I once visited a chemical plant where stainless steel fittings had failed, but the brass ones in the same line were flawless. This firsthand experience cemented my understanding of brass’s unique value in demanding applications.

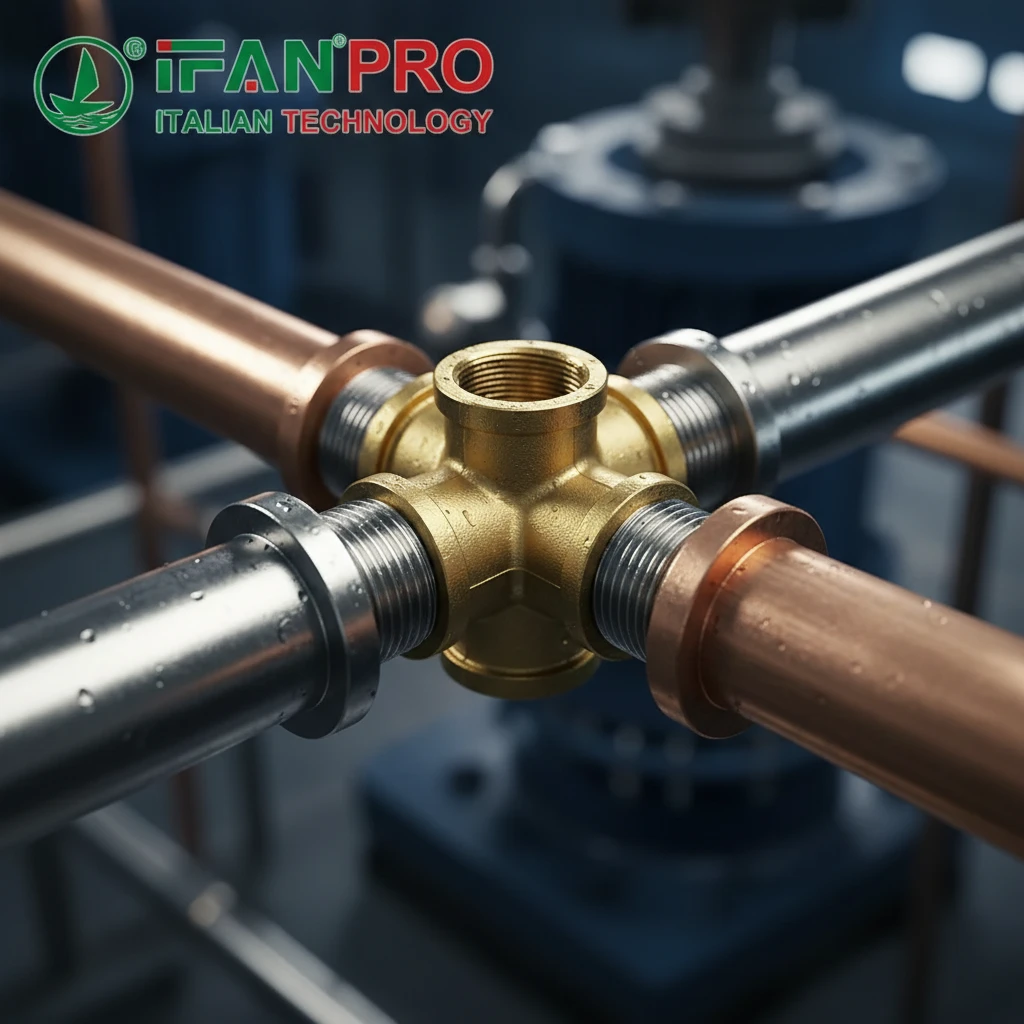

Brass is the preferred material for durable cross fittings because it offers an unmatched balance of corrosion resistance, strength, machinability, and thermal stability. This combination ensures reliable performance in wet, pressurized systems over a very long lifespan, making it a trusted choice for engineers and plumbers.

Let’s break down the specific properties that make brass the go-to material for critical cross fittings.

How Does Brass Provide Excellent Corrosion Resistance in Wet Environments?

Water and metal usually spell trouble, but brass defies this expectation. I recall a marine project where brass fittings outlasted all others in saltwater spray.

Brass provides excellent corrosion resistance because it is an alloy primarily of copper and zinc, which naturally forms a protective patina layer on its surface. This layer shields the underlying metal from further oxidation and resists degradation from water, chlorinated water, and many chemicals, preventing the rust and pitting common in other metals.

The Science Behind the Protection

Corrosion is the gradual destruction of a metal by chemical reactions with its environment. In plumbing, this is a major cause of failure. Brass combats this effectively through its inherent material properties.

The key is the protective patina. When brass is exposed to air and moisture, it undergoes a controlled surface reaction. This reaction forms a thin, adherent layer of corrosion products—primarily copper carbonate. Importantly, this layer is stable and non-flaking. It acts as a barrier, dramatically slowing down any further corrosion of the metal beneath it. This is different from iron rust, which flakes off and exposes new metal to corrosion continuously.

Resistance to Different Media

Brass performs well against various common threats in plumbing and industrial systems:

- Water and Chlorine: It has high resistance to dezincification (a selective leaching of zinc) in modern, properly alloyed brass grades, making it excellent for potable water systems.

- Atmospheric Exposure: It withstands humid and industrial atmospheres far better than plain steel.

- Chemicals: It shows good resistance to many salts and organic compounds.

Comparing Corrosion Resistance

This table compares how different fitting materials handle a corrosive wet environment.

| Material | Corrosion Resistance in Wet Environments | Key Weakness |

|---|---|---|

| Brass | Excellent. Forms stable protective patina. Highly resistant to water and many chemicals. | Can be susceptible to dezincification in very soft, acidic waters if not a proper grade. |

| Carbon Steel | Poor. Rusts quickly, requiring galvanization or coating which can be damaged. | The coating scratches, leading to rapid localized rust (pitting). |

| Stainless Steel | Very Good. Resists rust but can suffer from pitting in chloride-rich environments. | Pitting corrosion can occur in saltwater or heavy chlorine, leading to sudden failure. |

| PVC/Plastic | Excellent. Immune to electrochemical corrosion. | Can become brittle with UV exposure and temperature swings, leading to cracks. |

For engineers, this means specifying brass reduces the risk of sudden leaks, contamination from rust, and the high maintenance costs associated with replacing corroded fittings. It provides predictable, long-term performance.

What Makes Brass Strong Yet Machinable for Precise Threaded Fittings?

Achieving sharp, clean threads on a very hard metal is a challenge. Brass solves this perfectly, which is why we use it for complex valve bodies.

Brass is uniquely strong yet machinable because its alloy structure allows it to be cut cleanly with minimal tool wear, producing smooth surfaces and precise threads. This machinability ensures leak-tight seals in threaded connections, while its inherent strength allows the fittings to withstand high system pressures without deforming.

The Balance of Properties

This is the golden paradox of brass: it is tough enough to be durable but soft enough to be easily worked. This comes from the copper-zinc crystal structure. The zinc atoms dissolved in the copper matrix disrupt the lattice just enough to provide strength but not so much as to make it brittle or difficult to cut.

When we talk about machinability, we refer to how easily a material can be cut into a desired shape with a good surface finish. Brass scores exceptionally high here. It produces short, broken chips during machining instead of long, stringy ones. This leads to:

- Faster Production: Machines can run at higher speeds.

- Less Tool Wear: Cutting tools stay sharp longer, reducing costs.

- Superior Finish: The cut surfaces and threads are smooth and precise.

Importance for Threaded Connections

A threaded joint in a fluid system is a critical sealing point. Imperfect threads are a primary source of leaks.

- Precision: The excellent machinability of brass allows for the creation of threads with very tight tolerances (e.g., NPT, BSP). This precision means the male and female threads fit together perfectly, maximizing surface contact.

- Deformation for Seal: Brass has a slight malleability. When tightened, the threads can deform microscopically to fill any tiny imperfections, creating a metal-to-metal seal that is often enhanced with sealant tape or compound. This is harder to achieve with a harder, more brittle material.

Strength for Pressure Containment

While being machinable, brass has substantial mechanical strength. Its tensile strength is significantly higher than many plastics and sufficient for the vast majority of hydraulic and plumbing applications. A brass cross fitting will not crack under normal wrench tightening and will resist bursting under high water pressure. This combination means you get a fitting that is both easy to install during assembly and utterly reliable during decades of service.

Why Does Brass Maintain Its Integrity Over a Wide Temperature Range?

In a solar thermal system I worked on, fittings faced cycles from freezing nights to scorching days. Brass was specified for its stability.

Brass maintains its integrity over a wide temperature range because it has a high melting point, excellent thermal conductivity, and a low coefficient of thermal expansion. This means it does not soften at high temperatures, dissipates heat evenly to avoid hot spots, and expands/contracts less than many materials, preventing joints from loosening or becoming over-stressed.

Performance at High Temperatures

Many plumbing and industrial systems involve hot fluids. Brass performs reliably here where plastics would fail.

- No Softening: Brass retains its mechanical strength and hardness at elevated temperatures (often up to 200°C/400°F for many alloys). It will not deform or “creep” under load like plastics can when hot.

- Heat Dissipation: Its good thermal conductivity helps spread heat away from localized hot spots, preventing thermal stress cracking that can occur in materials with poor conductivity.

Performance at Low Temperatures

Brass remains ductile and tough even in sub-zero conditions. Unlike some materials that become brittle and prone to shattering upon impact in the cold, brass can still withstand vibration and pressure surges. This makes it suitable for outdoor applications and refrigeration lines.

Managing Thermal Expansion

All materials expand when heated and contract when cooled. If this movement is not managed, it creates stress at connections, leading to leaks. Brass has a relatively low coefficient of thermal expansion compared to materials like plastic.

The Impact on Fittings:

Imagine a cross fitting connecting four pipes. During a temperature cycle:

- Plastic Pipes/Fittings: Expand and contract a lot. This can put enormous shear and pull-out stress on the joints, potentially causing them to fail.

- Brass Fittings: Expand and contract much less. This dimensional stability means the stresses on the joint are lower. When connected to pipes with similar expansion rates (like copper), the system moves more uniformly, maintaining joint integrity.

Material Comparison for Thermal Cycling

| Material | Key Thermal Property | Risk in Temperature-Varying Systems |

|---|---|---|

| Brass | Low thermal expansion; high thermal conductivity. | Low risk. Stable dimensions reduce joint stress. Conducts heat evenly. |

| PP-R Plastic | Very high thermal expansion. | High risk. Can lead to sagging pipes and stressed, leaking joints if not properly supported with expansion loops. |

| Stainless Steel | Moderate thermal expansion. | Moderate risk. Can generate high thermal stress in restrained systems, but generally performs well. |

This thermal resilience makes brass a “set-it-and-forget-it” material for systems exposed to environmental cycles or handling fluids at varying temperatures.

How Does Its Durability Lead to a Lower Total Cost of Ownership?

A client once replaced cheap fittings every 3-5 years. Switching to brass eliminated that cycle, proving that initial price isn’t everything.

Brass’s durability leads to a lower total cost of ownership because its long service life eliminates frequent replacement costs, its reliability prevents expensive downtime and water damage repairs, and its maintenance-free nature reduces labor expenses over decades, making its higher initial cost a wise investment.

Understanding Total Cost of Ownership (TCO)

TCO looks at all costs associated with an asset over its entire service life. For pipe fittings, this includes:

- Initial Purchase Price

- Installation Labor

- Maintenance and Repairs

- Cost of Failure (Downtime, Damage)

- Replacement Cost

While brass fittings have a higher initial purchase price than galvanized steel or some plastic fittings, they dominate the TCO calculation by minimizing costs 3, 4, and 5.

How Brass Reduces Long-Term Costs

- Eliminates Replacement Cycles: A brass fitting can last 50+ years in a typical water system. A cheaper material may corrode, crack, or fail and need replacement multiple times within that same period. Each replacement carries the cost of the new part, plus labor, plus system downtime.

- Prevents Catastrophic Failure: A leaking cross fitting inside a wall can cause thousands of dollars in property damage (drywall, flooring, mold remediation). The reliability and corrosion resistance of brass make such failures extremely unlikely, providing immense risk mitigation.

- Reduces Maintenance: Brass does not require periodic re-tightening, coating, or inspection for rust. It is essentially maintenance-free once installed correctly.

TCO Comparison Scenario

Consider a cross fitting in a commercial building’s chilled water system over a 30-year period.

| Cost Factor | Brass Fitting | Galvanized Steel Fitting | Low-Cost Plastic Fitting |

|---|---|---|---|

| Initial Fitting Cost | $10.00 | $3.00 | $1.50 |

| Installation Labor | $5.00 | $5.00 | $5.00 |

| Estimated Replacements (30 yrs) | 0 | 2 | 3 |

| Cost of Replacements (Parts + Labor) | $0 | $16.00 | $19.50 |

| Risk of Leak Damage | Very Low | High | Moderate (Brittle Crack) |

| Estimated Total 30-Year Cost | $15.00 | $24.00 | $26.00 |

The Result: Despite costing 3-6 times more upfront, the brass fitting proves to be the most economical choice over time. It is an asset, not a consumable. For procurement managers, this is a crucial calculation: buying quality brass fittings is not an expense; it’s an investment in system reliability and lower future costs.

Conclusion

Brass remains the preferred material for durable cross fittings due to its unmatched balance of corrosion resistance, strength, and longevity. For reliable, high-performance brass fittings, consider IFAN’s range of precision-machined brass cross fittings for your next project.

Recent Comments