I once received a batch of failed pipe fittings that cracked under pressure. This frustrating experience taught me that not all brass is the same, and the alloy choice is everything for durability.

You should choose Dezincification Resistant Brass (DZR/Alloy CCA407) for socket pipes because its reduced zinc content and special composition make it highly resistant to corrosion, especially the destructive process called dezincification. This ensures long-term strength and reliability in demanding water supply systems, preventing premature failures and leaks.

Now, let’s look closely at what makes Alloy 407 the smart choice for professionals who cannot afford system failures.

How Does the Reduced Zinc Content in CCA407 Enhance Long-Term Durability?

Many believe brass is just brass, but its zinc content determines its fate. I’ve seen high-zinc brass fittings turn brittle and crumble.

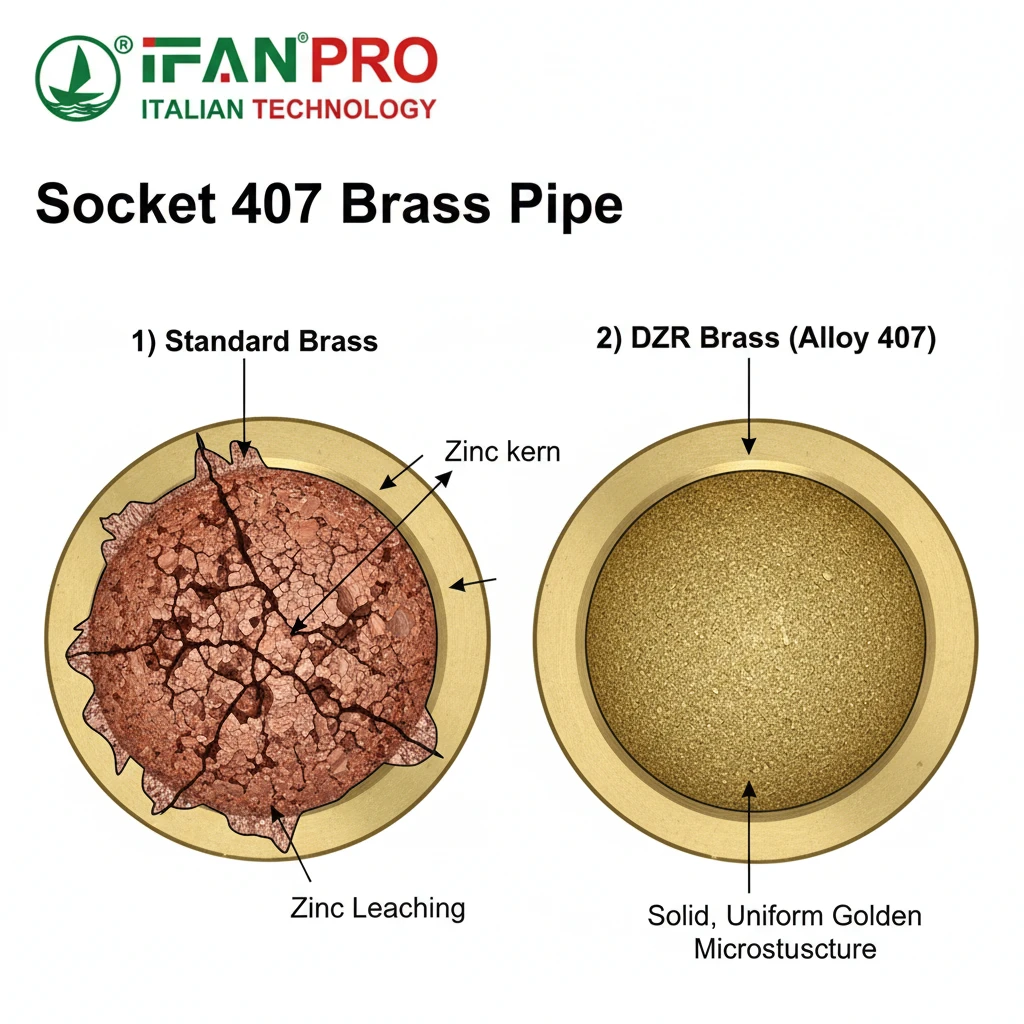

The reduced zinc content in Alloy CCA407 (around 36-38%, compared to over 39% in standard brass) significantly enhances long-term durability by making the material far less susceptible to dezincification. This is a corrosive process where zinc is selectively leached out by water, leaving behind a porous, weak, and brittle copper structure that easily fails under pressure.

Understanding the Dezincification Problem

First, we need to understand the main enemy of standard brass fittings: dezincification. This is not general rust or uniform corrosion. Instead, it is a selective attack. When certain water conditions are present—like soft water, low pH (acidic water), or elevated temperatures—zinc molecules within the brass alloy can be dissolved away.

The result is disastrous. The fitting loses its zinc, which is a key component for strength and machinability. What remains is a spongy, copper-rich structure that looks intact from the outside but has no mechanical strength. You can often poke a screwdriver right through a severely dezincified fitting. This leads to sudden leaks and catastrophic failures without any visible warning signs on the pipe’s exterior.

How Alloy CCA407 Fights Back

Alloy CCA407, also known as DZR brass, is specifically engineered to stop this process. The key is not just reducing the zinc content slightly, but also adding a small but critical amount of other elements, most notably Arsenic (As), and sometimes Tin (Sn) or Antimony (Sb).

Here is how this composition change creates a durable product:

- Chemical Barrier: The added Arsenic acts as an inhibitor at the molecular level. It alters the electrochemical reaction between the brass and water, effectively “poisoning” the process that leaches zinc out of the alloy.

- Stable Structure: The adjusted zinc percentage creates a more stable and uniform crystalline microstructure within the metal. This uniform structure is less prone to the selective corrosion that targets zinc-rich phases.

- Long-Term Integrity: By combating dezincification, the alloy maintains its original density and strength. A CCA407 fitting buried in a wall or under a floor will retain its as-manufactured properties for decades, ensuring the sealed system remains intact.

The Result of Choosing the Right Alloy

The table below shows the stark difference in outcome between standard brass and DZR brass like CCA407.

| Condition | Standard Brass (High Zinc) | DZR Brass (Alloy CCA407) |

|---|---|---|

| Exposure to Soft, Acidic Water | High risk of rapid dezincification. | Highly resistant; minimal material loss. |

| Internal Structure After 10 Years | Porous, weakened, copper-colored residue. | Dense, intact, retains original metallurgy. |

| Mechanical Strength Over Time | Can drop by over 50%, leading to cracks. | Remains consistent with original specifications. |

| Failure Mode | Sudden, brittle fracture with little warning. | Gradual, predictable wear if any; extremely reliable. |

In short, the reduced and stabilized zinc content in CCA407 isn’t a cost-cutting measure. It is a deliberate, scientific improvement that directly targets the number one cause of long-term brass fitting failure. This makes it the only responsible choice for pressurized potable water systems where failure means water damage, downtime, and costly repairs.

What Specific Environmental Conditions is Alloy 407 Particularly Resistant to?

Clients often worry about local water chemistry. I use Alloy 407 because it handles tough conditions that destroy ordinary fittings.

Alloy 407 is particularly resistant to environments that cause dezincification and stress corrosion cracking. This includes soft or acidic water (low pH), water with high oxygen or carbon dioxide content, and elevated water temperatures commonly found in hot water supply lines and heating systems.

Resistance to Problematic Water Types

The primary superpower of Alloy CCA407 is its resilience against specific, corrosive water conditions that are common in many regions. Standard brass fittings fail quickly in these environments, but CCA407 is built to last.

First, and most importantly, it is resistant to soft water and acidic water (low pH). Soft water, which is low in dissolved minerals like calcium and magnesium, is naturally more aggressive at leaching metals. Similarly, water with a pH below 7 is acidic and accelerates corrosion. Many municipal water supplies or private well waters can have these characteristics. CCA407’s DZR properties make it the standard choice in areas known for soft or acidic water to prevent systemic failures.

Second, it performs well in systems with high dissolved oxygen or carbon dioxide. Oxygen in water is a primary driver of corrosion reactions. Carbon dioxide forms weak carbonic acid, lowering the water’s pH. Recirculating hot water systems, like those in large buildings or district heating, often have higher oxygen content. CCA407 provides a much higher safety margin in these applications.

Performance in Temperature Extremes

Temperature is a major factor. Alloy 407 offers excellent resistance in hot water and heating systems. Heat dramatically accelerates chemical reactions, including corrosion. A fitting that might last 15 years in cold water could fail in 5 years in a hot water line if it’s made from the wrong brass.

- Hot Domestic Water: For temperatures commonly found in residential and commercial hot water tanks (typically 50-70°C or 120-160°F), CCA407 is highly recommended.

- Heating Systems: In closed-loop heating systems for radiators or underfloor heating, CCA407 is a preferred material due to its stability over long periods at sustained temperatures.

Resistance to Other Forms of Corrosion

Beyond dezincification, CCA407 also shows good general resistance to other corrosion types:

- Atmospheric Corrosion: It withstands humid and mildly industrial atmospheres better than many other copper alloys, making it suitable for exposed fittings in plant rooms or coastal areas (though for severe marine environments, specific bronze alloys might be considered).

- Stress Corrosion Cracking (SCC): While all brass alloys can be susceptible to SCC under a combination of high tensile stress and a specific corrosive environment (like ammonia), the more stable microstructure of CCA407 generally provides better resistance than high-zinc brasses.

Environmental Suitability Guide

The following table helps you decide when Alloy 407 is the necessary choice.

| Environmental Condition | Risk to Standard Brass | Alloy CCA407 Recommendation |

|---|---|---|

| Soft Water Supply | Very High | Essential |

| Water pH < 7.0 (Acidic) | Very High | Essential |

| Hot Water Systems (>60°C / 140°F) | High | Strongly Recommended |

| Closed-Loop Heating Systems | High | Strongly Recommended |

| High Oxygen Content Water | Moderate to High | Recommended |

| Standard Cold Water (Neutral pH) | Low | Excellent, provides maximum safety margin. |

In summary, Alloy 407 is your best defense against unpredictable and aggressive water conditions. It provides peace of mind by building a robust, failure-resistant barrier at every connection point in your plumbing system.

How Does Alloy 407 Compare to Other Brass Types in Mechanical Strength?

When a pipe bursts, it’s not just about corrosion. The fitting must be strong from day one. I specify materials based on proven strength data.

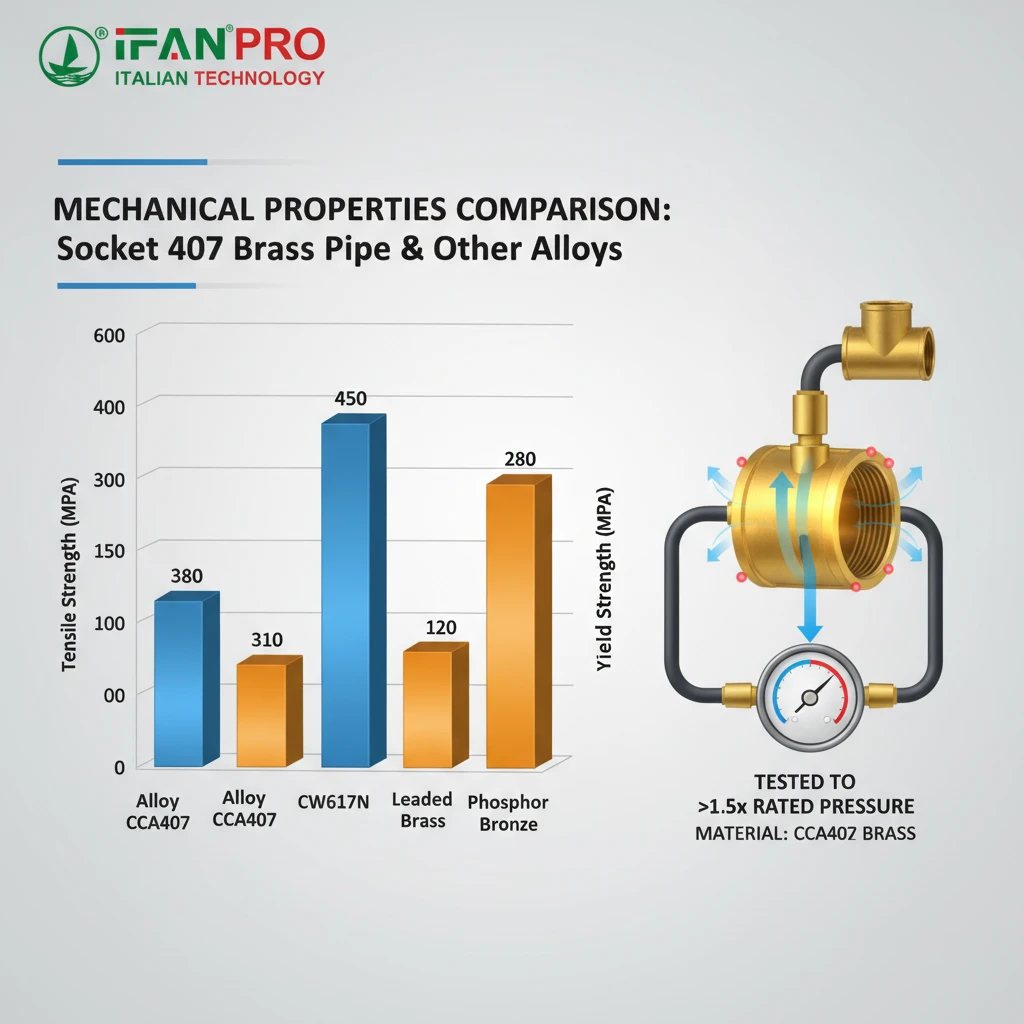

Alloy 407 offers an excellent balance of mechanical strength, comparable to or exceeding that of common plumbing brasses like CW617N. While not as strong as some phosphor bronzes, its tensile and yield strength are more than sufficient for all standard and high-pressure plumbing applications, especially when combined with its superior corrosion resistance.

Defining Key Strength Metrics

To compare alloys, we look at specific mechanical properties. For pipe fittings, the most important ones are:

- Tensile Strength: The maximum stress the material can withstand while being stretched before breaking.

- Yield Strength: The stress at which the material begins to deform permanently. This is often more important than tensile strength for fittings, as we never want them to permanently deform in service.

- Elongation: A measure of ductility—how much the material can stretch before breaking. Some ductility is good for absorbing vibration and pressure surges.

Head-to-Head Comparison with Common Alloys

Let’s see how Alloy CCA407 stacks up against other common brass and bronze alloys used for fittings.

| Property / Alloy | Alloy CCA407 (DZR Brass) | CW617N (Standard Brass) | C85700 (Leaded Brass) | C84400 (Leaded Red Brass) |

|---|---|---|---|---|

| Typical Tensile Strength | ~370 MPa | ~340 MPa | ~380 MPa | ~275 MPa |

| Typical Yield Strength | ~150 MPa | ~130 MPa | ~170 MPa | ~125 MPa |

| Elongation at Break | ~25% | ~30% | ~20% | ~20% |

| Primary Advantage | Superior corrosion resistance (DZR). | Good balance of cost & machinability. | Excellent machinability for complex parts. | Good corrosion resistance, lower cost than bronze. |

| Biggest Weakness | Slightly higher material cost. | Prone to dezincification. | Prone to dezincification; contains lead. | Lower mechanical strength. |

Analysis of the Comparison:

- Vs. CW617N (Standard Plumbing Brass): CCA407 has clearly higher tensile and yield strength. This means a CCA407 fitting can handle higher system pressures and is less likely to deform. Given that it also provides vastly superior corrosion resistance, it is a direct upgrade in every performance aspect.

- Vs. Leaded Brasses (C85700): While some leaded brasses might show slightly higher tensile numbers, they lack the critical DZR property. They are also increasingly restricted for potable water use due to lead content regulations. CCA407 provides a safer, more durable, and more globally acceptable alternative.

- Vs. Phosphor Bronze (e.g., C54400): Phosphor bronze is stronger and has excellent corrosion resistance. However, it is significantly more expensive, harder to machine, and often over-specified for standard plumbing. CCA407 provides about 80-90% of the strength at a much more competitive price, making it the cost-effective “sweet spot.”

Strength in Real-World Applications

For practical purposes, the mechanical strength of Alloy 407 is more than adequate. It meets and exceeds the requirements of international standards for pressure-rated fittings, such as those defined by EN 1254 (for Europe) and ASME/ANSI (for the US).

Furthermore, strength is not just about the raw material. The reliability of a fitting comes from the combination of strength and corrosion resistance. A stronger alloy that corrodes quickly will fail before a slightly less strong alloy that remains intact. Alloy 407 wins because it maintains its strength over time. A CW617N fitting may start with a yield strength of 130 MPa, but after years of dezincification, its effective strength in the corroded zones can drop to near zero. A CCA407 fitting will maintain its 150 MPa yield strength for the life of the installation.

Therefore, when you choose Alloy 407, you are not sacrificing strength. You are choosing a material with excellent initial strength that is guaranteed to last, ensuring the long-term integrity of the entire pressurized system.

Why Is Consistent Material Quality Crucial for Pressure-Rated Plumbing Systems?

I have seen projects delayed because of failing batch tests. In pressure systems, inconsistency is the enemy of safety and performance.

Consistent material quality is absolutely crucial because any variation in the alloy composition, microstructure, or manufacturing defects can create weak points. Under constant or cyclic water pressure, these weak points can lead to sudden leaks or catastrophic bursts, causing severe water damage, safety hazards, and costly system downtime.

The Risks of Inconsistent Material

A pressure-rated plumbing system is a chain. Like any chain, it is only as strong as its weakest link. In a system with hundreds of fittings, just one faulty fitting made from inconsistent material can cause failure.

- Risk of Sudden Failure: Inconsistent chemistry can lead to localized areas prone to rapid corrosion or areas with lower mechanical strength. A fitting might pass a factory test but fail in the wall after a year of service due to a hidden flaw.

- Unpredictable Performance: If the alloy mix varies from batch to batch, engineers cannot rely on the published performance data. This makes proper system design and safety margin calculation impossible.

- Failed Certifications: Products for potable water and pressure applications require strict certifications (like NSF/ANSI 61, WRAS, ACS). These certifications are granted for a specific, consistent product formula and manufacturing process. Any deviation can invalidate the certification, leaving the installer and building owner liable.

Key Areas Where Consistency Matters Most

Consistency must be maintained at every stage:

A. Raw Material Chemistry:

Every batch of brass ingot must have the same precise percentages of Copper (Cu), Zinc (Zn), Arsenic (As), and other trace elements. Even a small deviation in arsenic content can compromise the dezincification resistance of CCA407.

B. Manufacturing Process Control:

The processes of casting, forging, machining, and cleaning must be standardized.

- Casting/Forming: Must produce a uniform, dense microstructure without internal pores or voids (which become high-stress points).

- Machining: Must be precise to ensure threads are clean and deep enough, and sealing surfaces are smooth.

- Deburring and Cleaning: Must be thorough to remove all metal chips and cutting fluids that could later cause blockages or contamination.

C. Quality Inspection and Testing:

Rigorous, standardized testing is not optional. This includes:

- Spectrometer Testing: Verifying the chemical composition of each production melt.

- Mechanical Testing: Sampling fittings to verify tensile strength, yield strength, and pressure rating.

- Dimensional Checks: Ensuring every fitting meets exact thread and size specifications to guarantee a leak-tight seal.

- Corrosion Testing: Performing standardized tests (like the ISO 6509 dezincification test) to confirm corrosion resistance.

The IFAN Quality Assurance Framework

A reliable supplier like IFAN ensures consistency through a documented quality management system. Here is what a robust system looks like in practice:

| Stage | Control Point | How Consistency is Ensured | Consequence of Failure |

|---|---|---|---|

| 1. Sourcing | Raw Material Ingots | Procurement from certified mills with Mill Test Certificates (MTCs). | Uncertified material may not have the correct DZR properties. |

| 2. Production | Melting & Casting | Computer-controlled furnaces, regular spectrometer checks of the molten metal. | Incorrect alloy chemistry leads to poor corrosion resistance or weak material. |

| 3. Manufacturing | Machining & Threading | CNC machines with regular tool wear checks and calibration. | Poor threads cause installation leaks or fitting blow-outs under pressure. |

| 4. Inspection | Final Product | AQL-based sampling for dimensions, pressure tests, and visual defects. | Defective products reach the customer, causing field failures and returns. |

| 5. Documentation | Traceability | Lot numbers trace each batch back to its raw material source and production data. | Impossible to isolate problems or recall specific faulty batches. |

In conclusion, choosing a supplier that prioritizes material consistency is not just about getting a good product; it is about managing risk. It ensures every single fitting in your project delivers the same reliable performance, creating a plumbing system you can trust for decades. This is why at IFAN, we build our reputation on the consistency of our IFAN DZR/CCA407 Brass Fittings, backed by full traceability and international certifications.

Conclusion

For durable, pressure-safe brass socket pipes that resist corrosion and maintain strength, Alloy 407 is the proven choice. Ensure reliability in your next project with certified IFAN DZR/CCA407 Brass Pipe Fittings and Sockets.

Recent Comments