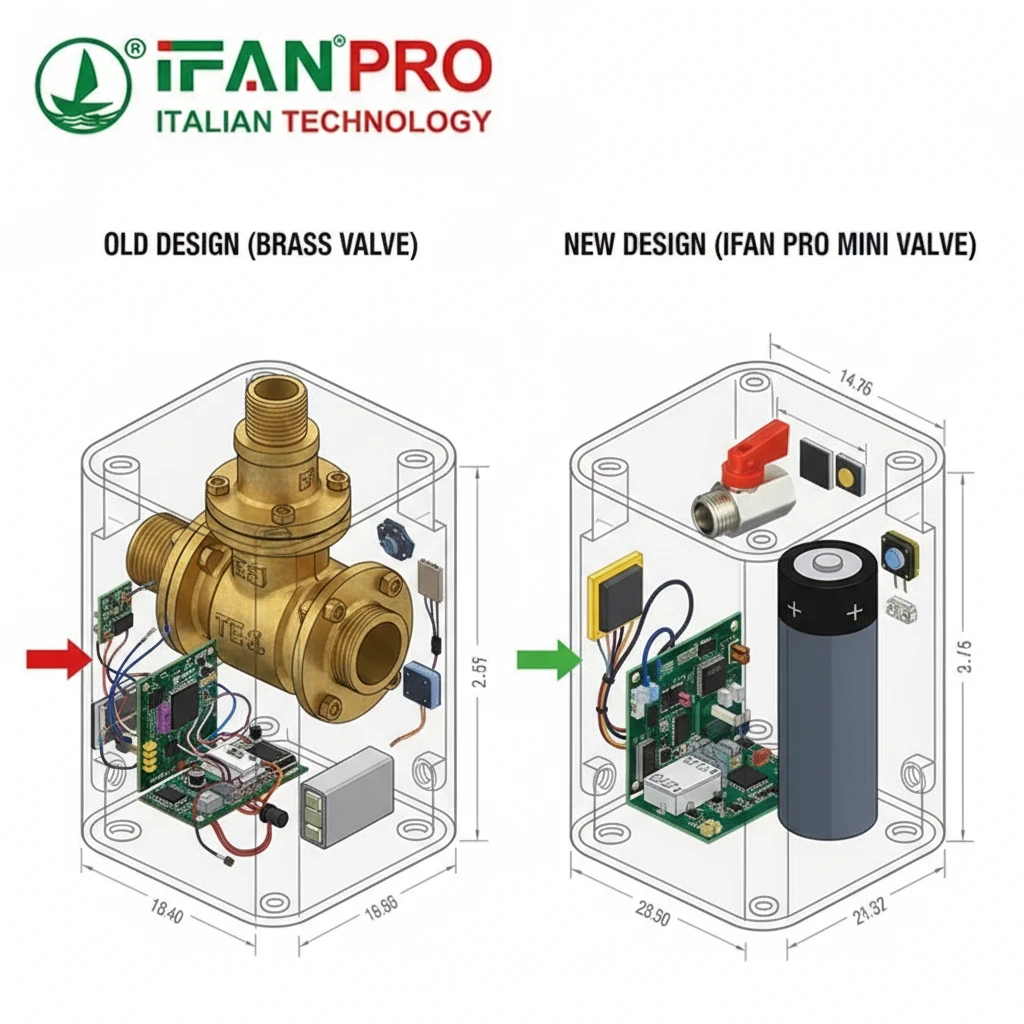

I once saw a brilliant prototype fail because its valve was simply too big and heavy. This frustrating moment cemented my belief in the power of miniaturization for control systems.

You should choose a mini valve for compact equipment control because it directly solves core challenges of space, weight, and integration in modern design. These valves free up crucial real estate, reduce system load, simplify automation, and accelerate development, making them essential for efficient and innovative devices.

Let’s break down the specific reasons why switching to a mini valve can be a game-changing decision for your project.

How Does the Compact Size of a Mini Valve Save Crucial Space in Designs?

Engineers constantly fight for every cubic millimeter inside a device. A standard-sized valve can derail an entire layout.

The compact size of a mini valve saves crucial space by occupying a fraction of the footprint of a traditional valve. This allows designers to place it directly where control is needed, eliminate long piping runs, and free up room for other critical components like batteries, sensors, or processors, leading to a more integrated and efficient overall design.

The Problem of Wasted Space

In compact equipment—think portable analyzers, robotic arms, or medical devices—internal space is a premium resource. A large valve doesn’t just take up its own volume; it forces the entire system design to accommodate it. This often means larger enclosures, longer fluid or air pathways, and components being pushed into suboptimal positions.

A mini valve changes this equation. Its small size allows for direct integration at the point of use. Instead of having a central, bulky valve bank with tubes running everywhere, you can place mini valves right on the tool head, the sensor module, or the actuator. This reduces the volume needed for the control system itself.

Direct Benefits of a Smaller Footprint

The space savings translate into several direct benefits:

- Smaller Overall Devices: The most obvious result is that your end product can be smaller and more ergonomic. This is critical for handheld tools, wearable devices, or equipment that needs to fit in tight spaces.

- Room for More Features: The saved space can be used to add a larger battery for longer life, an extra sensor for more functionality, or a more powerful CPU. This enhances the product’s capabilities without increasing its size.

- Cleaner Internal Layout: Shorter fluid or air paths mean less tubing, fewer connections, and a lower risk of leaks. This makes the assembly cleaner, more reliable, and often easier to service.

Space Allocation Comparison

The table below shows a hypothetical comparison in a compact pneumatic gripper design.

| Design Aspect | Using Standard Valves | Using Mini Valves |

|---|---|---|

| Valve Enclosure Size | 120 x 80 x 50 mm | 40 x 30 x 25 mm |

| Tubing Length Required | ~500 mm | ~150 mm |

| Space Freed for Battery | Standard size (1000 mAh) | 30% larger size (1300 mAh) |

| Overall Device Profile | Bulky and rectangular | Sleek and streamlined |

Enabling New Design Possibilities

Furthermore, the small size isn’t just about saving space in existing designs; it enables entirely new ones. It allows for the creation of multi-valve manifolds or arrays that were previously impossible, providing precise, multi-point control in a single, tiny package. For designers, this means freedom and flexibility. You are no longer designing around the valve; you are designing with it as a seamless component.

Why is Light Weight Essential for Valves in Portable or Handheld Devices?

Every gram matters in a device meant to be carried or moved. A heavy valve increases fatigue and limits application.

Light weight is essential because it directly reduces the overall mass of the portable device, decreasing user fatigue, improving handling, and lowering the energy required for movement in robotic or automated systems. This leads to longer battery life, better ergonomics, and greater practicality for field or mobile use.

Impact on User Experience and Fatigue

For any device operated by a person—a diagnostic tool, a sprayer, a surgical instrument—weight is a primary factor in usability. A heavy component like a valve contributes to muscle strain and user fatigue during prolonged operation. This can reduce precision, increase error rates, and make the product unpleasant to use.

Mini valves, often constructed from engineered plastics or lightweight alloys, dramatically cut this mass. Reducing the weight at the point of operation (like the head of a tool) is especially important, as it improves balance and makes the device feel more agile. This is a key selling point for professionals who use equipment all day long.

Critical for Robotics and Dynamic Systems

The importance of weight extends beyond human use. In portable robots, drones, or automated guided vehicles (AGVs), every added gram requires more energy to move and stop. Heavier systems need larger motors, stronger structures, and bigger batteries. This creates a cycle of increasing size and cost.

Key Weight-Related Advantages:

- Extended Battery Life: A lighter system consumes less power to operate. For battery-powered portable equipment, using a mini valve can directly contribute to longer runtimes between charges, a major competitive advantage.

- Increased Payload Capacity: In robotics, the weight saved by using mini valves can be reallocated to the actual “payload”—the sensor, camera, or gripper that does the work. This makes the machine more capable and efficient.

- Faster Response Times: Lighter moving parts can accelerate and decelerate more quickly. This improves the responsiveness and cycle time of automated equipment.

Weight and Performance Trade-offs

Consider this comparison for a portable air-operated device:

| Component | Brass Solenoid Valve (Standard) | POM Plastic Mini Valve |

|---|---|---|

| Weight per Valve | ~250 grams | ~45 grams |

| Effect on Device Weight | Adds significant heft | Negligible addition |

| Typical Power Consumption | Higher (heavier coil to move metal parts) | Lower |

| Best Use Case | Stationary industrial machinery | Portable, battery-powered equipment |

Choosing a lightweight mini valve is therefore not just a detail; it’s a strategic decision that impacts the fundamental performance, cost, and user acceptance of a portable or handheld product.

How Do Small Actuators Simplify Integration into Automated Control Modules?

Automation demands smart, dense packaging of components. A bulky valve actuator complicates this immensely.

Small actuators simplify integration because they fit easily onto printed circuit boards (PCBs) or into dense mechatronic assemblies. They allow for direct electrical control from a microcontroller, enable the creation of compact multi-valve manifolds, and reduce the need for complex mechanical interfaces, making the entire control module simpler, more reliable, and cheaper to produce.

Enabling Direct PCB Mounting

The true power of a mini valve for automation lies in its actuator—typically a small, low-power solenoid. Its compact size and standardized footprint often allow for direct PCB mounting. This is a revolutionary advantage.

Instead of mounting valves on a separate metal sub-panel and then wiring them individually to a control cabinet, you can now solder the valves directly onto your main control board. This eliminates a huge amount of manual wiring, connectors, and potential failure points. The control signal travels a few millimeters of PCB trace rather than meters of wire.

Building Compact Control Manifolds

This PCB-mount capability enables the design of integrated control modules. You can line up several mini valves on a single, custom-designed PCB to create a multi-channel manifold. This manifold can include the valves, their driver circuits, feedback sensors, and even the main system microcontroller all in one ultra-compact package.

Advantages of an Integrated Valve Manifold:

- Reduced Parts Count: Fewer separate components, brackets, and tubes.

- Faster Assembly: The module can be assembled and tested as a single unit before being installed in the machine.

- Easier Troubleshooting: Electrical and pneumatic connections are centralized and organized.

- Scalable Design: Need more control channels? Simply extend the PCB design and add more valves in the same modular format.

Simplifying the Design Process

From a design engineering perspective, this integration simplifies the entire control system architecture. The mechanical design team doesn’t need to find space for a large valve block and its mounting hardware. The electrical team doesn’t have to design a complex wiring harness. Instead, both teams work with a single, smart module that interfaces cleanly with power, air, and a data bus (like CAN or IO-Link).

Integration Complexity Comparison

| Integration Task | Traditional Valve Package | Mini Valve on PCB Module |

|---|---|---|

| Mechanical Mounting | Custom bracket, multiple screws. | 4 standoffs or screws for the entire PCB. |

| Electrical Connection | Individual wires per valve to terminal blocks. | A single multi-pin connector for power and data. |

| Pneumatic Connection | Multiple tube fittings on different sides. | A single, aligned row of fittings on one edge of the PCB. |

| In-Field Modification | Difficult; requires rewiring and replumbing. | Easier; swap the entire pre-tested module. |

This approach drastically reduces assembly time, improves reliability, and lowers total system cost, making automation more accessible and robust.

What Advantages Do Mini Valves Offer for Prototyping and Iterative Design?

The prototyping phase is where ideas meet reality. Slow, expensive part sourcing can kill momentum and creativity.

Mini valves offer major advantages for prototyping because they are low-cost, readily available, and easy to implement. They allow engineers to quickly test concepts, iterate on designs without major retooling, and create functional prototypes that closely resemble the final product, significantly speeding up the entire development cycle and reducing project risk.

Lowering the Barrier to Experimentation

Prototyping is all about learning and iteration. The cost and lead time of components can severely limit how much experimenting a team can do. Large, custom-made industrial valves are expensive and can take weeks to procure.

Mini valves, in contrast, are often standard, catalog items with lower unit costs and are frequently kept in stock. This allows a development team to order a handful of different models quickly and affordably. Engineers can physically test flow rates, response times, and mounting options on their bench within days, not months. This rapid feedback is invaluable.

Facilitating Agile Design Changes

During iterative design, the specifications often change. A fluid path might move, a new control channel might be added, or the entire device might get smaller. Mini valves, with their small footprint and weight, provide the flexibility to adapt to these changes.

Because they take up little space, modifying a design to accommodate a slightly different mini valve or to add an extra valve is often straightforward. You are not forced to redesign the entire chassis. This agility keeps the project moving forward and prevents teams from getting locked into a suboptimal design early on due to component constraints.

From Prototype to Production

A key advantage is the ability to use the same or very similar valve in the prototype and the final product. This is not always possible with traditional valves, where a prototype might use a bulky, over-specified valve because it’s available, while the production version is custom.

Prototyping Workflow Benefits:

- Reduced Risk: Testing with the actual valve technology planned for production gives high-confidence performance data.

- Accurate Modeling: The physical prototype’s size, weight, and power consumption will closely match the final product, leading to better design decisions.

- Simplified Sourcing: The supply chain is validated early. You’re not scrambling to find a different valve supplier after the prototype is approved.

Prototyping Efficiency Table

| Stage | Using Large/Custom Valves | Using Standard Mini Valves |

|---|---|---|

| Initial Sourcing | Long lead times (4-8 weeks), high cost. | Short lead times (days), low cost per unit. |

| Concept Testing | Difficult; often done only in simulation. | Easy and practical with real hardware. |

| Design Iteration | Costly and slow; may require new machined parts. | Fast and cheap; often just a PCB or bracket redesign. |

| Functional Demo | Prototype is large, heavy, and not representative. | Prototype is compact and close to final form factor. |

| Path to Production | May require a second, costly redesign for manufacturing. | Smooth transition; production uses same valve family. |

This makes mini valves a powerful tool for innovation, allowing teams to fail fast, learn quickly, and arrive at a better, more reliable final design with less time and money spent.

Conclusion

Mini valves solve the critical challenges of space, weight, and integration in modern equipment. For reliable, high-performance mini valves that excel from prototype to production, explore the IFAN range of compact valve solutions.

Recent Comments