During a hospital renovation project, I discovered that incorrect PPR pipe color coding nearly led to cross-connections between hot water circulation and medical gas lines. This close call demonstrated how color codes serve as the first line of defense against potentially dangerous installation errors.

PPR pipe color codes are critically important because they provide immediate visual identification of pipe contents, pressure ratings, and temperature capabilities. These color standards prevent installation errors, ensure system safety, and facilitate proper maintenance throughout the plumbing system’s lifespan.

Understanding color coding goes beyond simple recognition—it directly impacts system performance and safety. Let’s explore what different colors signify and why proper color application matters in real-world installations.

What Do the Different PPR Pipe Colors Indicate About Their Properties?

While working on an international school project, we managed piping systems from three different countries, each with unique color codes. This experience taught me that color understanding is essential for proper system integration and maintenance planning.

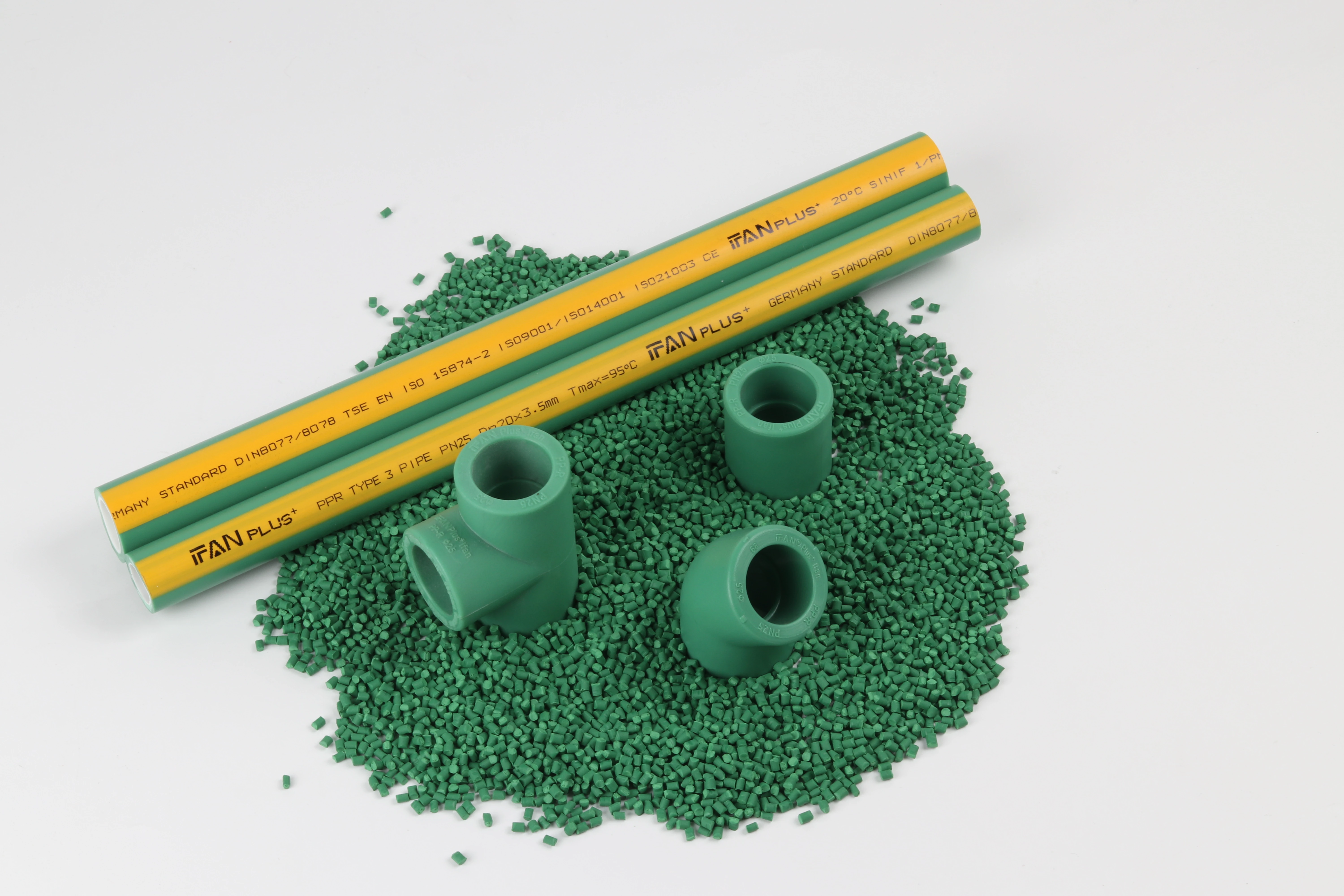

PPR pipe colors indicate specific properties: green identifies cold water pipes (PN 1.0-1.6), red designates hot water pipes (PN 2.0-2.5), blue signifies potable water, gray indicates universal applications, and orange often marks industrial or special chemical applications, with each color corresponding to different pressure and temperature ratings.

Comprehensive Color Guide

Each color communicates vital technical information:

Green PPR Pipes

- Cold water applications only

- Pressure ratings: PN 1.0 or PN 1.6

- Maximum temperature: 45°C continuous

- Typical uses: cold water supply, drainage, irrigation

- Material: Standard PPR random copolymer

Red PPR Pipes

- Hot water and heating systems

- Pressure ratings: PN 2.0 or PN 2.5

- Maximum temperature: 95°C continuous

- Typical uses: domestic hot water, radiator systems, solar thermal

- Material: Heat-stabilized PPR with thicker walls

Special Application Colors

- Blue stripes: Potable water certification

- Gray base: Universal hot/cold applications

- Orange/red: Industrial or high-temperature uses

- Yellow: Gas applications (where approved)

- Brown: Industrial fluid transport

Technical Specifications by Color

The color system directly correlates with performance capabilities:

| Pipe Color | Pressure Rating | Temperature Range | Wall Thickness | Application Scope |

|---|---|---|---|---|

| Green | PN 1.0-1.6 | 5-45°C | Standard | Cold water only |

| Red | PN 2.0-2.5 | 10-95°C | 20-30% thicker | Hot water systems |

| Blue | PN 1.6-2.0 | 5-65°C | Standard | Drinking water |

| Gray | PN 2.0 | 5-95°C | Intermediate | Dual purpose |

| Orange | PN 2.5-3.2 | 10-110°C | 30-40% thicker | Industrial use |

Can Using Incorrect Pipe Colors Affect Plumbing System Performance?

A luxury apartment project experienced repeated pipe failures until we discovered the installer used green cold-water pipes in the hot water system. The resulting repairs cost 40% more than proper installation would have, demonstrating how color errors create tangible performance issues.

Using incorrect pipe colors directly affects plumbing performance by causing material failures, reducing system lifespan, and creating safety hazards. Cold water pipes (green) lack heat stabilization and will deform in hot applications, while hot water pipes (red) in cold systems represent unnecessary cost without performance benefits.

Performance Impact Analysis

Color misapplication creates multiple problems:

Material Failure Risks

Cold water PPR pipes (green) in hot water applications experience rapid degradation because they lack heat stabilizers. This leads to pipe expansion beyond design limits, wall thinning under pressure, and ultimate failure at connection points. The material becomes brittle and develops micro-cracks that eventually cause leaks.

System Efficiency Reduction

Using incorrect colors disrupts system balancing and maintenance. For example, insulation requirements differ between hot and cold pipes, and flow characteristics vary based on pipe pressure ratings. Maintenance teams may apply wrong procedures during repairs, and energy efficiency suffers from improper pipe selection.

Cost and Safety Consequences

The practical impacts extend beyond immediate performance:

Financial Implications

- Increased material costs from over-specification

- Premature system failure and replacement

- Higher energy consumption from inefficiency

- Extended downtime during repairs

- Increased insurance premiums from repeated claims

Safety Considerations

- Potential for scalding from mixed temperatures

- Structural damage from pipe failures

- Water contamination risks

- Electrical hazards from leaking pipes

- Mold growth from undetected leaks

How Do International Standards Regulate PPR Pipe Color Coding Systems?

When our company expanded to Middle Eastern projects, we encountered four different color coding systems within the same region. This experience highlighted the importance of understanding international standard variations for successful project execution.

International standards like ISO 15874, European EN ISO 15874, Chinese GB/T, and American ASTM provide color coding guidelines, but significant regional variations exist. While most systems use red for hot water and green/blue for cold water, specific stripe patterns, additional markings, and certification requirements differ substantially between regions.

Major Standard Comparisons

Understanding global variations prevents installation errors:

ISO 15874 Global Standard

- Red with white lettering: Hot water

- Green or blue: Cold water

- Gray: Universal applications

- Requires continuous color stripes

- Mandates printed pressure ratings

European EN Standards

- Red with two white stripes: Heating

- Green with two white stripes: Cold water

- Blue with white stripes: Potable water

- Specific stripe spacing requirements

- CE marking mandatory

Asian Regional Variations

- China GB/T: Similar to ISO with additional certification marks

- Japanese JIS: Unique color bands for different applications

- Korean standards: Manufacturer-specific variations allowed

- Southeast Asia: Often follows European or American standards

Compliance Requirements

Meeting international standards involves multiple aspects:

Certification Markings

Legitimate PPR pipes display:

- Standard compliance marks (ISO, GB, ASTM)

- Manufacturer identification codes

- Pressure rating designations

- Production dates and batch numbers

- Third-party certification logos

Documentation Verification

Professional installers should:

- Request compliance certificates

- Verify testing reports

- Check manufacturer certifications

- Maintain material traceability records

- Document color standard adherence

Why Should Installers Verify Pipe Colors During Material Selection Process

We implemented a strict color verification protocol after a project failure where subcontractors installed industrial orange pipes in a residential hot water system. The subsequent leaching issues caused complete system replacement and taught us that color verification is non-negotiable.

Installers must verify pipe colors during material selection to prevent performance issues, ensure regulatory compliance, and avoid costly rework. Color verification confirms pressure ratings, temperature capabilities, chemical compatibility, and certification compliance that directly impact system safety and longevity.

Verification Protocol

Implement this systematic verification process:

Pre-Installation Checks

- Verify color against project specifications

- Confirm pressure rating matches application needs

- Check temperature ratings for intended use

- Validate certification markings

- Document material batch numbers

Quality Assurance Steps

- Test pipe samples if possible

- Verify storage conditions haven’t affected materials

- Check for color consistency within batches

- Confirm printing clarity and permanence

- Validate supplier credentials

Consequences of Poor Verification

Neglecting color verification leads to multiple problems:

Immediate Installation Issues

- Incorrect jointing techniques applied

- Wrong support spacing installed

- Improper insulation selection

- Incorrect fusion parameters

- Wrong tools selected for connection

Long-Term System Problems

- Reduced system lifespan

- Increased maintenance frequency

- Voided manufacturer warranties

- Compliance violations

- Insurance coverage issues

Best Practice Implementation

Successful projects incorporate these verification steps:

| Verification Stage | Checkpoints | Documentation Required |

|---|---|---|

| Material Ordering | Color specifications, standards compliance | Technical data sheets |

| Delivery Inspection | Color consistency, markings clarity | Delivery certificates |

| Pre-Installation | Batch verification, sample testing | Quality control reports |

| Installation | Color application verification | Installation photographs |

| Final Inspection | System color compliance | Commissioning certificates |

Conclusion

PPR pipe color codes serve as critical visual communication tools that directly impact system performance, safety, and regulatory compliance. By understanding color significance, adhering to international standards, and implementing rigorous verification processes, installers can prevent costly errors and ensure plumbing systems perform as designed throughout their operational lifespan.

Recent Comments