I once saw a client’s water tank flood a warehouse because a corroded metal valve failed to shut off. This costly lesson sent me searching for a better solution.

Yes, a modern plastic float valve can effectively prevent overflow and waste by providing reliable, leak-proof shut-off. Its plastic construction resists corrosion, ensuring consistent performance over time, and its simple mechanical design offers a durable and cost-effective solution for automatic water level control in many applications.

If you’re tired of dealing with leaky, rusty, or unreliable water shut-off, keep reading. You will understand why modern plastic float valves are a smart choice.

How Reliable Are Modern Plastic Float Valves for Leak-Proof Shut-Off?

A leaking float valve is more than an annoyance; it’s a source of constant waste and potential damage. In fact, the fear of returning to a flooded room is very real.

Modern plastic float valves are highly reliable for leak-proof shut-off because they utilize a precision-machined sealing mechanism, often with a durable silicone or EPDM diaphragm or seal. This design ensures a tight, positive shut-off against the water inlet, preventing dribble or continuous flow once the water level is reached.

The Heart of Reliability: The Sealing System

The reliability of any float valve hinges entirely on its ability to seal completely and consistently. Fortunately, modern plastic valves have evolved significantly from old, simple designs. Specifically, the key is in the sealing mechanism. Instead of relying on a simple plunger, many high-quality valves now use a diaphragm seal.

Here is how it works: First, the float arm connects to a small piston. When the water level rises, the float lifts, and then this piston presses against a flexible diaphragm. Next, the diaphragm deforms to press firmly and evenly against the water inlet port. As a result, this even pressure across the entire sealing surface creates a perfect, watertight seal. Overall, this diaphragm system is far more forgiving of minor debris and provides a more consistent seal than older metal-to-metal or plastic-to-plastic seat designs.

Material and Design Synergy

Manufacturers do not use just any plastic. In fact, high-quality valves are made from engineered polymers like reinforced nylon or ABS. They choose these materials for their dimensional stability and strength. Consequently, these materials do not warp or degrade easily, which means the critical alignment between the seal and the inlet port remains perfect over thousands of cycles. Additionally, the seals themselves are made from water-resistant elastomers like silicone or EPDM, which stay flexible and effective for years without hardening or cracking.

Comparison of Shut-Off Mechanisms

Let’s compare the common shut-off mechanisms to see why modern designs are superior.

| Mechanism Type | How It Works | Reliability & Potential Issues |

|---|---|---|

| Traditional Plunger/Seat | A float arm pushes a plunger directly into a seat. | Prone to wear, requires perfect alignment. Debris can prevent full sealing, leading to dribble. |

| Diaphragm Seal (Modern Standard) | Float arm actuates a piston that presses a diaphragm over the inlet. | Provides even, positive sealing. Tolerant of minor debris. Diaphragm absorbs pressure variations, ensuring a tight seal. |

| Pilot-Operated | Uses water pressure to assist in closing a larger main seal. | Excellent for high-pressure/high-flow applications. More complex but very reliable when sized correctly. |

Ensuring Lasting Performance

Furthermore, manufacturers test reliability rigorously. For example, reputable companies subject their valves to cycle testing—simulating years of open-and-close operation—and pressure testing to ensure no leaks under standard and peak pressure conditions. For you, the user, this translates to set-and-forget operation. Simply put, you install it, adjust the water level, and then trust that the valve will open to fill and close to stop, every single time, without constant monitoring. Ultimately, this reliability is the core of how it prevents overflow and stops water waste.

Are Plastic Floats and Levers Durable Enough for Long-Term Water Contact?

The image of a plastic part breaking off in a tank is a common worry. Many people often think metal must be stronger, but that’s not always true for this job.

Yes, high-quality plastic floats and levers are exceptionally durable for long-term water contact. They are made from UV-stabilized, chemical-resistant polymers that will not corrode, rust, or degrade in water. Their design often includes robust pivot points and reinforced arms to withstand constant movement without fatigue failure.

Understanding the Material Science

The question of durability comes down to the specific plastic material and its design. Importantly, the floats and levers in a quality valve are not made from cheap, brittle plastic. Instead, manufacturers injection-mold them from premium, engineering-grade materials.

Common materials include Polypropylene (PP) or Acrylonitrile Butadiene Styrene (ABS). Engineers choose these plastics for a specific set of properties:

- Water Resistance: They do not absorb water, so they won’t become waterlogged, heavy, and sink over time.

- Chemical Resistance: They are unaffected by the chlorine and other minerals commonly found in tap water, which can corrode metals.

- UV Stabilization: For outdoor applications, the plastics are treated with UV inhibitors. This treatment prevents sunlight from breaking down the polymer chains, which would otherwise cause the plastic to become brittle and crack.

Design for Endurance

Durability isn’t just about the material; it’s also about smart design. Typically, a weak pivot point is the most common point of failure. In a good valve, the lever arm is thick and reinforced at stress points. Often, the pivot pin hole is bushed with a more durable material or designers add extra material around it to prevent wear and tear.

The float itself is a sealed, hollow chamber. Its main job is to provide consistent buoyancy forever. A quality float is ultrasonically welded or has a chemical bond that guarantees it remains airtight. If the float ever did take on water, it would fail to rise and then the valve would not shut off, so this is a critical quality control point.

Durability Comparison: Plastic vs. Metal in Water Environments

This table shows why plastic often outperforms metal in this specific application.

| Durability Factor | Plastic Float & Lever | Metal (Brass/Stainless) Float & Lever |

|---|---|---|

| Corrosion | Will not corrode or rust. | Brass can dezincify; lower-grade steel will rust. |

| Scale Buildup | Smooth surface prevents mineral adhesion. | Rough corrosion spots can trap lime scale. |

| Weight | Lightweight, less stress on pivot points. | Heavier, putting more constant stress on the system. |

| Impact Resistance | Good; can flex under impact. | Can dent or bend, potentially jamming the mechanism. |

| Long-Term Cost | Low initial cost, no degradation. | Higher initial cost, may need replacement due to corrosion. |

Real-World Longevity

In practice, a well-made plastic float valve assembly can outlast a metal one in most standard water conditions. While a metal arm might look stronger, it is susceptible to galvanic corrosion, especially at the pivot where different metals meet. Conversely, a plastic system avoids this entirely. The constant wet-dry cycles that cause metal to rust have no effect on high-grade plastic. Therefore, for long-term, trouble-free service in water, a properly engineered plastic float and lever system is not just durable enough—it is often the superior choice.

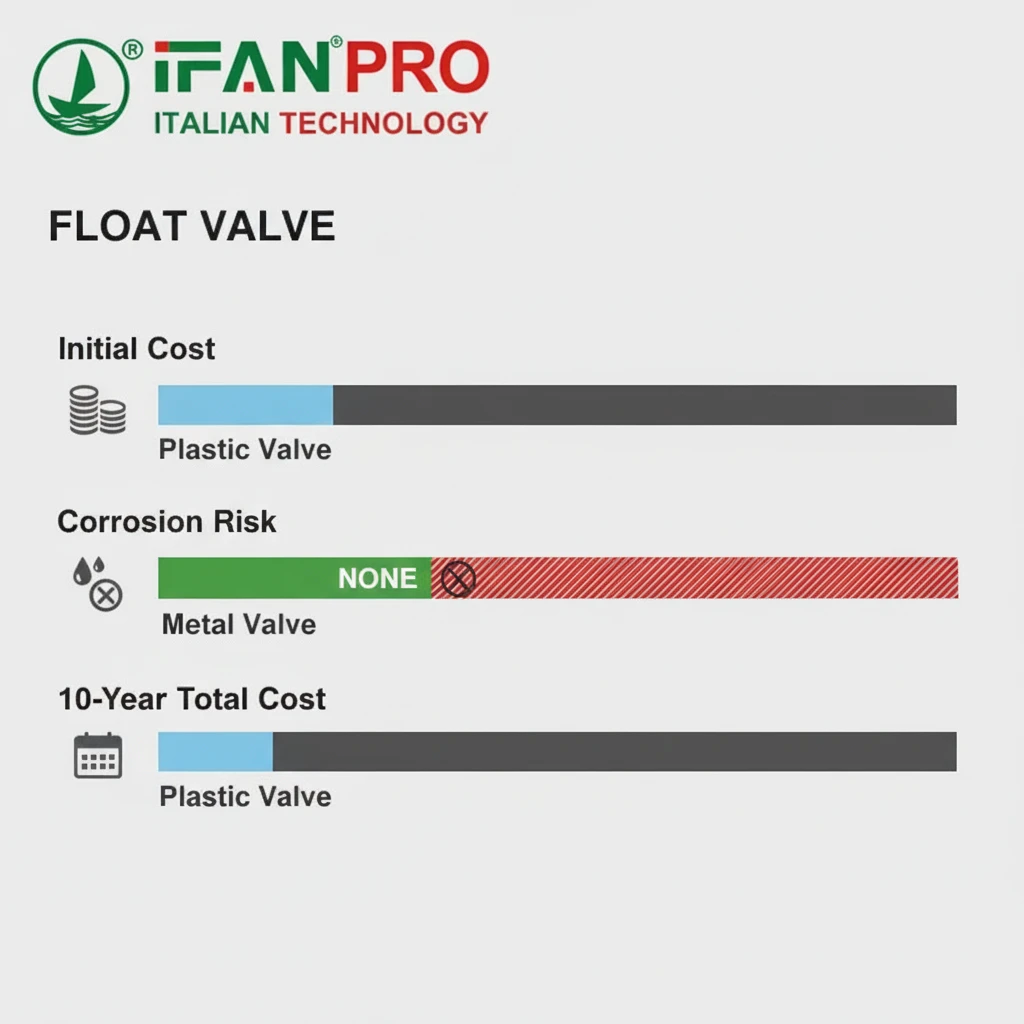

What Are the Cost and Corrosion Resistance Advantages of Plastic Valves?

Choosing a valve often feels like a trade-off: pay more for corrosion resistance or save money and risk failure. However, plastic valves break this dilemma.

The primary advantages of plastic float valves are significant cost savings and complete corrosion resistance. They are cheaper to manufacture and purchase than brass or stainless steel valves and are utterly immune to rust and corrosion from water and chemicals, ensuring a longer, maintenance-free service life in most environments.

Direct Cost Savings: Initial and Lifelong

Let’s talk about cost first. Clearly, the advantage is present and happens at multiple stages.

1. Lower Purchase Price: The raw materials and manufacturing processes for plastic valves cost less than for metal valves. Manufacturers pass this saving directly to you, the buyer. As a result, a plastic float valve can cost a fraction of an equivalent brass valve, and only a tiny fraction of a stainless-steel one.

2. Reduced Installation and Maintenance Cost: Plastic valves are lightweight and easy to handle. They often come with easy-connect threads or slip fittings compatible with plastic piping systems, which makes installation quick. Most importantly, their corrosion resistance means you will almost certainly never need to replace them due to rust failure. Therefore, you avoid the cost of the new part and the labor to install it.

The Unbeatable Advantage: Total Corrosion Resistance

Corrosion is the number one enemy of metal plumbing components. Fortunately, plastic valves eliminate this problem completely.

- No Rust: Iron and steel components rust. In contrast, plastic cannot.

- No Dezincification: Brass, a common metal for valves, can suffer from dezincification in certain water conditions. This process leaches zinc out of the alloy, leaving behind a weak, porous copper structure that can fail catastrophically. However, plastic remains unaffected.

- Chemical Resistance: Plastic valves are ideal for use with mildly aggressive water, such as in agricultural settings (fertilizer contamination), or in RVs and boats where water might sit stagnant. They won’t degrade from chlorine or other water treatment chemicals.

Total Cost of Ownership Analysis

To truly see the value, we must look beyond the sticker price. Here is a comparison over a 10-year period for a typical application:

| Cost Factor | Plastic Float Valve | Standard Brass Float Valve |

|---|---|---|

| Initial Purchase Price | $10 – $25 | $30 – $80 |

| Estimated Installation Time/Cost | Lower (lightweight, easy) | Standard |

| Likelihood of Failure from Corrosion | Extremely Low | High in aggressive water |

| Potential Replacement Parts & Labor (10 yrs) | $0 | $50 – $150+ (for new valve + labor) |

| Risk of Water Damage from Failure | Low | Moderate to High |

| Total Estimated 10-Year Cost | $10 – $25 | $80 – $230+ |

Making the Smart Choice

As the table shows, the plastic valve’s low initial cost is just the beginning. Indeed, its true economic advantage lies in its predictable, maintenance-free longevity. Essentially, you are not buying a cheap part that will break soon; you are buying an affordable part that is perfectly suited to its environment and will last for many years. For the vast majority of residential, commercial, and agricultural water containment applications, the corrosion resistance of plastic provides the best value and the most reliable service.

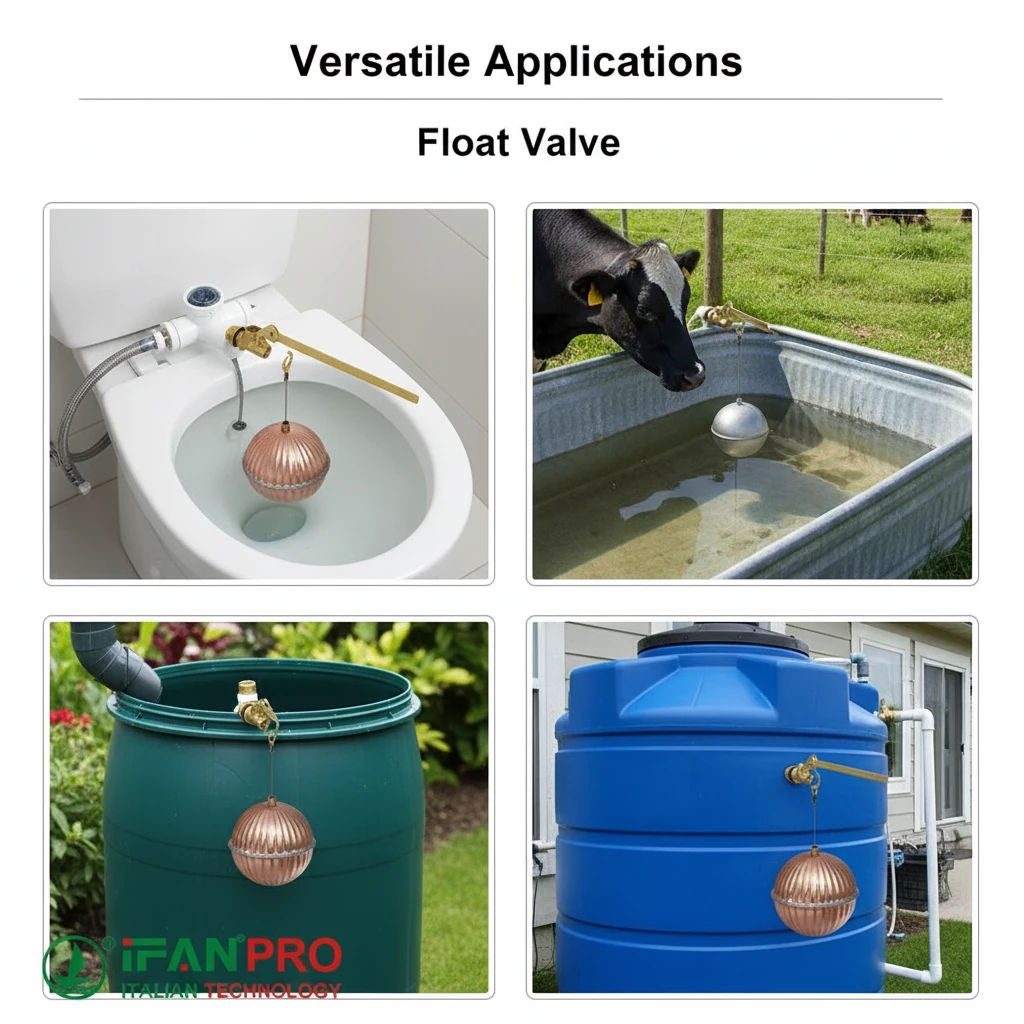

In Which Applications Are Plastic Float Valves the Most Suitable Choice?

Not every valve is right for every job. Therefore, knowing where plastic float valves excel helps you avoid problems and get the best performance.

Plastic float valves are the most suitable choice for controlling water levels in non-pressurized storage tanks, toilet cisterns, livestock water troughs, irrigation systems, and domestic appliances. They are ideal for use with cold water and in environments where corrosion is a primary concern, offering the best balance of performance, durability, and value.

Ideal Application Environments

Plastic float valves thrive in specific conditions. Specifically, their design and material properties make them the top contender for a wide range of common uses.

1. Residential and Commercial Water Storage Tanks: This is a classic application. Whether it’s a rooftop tank, a basement storage tank, or a cistern, plastic float valves provide reliable, automatic filling. Their corrosion resistance is key here, as water can sit for long periods.

2. Toilet Cisterns: The modern toilet fill valve is a type of plastic float valve (often a diaphragm type). It’s quiet, reliable, and cheap to replace. Its plastic construction prevents corrosion from constant contact with water.

3. Agriculture and Livestock Watering: For animal drinking troughs, plastic valves are perfect. They are safe, non-toxic, and completely unaffected by the minerals and minor contaminants often found in well water or farm environments. Also, if they get bumped by an animal, they are less likely to bend permanently than a metal lever.

4. DIY and Hobbyist Projects: From automatically topping up a garden pond to filling a rainwater collection barrel for irrigation, plastic valves are the go-to choice. They are affordable, easy to install with common tools, and readily available.

Understanding the Limits

For all their strengths, plastic float valves have boundaries. So, knowing these prevents misuse and ensures reliability.

- Temperature: Most standard plastic valves are designed for cold water use only. Importantly, continuous exposure to hot water (above 60°C / 140°F) can soften or warp the plastic, leading to failure. Therefore, always check the manufacturer’s temperature rating.

- Pressure: They are best for low to medium water pressure systems (typical municipal water pressure is fine). However, extremely high pressure can stress the plastic components over time.

- Chemical Exposure: While resistant to water and common chemicals, they may not be suitable for highly aggressive industrial chemicals or solvents. As a rule, always verify chemical compatibility.

Application Suitability Guide

This table will help you quickly decide if a plastic float valve is the right tool for your job.

| Application | Is a Plastic Float Valve Suitable? | Key Reasons |

|---|---|---|

| Home Toilet Tank | Excellent Choice | Standard use. Reliable, quiet, and cost-effective. |

| Garden Water Storage Tank | Excellent Choice | Resists corrosion from stagnant water; perfect for automatic filling. |

| Livestock Drinking Trough | Excellent Choice | Safe, durable, and corrosion-proof. |

| Residential Hot Water Heater Inlet | Not Suitable | Water temperature is too high for standard plastic valves. |

| High-Pressure Industrial Main Line | Not Suitable | Pressure may exceed the valve’s rating; a pilot-operated or metal valve is needed. |

| RV/Marine Fresh Water Tank | Good Choice | Lightweight and corrosion-resistant, but ensure it’s rated for potable water. |

| Commercial Cooling Tower Make-up | Conditional | Suitable if chemicals used are compatible with the plastic material. |

Making the Final Decision

In summary, if your application involves controlling cold, fresh, or mildly aggressive water in a tank or cistern, a plastic float valve is almost certainly the most suitable, reliable, and economical choice. It solves the core problems of overflow and waste without introducing the common failure points of metal valves. Alternatively, for specialized high-temperature or extreme-pressure applications, you would look to more robust materials. But for perhaps 80% of everyday water level control needs, plastic is the perfect fit.

Conclusion

Plastic float valves reliably and cost-effectively prevent water overflow and waste in countless common applications. For a durable, corrosion-proof float valve you can install and forget, explore the range of high-quality options available from IFAN.

Recent Comments