A client once faced massive water bill disputes across multiple properties. Guessing usage was over; they needed proof. Modern smart valves provide that proof by turning guesswork into precise numbers.

Yes, modern smart valves can provide real-time data on fluid consumption. They achieve this by integrating flow meters and sensors that continuously measure the volume of liquid passing through, then instantly transmitting this data to a digital platform where you can view, analyze, and use it for immediate decision-making.

This capability transforms a simple shut-off device into a powerful management tool. Next, let’s break down exactly how these smart valves work and the concrete benefits they deliver.

What Metering Capabilities Are Integrated into the Smart Valve?

The core of any data-providing valve is its metering system. It’s what turns a pipe component into a data source.

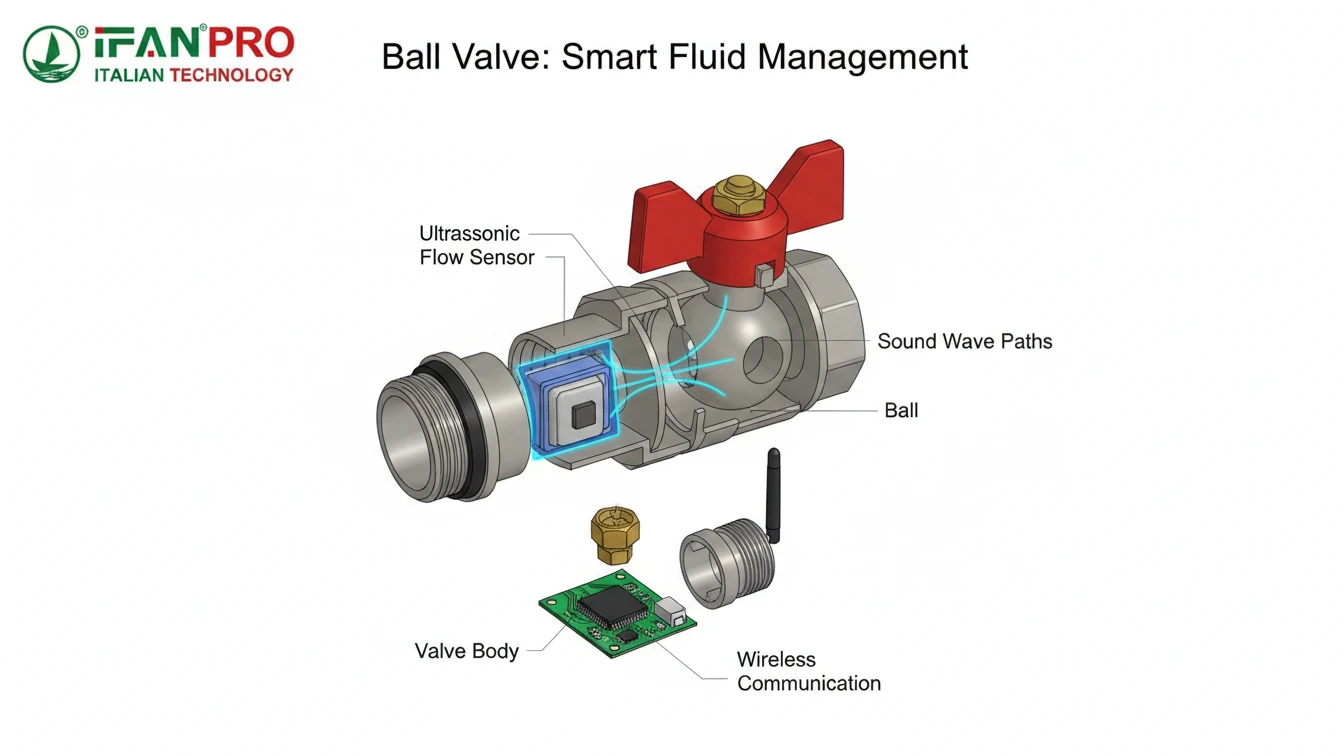

Smart valves integrate precise flow meters, typically using turbine, electromagnetic, or ultrasonic sensors, to measure the volume and rate of liquid flow. Additionally, they often include sensors for pressure and temperature, providing a complete picture of the system’s conditions alongside consumption data.

How Flow Meters Work Inside a Valve

The magic happens inside the valve body. A traditional valve just opens and closes. In contrast, a smart valve has a measuring device built right into its flow path. Manufacturers use a few common technologies, each suited to different fluids and accuracy needs.

First, let’s look at turbine meters. Here, a small, free-spinning turbine sits in the flow path. As liquid passes, it spins the turbine. Then, a sensor counts each rotation. Because each rotation corresponds to a specific volume of liquid, the system can calculate the total flow. This method offers a reliable and cost-effective solution for clean water.

Second, electromagnetic meters work best with conductive liquids like water. They use Faraday’s Law of electromagnetic induction. Specifically, the valve generates a magnetic field across the pipe. As the conductive fluid flows through, it generates a voltage proportional to its flow rate. Importantly, this method has no moving parts, which makes it very durable.

Third, ultrasonic meters are highly advanced. They send ultrasonic sound waves across the pipe. The time it takes for the sound to travel changes with the flow speed of the liquid. By measuring this difference, the meter calculates the flow rate with high accuracy. This method is excellent for dirty or corrosive fluids because nothing touches the liquid.

Beyond Volume: Pressure and Temperature

A truly smart valve does more than just count gallons or liters. It also monitors the environment inside the pipe. Therefore, many units include pressure transducers and temperature sensors.

For example, a pressure sensor can tell you if a dangerous pressure surge occurs, a leak happens (which often causes a pressure drop), or a pump starts failing. Similarly, a temperature sensor is crucial for heating or cooling systems, as it ensures the fluid stays at the correct temperature. Together, these sensors create a comprehensive data profile.

Comparison of Integrated Metering Technologies

| Technology | How It Works | Best For | Key Advantage |

|---|---|---|---|

| Turbine Meter | Fluid spins a turbine; rotations are counted. | Clean water, oils, chemicals. | Simple, reliable, cost-effective. |

| Electromagnetic Meter | Measures voltage induced by conductive fluid moving through a magnetic field. | Water, slurries, conductive liquids. | No moving parts, handles dirty liquids well. |

| Ultrasonic Meter | Measures the speed difference of ultrasonic waves traveling with and against the flow. | All liquid types, especially corrosive or dirty fluids. | High accuracy, no pressure drop, very versatile. |

In summary, choosing the right metering technology depends on your fluid type, required accuracy, and budget. However, the result is the same: a valve that knows exactly how much is flowing through it at every second.

How Is Consumption Data Collected, Displayed, and Communicated?

Data inside a valve is useless unless it gets to the people who need it. Therefore, the collection and communication system acts as the vital link.

Consumption data is collected by the valve’s internal sensor and processed by a built-in microprocessor. Then, the system can display it locally on optional digital screens and communicate it wirelessly via IoT networks (like LoRaWAN or cellular) to cloud-based software platforms. Finally, users can visualize the data on dashboards accessible from computers or smartphones.

The Data Journey: From Sensor to Screen

The process happens in a continuous, automated loop. Understanding each step shows how seamless the system can be.

Step 1: Collection & Processing

First, the flow, pressure, and temperature sensors generate raw electronic signals. Then, a small but powerful microprocessor inside the valve’s housing instantly reads these signals. It converts the raw data into meaningful units—like liters per minute, bar of pressure, or degrees Celsius. After that, the system timestamps this processed data and stores it in the valve’s local memory.

Step 2: Communication

This is where the “smart” label truly shines. Specifically, the valve transmits its data without any manual effort. It uses wireless IoT (Internet of Things) modules. For instance, for facilities spread over a large area like a campus, LoRaWAN is popular because it sends small data packets over long distances with very low power. For remote sites, cellular (4G/5G) modules can send data directly to the cloud. In buildings, Wi-Fi or dedicated industrial networks might be a better choice.

Step 3: Display & Visualization

Once the data reaches the secure cloud platform, the real-time dashboard comes to life. Consequently, authorized users can log in from anywhere. Typically, a dashboard shows:

- Real-Time Gauges: Current flow rate, pressure, and totalizer (lifetime volume).

- Trend Graphs: Charts showing consumption over hours, days, or months.

- Alarm Panels: Instant alerts for leaks (sudden continuous flow), low pressure, or high temperature.

- Data Tables: Exportable logs of all historical readings.

Furthermore, some valves also have a small local LCD screen that shows key readings right at the installation point for maintenance staff.

Communication Method Comparison

| Method | Range | Power Use | Ideal For |

|---|---|---|---|

| LoRaWAN | Very Long (several km) | Very Low | Large campuses, city-wide water networks, agriculture. |

| Cellular (4G/5G) | Global (with signal) | Moderate to High | Remote tanks, construction sites, temporary installations. |

| Wi-Fi | Medium (within a building) | Low | Commercial buildings, factories, indoor systems. |

| Wired (RS-485, Ethernet) | Limited by cable length | Low | Industrial plants where reliability is critical and wiring exists. |

In conclusion, this automated pipeline of information eliminates manual meter reading. As a result, it provides a constant, accurate, and remote view of your fluid systems.

How Can This Data Be Used for Analytics and Billing Purposes?

Raw data becomes valuable when it drives action and creates financial clarity. Therefore, smart valve data excels in both operational and financial analytics.

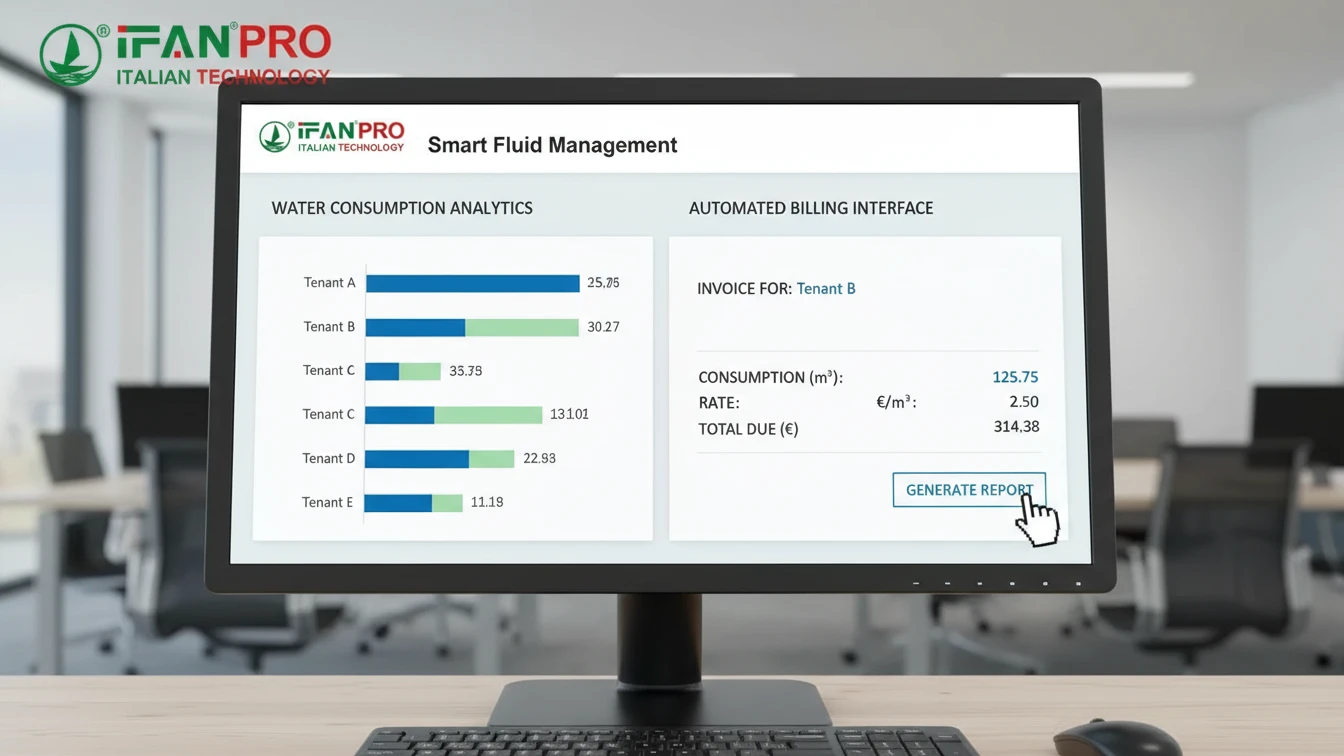

This data enables accurate, automated billing by providing indisputable consumption totals for specific tenants, processes, or buildings. For analytics, it allows for detailed usage pattern analysis, cost allocation across departments, and identification of billing anomalies or inefficiencies. Ultimately, this turns data into actionable financial intelligence.

Transforming Data into Accurate Bills

For property managers or industrial facilities billing multiple tenants or departments, manual estimation is a major pain point. However, smart valves solve this definitively.

Automated Sub-metering is the key application. For example, a smart valve installed on the supply line to each tenant’s unit acts as a dedicated sub-meter. Then, the cloud platform automatically associates the consumption from each valve with a specific customer.

At the end of the billing period, the software generates a report with the exact consumption recorded. This report is transparent, so you can share it with the tenant as proof. Consequently, this process eliminates disputes, ensures fairness, and streamlines accounting work. Moreover, the system can even automate invoice creation by integrating with billing software.

Advanced Analytics for Cost Control

Beyond simple totals, the data enables deep analysis to save money.

1. Usage Pattern Analysis: The dashboard can show when and how much fluid is used. For instance, a factory manager can see if water is running unnecessarily on weekends. Similarly, a building manager can identify overly long irrigation cycles. This insight allows for scheduling adjustments that directly reduce waste.

2. Cost Allocation and Benchmarking: In a factory, you can precisely assign the water or coolant cost of manufacturing “Product A” versus “Product B.” This improves product costing accuracy. Additionally, you can benchmark similar buildings or production lines against each other to identify outliers that are using too much.

3. Leak Detection and Loss Accounting: A continuous, small flow when all processes should be stopped clearly indicates a leak. The system can flag this immediately, potentially saving thousands in wasted water. It also precisely quantifies the volume lost, which is important for loss accounting in utility management.

Practical Billing & Analytics Workflow Table

| Step | Manual System Pain Point | Smart Valve Solution |

|---|---|---|

| 1. Measurement | Physical meter reading is time-consuming and prone to human error. | The system collects and transmits data automatically, 24/7, with perfect accuracy. |

| 2. Aggregation | Manually compiling readings from multiple meters into a spreadsheet. | The cloud platform automatically aggregates data by tenant, zone, or time period. |

| 3. Analysis | Difficulty spotting trends or anomalies from static monthly totals. | Interactive dashboards visually highlight patterns, spikes, and inefficiencies. |

| 4. Billing | Generating invoices based on estimates or delayed readings leads to disputes. | Automated reports with precise, date-stamped consumption data support fair and fast invoicing. |

| 5. Action | Reacting to high bills months after the waste occurred. | Real-time alerts allow for immediate investigation and correction of issues. |

In summary, this shift from reactive bill-paying to proactive consumption management is the primary financial benefit of smart valve data.

What Insights Does Trend Data Offer for System Optimization?

Real-time alerts are crucial, but the long-term trend data is where the deepest operational insights and cost savings are hidden.

Trend data reveals patterns in consumption, pressure, and temperature that are invisible in daily snapshots. As a result, these insights allow for predictive maintenance, system efficiency tuning, capacity planning, and verification of repair effectiveness. Therefore, they move operations from a reactive “fix-it-when-it-breaks” model to a proactive, optimized state.

From Reactive to Predictive Maintenance

Waiting for a pump to fail or a pipe to burst is expensive. However, trend data helps you see problems coming.

Pump Performance Degradation: A smart valve monitoring pressure and flow can show if a pump is working harder to deliver the same output. For example, a gradual increase in pump runtime or a gradual decrease in discharge pressure can signal wear. Consequently, this allows you to schedule maintenance before a catastrophic failure stops production.

Filter Clogging: In a system with filters, you can monitor the pressure differential across the filter. A clean filter has a small pressure drop. As it clogs, the pressure drop increases steadily. The trend data will show this climb, telling you the optimal time to change the filter—not too early (wasting filter life) and not too late (straining the system).

Optimizing for Efficiency and Capacity

Trends tell you how your system actually operates, not just how it was designed to operate.

1. Identifying Base Load vs. Peak Load: Analyzing daily or weekly flow charts shows your system’s “base load” (constant, unavoidable usage) and “peak load” (short periods of high demand). You might find that a smaller, more efficient pump could handle the base load, with a larger pump kicking in only for peaks. Therefore, this strategy can save significant energy.

2. Thermal System Efficiency: For heating or cooling systems, correlating flow rate with temperature input and output over time can reveal inefficiencies. For instance, the data might show that a system is overheating water and then mixing in cold water to reach the desired temperature—a wasteful practice. This insight allows for precise recalibration of setpoints.

3. Right-Sizing and Planning: Long-term (yearly) consumption trends are invaluable for planning. If data shows a 10% annual increase in water use in a building, you can plan for future expansion. Conversely, it can prevent you from over-investing in new supply lines or storage tanks that you don’t actually need.

Key Trend Analysis Insights and Actions

| Trend Pattern | What It Might Indicate | Proactive Optimization Action |

|---|---|---|

| Gradual upward creep in base flow | A small, growing leak in the distribution network. | Use the data to locate the general area of the leak and schedule repair before it escalates. |

| Spikes in consumption at odd hours | Automated processes (like irrigation) running at non-optimal times or malfunctions. | Reschedule processes to off-peak utility rate hours or investigate the equipment causing the spike. |

| Seasonal pressure variations | Changing demand on a shared municipal supply or issues with pressure-reducing valves. | Install or adjust compensating equipment to ensure consistent pressure year-round for equipment. |

| Declining temperature efficiency over months | Scaling or fouling inside heat exchangers or boilers. | Schedule a chemical descaling or cleaning procedure to restore efficiency and save energy. |

In conclusion, by studying these trends, you move from simply monitoring your fluid systems to actively learning from them and engineering them for peak performance and lowest lifetime cost.

Conclusion

Smart valves transform invisible consumption into clear, actionable data for accurate billing, predictive maintenance, and system optimization. For reliable smart valve solutions with robust data capabilities, explore IFAN’s range of intelligent monitoring products.

Recent Comments