Last year, a client faced a $50,000 loss from an undetected valve leak. This disaster made the promise of smart valves very real for me. Can they actually prevent this?

Yes, a modern IoT ball valve can effectively prevent leaks and send alerts. It uses built-in sensors to monitor its own health and flow conditions, automatically shuts off when a threat is detected, and immediately sends alerts via text, email, or app notifications to operators. This proactive system stops small issues from becoming major losses.

Let’s break down exactly how this technology works to protect your operations.

What Built-In Sensors Detect Potential Leaks or Seal Failures Early?

Waiting for a puddle on the floor is not a strategy. I’ve seen too many failures that sensors could have caught weeks in advance.

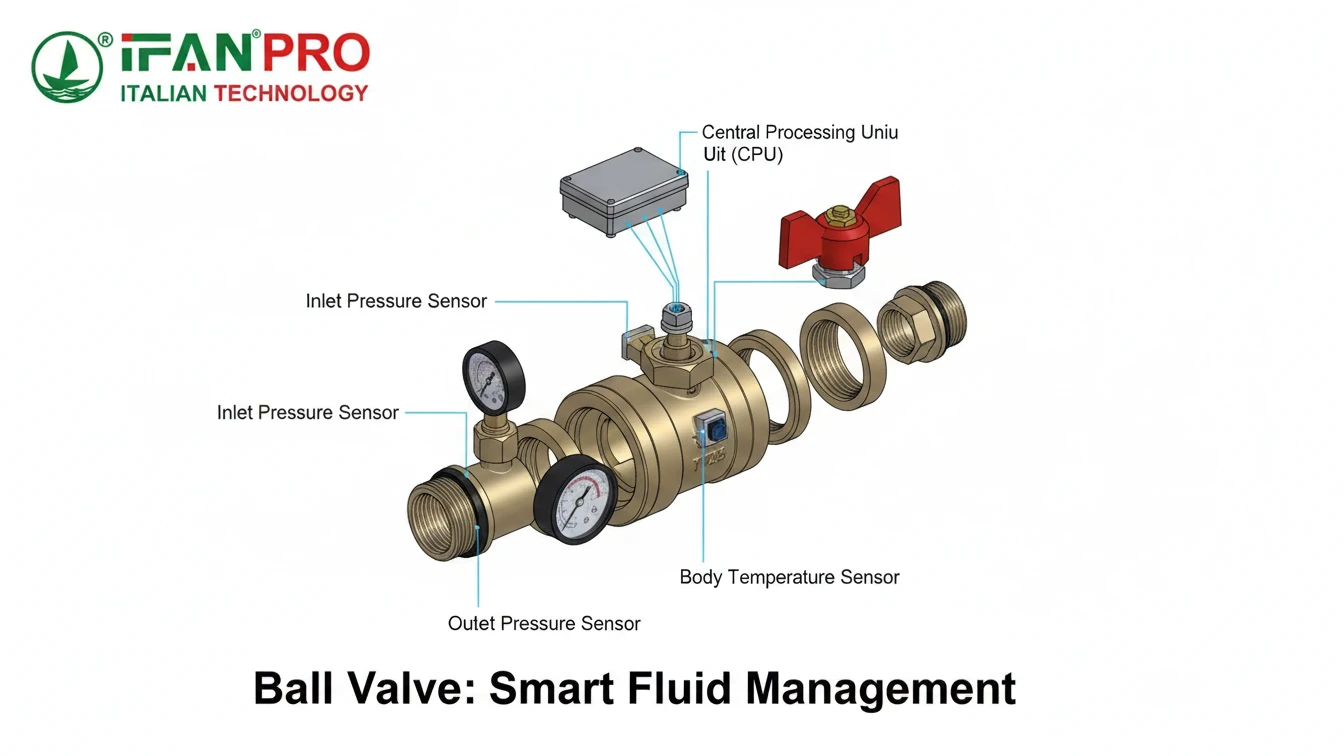

IoT ball valves use a combination of sensors like pressure transducers, temperature sensors, and torque or position sensors. These work together to detect early signs of trouble, such as unexpected pressure drops indicating a leak, abnormal temperature changes, or increased resistance in the valve’s movement signaling seal wear or blockage.

The Role of Core Monitoring Sensors

An IoT valve is only as good as its sensors. They are its eyes and ears, constantly checking its health and the fluid it controls. The main goal is to find problems before they cause a leak or a complete shutdown.

First, pressure sensors are the primary leak detectors. They monitor the pressure both upstream and downstream of the valve. In a closed system, the pressure should remain stable. If the valve is closed but the downstream pressure starts to rise, it suggests the valve is not sealing properly—an internal leak. A sudden drop in pressure when the valve is open can indicate a burst pipe or fitting elsewhere in the line. The sensor notices this change instantly.

Second, temperature sensors provide important context. A sudden drop in temperature in a pipe carrying hot fluids might indicate a leak or a cold water intrusion. Conversely, overheating can signal excessive friction from a failing seal or an actuator working too hard. Monitoring temperature helps rule out other causes and confirms what the pressure data suggests.

Monitoring Valve Health and Performance

Third, torque and position sensors inside the valve actuator are crucial for predicting mechanical failure. The valve motor uses a certain amount of force (torque) to turn the ball to the open or closed position. Over time, as seals wear out or debris builds up, the valve becomes harder to turn. The sensor detects this increased torque. It sends a warning that maintenance is needed long before the valve seizes up or fails to seal completely.

Additionally, some advanced valves include acoustic/vibration sensors. These can “listen” for the high-frequency sound of fluid escaping through a tiny crack or a loose fitting—a sound humans would never hear.

Common Sensor Types and Their Functions

The table below summarizes how each sensor contributes to early detection:

| Sensor Type | What It Measures | What Problem It Detects Early |

|---|---|---|

| Pressure Transducer | Fluid pressure before and after the valve. | Internal valve leakage, pipe bursts, or blockages. |

| Temperature Sensor | Fluid or actuator temperature. | Fluid leaks, seal degradation, or motor overload. |

| Torque Sensor | Force needed to rotate the valve. | Worn seals, debris buildup, or mechanical wear. |

| Position Sensor | Exact open/close angle of the ball. | Valve not fully seating, leading to partial flow when closed. |

| Acoustic Sensor | High-frequency sounds/vibrations. | Pinhole leaks or cavitation in the pipeline. |

This network of sensors creates a full picture of valve health. It moves maintenance from a reactive “fix it when it breaks” model to a predictive “service it before it fails” model. For a plant manager, this means avoiding unplanned downtime and the huge costs that come with it.

How Does the Valve Automatically Shut Off Upon Detecting a Leak?

An alert is good, but automatic action is better. I value systems that act first and explain later when preventing damage.

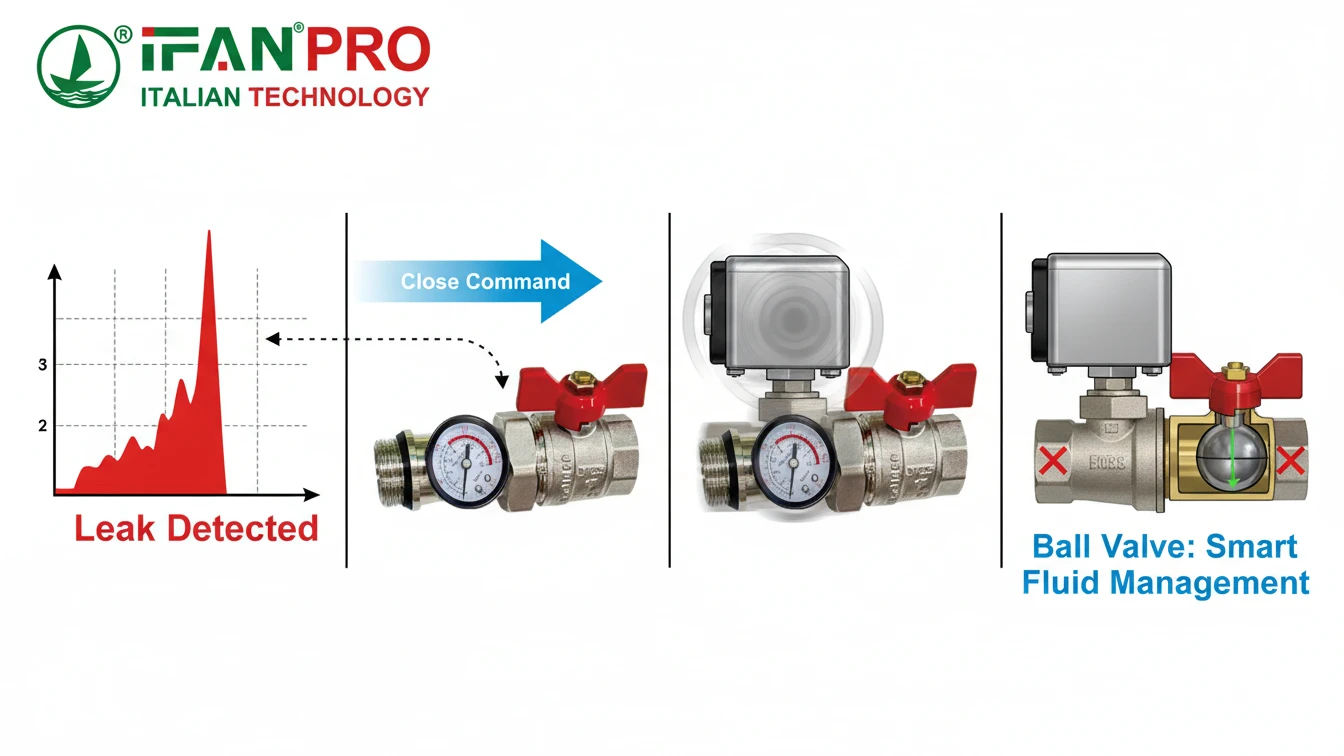

The valve automatically shuts off through its smart actuator. When the sensor data crosses a pre-set danger threshold (like a rapid pressure drop), the valve’s onboard control logic immediately commands the electric or pneumatic actuator to rotate the ball to the fully closed position, isolating the section of pipe to stop the flow within seconds.

The Decision and Command Process

The “automatic” in automatic shut-off relies on smart, local decision-making. Here is a step-by-step look at the process.

The system constantly compares incoming sensor data against safe operating parameters programmed by the engineer. These are your “rules,” like “if downstream pressure rises by 10% while valve is commanded closed, initiate shutdown.” The logic is stored right in the valve’s gateway or controller; it doesn’t need to wait for a signal from a faraway cloud server. This local analysis is key for speed.

Once a leak-signaling rule is triggered, the controller sends a command to the actuator. In an electric actuator, this means sending a current to the motor to drive the valve stem to the closed position. In a pneumatic actuator, it means energizing a solenoid to divert air pressure to close the valve. This happens in less than a second from detection.

Ensuring Reliable Closure in an Emergency

A critical feature is fail-safe design. Most smart valves used for safety are configured as “fail-close.” This means if the system loses power or communication, the valve will automatically close by default. A spring or a battery backup system drives the valve shut. This ensures protection even during a total power outage, which often accompanies major incidents.

Furthermore, the valve provides confirmation feedback. As it closes, the position sensor verifies the ball has reached the 100% closed position. It then sends a confirmation signal back to the system: “Leak detected at Valve X-101. Emergency shut-off command executed. Valve confirmed fully closed.” This closes the loop and lets operators know the action was successful.

Shut-Off Sequence Timeline

The table below shows how quickly a modern IoT valve can respond compared to a manual process.

| Action | IoT Valve (Automatic) | Traditional Manual Response |

|---|---|---|

| 1. Leak Detection | Instantaneous via sensors (0-2 seconds). | Relies on visual sighting or scheduled check (minutes to hours). |

| 2. Alarm & Decision | Automated logic makes decision (<1 second). | Operator hears alarm, verifies, decides to act (1-5 minutes). |

| 3. Shut-Off Execution | Actuator closes valve (5-30 seconds). | Technician runs to location and manually turns handwheel (2-10 minutes). |

| 4. Confirmation | Position sensor confirms closure (instant). | Visual or secondary pressure check needed. |

| Total Response Time | 10 seconds to 1 minute. | 15 minutes to several hours. |

This automatic response is the core of its protective value. It acts as a vigilant, unblinking guard that can react at machine speed. It stops a small leak from becoming a flood, giving your team time to safely plan the repair without the pressure of an active, worsening crisis.

What Alert Methods Notify Operators About Valve Status or Faults?

Information is useless if it doesn’t reach the right person, at the right time, in the right way. I’ve seen good data get lost in a noisy control room.

Operators receive alerts through multiple, redundant methods. Primary alerts are sent via mobile apps with push notifications, SMS text messages, and emails. These alerts are also logged in the valve’s cloud or on-premise dashboard, providing detailed status history, fault codes, and recommended actions for maintenance teams.

Primary and Immediate Alert Channels

The goal of notification is to make critical information impossible to ignore, whether the operator is at their desk, on the factory floor, or off-site.

The most direct method is the mobile app push notification. Dedicated apps for asset management display a live dashboard of all valves. When a fault occurs, a pop-up appears on the smartphone or tablet screen, often with a distinct sound. This is ideal for on-duty engineers moving around a facility. The notification can include one-touch buttons like “Acknowledge” or “View Details.”

For major alarms, like an automatic shut-off, SMS text messages are sent. Text messages are highly reliable because they use cellular networks separate from the plant’s Wi-Fi. They get through even if the local network is busy. A text can read: “URGENT: Valve V-205 Auto-Closed due to Pressure Drop. Line 3 Isolated.” This ensures key personnel are alerted immediately, 24/7.

Secondary and Detailed Reporting Channels

Simultaneously, email alerts are generated. Emails are perfect for non-critical warnings (like a torque increase suggesting future maintenance) and for creating a permanent, searchable audit trail. They can contain more detail, such as graphs of pressure trends leading up to the event, and can be easily forwarded to managers or maintenance planners.

All this information feeds into a central web-based dashboard. This is the system’s “mission control.” Here, operators see a real-time map of all valves color-coded by status (green for normal, yellow for warning, red for alarm/fault). They can click on any valve to see its complete history, all sensor readings, past alerts, and maintenance records.

Alert Method Comparison for Different Scenarios

Different situations call for different alerts. The table below helps match the method to the need:

| Alert Method | Best For | Speed | Information Detail |

|---|---|---|---|

| SMS Text | Critical, time-sensitive emergencies (Leak, Auto-Shutoff). | Very Fast (Seconds) | Low to Medium. Short, urgent message with key facts. |

| App Push Notification | High-priority alerts for on-site, mobile technicians. | Fast (Seconds) | Medium. Quick summary with a link to more data in the app. |

| Non-critical warnings, maintenance schedules, daily reports. | Slower (Minutes) | High. Can include full data logs, charts, and attachments. | |

| Dashboard Alarm | Centralized monitoring for control room operators. | Instant (on-screen) | High. Full visual and historical context on a large screen. |

| Audible/Visual Siren | Immediate local warning in the physical valve area. | Instant | Very Low. Simple sound/light indicating a problem nearby. |

This layered approach ensures no single point of failure in communication. If the Wi-Fi is down, SMS works. If a technician misses a text, the email record is there. It guarantees that the right people know about a problem as soon as it happens, with the information they need to act.

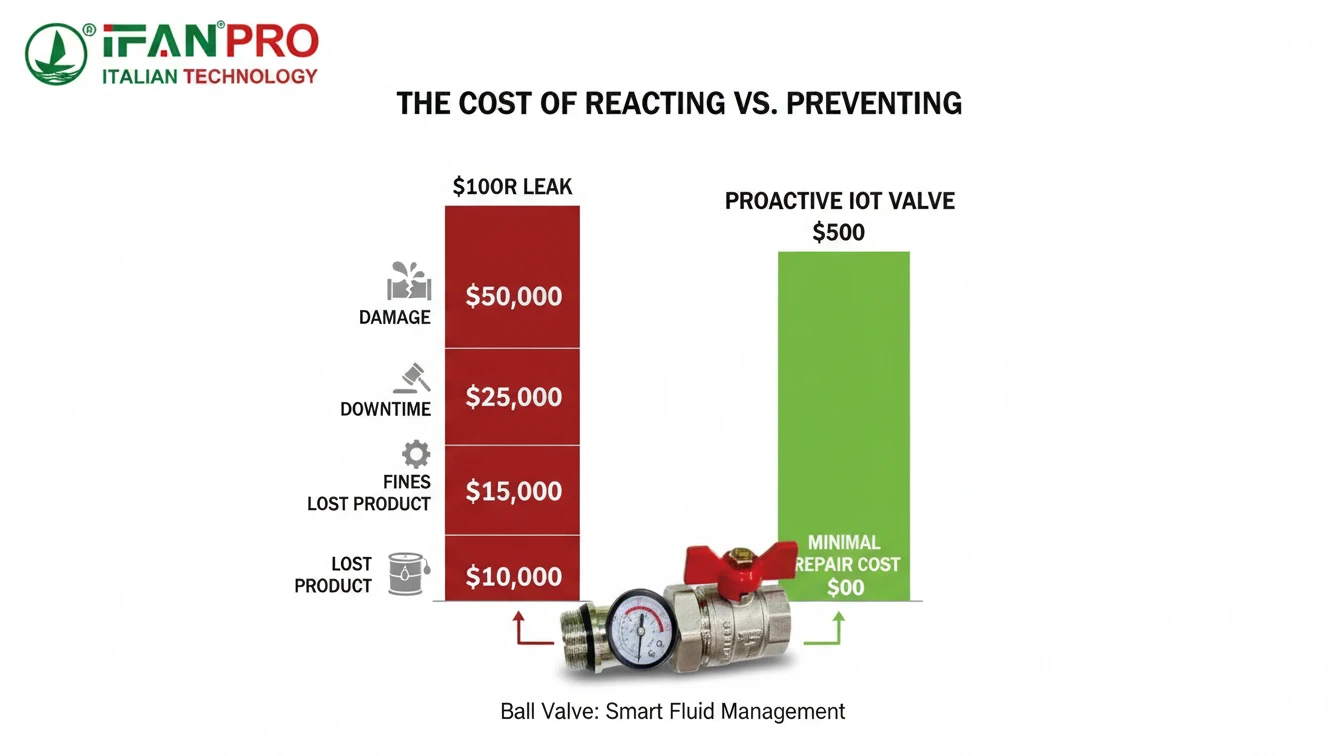

How Does This Proactive Feature Prevent Costly Water or Fluid Loss?

Proactivity isn’t an expense; it’s the cheapest form of insurance. My clients measure savings in repaired assets, avoided fines, and continuous production.

Proactive monitoring prevents costly loss by stopping leaks at the earliest second, minimizing spill volume. It avoids the secondary costs of production downtime, environmental cleanup fees, damage to equipment and infrastructure, and potential regulatory fines. This transforms a potential disaster into a small, manageable maintenance event.

Minimizing the Direct Cost of Lost Fluid

The most obvious saving is in the fluid itself. Whether it’s expensive chemicals, treated water, or fuel, every drop lost is money wasted. A tiny leak from a seal might lose gallons per hour. Over weeks or months before a manual inspection finds it, this adds up to thousands of dollars. A pinhole leak under pressure can spray a surprising amount.

An IoT valve stops this loss within seconds or minutes of detection. By comparing a slow, undetected leak to a fast, stopped one, the math is simple. Let’s say a leak loses 2 gallons per minute. A manual check finds it in 7 days (10,080 minutes): 20,160 gallons lost. An IoT system detects and shuts it off in 1 minute: only 2 gallons lost. The savings on the product alone can pay for the valve.

Avoiding Catastrophic Secondary Costs

However, the true financial power of proactivity is in avoiding the domino effect of a major leak. These secondary costs are often 10 to 100 times higher than the value of the lost fluid.

First, production downtime is a massive cost. A major leak often forces an entire line or process to shut down for repairs. This halt in production means lost revenue, missed orders, and idle labor. A small, automatically isolated leak might allow production to continue on a backup line while repair happens, avoiding downtime completely.

Second, environmental and cleanup costs can be enormous. Leaks of oil, chemicals, or even nutrient-rich wastewater can lead to soil contamination, stormwater system pollution, and hefty government fines. The cost of emergency spill response teams, cleanup contractors, and legal fees can be astronomical. Proactive containment keeps the spill inside the pipe or a very small area.

The Full Financial Impact: A Comparison

Third, damage to other equipment and structures is common. Water leaks ruin electrical systems, cause mold, and weaken foundations. Chemical leaks corrode surrounding equipment. Preventing a large-scale spill prevents this widespread damage.

Finally, there are reputational and regulatory risks. Companies face strict penalties for environmental incidents and safety violations. A proactive system demonstrates due diligence and can significantly reduce insurance premiums.

Cost-Benefit Analysis of Proactive IoT Valves

The table below contrasts the financial outcomes of a reactive versus a proactive approach to a significant leak.

| Cost Category | Traditional Reactive Scenario (Major Leak) | IoT Proactive Scenario (Minor, Contained Leak) |

|---|---|---|

| Lost Fluid/Product | High (Thousands of gallons) | Very Low (A few gallons) |

| Emergency Repair | High (Overtime labor, rush parts) | Low (Scheduled, normal-rate repair) |

| Production Downtime | Very High (Hours or days of lost output) | None or Minimal (Bypass used) |

| Cleanup & Fines | Potentially Catastrophic | None or Very Minor |

| Secondary Damage | Likely (Corrosion, electrical damage) | Unlikely |

| Total Estimated Impact | $50,000 – $500,000+ | $500 – $5,000 |

Investing in smart, proactive valves is not a plumbing upgrade; it’s a financial risk mitigation strategy. It protects your bottom line from unpredictable, devastating losses by turning catastrophic failures into routine, low-cost maintenance items.

Conclusion

IoT ball valves offer a powerful solution by detecting threats early, acting automatically, and alerting instantly. To integrate this proactive protection into your systems, explore the IFAN Smart Valve Series for reliable monitoring and control.

Recent Comments