Brass fittings are essential components in various industries, offering durability, versatility, and corrosion resistance. However, when it comes to selecting fittings for specific applications, it’s essential to consider various factors, including material composition, performance, and cost-effectiveness. In this article, we’ll compare brass fitting with other commonly used materials, highlighting their differences and applications.

Brass Fittings: Strengths and Versatility

1. Corrosion Resistance

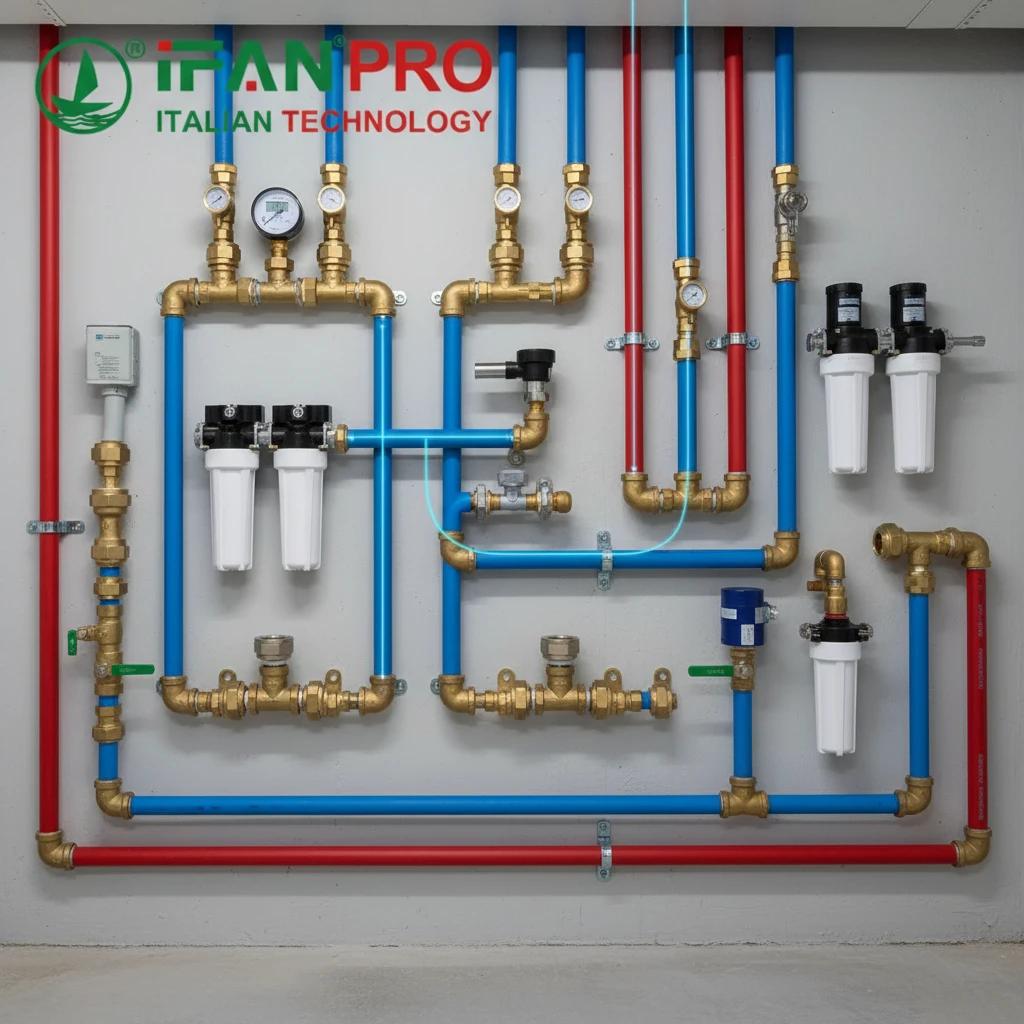

Brass fittings, primarily consisting of copper and zinc, exhibit excellent corrosion resistance, making them suitable for applications where exposure to moisture or harsh environments is expected.

2. Durability

Brass fittings are renowned for their durability and longevity. They can withstand high temperatures, pressure fluctuations, and mechanical stresses, ensuring reliable performance in demanding conditions.

3. Versatility

Brass fitting are available in various shapes, sizes, and configurations, offering versatility in design and installation. They can be easily adapted to different piping systems, enhancing flexibility and ease of use.

Comparison with Other Materials

1. PVC Fittings

PVC fittings, made from polyvinyl chloride, are lightweight and cost-effective. However, they may degrade over time when exposed to sunlight or certain chemicals, limiting their suitability for outdoor or industrial applications.

2. Stainless Steel Fittings

Stainless steel fittings offer superior corrosion resistance and strength compared to brass. However, they are often more expensive and may require specialized tools and expertise for installation.

3. Copper Fittings

Copper fittings share similar corrosion resistance properties with brass but are more expensive. They find common use in plumbing and HVAC systems where aesthetics and antimicrobial properties are critical.

4. Plastic Fittings

Plastic fittings, including PPR and CPVC, are lightweight and easy to install. However, they may not withstand high temperatures or pressure as effectively as brass fitting, limiting their use in certain applications.

Conclusion

While brass fitting offer a balance of strength, durability, and corrosion resistance, each material has its advantages and limitations. When selecting fittings for a particular application, it’s essential to consider factors such as environmental conditions, budget constraints, and performance requirements. By understanding the differences between brass fittings and other materials, industries can make informed decisions to ensure optimal functionality and longevity of their piping systems.

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interested in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments