A client once called me in a panic. A brass fitting in their system had failed during a pressure surge, causing a shutdown. This moment made me realize how crucial it is to truly understand the limits of your components.

Yes, high-quality brass conversion fittings are designed to withstand significant pressure and temperature changes, making them reliable for demanding plumbing and industrial systems. Their performance depends on the brass alloy, manufacturing process, design, and correct installation. For extreme conditions, specialized high-pressure models are essential for safety and durability.

Let’s examine the specific factors that determine how well a brass fitting performs under stress.

What Pressure Ratings Do Standard Brass Conversion Fittings Have?

Many assume all brass fittings are equally strong. I’ve seen projects delayed because the chosen fitting’s pressure rating didn’t match the system requirements.

Standard brass conversion fittings typically have pressure ratings between 150 PSI (10 bar) and 600 PSI (41 bar) for water at room temperature. The exact rating depends on the fitting’s size, wall thickness (schedule), and the specific brass alloy used. Always check the manufacturer’s stamped rating on the fitting itself, as this is the guaranteed safe working pressure.

Understanding Pressure Rating Labels

The pressure rating on a fitting is not a random number. It tells you the maximum internal pressure the fitting can safely handle continuously. This rating is established through rigorous hydrostatic burst testing. A common standard for many plumbing applications is 150 PSI Working Pressure (WP). This is suitable for most residential and commercial building water systems, where pressure rarely exceeds 80 PSI.

However, for industrial applications, heating systems, or compressed air lines, you will need fittings with higher ratings, such as 300 PSI or 600 PSI. It’s crucial to know that this rating is for a cold water service. Temperature dramatically affects the strength of materials.

How Size and Shape Affect Strength

Pressure capacity isn’t the same for every fitting, even from the same batch. Two main factors change it:

- Size: Generally, smaller diameter fittings (like 1/2″) can handle higher pressures than larger ones (like 2″) of the same design and material. This is because the internal forces are distributed over a smaller area.

- Design & Schedule: A simple brass nipple has a different stress profile than a complex tee or reducer. Furthermore, fittings come in different “schedules” (like Schedule 40 or 80), which indicate wall thickness. A Schedule 80 fitting has a thicker wall than a Schedule 40 fitting of the same size, giving it a higher pressure rating.

Common Pressure Ratings by Application

This table gives a general overview of where different ratings are typically applied.

| Fitting Type / Standard | Typical Pressure Rating (PSI) | Common Applications |

|---|---|---|

| Standard Plumbing (ASME B16.15) | 150 – 300 PSI | Residential hot/cold water, standard commercial buildings. |

| Industrial Forged Brass (ASME B16.15) | 300 – 600 PSI | Industrial process lines, boiler feed water, higher-pressure commercial systems. |

| Compressed Air Fittings | 200 – 300 PSI | Factory air lines, pneumatic tools (note: ratings are for air, not water). |

| Refrigeration Fittings (ACR) | 400 – 500 PSI | HVAC/R systems handling refrigerants. |

Important Note: You must also consider the system’s pressure. Your fitting’s rating must be higher than the maximum pressure the system can produce, including pressure spikes from pumps or water hammer. A good safety practice is to select fittings with a rating at least 1.5 times your system’s maximum operating pressure.

How Does Brass Handle Thermal Expansion from Hot Water Systems?

Systems heat up and cool down daily. I recall a hotel project where noisy pipes and leaking joints were traced to ignored thermal expansion.

Brass handles thermal expansion well because it has a moderate thermal expansion coefficient and high strength. When hot water flows through, the pipe and fitting expand together. Brass’s durability prevents deformation, and its malleability allows it to absorb some stress, reducing the risk of cracks or joint failure compared to more brittle materials.

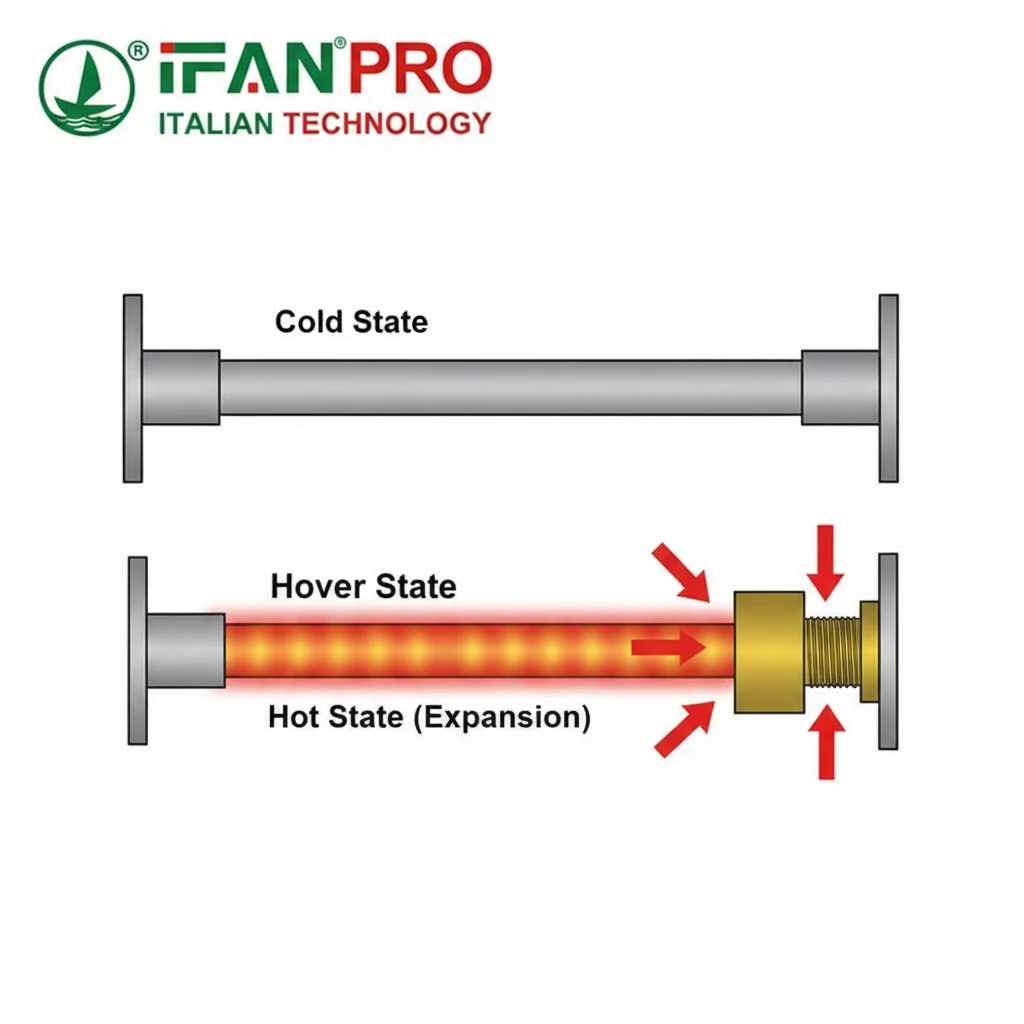

The Science of Expansion and Stress

All materials expand when heated and contract when cooled. In a plumbing system, when hot water (up to 82°C or 180°F) flows, the copper, steel, or plastic pipes get longer. The brass fittings connecting them are also heating up and expanding. The key is whether different parts expand at the same rate and how the system manages the resulting forces.

Brass has a linear thermal expansion coefficient of about 19 x 10⁻⁶/°C. This is higher than steel but lower than most plastics. In practical terms, a 10-meter run of copper pipe will expand more than the brass fitting itself. This difference creates stress at the threaded or brazed connections.

Why Brass is a Good Choice

Brass performs reliably in these conditions for two main reasons:

- Strength and Ductility: Brass is strong enough to resist the pulling or pushing forces from the expanding pipes without deforming. More importantly, it is ductile (malleable). This means that under stress, it can undergo slight, permanent deformation without cracking. This “give” helps relieve stress points.

- Compatibility with Common Pipes: Brass has an expansion rate reasonably close to that of copper, a very common pipe material. This reduces the differential expansion stress at the joints. For systems with steel pipes, proper support and anchoring are more critical, but brass fittings remain a robust connection point.

Managing Expansion in System Design

Even with a good material like brass, thermal expansion must be managed at the system level. Relying solely on the fitting to absorb all stress is a design flaw. Here are key strategies:

- Expansion Loops or Offsets: Building U-shaped bends in long pipe runs allows the pipe to flex safely.

- Expansion Joints: Mechanical devices specifically designed to absorb length changes.

- Proper Anchoring and Support: Pipes must be anchored at specific points to control the direction of expansion and prevent it from all pushing against a single, weak fitting.

Common Failure Point: The greatest stress often occurs at the threads. If a system has no expansion control, the repeated push/pull on threads during heat cycles can eventually lead to fatigue, loosening, and leaks. Using a high-quality thread sealant and proper tightening techniques is essential.

Are There High-Pressure Models for Demanding Industrial Applications?

Absolutely. When a chemical plant client needed fittings for a 1000 PSI line, standard plumbing fittings were not an option.

Yes, there are specialized high-pressure brass fittings designed for demanding industrial applications. These are typically forged (not cast) from superior brass alloys like C37700 or C36000, have thicker walls (Schedule 80 or 160), and feature more robust threading. They are rated for 1000 PSI, 2000 PSI, or even higher for hydraulic or process fluid systems.

Key Differences from Standard Fittings

High-pressure models are not just “stronger” versions of standard fittings. They are engineered differently from the ground up for extreme service.

1. Manufacturing Process: Forging vs. Casting

Most standard fittings are made by casting molten brass into a mold. High-pressure fittings are almost always forged. Forging involves shaping solid brass under immense pressure while it is hot. This process aligns the metal’s grain structure, making it denser, stronger, and more uniform, with far fewer internal flaws than cast fittings. This eliminates potential weak points that could fail under high cyclic stress.

2. Material: Premium Brass Alloys

While standard fittings use workable alloys like C27000 (Yellow Brass), high-pressure fittings use alloys with superior mechanical properties.

- C36000 (Free-Cutting Brass): Excellent machining and strength.

- C37700 (Forging Brass): Specifically designed for hot forging, offering high strength and corrosion resistance.

3. Design: Heavier Construction

You can visually and physically identify a high-pressure fitting. They are heavier, with noticeably thicker walls and deeper, more robust hex sections for wrenching. The threads are often tapered (NPT) and machined to finer tolerances to ensure a deep, leak-free seal.

Common Standards and Applications

These fittings conform to strict standards like ASME B16.15 (Forged Fittings) or SAE J514 for hydraulic applications. They are essential in:

- Hydraulic power units and machinery

- High-pressure washing and cleaning systems

- Industrial process lines (chemical, oil & gas)

- Compressed air systems in manufacturing plants

- Refrigeration and heat pump systems

Selection Guide for High-Pressure Service

Choosing the right fitting requires careful cross-referencing.

| System Requirement | Critical Fitting Specification | What to Look For / Ask Supplier |

|---|---|---|

| Operating Pressure: 1500 PSI | Pressure Rating | Fitting must be rated for at least 1500 PSI for the specific fluid (oil, water, air). |

| Fluid: Hydraulic Oil | Material & Fluid Compatibility | Ensure brass is suitable for the oil type. Buna-N or other compatible seals may be needed. |

| Temperature: 120°C | Temperature-Pressure Derating | Check manufacturer’s chart. A 2000 PSI rating at 20°C may drop to 1600 PSI at 120°C. |

| Vibration Present | Construction & Seal Type | Forged body is essential. Consider O-ring face seal (ORFS) fittings for best vibration resistance. |

Pro Tip: Never substitute a standard plumbing fitting for a true high-pressure application. The risk of catastrophic failure, safety hazards, and downtime costs far outweighs the small savings on component costs.

What Factors Affect Its Performance Under Temperature Cycles?

A solar heating system installer told me their biggest issue wasn’t constant heat, but the daily on-off cycles that fatigued their old fittings.

Several key factors affect a brass fitting’s performance under temperature cycles: the quality of the brass alloy, the integrity of the manufacturing process, the type of joint (threaded vs. braze), and the system’s design to manage expansion. Poor quality fittings will fatigue and crack over time, while well-chosen and properly installed fittings will last for thousands of cycles.

The Enemy: Thermal Fatigue

Temperature cycling is the repeated heating and cooling of a component. Each cycle causes the material to expand and contract, creating stress. Over time, this stress can lead to thermal fatigue—the formation and growth of microscopic cracks that eventually lead to failure. This is a different challenge than handling constant high pressure or temperature.

Factor 1: Material Quality and Grain Structure

The internal structure of the brass is paramount. Cast fittings can have microscopic porosity, sand inclusions, or uneven grain structure. These act as stress concentrators—tiny weak points where cracks start. A high-quality forged or extruded brass fitting has a fine, uniform grain structure that distributes stress evenly, resisting the initiation of fatigue cracks.

Factor 2: Joint Type and Installation

The joint is usually the weakest link in a cycling system.

- Threaded Joints: These are most vulnerable. During heating, the female thread expands slightly more than the male thread, potentially loosening the grip. Repeated cycles can cause the threads to “walk” or fatigue. Solution: Use a high-quality thread sealant that remains flexible (like PTFE tape or a non-hardening paste) and ensure proper but not over-tightening.

- Brazed/Soldered Joints: A properly made capillary joint creates a metallic bond that is often stronger than the pipe itself and handles expansion as a single unit. It is generally superior for cyclic service if the entire assembly can move freely.

Factor 3: System Stress and Design

Even a perfect fitting will fail if the system design is poor. If pipes are rigidly anchored with no room to move, all the expansion force is transferred directly to the fittings. As discussed earlier, expansion loops, joints, and correct anchoring are not optional for systems with frequent temperature cycles.

Maintenance and Monitoring Checklist

For systems subject to frequent cycling (like solar thermal, heat pumps, batch processes), proactive checks are vital.

| Cycle Phase | Potential Issue | Inspection & Maintenance Action |

|---|---|---|

| After Installation | Initial stress | Check for leaks after first few heat-up and cool-down cycles. Re-tighten threaded joints if necessary (following proper torque specs). |

| Ongoing Operation | Fatigue accumulation | During routine maintenance, visually inspect fittings for signs of stress: discoloration (from excessive heat), micro-cracks, or corrosion. |

| Long-Term (Yearly) | Creep and seal degradation | For critical systems, consider a scheduled re-torquing of key threaded connections after a year of operation, as materials can settle. |

The goal is to create a system where pipes and fittings work together as a team during temperature changes. Choosing the right fitting (like IFAN’s range of forged brass fittings designed for durability), installing it correctly, and designing a sensible pipe layout are the three pillars of surviving temperature cycles.

Conclusion

Selecting the right brass fitting requires understanding pressure, temperature, and cyclic stresses. For reliable performance in demanding conditions, choose IFAN’s high-grade forged brass fittings, engineered for strength and durability.

Recent Comments