A client once asked me if their new brass plumbing could handle their building’s intense hot water system. The answer wasn’t simple, but it centered on the specific alloy: CCA407.

Yes, a 407 brass socket pipe can reliably handle high-temperature water. Its lead-free, dezincification-resistant (DZR) brass alloy is designed for hot water service. It maintains strength at high heat, resists corrosion, and when properly soldered, forms a robust joint that can withstand continuous thermal stress, making it a trusted choice for commercial and residential systems.

Let’s examine the specific technical details that explain why and how 407 brass performs under heat.

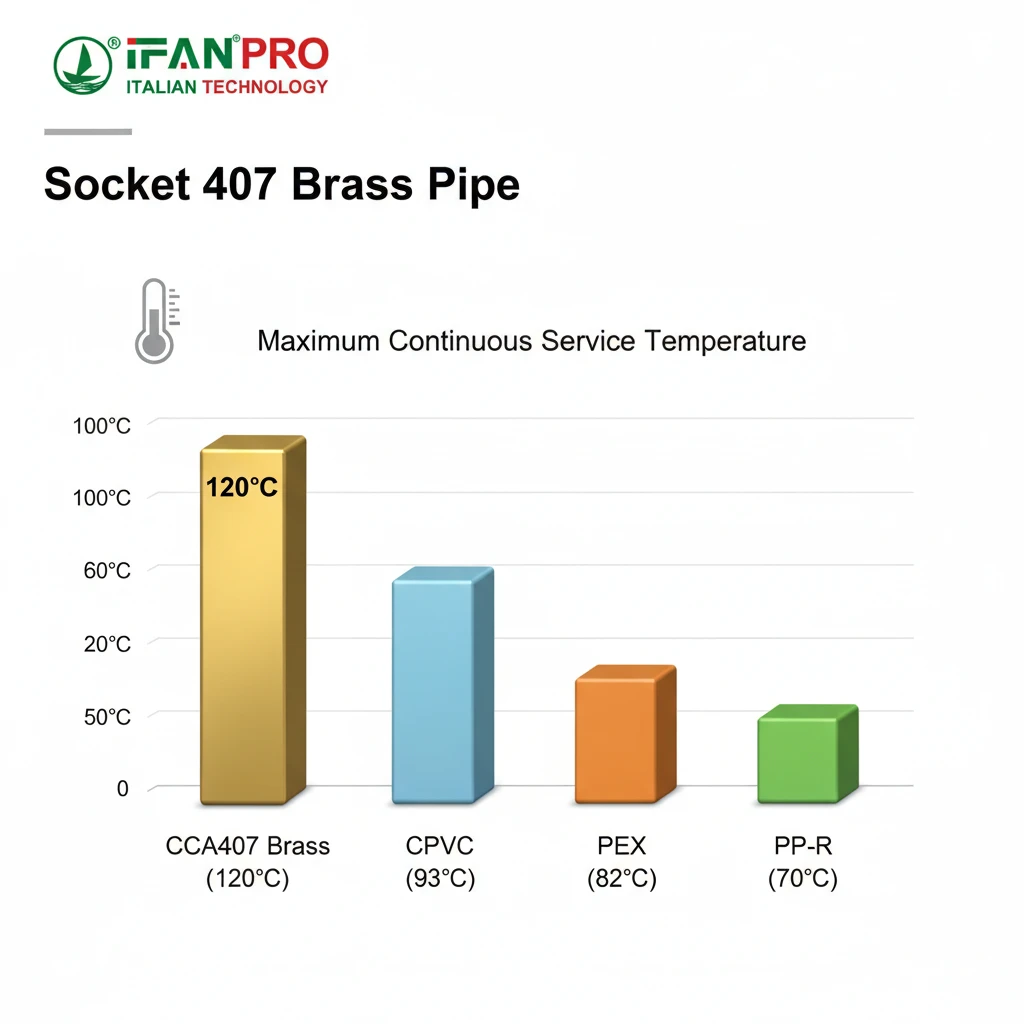

What is the Maximum Continuous Service Temperature for CCA407 Brass Pipes?

Engineers always ask for the exact number first. I recall a project where using the wrong temperature rating nearly caused a system failure.

The maximum continuous service temperature for CCA407 (DZR) brass pipes and fittings is typically 120°C (248°F). For most residential and commercial hot water systems, which operate below 80°C (176°F), this provides a significant and safe performance margin, ensuring long-term material stability and safety.

Understanding Temperature Ratings

When we talk about “maximum continuous service temperature,” we mean the highest temperature at which a material can operate safely and reliably for its expected lifespan without losing its key properties. For CCA407 brass, this rating is high for a good reason.

The alloy composition of CCA407 is key. It is a lead-free, dezincification-resistant brass. This means it is specifically formulated to resist a corrosive process called dezincification, which can be accelerated by hot, soft water. The alloy’s structure remains stable at elevated temperatures, unlike some plastics that can soften or creep.

Why the Margin of Safety Matters

Most domestic hot water systems are set between 50°C (122°F) and 60°C (140°F) to prevent scalding. Even in high-demand commercial settings like hotels, temperatures rarely exceed 80°C (176°F). The 120°C rating of 407 brass means the material is not working at its limit. This safety margin is crucial. It accounts for unexpected temperature spikes, such as those from a faulty thermostat, without risking immediate system failure.

Comparing Temperature Limits

The table below shows how CCA407 brass compares to common plastic alternatives in hot water service.

| Material | Max Continuous Service Temp | Key Limitation at High Heat |

|---|---|---|

| CCA407 (DZR Brass) | 120°C (248°F) | Can become more susceptible to stress corrosion in certain water conditions over very long periods. |

| PP-R (Plastic) | 70°C (158°F) | Long-term pressure capacity drops significantly; material can soften and creep. |

| PEX (Plastic) | 82°C (180°F) for some types | Permeable to oxygen at high temps, which can cause internal system corrosion. |

| CPVC (Plastic) | 93°C (200°F) | Becomes brittle over time and requires more supports as it sags when hot. |

Practical Application and Suggestion

A common client pain point is specifying a material that is “just good enough,” which leaves no room for error. My practical advice is to always choose a material whose maximum rating is at least 20-30°C above your system’s normal maximum operating temperature. This approach protects your investment. For systems consistently near 80°C, 407 brass is a robust choice, while plastics operate too close to their limits for comfort.

How Does Its Performance in Hot Water Compare to Plastic Alternatives?

I’ve seen plastic systems sag and fail under sustained heat, while brass installations from decades ago remain in service.

In hot water, CCA407 brass performs significantly better than plastic alternatives like PP-R or PEX. Brass maintains its pressure rating, does not sag or creep, and is an effective oxygen barrier, preventing internal corrosion. Plastics lose strength, require extensive support, and can allow oxygen diffusion that damages other metal components in the system.

The Problem of Thermal Creep and Sagging

Performance under heat isn’t just about not melting. A critical factor is “creep” – the tendency of a material to slowly deform under constant stress and heat. Plastic pipes are highly susceptible to this. Over time, a hot plastic pipe can sag between supports, putting stress on joints and potentially leading to failure. Brass, as a metal, has a much higher modulus of elasticity and does not creep at water system temperatures. Once installed, it stays in place.

Pressure Rating Stability

Every pipe has a pressure rating. For plastic pipes, this rating plummets as the water temperature rises. A PP-R pipe rated for 10 bars at 20°C might only be safe for 2-3 bars at 70°C. Brass, however, retains nearly all of its pressure rating at high temperatures. This means a brass system designed for a certain pressure will perform reliably with hot water, without needing to be massively over-specified for cold water just to handle the hot side.

The Oxygen Diffusion Issue

This is a hidden痛点. Some plastic pipes, like PEX, are permeable to oxygen at high temperatures. Oxygen dissolved in hot water can diffuse through the pipe wall and enter the system. This oxygen then accelerates the corrosion of any ferrous (iron-based) components in the system, such as boilers, pumps, or steel radiators, leading to premature failure. Brass is a complete barrier to oxygen, protecting the entire system.

Side-by-Side Performance Analysis

| Performance Factor | CCA407 Brass | Common Plastic (PP-R/PEX) |

|---|---|---|

| Strength at High Temp | Maintains strength; no creep. | Strength drops sharply; subject to creep and sagging. |

| Pressure Rating | Stable across temperature range. | Derates significantly with increasing temperature. |

| Oxygen Barrier | Complete barrier, protects system. | Can be permeable, risks internal corrosion. |

| Support Spacing | Standard, wide spacing adequate. | Requires much more frequent support to prevent sag. |

| Thermal Expansion | Low linear expansion. | High linear expansion; requires expansion loops. |

Practical Advice for Selection

The choice becomes clear for high-heat or high-reliability applications. If your system runs hot (above 60°C continuously), is in an accessible area where sagging pipes are unacceptable, or contains expensive ferrous equipment, brass is the superior choice. Plastic may be adequate for low-temperature residential use, but for performance under true heat stress, metal wins. IFAN always recommends a full system analysis to prevent the costly mistake of material mismatch.

Does Repeated Thermal Cycling Affect the Integrity of Soldered 407 Joints?

Thermal cycling is the silent killer of many plumbing systems. I’ve inspected joints that failed not from pressure, but from constant expansion and contraction.

Yes, repeated thermal cycling can affect soldered joints if they are poorly made. However, a properly soldered joint on CCA407 brass is highly resistant to fatigue. The brass and the solder expand and contract at similar rates, and the metallurgical bond is flexible enough to absorb stress, making a well-made joint highly durable under cyclic conditions.

What is Thermal Cycling and Why It Matters?

Thermal cycling is when a system repeatedly heats up and cools down. Think of a domestic hot water line that runs hot for a shower, then cools down, over and over. Each cycle causes the pipe and fittings to expand and contract slightly. If the joint between them is rigid and brittle, this repeated stress can lead to fatigue cracks and, eventually, leaks.

The Science of a Good Solder Joint

A capillary solder joint on brass is not just glue. It is a metallurgical bond. The molten solder is drawn into the microscopic gap between the fitting and the pipe, alloying with the surface of the brass itself. When done correctly, this creates a seamless, strong connection. The key is that the solder alloy (typically a tin-silver or tin-copper blend for lead-free systems) has mechanical properties, including a degree of malleability, that allow it to flex slightly with the brass during expansion and contraction.

The Critical Role of Proper Installation

This is where the major client pain point appears. Joint failure due to thermal cycling is almost always an installation issue, not a material failure. Common mistakes include:

- Insufficient Heat: Not achieving full capillary flow, creating a weak, incomplete bond.

- Overheating: Burning the flux, which then contaminates the joint and creates a brittle connection.

- Poor Cleaning: Failure to properly deburr and clean oxide from the surfaces before soldering, preventing a proper bond.

- “Dry” Joint: Moving the joint before the solder solidifies, breaking the capillary seal.

How to Ensure Joint Integrity for Thermal Cycling

Here is a practical checklist derived from IFAN’s factory audit and process control experience:

| Step | Action | Why It Matters for Thermal Cycling |

|---|---|---|

| 1. Preparation | Cut square, deburr inside/outside, clean with abrasive cloth until shiny. | Ensures a perfect gap for capillary action and a clean surface for bonding. |

| 2. Fluxing | Apply a thin, even layer of appropriate flux. | Prevents oxidation during heating and promotes solder flow. |

| 3. Heating | Heat the fitting evenly with a torch, applying heat to the base of the cup, not the solder. | Ensures the entire joint reaches the correct temperature for a full bond. |

| 4. Soldering | Touch solder wire to the joint seam; it should melt and be drawn in instantly. Apply until a bead appears all around. | Creates a complete, continuous metallurgical bond throughout the joint. |

| 5. Cooling | Let the joint cool naturally without disturbance. | Allows the solder to crystallize into a strong, coherent structure. |

By following these steps, the resulting joint becomes one of the strongest parts of the system, fully capable of withstanding decades of thermal cycling. IFAN’s quality control process for contract manufacturing emphasizes verifying these installation procedures to prevent field failures.

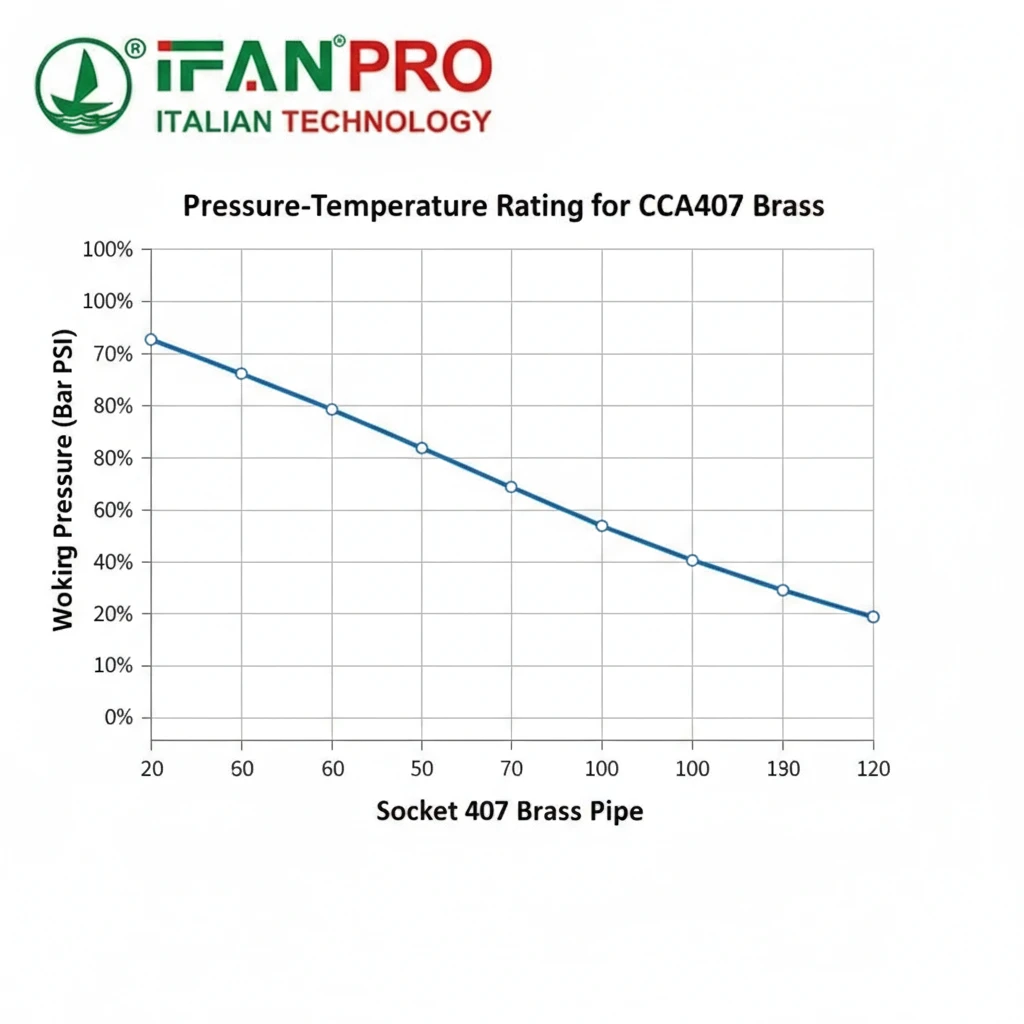

Are There Pressure Derating Factors for High-Temperature Applications?

Absolutely. Ignoring pressure derating is like overloading a truck – it might work for a while, but failure is inevitable.

Yes, there are pressure derating factors for all piping materials at high temperatures, including brass. While brass derates less than plastics, its working pressure must still be adjusted. For CCA407 brass, the pressure rating at 120°C is approximately 50% of its rating at room temperature. System designers must always consult derating tables for safe operation.

What is Pressure Derating?

A pipe’s pressure rating, or Pressure Rating (PN), is typically given for water at 20°C (68°F). As the temperature of the water increases, the strength of the material decreases slightly, and the internal stress on the pipe wall increases. Therefore, the safe working pressure for that pipe decreases. This reduction is called derating.

Derating Brass vs. Derating Plastic

It is a critical mistake to apply the same derating logic to all materials. The derating curve for brass is much flatter than for plastic. For example, a brass fitting might retain 80% of its pressure rating at 80°C, while a plastic fitting might only retain 30%. This is a fundamental advantage of metal. However, this does not mean derating can be ignored for brass.

How to Find and Apply the Correct Factor

Manufacturers provide pressure-temperature (P-T) rating tables for their products. For standardized CCA407 brass components, industry guidelines exist. You should never guess. The derating is not linear and depends on the specific alloy and manufacturing standard.

Example Pressure-Temperature Table for CCA407 Brass Fittings

| Water Temperature | Maximum Recommended Working Pressure (as % of Cold Water Rating) | Practical Example: For a fitting rated at 16 Bar (cold) |

|---|---|---|

| 20°C (68°F) | 100% | 16.0 Bar |

| 60°C (140°F) | ~85% | 13.6 Bar |

| 80°C (176°F) | ~75% | 12.0 Bar |

| 100°C (212°F) | ~60% | 9.6 Bar |

| 120°C (248°F) | ~50% | 8.0 Bar |

Note: This is a simplified illustrative table. Always use the official table from your component supplier.

The Pain Point and Practical Solution

A major pain point occurs when a system designed for cold water pressure is used for hot water without recalculation. A valve or pump set to a pressure safe for cold water could exceed the derated safe pressure for hot water, risking a burst.

The practical advice is a three-step process:

- Identify: Determine the highest sustained temperature each section of your piping will experience.

- Consult: Obtain the official P-T rating chart from your brass component supplier (like IFAN).

- Calculate: Use the derating factor from the chart to calculate the maximum allowable working pressure for your hot water lines. Your system’s operating pressure must be set below this limit.

This engineering diligence is non-negotiable for safe, reliable high-temperature water systems. It is a core part of the project management service IFAN provides to ensure client designs are not only functional but also inherently safe.

Conclusion

CCA407 brass is a robust choice for high-temperature water when its limits and installation rules are respected. For reliable, certified CCA407 DZR Brass Fittings and Sockets, trust IFAN’s supply chain and technical support.

Recent Comments