist on seeing the certification documents first.

The key certifications that approve HDPE female valves for potable water contact are NSF/ANSI 61, WRAS (UK), KIWA (Europe), and ACS (France). These standards test the material to ensure it does not contaminate water with toxins, metals, or organic compounds above strict safety limits, making the valve legally suitable for drinking water systems.

Understanding the “Why” Behind Certifications

Think of certifications as a valve’s passport for potable water. Without them, you are taking a significant risk. These are not just marketing stamps; they are the result of rigorous laboratory testing.

The most globally recognized standard is NSF/ANSI 61: Drinking Water System Components – Health Effects. This certification is the gold standard in North America and is highly respected worldwide. To earn it, the valve material is soaked in water under controlled conditions. Scientists then test this water for a wide range of contaminants, including metals, chemicals, and other potential leachates. The levels must be far below those considered harmful to human health.

Other regions have their own equivalent standards. For example, in the United Kingdom, the WRAS (Water Regulations Advisory Scheme) approval is mandatory. In many European countries, KIWA or ACS approvals are required. These certifications follow similar principles but are tailored to local regulations and water conditions.

A Guide to Global Water Contact Certifications

The table below explains the major certifications you should look for.

| Certification | Region of Focus | What It Specifically Tests For |

|---|---|---|

| NSF/ANSI 61 | North America & Global Benchmark | Leaching of contaminants (metals, chemicals) into drinking water. |

| WRAS | United Kingdom | Compliance with UK water byelaws for safety and mechanical performance. |

| KIWA | European Union | Material safety, durability, and suitability for long-term contact with drinking water. |

| ACS | France | Compliance with French sanitary regulations for materials in contact with drinking water. |

When you evaluate a valve, always ask the manufacturer for the official certificate for the specific product line. A reputable company like IFAN will provide these documents transparently. This step is your primary defense against using a non-compliant product that could fail a health inspection or, worse, affect public health.

How Does HDPE Material Ensure Water Taste and Odor Remain Unaffected?

Nobody wants their water to taste like plastic. I’ve tested pipes and valves from various materials, and HDPE consistently performs best for purity.

HDPE material ensures water taste and odor remain unaffected because it is an inert, high-density polymer with no plasticizers or stabilizers that can leach out. Its non-porous, smooth surface does not react with chlorine or other water treatment chemicals, preventing the formation of taste-altering compounds and preserving the water’s original quality.

The Science of an Inert Barrier

The core reason HDPE protects water taste is its chemical inertness. Unlike some other plastics, high-quality HDPE used for potable water does not require added plasticizers (which make plastic flexible) or metal-based stabilizers. These additives are common sources of taste and odor contamination in lower-grade plastics. HDPE’s structure is stable and non-reactive.

When water, especially chlorinated tap water, flows through less inert materials, it can cause a reaction. This reaction can create chlorinated compounds that give water a noticeable “plastic” or “chemical” taste. HDPE’s resistance to this reaction is a key reason it is chosen for bottled water and food-grade applications.

Surface Smoothness and Cleanability

Another factor is the material’s surface. HDPE has an extremely smooth, non-porous internal surface. This is important for two reasons related to taste:

- No Adhesion for Contaminants: Minerals, bacteria, or organic matter cannot easily stick to the smooth HDPE surface. In rougher or metallic surfaces, these deposits can build up over time and slowly degrade, affecting taste and odor.

- No Corrosion: Metals like iron or copper can corrode over time. Even at low levels, this corrosion releases metal ions into the water, leading to a metallic taste. HDPE does not corrode, eliminating this source of flavor change entirely.

Comparison of Material Impact on Water

The following table contrasts how different valve body materials can influence water quality.

| Valve Body Material | Risk to Taste & Odor | Primary Cause |

|---|---|---|

| Certified HDPE | Very Low | Inert material; no leaching of plasticizers or stabilizers. |

| Uncertified Plastic | High | Leaching of additives and chemical reaction with chlorine. |

| Brass (with lead-free seal) | Medium | Potential for metallic taste from corrosion over very long periods. |

| Cast Iron | High | High corrosion potential, leading to strong metallic taste and discoloration. |

In short, HDPE acts as a neutral barrier. It does not add anything to the water, and its smoothness prevents it from holding onto substances that could later affect quality. For anyone serious about maintaining water purity from source to tap, specifying certified HDPE components is a fundamental best practice.

What Are the Installation Guidelines for Valves in Drinking Water Systems?

A perfect valve can fail if installed incorrectly. I’ve seen projects delayed because of simple installation errors that contaminated the system.

The key installation guidelines for valves in drinking water systems are: use proper fusion equipment for HDPE, keep all components clean and dry before joining, follow the manufacturer’s exact heating and cooling times, and thoroughly flush and disinfect the entire system before putting it into service to ensure sanitary conditions.

Pre-Installation: The Foundation of Success

Installation starts long before the valve is touched. First, you must store the valves and pipes correctly. Keep them in a clean, dry area away from sunlight and dirt. Before installation, inspect all components for any damage or contamination. Even a small amount of dirt inside a valve can compromise the entire water line.

The most critical rule for HDPE systems is cleanliness. Any dust, moisture, or grease on the fusion surfaces will weaken the joint, creating a potential leak point and a haven for bacteria. Always clean the pipe end and valve socket with a clean, lint-free cloth and isopropyl alcohol before heating.

The Fusion Process: Precision is Key

For HDPE valves, the main installation method is butt fusion or socket fusion. This is not a step where you can guess.

- Use the Right Tool: You must use a fusion machine that is properly maintained and calibrated for the exact pipe and valve diameter.

- Follow Time & Temperature: The manufacturer provides specific heating times and temperatures based on the material grade and size. Do not deviate from these. Under-heating creates a weak joint; over-heating degrades the plastic.

- Apply Correct Pressure: After heating, join the pieces and apply the specified fusion pressure. Hold this pressure for the full cooling time. Do not move or stress the joint while it cools.

Post-Installation: Commissioning for Safety

Once the valve is installed, your job is not done. The entire system must be commissioned for potable use.

- Flushing: First, flush the system at high velocity with clean water to remove any construction debris or loose particles.

- Disinfection: Next, you must disinfect. This usually involves filling the system with a water-chlorine solution at a specific concentration (e.g., 50 mg/L). This solution must remain in the system, with all valves cycled open and closed, for a minimum contact time (often 24 hours).

- Final Rinse & Test: Finally, thoroughly flush the system with potable water until the chlorine is gone. A water quality test should be conducted to confirm the water is safe and meets all standards before the system is opened for public or residential use.

Critical Installation Do’s and Don’ts

| Do’s | Don’ts |

|---|---|

| Keep pipe ends and valve sockets perfectly clean. | Touch the heated fusion surfaces with your hands or dirty gloves. |

| Use a dedicated, calibrated fusion machine. | Use an open flame or improper tool to try and melt the HDPE. |

| Follow the manufacturer’s fusion parameters exactly. | Guess the heating or cooling time. |

| Flush and disinfect the entire system after installation. | Put a new system into service without disinfection. |

Following these guidelines is non-negotiable. They ensure the mechanical integrity of the valve installation and, more importantly, the sanitary safety of the drinking water that will flow through it.

How Do HDPE Valves Prevent Biofilm Growth Compared to Metal Alternatives?

Biofilm is a silent problem in water systems. I’ve consulted on projects where biofilm in old metal pipes caused persistent water quality issues.

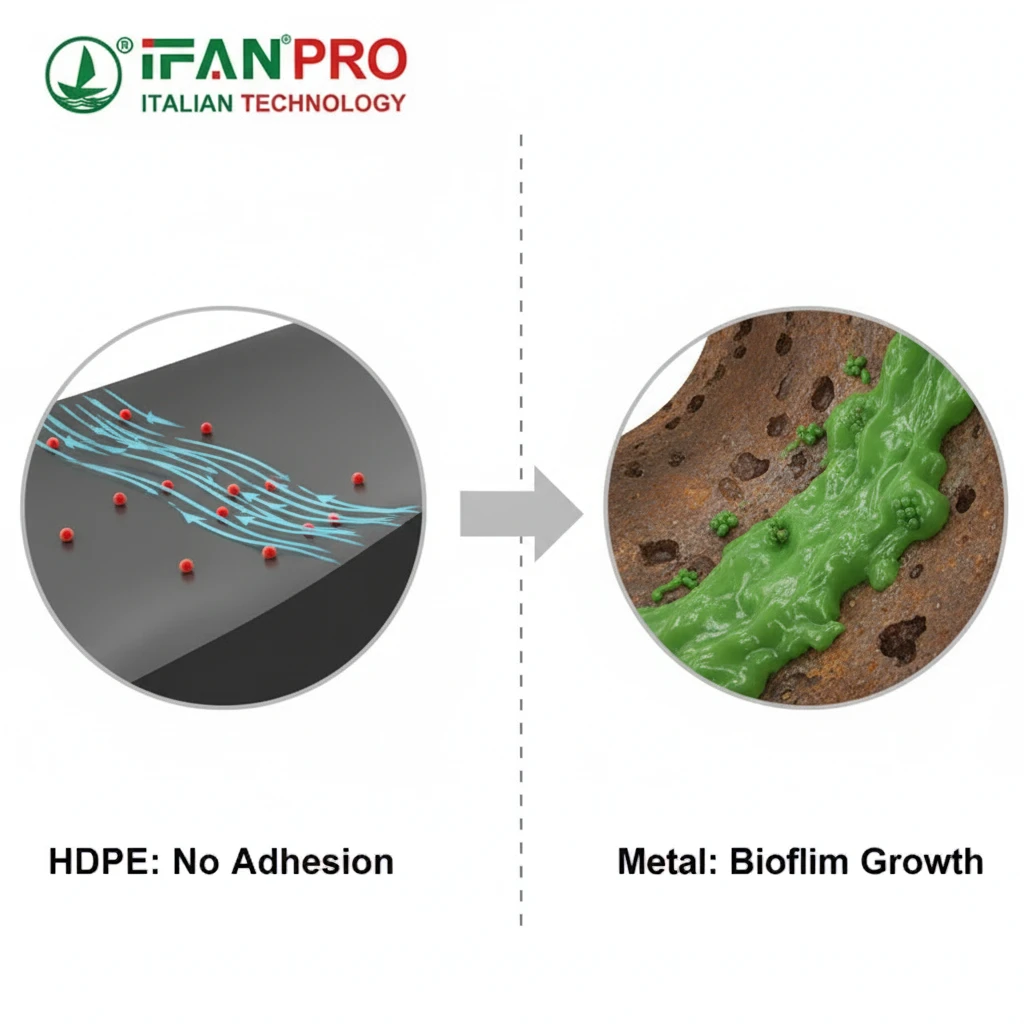

HDPE valves prevent biofilm growth more effectively than metal alternatives primarily due to their ultra-smooth, non-porous internal surface, which offers no niches for bacteria to attach. Additionally, HDPE does not corrode, eliminating the rough, pitted surface and iron nutrients that corrosion creates, which actively promote biofilm formation in metal pipes and valves.

The Biofilm Challenge in Water Systems

Biofilm is a thin, slimy layer of microorganisms that sticks to wet surfaces. It acts like a glue, trapping more bacteria and nutrients. Once established, it is very difficult to remove and can harbor harmful pathogens like Legionella. It also causes taste, odor, and corrosion problems. The goal is to make the pipe and valve interior as inhospitable as possible to initial bacterial attachment.

HDPE’s Defensive Properties

HDPE fights biofilm in two main ways:

- Surface Smoothness: The internal surface of a high-quality HDPE valve is hydraulically smooth. Under a microscope, it has very few pits or scratches. Bacteria need microscopic roughness or pores to get a foothold. The smooth HDPE surface gives them nothing to grip, so they are more easily swept away by the flowing water.

- Non-Corrosiveness: This is the most significant advantage over metals. Metal surfaces, even stainless steel, can eventually experience microscopic corrosion or pitting. This corrosion:

- Creates Roughness: It makes the surface texture much rougher, perfect for bacteria to hide and adhere.

- Provides Food: Corrosion releases metal ions (like iron) into the water. Some bacteria use these ions as nutrients, actually thriving near corroding metal surfaces.

HDPE does not corrode. Its surface remains smooth and chemically stable for decades, providing a consistently hostile environment for biofilm formation.

Metal Valve Limitations

Metal valves, such as those made from cast iron or even brass, have inherent drawbacks:

- Surface Degradation: Over time, mineral scale (limescale) builds up on metal surfaces. This scale is extremely porous and rough, creating an ideal matrix for biofilm to grow in and under.

- Corrosion By-Products: The rust or corrosion from metals forms a layer that not only is rough but can also protect biofilm colonies from the scouring effect of water flow and from disinfectants like chlorine.

Biofilm Risk Factor Comparison

| Material Characteristic | HDPE Valve | Typical Metal Valve | Impact on Biofilm |

|---|---|---|---|

| Surface Smoothness | Very High (Inherent) | Low (Degrades over time) | Smooth HDPE prevents attachment. |

| Corrosion Potential | None | Medium to High | Corrosion on metal feeds and shelters bacteria. |

| Chemical Inertness | High | Low (Reactive) | HDPE does not interact with disinfectants. |

| Long-Term Stability | Excellent (No change) | Poor (Gets rougher) | HDPE performance stays constant. |

Therefore, while no system is 100% biofilm-proof, HDPE valves offer a significantly higher level of inherent protection compared to metal alternatives. This leads to more biologically stable water, reduced need for high disinfectant doses, and lower long-term maintenance risks. For systems where water quality is paramount, such as in hospitals, schools, or municipal supplies, this material advantage is a critical design consideration.

Conclusion

Using the right valve in a potable water system is essential for safety and quality. For certified, reliable, and biofilm-resistant HDPE female valves, trust IFAN to provide the solution for your project.

Recent Comments